Hydro-Grit Removal System

Diunggah oleh

Phyu Mar Thein Kyaw0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

31 tayangan3 halamanGrit is the scourge of a Wastewater Treatment works - a nuisance that causes abrasive wear to mechanical equipment, increasing maintenance and operational costs. Hydro's marcia sherony explains how a better understanding of these issues can prevent problems caused by grit in Wastewater Treatment plants. Grit gets into incoming raw sewage from a variety of sources, e.g. Through wind-blown sands and dust, surface water runoff over soil and hard

Deskripsi Asli:

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniGrit is the scourge of a Wastewater Treatment works - a nuisance that causes abrasive wear to mechanical equipment, increasing maintenance and operational costs. Hydro's marcia sherony explains how a better understanding of these issues can prevent problems caused by grit in Wastewater Treatment plants. Grit gets into incoming raw sewage from a variety of sources, e.g. Through wind-blown sands and dust, surface water runoff over soil and hard

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

31 tayangan3 halamanHydro-Grit Removal System

Diunggah oleh

Phyu Mar Thein KyawGrit is the scourge of a Wastewater Treatment works - a nuisance that causes abrasive wear to mechanical equipment, increasing maintenance and operational costs. Hydro's marcia sherony explains how a better understanding of these issues can prevent problems caused by grit in Wastewater Treatment plants. Grit gets into incoming raw sewage from a variety of sources, e.g. Through wind-blown sands and dust, surface water runoff over soil and hard

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

Formerly World Water & Environmental Engineering

Volume 36 / Issue 6

November / December 2013

Groundwater

Increasing well production. Page 13

Hydropower

Curved pipe for penstock routing. Page 16

Potable Water

In-tank aeration lowers THMs. Page 35

Keeping up the flow

of water wells

Wastewater Treatment 33

Improving grit removal design

in wastewater treatment

Understanding the characteristics of grit and its behavior can improve

the design of grit removal systems, leading to substantial operating and

maintenance cost savings. Marcia Sherony of Hydros US Wastewater Division

explains how a better understanding of these issues can prevent problems

caused by grit in wastewater treatment plants.

Grit is the scourge of a wastewater treatment

works a nuisance that causes abrasive wear to

mechanical equipment, increasing maintenance

and operational costs while reducing plant

performance and useful life.

Grit gets into incoming raw sewage from a

variety of sources, e.g. through wind-blown

sands and dust, surface water runoff over

soil and hard surfaces, and collection system

degradation. Grit can be present in substantial

amounts depending on local conditions.

Mechanical equipment such as pumps and

dewatering screws, centrifuges and components

such as bearings, chain links, and seals are at

risk of degradation in performance and even

failure through grit abrasion and wear, which

may lead to expensive shutdowns and equipment

replacement before the end of its expected

design life.

Grit settles out at low ow points in the plant

and over time accumulates to block and choke

the ow. It can lead to a reduction in process

tank volume and increased velocity through

those processes. Grit in aeration processes can

reduce air transfer efciency ratios.

Operators are often dissatised with their grit

removal systems, but may not be clear as to why

they are not performing as required. Even where

a headworks grit removal system is designed

to remove particles up to the conventionally

accepted size of 210 micron, all too often only

a small percentage of the total grit is being

successfully removed.

In some parts of the world, grit is still being

treated as a costly maintenance nuisance

rather than integral to treatment plant design

and operation. There is also a danger that grit

protection and elimination may be designed as

an afterthought where grit is common in large

quantities. Even where operators fully recognize

the problems caused by grit, their equipment

does not remove the correct size of particles in

the inow.

Operators are often

dissatised with their grit

removal systems.

The good news is that grit systems work

as intended when they are designed with

an accurate understanding of the nature

and characteristics of the grit arriving at the

treatment plant and how it actually behaves in

wastewater. In addition, this understanding needs

to be followed through in careful equipment

selection. An effective system addresses both

size and settleability, produces a clean, dry

product for disposal, and minimizes deposits and

accumulations in the plant.

