PLC Implementation of The Bottle-Filling Application - EEP

Diunggah oleh

666667Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PLC Implementation of The Bottle-Filling Application - EEP

Diunggah oleh

666667Hak Cipta:

Format Tersedia

6/2/2015

PLCimplementationofthebottlefillingapplication|EEP

Home Technical Articles Article Categories Contact us Subscribe to articles Subscribe to downloads

El. Enginering Guides

EE General guides

Power Substations

Schneider Electric CTs

Siemens Basics of EE

ABB Drives Guides

Industry Automation

Relay control/protection

Alternative Energy

Electrical Software MS Excel Spreadsheets Electrical Design Docs Engineering Resources

Video Lectures Electrical Engineering

PLC Programming Training

Electric Testing and Maintenance (VIDEO)

Network Theorems and Laws

-

PLCimplementationofthebottlefilling

application

PLC implementation of the bottle-filling application (photo credit: aircontrolindustries.com)

Detectionofposition

In this example (see Figure 1), we will implement a control program that detects the position of a

bottle via a limit switch, waits 0.5 seconds, and then fills the bottle until a photosensor detects a

filled condition.

After the bottle is filled, the control program will wait 0.7 seconds before moving to the next bottle.

The program will include start and stop circuits for the outfeed motor and the start of the process.

Table 1 shows the I/O address assignment, while Tables 2 and 3 present the internal and register

assignments, respectively.

These assignments include the start and stop process signals.

Figure 1 Bottle-filling system

http://electricalengineeringportal.com/plcimplementationofthebottlefillingapplication

1/5

6/2/2015

PLCimplementationofthebottlefillingapplication|EEP

Table 1 I/O address

assignment

http://electricalengineeringportal.com/plcimplementationofthebottlefillingapplication

2/5

6/2/2015

PLCimplementationofthebottlefillingapplication|EEP

Module Type

I/O Address

Rack

Group

Terminal

Description

Start process PB1

Stop process PB2 (NC)

Limit switch (position detect)

Photoeye (level detect)

Feed motor M1

Outfeed motor M2 (system ON)

Solenoid control

Input

Output

Table 2 Internal output assignment

Device

Internal

Description

Timer

1001

Timer for 0.5 sec delay after position detect

Timer

1002

Timer for 0.7 sec delay after level detect

1003

Bottle filled, timed out, feed motor M1

Table 3 Register assignment

Register

Description

4000

Preset value 5, time base 0.1 sec (1001)

4001

Accumulated value for 1001

4002

Preset value 7, time base 0.1 sec (1002)

4003

Accumulated value for 1002

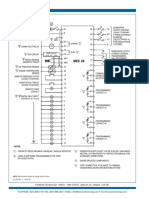

Figure 2 illustrates the PLC ladder implementation of the bottle-filling application. Once the start

push button is pushed, the outfeed motor (output 031) will turn ON until the stop push button is

pushed.

The feed motor M1 will be energized once the system starts (M2 ON) it will stop when the

limit switch detects a correct bottle position. When the bottle is in position and 0.5 seconds have

elapsed, the solenoid (032) will open the filling valve and remain ON until the photoeye (PE) detects

a proper level.

http://electricalengineeringportal.com/plcimplementationofthebottlefillingapplication

3/5

6/2/2015

PLCimplementationofthebottlefillingapplication|EEP

The bottle will remain in position for 0.7 seconds, then the energized internal 1003 will start the

feed motor. The feed motor will remain ON until the limit switch detects another bottle.

Figure 2 PLC implementation of the bottle-filling application

Reference: Introduction to PLC Programming and Implementation from relay logic to PLC logic

- globalautomation.info

RecommendedEEarticles//

Sharewithengineers//

AboutAuthor//

http://electricalengineeringportal.com/plcimplementationofthebottlefillingapplication

4/5

6/2/2015

PLCimplementationofthebottlefillingapplication|EEP

Edvard Csanyi

Edvard - Electrical engineer, programmer and founder of EEP. Highly

specialized for design of LV high power busbar trunking (<6300A) in power

substations, buildings and industry fascilities. Designing of LV/MV

switchgears. Professional in AutoCAD programming and web-design.

Present on Google+

2015 EEP - Electrical Engineering Portal. All Rights Reserved | Privacy

Policy | 30 queries in 0.208 seconds.

