Ferroflex Leaflet English 02

Diunggah oleh

Torranin KansuntisukmongkolDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ferroflex Leaflet English 02

Diunggah oleh

Torranin KansuntisukmongkolHak Cipta:

Format Tersedia

The world

standard in

quality and

reliability

Dunlop FERROFLEX conveyor belts.

The cost-effective solution to a

wide range of demands.

Tensile strengths available from

500 N/mm up to 2000 N/mm

Wide range of widths available,

from 500 up to 2200mm

High quality cover compounds suitable

for -60C up to +400C, fire resistant,

oil, grease and abrasion resistant

Low elongation 0.25% at 10% of the

normal tensile strength

High impact and tear resistance due

to dense steel cord carcass

Small pulley diameters

FE0108E

Excellent availability from stock

www.dunlopconveyorbelting.com

Dunlop Conveyor Belting - Value for money guaranteed

The highly versatile Dunlop Ferroflex belt is a tried and tested

carcass construction with particularly good low elongation

characteristics and is used wherever tensile strength and cover

grade qualities need to be adaptable to meet the prevailing service

conditions. This applies to all areas of bulk material handling,

particularly with demanding long distance applications and under

high impact conditions in a wide cross-section of industries.

There are two Ferroflex constructions available - FIW and FSW.

Both have a tension layer composed of longitudinal steel cords

through which power transmission is effected. The FIW carcass has

a single transversal layer of steel cords on top of the longitudinal

steel cords, whereas the FSW has two transversal layers of steel

cords situated at both sides of the longitudinal steel cords. The

transverse steel cords reinforce the belt and also protect against

impact and tears, providing excellent reliability and durability.

The FSW construction is particularly suitable for elevator belts

especially for use in the cement industry in combination with the

heat resistant Delahete cover grade quality. The FSW reinforced

belt can be supplied with cable free zones to make the installation

of buckets and fasteners easier and to create a dynamically

stronger endless belt. Both constructions are available in all

Dunlop cover qualities.

Unrivalled technical support and guidance

When you buy from Dunlop you get more than just quality conveyor

belts because we have one of the largest, most experienced and

highly trained teams of conveyor belt specialists and application

engineers in the industry.

Dunlop provides an unrivalled level of customer service - visiting our

customers on-site, providing advice, guidance and practical support

including: Site visits and surveys

Belt calculation services

Technical training (on-site and Dunlop based)

Splice training

Trouble shooting and problem solving

In-house research, testing and development

After-sales support

24/7 helpline +31 (0) 512 585 555

Our 24-hour Helpline means that we are never more than a

phone call away when our customers need our help or advice.

This service is extremely well supported by our extensive

network of highly reputable Dunlop Authorised Distributors,

Vulcanisers and Approved Agents.

FERRoflex

ferroflex

Technical INFORMATION

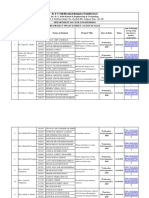

the extensive ferroflex product range

Pulley diameters*

Belt

type

Carcass

thickness

(mm)

Carcass

weight

(kg/m2)

A

(mm)

B

(mm)

F 500 IW

SW

F 630 IW

SW

F 800 IW

SW

F 1000 IW

SW

F 1250 IW

SW

F 1600 IW

SW

F 2000 SW

3.2

4.7

3.2

4.7

4.5

5.4

4.5

5.4

6.0

7.1

6.0

7.1

7.1

5.7

7.3

5.9

8.1

8.6

9.5

9.3

10.4

12.2

13.2

13.5

14.6

16.0

500

500

500

500

630

630

630

630

800

800

800

800

800

400

400

400

400

500

500

500

500

630

630

630

630

630

Max. belt width (mm) for satisfactory load

support with material density of t/m3 : **

C

(mm)

Min.

width**

(mm)

<0.75

0.75-1.5

1.5-2.5

2.5-3.2

315

315

315

315

400

400

400

400

400

400

400

400

400

500

800

500

800

650

800

650

800

800

1000

800

1000

1000

1600

2200

1600

2200

2200

2200

2200

2200

2200

2200

2200

2200

2200

1400

2000

1400

2000

2000

2200

2000

2200

2200

2200

2200

2200

2200

1200

1800

1200

1800

1800

2000

1800

2000

2200

2200

2200

2200

2200

1000

1600

1000

1600

1600

1800

1600

1800

2200

2200

2200

2200

2200

Explanation:

To determine the total belt thickness:

Add the sum of the covers to the carcass thickness.