Grit behavior in wastewater ows is a complex

phenomenon governed by a number of factors

such as size, specic gravity, shape, tendency

for agglomeration with other wastewater

constituents, and by environmental conditions

such as wet weather.

Settling velocity is frequently overestimated

as conventional design guidelines target removal

of grit larger than 210 micron, and grit particles

have been assumed to be perfect spheres of silica

sand with a 2.65 specic gravity (SG) settling

fast through laminar conditions in clean water.

Such idealized assumptions do not represent the

true behavior of inuent grit in a wastewater

treatment plant.

To deliver an effective grit removal system

it is important to rst understand the size and

composition of incoming grit, as both the size

and the settling velocity of the grit particles will

determine an effective design. Using both size

distribution and settling velocity distribution

enables the designer to establish a removal

efciency target and determine the minimum

particle size to be removed.

Where possible, a set of grit characteristics

should be developed specic to the wastewater

ow being treated. Where not available, for

example in new treatment plant construction,

a cut point designed at 75-106 micron will

generally remove 85 to 95 percent of the grit

entering the treatment plant.

Certain locations may be known for ne grit,

sugar sand or loess soils (a result of wind

erosion in regions characterized by high winds),

and the ner cut point of 75 micron should be

used. Many other areas may achieve adequate

results with a 106-micron cut point.

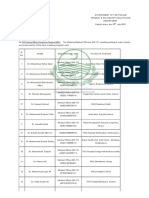

Manual removal of grit from a digester Photo by

Hydro International

World Water November/December 2013

Wastewater Treatment 35

Once collected, the grit

must be washed and

dewatered in order to

produce a clean, dry

product for landll.

Meanwhile, the larger, heavier grit that is

transported to the treatment plant during higher

ows seen during diurnal ow cycles, seasonal

variations, and spikes in ow from wet weather

events, is easily captured.

On-site studies

Conventional design criterion for removal of 210

micron has allowed passage of large quantities

of grit into wastewater treatment plants. To

illustrate, Figure 1 shows the size distribution

of grit found from onsite studies at a number of

plants in the United States. It can be seen that in

many plants 50 percent of the incoming grit is

smaller than the conventional design cut point of

210 micron. To modify design criteria to remove

90 percent of the incoming grit, the design cut

point needs to be changed to somewhere between

75 to 150 micron, depending on the actual size

distribution.

The conventional design assumption that

grit settles like silica sand with a specic gravity

of 2.65 is too simplistic. Wastewater grit may

consist of asphalt, limestone, concrete, slowly

degrading organics, and various other materials

that rarely have a specic gravity of 2.65.

Grit particles vary in shape, are rarely spheres,

and many plants have noted that much of their

larger grit is at. An angular particle will settle

more slowly than a sphere as its drag coefcient

is higher so designs allowing for such settling

are desirable.

While in the collection system, the grit particles

are exposed to a variety of common materials

including fats, oils, and greases (FOG), soaps,

scum, and some chemical constituents that can

attach to the grit particles and alter the particles

settling characteristics.

Top of page: the HeadCell system from Hydro

International

Above: Clean silica sand as shown through digital

imaging particle analysis.

Wet weather can result in peak ow and peak

collection of entrained grit; heavy accumulations

may overload collection systems and treatment

plant.

Grit washing and dewatering

Once collected, the grit must be washed and

dewatered in order to produce a clean, dry

product for landll. Washing and dewatering

must each be as effective as the collection device

otherwise the overall system efciency will suffer.

A recent study at a plant showed that while the

aerated grit basin removed 58 percent of total

entering grit volume, the cyclone/screw classier

washing and dewatering equipment only retained

17 percent of what it received. The loss of grit

reduced the systems overall removal efciency

to only 10 percent.