Powered by CsanyiGroup

SHARE

TOP

Get

PDF

http://electricalengineeringportal.com/plcimplementationofthebottlefillingapplication

5/5

Anda mungkin juga menyukai

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosDari EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosPenilaian: 5 dari 5 bintang5/5 (1)

- Lab Manual Control Systems (EEE325) : 2 Edition August 2011Dokumen7 halamanLab Manual Control Systems (EEE325) : 2 Edition August 2011Yasir HussainBelum ada peringkat

- Mechatronic System Design (ENT473) : Session 2008/2009 Semester 1Dokumen7 halamanMechatronic System Design (ENT473) : Session 2008/2009 Semester 1Iyyan ParamanandamBelum ada peringkat

- PLC Final Project (Uthm)Dokumen15 halamanPLC Final Project (Uthm)K.Magenthran (UTHM)100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDari EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Lab-6 CounterTimer 2022Dokumen8 halamanLab-6 CounterTimer 2022Sivakorn TALUENGPETBelum ada peringkat

- Introduction to the simulation of power plants for EBSILON®Professional Version 15Dari EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Belum ada peringkat

- IJSRDV8I20003Dokumen3 halamanIJSRDV8I20003Ahmad HamoudaBelum ada peringkat

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorDari EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorBelum ada peringkat

- Ministry of Education West Yangon Technological University Department of Electronic EngineeringDokumen9 halamanMinistry of Education West Yangon Technological University Department of Electronic EngineeringKg Myat HtutBelum ada peringkat

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDari EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusBelum ada peringkat

- 164-11 Falla D6 DragaSurDokumen11 halaman164-11 Falla D6 DragaSurManuel ContrerasBelum ada peringkat

- Ladder Logic For Bottle FillingDokumen14 halamanLadder Logic For Bottle FillingZack NduatiBelum ada peringkat

- Smart Traffic Control System Using PLC ScadaDokumen14 halamanSmart Traffic Control System Using PLC ScadaSaravanan ViswakarmaBelum ada peringkat

- Engine Fan Control Solenoid Circuit - Test: TroubleshootingDokumen8 halamanEngine Fan Control Solenoid Circuit - Test: Troubleshootingtommy lanyonBelum ada peringkat

- PLC Lab #4 Event SequencingDokumen15 halamanPLC Lab #4 Event SequencingIan SpacekBelum ada peringkat

- New Microsoft Word Document Tofik ProposalDokumen12 halamanNew Microsoft Word Document Tofik ProposalenbakomBelum ada peringkat

- Soochna 2012 FinalDokumen140 halamanSoochna 2012 FinalHanuma Reddy100% (1)

- Service Experience MAN 2 STROKEDokumen32 halamanService Experience MAN 2 STROKEBenjamin van DierenBelum ada peringkat

- PLC Full ReportDokumen10 halamanPLC Full ReportJian Jie0% (1)

- Control Panel OCP 4.3Dokumen4 halamanControl Panel OCP 4.3rubenBelum ada peringkat

- El 200b ExcavadoraDokumen8 halamanEl 200b Excavadoradinny blancoBelum ada peringkat

- Programmable Logic Controller (PLC) : Abhishek SoniDokumen36 halamanProgrammable Logic Controller (PLC) : Abhishek SoniAbhishek SoniBelum ada peringkat

- PLC Based Sequential Batch Process Control SystemDokumen11 halamanPLC Based Sequential Batch Process Control SystemAmol PawarBelum ada peringkat

- Dosif Floculante200t PDFDokumen21 halamanDosif Floculante200t PDFRodrigo PaezBelum ada peringkat

- Autostart Control Panels - Analog Control System - Product Training Department - OLYMPIAN PDFDokumen22 halamanAutostart Control Panels - Analog Control System - Product Training Department - OLYMPIAN PDFpevare100% (18)

- Diagnostic ET. Transmision 140H - DocxDokumen38 halamanDiagnostic ET. Transmision 140H - Docxjorgemorales416100% (2)

- ME2010 - Lab3 - Sequential Control DesignDokumen7 halamanME2010 - Lab3 - Sequential Control DesignQuang KisitoBelum ada peringkat

- VOLVO BP (Public) Serving Traning-1Dokumen204 halamanVOLVO BP (Public) Serving Traning-1kogyi.tty987Belum ada peringkat

- Electro Pneumatics m3 Student VersionDokumen22 halamanElectro Pneumatics m3 Student VersionArt NidayBelum ada peringkat