* Diameter for belt-loads from 60% up to 100%.

For lower loads a smaller diameter can also be suitable.

To determine the belt-weight per square metre

(excluding fire resistant belts for which other weights apply):

Multiply the sum of the covers by 1.15 and add the result to the

carcass weight.

** The load support of a belt is a factor of the belt width, belt strength and bulk

material density. The table indicates the limits for correct load support, based

on three idlers of the same length set at 30.

We are here to help!

If you have any concerns or questions, please call our

Application Engineering Department on +31 (0) 512 585 555

A wide range of cover qualities

All Dunlop cover qualities are anti-static according to EN 20284

Dunlop cover quality

Din

quality

Abrasion

Resistant

RA

RS

RE

Y

W

X

Heat

Resistant

Betahete

Deltahete

Oil and fat

Resistant

Fire

Resistant

en/iso

quality

D

D

H

Permissible temp.C *

Base

min.

cont.

peak polymer

Ambient Material Material

Technical features

Application area

-30

-40

-40

80

80

80

100

90

90

SBR

NR/SBR

NR

T

T

-20

-20

150

200

170

400

SBR

EPDM

ROS

-20

80

120

NBR

Oil and fat resistant for products containing mineral oils.

BVX

S**

-20

80

90

SBR

Fire resistant for the transport of inflammable and explosive materials such as coal

dust etc. According to EN 20340. Suitable for hazardous zones according to ATEX 95.

* For elevator belts other values apply. For low ambient

temperatures please ask for information regarding our

Coldstar range.

High abrasion resistance for normal service conditions.

Extra wear resistance to meet the demands of conveying highly abrasive materials.

Excellent resistance to cuts, impact, abrasion and gouging resulting from large

lump sizes of heavy, sharp materials and high drop heights.

Heat resistant for materials at moderate temperatures.

Superior heat resistant for heavy duty service conditions, up to 400C for a short

period(coke, clinker etc.)

** S = fire-resistant with or without covers.

Other cover grade qualities for special

applications are available upon request.

All data and recommendations in this brochure have been supplied to the best of our knowledge, as accurately as possible and updated to reflect the most recent technological developments.

Some products may have been rendered obsolete in the light of more recent technological developments. We cannot accept any responsibility for recommendations based solely on this brochure.

Dunlop Conveyor Belting (Head Office) Oliemolenstraat 2, PO box 14 9200 AA Drachten The Netherlands Tel. +31 (0) 512 585 555 Fax +31 (0) 512 524 599

France Telephone: +33 (0) 1 30 55 39 03 Spain Telephone: +34 9 380 55 446 Russia Telephone: +7 495 223 6718 UK Telephone: +44 7951 070800

Italy Telephone: + 39 340 3008381 belgium Telephone: +32 477 698295 germany Telephone: +49 172 9729302

www.dunlopconveyorbelting.com

Anda mungkin juga menyukai

- Tree Faller's Manual: Techniques for Standard and Complex Tree-Felling OperationsDari EverandTree Faller's Manual: Techniques for Standard and Complex Tree-Felling OperationsPenilaian: 5 dari 5 bintang5/5 (2)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDari EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionBelum ada peringkat

- TechnipFMC Project MobilizationDokumen9 halamanTechnipFMC Project MobilizationJobJob100% (8)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDari EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsPenilaian: 5 dari 5 bintang5/5 (1)