Developing a site-specic design

Each grit removal system developed for a

wastewater treatment plant is different and will

require its own design solution. To achieve grit

collection engineered for a specic treatment

site, it is preferable to rst measure the grit size

distribution and settling velocity. Care must

be taken in collecting the sample to ensure it is

representative of all sizes of incoming grit and

ow conditions such as weather, seasons, inow

channel shape, and depth.

Once sampling is complete, the size distribution and effective settling velocity or effective

specic gravity of the grit sample must be

determined. Both characteristics are needed

in order to have accurate data upon which to

base a system design.

In the absence of site-specic information,

a conservative approach is to base the design

on the smallest practicable particle size, which

would typically be in the 75- to 106-micron

size range.

Future trends

Recent surveys over a range of treatment plants

and localities in the United States have conrmed

the variation in particle specic gravity, and the

effect of organic material on specic gravity

through agglomeration with grit particles. They

conrm that bulk density and specic gravity of

wastewater grit are lower than for clean silica

sand, indicating a shift in design considerations.

Newer editions of design manuals, such as the

Water Environment Federations (USA) Manual

of Practice 8: Design of Municipal Wastewater

Treatment Plants, are recommending targeting

particles smaller than 212 micron in grit system

design and many grit removal systems being

designed today are targeting removal of particles

in the 75-106-150 micron size range.

Advanced Grit Management

In North America, Hydro International is

pioneering the philosophy of Advanced Grit

Management with a stated objective of

+95-percent removal efciency of particles in

the 75- to 150-micron range, and 85 to 95

percent efciency of the total grit load entering

a treatment plant. A new website www.

AdvancedGritManagement.com provides a

clearing house for science-based information

on grit removal design, which can be used by

engineers, operators, and owners to select the

best solution for their projects needs.

Key to this approach has been the intensive

study of grit parameters and behavior, and the

design of grit-removal solutions with a small

footprint, low headloss, low power use, and low

operating costs.

Hydro Internationals HeadCell, accepted as

the next generation of grit separation technology,

is a modular, multiple-tray settleable solids

concentrator that achieves high-performance

removal of ne grit as small as 75 micron. The

company says it eliminates the inefciencies of

conventional forced vortex grit removal systems.

Its stacked tray design optimizes the capacity for

grit separation within a small footprint making

it useful for new and retrot applications.

The Hydro Grit King is an advanced

hydrodynamic vortex separator that augments

gravitational forces to separate grit from water

with minimal headloss. Its small footprint

design uses no power and has no moving parts,

achieving low operating and maintenance costs.

Authors Note

Marcia Sherony is the national sales manager

for Hydros US Wastewater Division, based

in Hillsboro, Oregon. For advice, knowledge

or grit removal product information email

questions@hydro-int.com or visit

www.hydro-int.com.

World Water November/December 2013

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- PH Miracle Complete Whole Body Alkalizing Program-1201724Dokumen20 halamanPH Miracle Complete Whole Body Alkalizing Program-1201724joao carlos100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Calculation of Pipe SupportDokumen8 halamanCalculation of Pipe SupportPhyu Mar Thein Kyaw67% (6)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Calculation of Pipe Bend Trust ForceDokumen4 halamanCalculation of Pipe Bend Trust ForcePhyu Mar Thein Kyaw100% (1)

- Calculation of Orifice Plate DiameterDokumen2 halamanCalculation of Orifice Plate DiameterPhyu Mar Thein Kyaw100% (1)

- Pharma Pathway SopDokumen350 halamanPharma Pathway SopDinesh Senathipathi100% (1)

- Basic Calculations Piping System Design PDFDokumen14 halamanBasic Calculations Piping System Design PDFjeff_shawBelum ada peringkat

- Basic Calculations Piping System Design PDFDokumen14 halamanBasic Calculations Piping System Design PDFjeff_shawBelum ada peringkat

- Case Study, g6Dokumen62 halamanCase Study, g6julie pearl peliyoBelum ada peringkat