- Starting System and Engine Cooling InspectionDokumen8 halamanStarting System and Engine Cooling InspectionErwinBelum ada peringkat

- Electronically Controlled Diesel EngineDokumen50 halamanElectronically Controlled Diesel EngineVictorIjadunminiyi100% (2)

- PLC Based Water Bottle Filling and Caping SystemDokumen4 halamanPLC Based Water Bottle Filling and Caping SystemSajid BashirBelum ada peringkat

- Programmable Logic Controller (PLC) and AutomationDokumen20 halamanProgrammable Logic Controller (PLC) and AutomationJeeva RajBelum ada peringkat

- Assignment On PLCDokumen4 halamanAssignment On PLCNirman ParasharBelum ada peringkat

- Engine Cranks But Does Not Start: Diagnostic Codes, and Electrical Power Supply To The ECMDokumen3 halamanEngine Cranks But Does Not Start: Diagnostic Codes, and Electrical Power Supply To The ECMFaresBelum ada peringkat

- Industrial AutomationDokumen33 halamanIndustrial AutomationTimothy FieldsBelum ada peringkat

- What Are The Various PLC System in SIMATIC S7 Range ?Dokumen10 halamanWhat Are The Various PLC System in SIMATIC S7 Range ?Qamar Hassan IqbalBelum ada peringkat

- Laporan PLC Analog - Injektor Plastik Moulding - Kelompok 1Dokumen8 halamanLaporan PLC Analog - Injektor Plastik Moulding - Kelompok 112 MIPA 2Ramadhani Madimas SaputraBelum ada peringkat

- Motor Bi-Direction Rotation and Dynamic Braking Control ExperimentDokumen3 halamanMotor Bi-Direction Rotation and Dynamic Braking Control ExperimentJayson AlvaBelum ada peringkat

- Practical 3 (3 Hours) PLC Application in The Industry 2 (Water Level and Mixer Control)Dokumen2 halamanPractical 3 (3 Hours) PLC Application in The Industry 2 (Water Level and Mixer Control)Kosigar ChelladoraiBelum ada peringkat

- Jeep Ignition SystemDokumen15 halamanJeep Ignition Systembillh@optonline.net100% (1)

- EML System On BMW 12cyl Engines - Theory of OpsDokumen6 halamanEML System On BMW 12cyl Engines - Theory of OpsDOMINO66Belum ada peringkat

- Ec240 Volvo 1 102Dokumen102 halamanEc240 Volvo 1 102Muriel Remberto100% (23)

- 20-ME-9 Uzair Akram FM Lab 13Dokumen12 halaman20-ME-9 Uzair Akram FM Lab 13uzair akramBelum ada peringkat

- PCT 100 (Level)Dokumen10 halamanPCT 100 (Level)Danang Pradika PurnomoBelum ada peringkat

- Practical File of PLC and SCADADokumen17 halamanPractical File of PLC and SCADAvara prasadBelum ada peringkat

- Process Control Servo SystemDokumen16 halamanProcess Control Servo SystemCarlos RamirezBelum ada peringkat

- Assignment 1Dokumen12 halamanAssignment 1Mohamad HafizBelum ada peringkat

- PLC S7 - 300 Applications: Electric Power / ControlsDokumen24 halamanPLC S7 - 300 Applications: Electric Power / ControlsChu Văn ThànhBelum ada peringkat

- 20-ME-9 Uzair Akram FM Lab 14Dokumen12 halaman20-ME-9 Uzair Akram FM Lab 14uzair akramBelum ada peringkat

- ECEg6223 Sample Exam PDFDokumen5 halamanECEg6223 Sample Exam PDFGenet BekeleBelum ada peringkat

- Dse720 ManualDokumen25 halamanDse720 ManualJesus Manuel Aguirre AguirreBelum ada peringkat

- Introduction To Programmable Logic ControllersRev2Dokumen43 halamanIntroduction To Programmable Logic ControllersRev2bd9051Belum ada peringkat

- PLC Lab ManualDokumen64 halamanPLC Lab ManualNaveen Kumar100% (4)

- Introduction To Programmable Logic ControllersRev2Dokumen43 halamanIntroduction To Programmable Logic ControllersRev2apelokayaBelum ada peringkat

- 05 Fuel Injection SystemDokumen42 halaman05 Fuel Injection SystemVishal JohaheerBelum ada peringkat