- PIP PCECV001 Guidelines For Application of Control ValvesDokumen39 halamanPIP PCECV001 Guidelines For Application of Control ValvesAndresBelum ada peringkat

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- De WaltDokumen52 halamanDe WalttheBlueLightBelum ada peringkat

- Sidewall Brochure E Oct 14Dokumen4 halamanSidewall Brochure E Oct 14canito73Belum ada peringkat

- Geotextiles and Geomembranes HandbookDari EverandGeotextiles and Geomembranes HandbookT.S. IngoldPenilaian: 5 dari 5 bintang5/5 (1)

- Raysan CatalogueDokumen56 halamanRaysan Catalogueفارس معتوقBelum ada peringkat

- 3 M Electrical CatalogDokumen377 halaman3 M Electrical CatalogClifton JamisonBelum ada peringkat

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesDari EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesPenilaian: 5 dari 5 bintang5/5 (1)

- Chiller Flow Rates and Guidelines For Chilled Water System PipingDokumen3 halamanChiller Flow Rates and Guidelines For Chilled Water System PipingTanveer Aziz100% (3)

- Comflex Expansion Joints GuideDokumen8 halamanComflex Expansion Joints Guideterencejustine100% (1)

- Unaflex - Rubber Expansion Joint CatalogDokumen43 halamanUnaflex - Rubber Expansion Joint CatalogJohn Gordon-SmithBelum ada peringkat

- Damper Technology BrochureDokumen8 halamanDamper Technology Brochurejoy100% (1)

- Shaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Dokumen21 halamanShaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Carlos Arturo Casas HuamánBelum ada peringkat

- SEMPERIT Belt PDFDokumen92 halamanSEMPERIT Belt PDFJaya Kumaar100% (2)

- 5566 Drag ConveyorsDokumen8 halaman5566 Drag ConveyorsEduardo SaucedoBelum ada peringkat

- Hmpe Manual Rev 1Dokumen11 halamanHmpe Manual Rev 1Kathrin KatsBelum ada peringkat

- Multitrans UkDokumen4 halamanMultitrans UknmaafonsoBelum ada peringkat

- Gasket Jointing FullDokumen48 halamanGasket Jointing FullManishBoyBelum ada peringkat

- Lindner KatalogDokumen64 halamanLindner KatalogAnonymous hISvHbfiB1Belum ada peringkat

- Green School BaliDokumen83 halamanGreen School BaliWayanParwitaBelum ada peringkat

- Dunlop Conveyor Belt Design ManualDokumen44 halamanDunlop Conveyor Belt Design Manualอภิรักษ์ มานะกิจศิริสุทธิ100% (2)

- 07 CB Conveyor Belt Design ManualDokumen44 halaman07 CB Conveyor Belt Design ManualRavikanth AluriBelum ada peringkat

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDari EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Dunloflex Leaflet EnglishDokumen2 halamanDunloflex Leaflet EnglishTorranin KansuntisukmongkolBelum ada peringkat

- Superfort Multi Ply Conveyor Belt Leaflet EnglishDokumen2 halamanSuperfort Multi Ply Conveyor Belt Leaflet EnglishRaji VargheseBelum ada peringkat

- Conveyor BeltsDokumen16 halamanConveyor BeltsdjsmoniBelum ada peringkat

- Dyna Flight 08Dokumen12 halamanDyna Flight 08surachsBelum ada peringkat

- Steelcord enDokumen2 halamanSteelcord enJulio Vega AngelesBelum ada peringkat

- CVBHW FlexsteelDokumen10 halamanCVBHW FlexsteelfranciscocvBelum ada peringkat

- CVBHW FlexsteelDokumen10 halamanCVBHW FlexsteelSrini KumarBelum ada peringkat

- Dunlop Belting Conveyor Belting RangeDokumen10 halamanDunlop Belting Conveyor Belting RangeOctavio Tornero MartosBelum ada peringkat