- Bedok WRP velocity and pumping calculationsDokumen3 halamanBedok WRP velocity and pumping calculationsPhyu Mar Thein Kyaw100% (1)

- Calculation of Flow VelocityDokumen3 halamanCalculation of Flow VelocityPhyu Mar Thein KyawBelum ada peringkat

- Publications FireSafetyDesign SDokumen369 halamanPublications FireSafetyDesign SJayachandra Reddy AnnavaramBelum ada peringkat

- A. What Is Balanced/objective Review or Criticism?Dokumen11 halamanA. What Is Balanced/objective Review or Criticism?Risha Ann CortesBelum ada peringkat

- Pipeline profile and reservoir water levelsDokumen7 halamanPipeline profile and reservoir water levelsPhyu Mar Thein KyawBelum ada peringkat

- Branch Discharge Line CalculationsDokumen2 halamanBranch Discharge Line CalculationsPhyu Mar Thein KyawBelum ada peringkat

- Calculation of Hydraulic Profile Single BranchDokumen14 halamanCalculation of Hydraulic Profile Single BranchPhyu Mar Thein KyawBelum ada peringkat

- Calculation of Blower Air Pipe Pressure Loss (Ave)Dokumen30 halamanCalculation of Blower Air Pipe Pressure Loss (Ave)Phyu Mar Thein Kyaw100% (2)

- Fabm2 q2 Module 4 TaxationDokumen17 halamanFabm2 q2 Module 4 TaxationLady HaraBelum ada peringkat

- FIDIC delay and disruption standardsDokumen7 halamanFIDIC delay and disruption standardsMohammad FayazBelum ada peringkat

- Calculation of Air Pipe SizeDokumen6 halamanCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- IncinerationDokumen11 halamanIncinerationPhyu Mar Thein KyawBelum ada peringkat

- IncinerationDokumen11 halamanIncinerationPhyu Mar Thein KyawBelum ada peringkat

- IncinerationDokumen11 halamanIncinerationPhyu Mar Thein KyawBelum ada peringkat

- Optimal Penstock Sizing for Increased FlowDokumen1 halamanOptimal Penstock Sizing for Increased FlowPhyu Mar Thein KyawBelum ada peringkat

- Air Compressor Specifiction (Atlas Copco)Dokumen3 halamanAir Compressor Specifiction (Atlas Copco)Phyu Mar Thein KyawBelum ada peringkat

- Calculation of Height of The Siphon SystemDokumen2 halamanCalculation of Height of The Siphon SystemPhyu Mar Thein Kyaw100% (1)

- Hot Water System Sizing CalculationDokumen1 halamanHot Water System Sizing CalculationPhyu Mar Thein KyawBelum ada peringkat

- Centrifugal Pumps PDFDokumen54 halamanCentrifugal Pumps PDFthomastheinkyaw100% (1)

- Calculation of Jet ProjectileDokumen32 halamanCalculation of Jet ProjectilePhyu Mar Thein KyawBelum ada peringkat

- Calculation For Rention TimeDokumen2 halamanCalculation For Rention TimePhyu Mar Thein KyawBelum ada peringkat

- Calculation For Water CapacityDokumen2 halamanCalculation For Water CapacityPhyu Mar Thein KyawBelum ada peringkat

- Infomation of GasDokumen31 halamanInfomation of GasPhyu Mar Thein KyawBelum ada peringkat

- ALL Purpose Worksheet (Conversions)Dokumen28 halamanALL Purpose Worksheet (Conversions)Phyu Mar Thein KyawBelum ada peringkat

- Infomation of Compressed Air LineDokumen8 halamanInfomation of Compressed Air LinePhyu Mar Thein KyawBelum ada peringkat

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDokumen85 halamanChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanBelum ada peringkat