- Chainflex ClassificationDokumen2 halamanChainflex ClassificationigusukBelum ada peringkat

- Get PDFDokumen2 halamanGet PDFPetralina NaibahoBelum ada peringkat

- Welding Solutions SensorsDokumen124 halamanWelding Solutions SensorsСања БанковићBelum ada peringkat

- Insulfrax S BlanketDokumen2 halamanInsulfrax S BlanketcanonplanosBelum ada peringkat

- Black Eagle Hose BE 4466-UKDokumen44 halamanBlack Eagle Hose BE 4466-UKmhollowayBelum ada peringkat

- EngDokumen12 halamanEngelangandhiBelum ada peringkat

- Wr430gb00b BMP Cat Discl EngDokumen12 halamanWr430gb00b BMP Cat Discl EngJoseph BernardBelum ada peringkat

- Hollow Core BushingDokumen4 halamanHollow Core BushingAkhileshkumar PandeyBelum ada peringkat

- Topdek 700 Concealed Clip RoofingDokumen16 halamanTopdek 700 Concealed Clip RoofingctaciutBelum ada peringkat

- Katalog Hoist PDFDokumen12 halamanKatalog Hoist PDFsupriadi90315Belum ada peringkat

- Polytrack Clinker Cooler: Proven, Reliable, Future-Proof - Step Up Your Plant ProductivityDokumen2 halamanPolytrack Clinker Cooler: Proven, Reliable, Future-Proof - Step Up Your Plant ProductivityemadsabriBelum ada peringkat

- Technical Literature Plasma 12 Strand Tech SheetDokumen2 halamanTechnical Literature Plasma 12 Strand Tech Sheetthanhtam3819Belum ada peringkat

- Mobile Weld FilterDokumen4 halamanMobile Weld FilterJeffrey Dela RosaBelum ada peringkat

- The Definitive O Ring Design GuideDokumen31 halamanThe Definitive O Ring Design GuideChezBelum ada peringkat

- Damival en 20120516Dokumen8 halamanDamival en 20120516ssingaram1965Belum ada peringkat

- Tubular Drag ConveyorsDokumen8 halamanTubular Drag ConveyorsLuiz CostaBelum ada peringkat

- Densit Wear Flex DetailsDokumen4 halamanDensit Wear Flex Detailsnsprasad88Belum ada peringkat

- The Complete Guide To Pressure and Vacuum Sealing AssembliesDokumen22 halamanThe Complete Guide To Pressure and Vacuum Sealing AssembliesLuiz Carlos Vidal100% (1)

- DataSheet-SlimVac en v7Dokumen2 halamanDataSheet-SlimVac en v7pimoesBelum ada peringkat

- Tkis-Polytrack-Factsheet-210 X 297-WebpdfDokumen2 halamanTkis-Polytrack-Factsheet-210 X 297-WebpdfHa Kim BJBelum ada peringkat

- Cablosam EN 20120516Dokumen8 halamanCablosam EN 20120516ssingaram1965Belum ada peringkat

- Fenner Dunlop EnglishDokumen16 halamanFenner Dunlop Englishsaeedifar_mohammad100% (1)

- Manta Aislante ThermalceramicsDokumen2 halamanManta Aislante Thermalceramicsjast111Belum ada peringkat

- GORE PTV ScrewIn Vents enDokumen2 halamanGORE PTV ScrewIn Vents enTurcanuGheorgheBelum ada peringkat

- The Last Cable Standing: Fire Resistant CablesDokumen36 halamanThe Last Cable Standing: Fire Resistant Cablesodemircioglu2Belum ada peringkat

- Gexol PDFDokumen36 halamanGexol PDFLimuel EspirituBelum ada peringkat

- Garlock Expansion Joints Catalog ManualDokumen29 halamanGarlock Expansion Joints Catalog ManualCRISTIAN GUZMÁNBelum ada peringkat

- 06 MEGALINEAR Day Gear BeltDokumen100 halaman06 MEGALINEAR Day Gear Beltmualac2007Belum ada peringkat

- Belt Conveyor Rubber GradeDokumen1 halamanBelt Conveyor Rubber GradeSholhan AzizBelum ada peringkat

- Arkeen Leaflet EnglishDokumen2 halamanArkeen Leaflet EnglishTorranin KansuntisukmongkolBelum ada peringkat

- Animal Bedding v4-3Dokumen2 halamanAnimal Bedding v4-3Torranin KansuntisukmongkolBelum ada peringkat

- Dunlop Steelcord Leaflet en Aug2013Dokumen2 halamanDunlop Steelcord Leaflet en Aug2013Torranin KansuntisukmongkolBelum ada peringkat

- Direct Shear Test: Measuring Soil Shear StrengthDokumen4 halamanDirect Shear Test: Measuring Soil Shear StrengthQUEIZBelum ada peringkat

- Colonia eDokumen20 halamanColonia eAdhe Sri MarjukiBelum ada peringkat

- Site Investigation Guidance for Tunnel ProjectsDokumen9 halamanSite Investigation Guidance for Tunnel ProjectsramatrisBelum ada peringkat

- Taco Expansion TankDokumen16 halamanTaco Expansion Tanksas999333Belum ada peringkat

- Sb2125 - Valve Head Cracking BreakageDokumen2 halamanSb2125 - Valve Head Cracking BreakageahmedalgaloBelum ada peringkat

- RBX1 Assembly Hardware V1.0Dokumen10 halamanRBX1 Assembly Hardware V1.0Mohamed ReGaiegBelum ada peringkat

- Work Method Statement - Fireproofing PaintDokumen4 halamanWork Method Statement - Fireproofing Paintarrojak maksumBelum ada peringkat

- Tree DeclarationDokumen2 halamanTree DeclarationMichael TilbrookBelum ada peringkat

- Rego-Fix Er Recool enDokumen28 halamanRego-Fix Er Recool endavicocasteBelum ada peringkat

- Bridge Building PDFDokumen4 halamanBridge Building PDFGio PadillaBelum ada peringkat

- POST Modern Theory 2Dokumen41 halamanPOST Modern Theory 2Madhuri GulabaniBelum ada peringkat

- Steel Column Buckling Axial and Transverse LoadingDokumen31 halamanSteel Column Buckling Axial and Transverse LoadingTor GrimlundBelum ada peringkat

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDokumen10 halamanSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedBelum ada peringkat

- CR (N) 2&4 D&RDokumen14 halamanCR (N) 2&4 D&RRudo RockBelum ada peringkat

- Dr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiDokumen3 halamanDr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiRao SahabBelum ada peringkat

- PRovincial Architecture GujratDokumen31 halamanPRovincial Architecture GujratPiyush Mahakalkar67% (3)

- Literature Study: Crosswinds AppartmentsDokumen14 halamanLiterature Study: Crosswinds AppartmentsPrakathish waranBelum ada peringkat

- Technobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFDokumen5 halamanTechnobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFJohn SmithBelum ada peringkat

- Wall Cladding & PanelsDokumen18 halamanWall Cladding & PanelsSubrata DeyBelum ada peringkat

- Accessories For Dosage and Application PDFDokumen7 halamanAccessories For Dosage and Application PDFmochkurniawanBelum ada peringkat

- Nagara Style at KhajurahoDokumen25 halamanNagara Style at KhajurahosalmanBelum ada peringkat

- 0.12 M, 0.36 M, and The Depth of The FoundationDokumen1 halaman0.12 M, 0.36 M, and The Depth of The FoundationMomen AdilBelum ada peringkat

- SectProp Tubeline RHS Nov2004pDokumen3 halamanSectProp Tubeline RHS Nov2004pdiszorthBelum ada peringkat

- Shaft and Raise Boring MachinesDokumen13 halamanShaft and Raise Boring MachineshidayahBelum ada peringkat