- Compressed Air Pressure Drop DiagramsDokumen6 halamanCompressed Air Pressure Drop DiagramsPhyu Mar Thein KyawBelum ada peringkat

- Air Tools and Air ConsumptionsDokumen2 halamanAir Tools and Air ConsumptionsPhyu Mar Thein KyawBelum ada peringkat

- Calculation of Relief CapacityDokumen6 halamanCalculation of Relief CapacityPhyu Mar Thein Kyaw100% (1)

- AP World History: Islamic Empires and Scientific AdvancementDokumen55 halamanAP World History: Islamic Empires and Scientific AdvancementJa'TasiaBelum ada peringkat

- Evolution BrochureDokumen4 halamanEvolution Brochurelucas28031978Belum ada peringkat

- KCL Thesis PrintingDokumen4 halamanKCL Thesis PrintingMelinda Watson100% (2)

- 2020 - Audcap1 - 2.3 RCCM - BunagDokumen1 halaman2020 - Audcap1 - 2.3 RCCM - BunagSherilyn BunagBelum ada peringkat

- 50hz Sine PWM Using Tms320f2812 DSPDokumen10 halaman50hz Sine PWM Using Tms320f2812 DSPsivananda11Belum ada peringkat

- Divide Fractions by Fractions Lesson PlanDokumen12 halamanDivide Fractions by Fractions Lesson PlanEunice TrinidadBelum ada peringkat

- Exercise C: Cocurrent and Countercurrent FlowDokumen6 halamanExercise C: Cocurrent and Countercurrent FlowJuniorBelum ada peringkat

- Robin Engine EH722 DS 7010Dokumen29 halamanRobin Engine EH722 DS 7010yewlimBelum ada peringkat

- Benefits of Eating OkraDokumen4 halamanBenefits of Eating Okraama931Belum ada peringkat

- 6a. ICMR STSDokumen15 halaman6a. ICMR STSVishnu Praba ABelum ada peringkat

- Funny Physics QuestionsDokumen3 halamanFunny Physics Questionsnek tsilBelum ada peringkat

- Earth and Beyond PDFDokumen5 halamanEarth and Beyond PDFNithyananda Prabhu100% (1)

- Module-1 STSDokumen35 halamanModule-1 STSMARYLIZA SAEZBelum ada peringkat

- Design of Steel Structures Handout 2012-2013Dokumen3 halamanDesign of Steel Structures Handout 2012-2013Tushar Gupta100% (1)

- An RNA Vaccine Drives Expansion and Efficacy of claudin-CAR-T Cells Against Solid TumorsDokumen9 halamanAn RNA Vaccine Drives Expansion and Efficacy of claudin-CAR-T Cells Against Solid TumorsYusuf DemirBelum ada peringkat

- Heads of Departments - 13102021Dokumen2 halamanHeads of Departments - 13102021Indian LawyerBelum ada peringkat

- SIO 12 Syllabus 17Dokumen3 halamanSIO 12 Syllabus 17Paul RobaiaBelum ada peringkat

- Project Final Report: Crop BreedingDokumen16 halamanProject Final Report: Crop BreedingAniket PatilBelum ada peringkat

- Government of The Punjab Primary & Secondary Healthcare DepartmentDokumen3 halamanGovernment of The Punjab Primary & Secondary Healthcare DepartmentYasir GhafoorBelum ada peringkat

- Corporate GovernanceDokumen35 halamanCorporate GovernanceshrikirajBelum ada peringkat

- 2 Case StudyDokumen8 halaman2 Case Studysehrish khawerBelum ada peringkat

- Batool2019 Article ANanocompositePreparedFromMagn PDFDokumen10 halamanBatool2019 Article ANanocompositePreparedFromMagn PDFmazharBelum ada peringkat

- Stress Out?: A Study of Trends in Workplace Stress Across The GlobeDokumen14 halamanStress Out?: A Study of Trends in Workplace Stress Across The GlobeVishesh Vij100% (1)