- Injector Solenoid Circuit - Test (RENR5096)Dokumen7 halamanInjector Solenoid Circuit - Test (RENR5096)Josip MiškovićBelum ada peringkat

- Superac: Instructions BookletDokumen42 halamanSuperac: Instructions Booklet666667Belum ada peringkat

- Bentley HevacompDokumen1 halamanBentley Hevacomp666667Belum ada peringkat

- FTTODokumen13 halamanFTTO666667Belum ada peringkat

- DC Vs AC MotorsDokumen2 halamanDC Vs AC Motors666667Belum ada peringkat

- Why Do My Contactor Coils Keep Burning OutDokumen2 halamanWhy Do My Contactor Coils Keep Burning Out666667Belum ada peringkat

- Calculate Size of Conduit 1.1.15Dokumen3 halamanCalculate Size of Conduit 1.1.15engrsaqibhusainBelum ada peringkat

- Men's Footwear Size Guide - ASOSDokumen3 halamanMen's Footwear Size Guide - ASOS666667Belum ada peringkat

- ContentsDokumen14 halamanContentsisukuru0% (1)

- BMS IO SummaryDokumen1 halamanBMS IO Summary666667Belum ada peringkat

- Modbus Over Serial LineDokumen44 halamanModbus Over Serial Linearindammanna123Belum ada peringkat

- Chapter 5: Compliance With Planning Policy Guidelines: 5.1 GeneralDokumen8 halamanChapter 5: Compliance With Planning Policy Guidelines: 5.1 General666667Belum ada peringkat

- Cable Design - New (22.8.12)Dokumen93 halamanCable Design - New (22.8.12)zanibabBelum ada peringkat

- Stairwell PressurisationDokumen2 halamanStairwell PressurisationsudeeshkumarsBelum ada peringkat

- Ect158 Calculation of Short-Circuit CurrentsDokumen36 halamanEct158 Calculation of Short-Circuit CurrentsSafetyjoe2Belum ada peringkat

- 1 PBDokumen11 halaman1 PB666667Belum ada peringkat

- SdofDokumen160 halamanSdofddanielwork2060Belum ada peringkat

- Vertical Farming - Automated Green House Blog - 8...Dokumen6 halamanVertical Farming - Automated Green House Blog - 8...666667Belum ada peringkat

- How To Input NUMBERS Through Arduino Serial - MonitorDokumen1 halamanHow To Input NUMBERS Through Arduino Serial - Monitor666667Belum ada peringkat

- Cylinder Concrete Mix ProportationsDokumen3 halamanCylinder Concrete Mix Proportations666667Belum ada peringkat

- Keypad Number Input and StoreDokumen2 halamanKeypad Number Input and Store666667Belum ada peringkat

- HC SR04 PDFDokumen3 halamanHC SR04 PDFVipan Sharma100% (1)

- Center of Mass and GravityDokumen14 halamanCenter of Mass and GravityLutfi IsmailBelum ada peringkat

- Selection of Coil Spring For Vibratory ScreenDokumen13 halamanSelection of Coil Spring For Vibratory Screen666667Belum ada peringkat

- Barry Isolators Selection GuideDokumen16 halamanBarry Isolators Selection GuideJason E. CortésBelum ada peringkat

- Ansi z10 Session 1r c2Dokumen29 halamanAnsi z10 Session 1r c2666667Belum ada peringkat

- COP WSH RegulationDokumen31 halamanCOP WSH RegulationAdam TangBelum ada peringkat

- 8 Main Disadvantages of HVDC Transmission - EEPDokumen5 halaman8 Main Disadvantages of HVDC Transmission - EEP666667Belum ada peringkat

- Technology Oscillating-Mountings enDokumen7 halamanTechnology Oscillating-Mountings en666667Belum ada peringkat

- RSQ Consolidated Style Sheet Final Version AmendedDokumen16 halamanRSQ Consolidated Style Sheet Final Version Amended666667Belum ada peringkat

- What's That Hissing, Cracking, Buzzing Noise - EEPDokumen5 halamanWhat's That Hissing, Cracking, Buzzing Noise - EEP666667Belum ada peringkat

- Connection Diagram: Thomson Technology - 9087A - 198Th Street, Langley, BC Canada V1M 3B1Dokumen4 halamanConnection Diagram: Thomson Technology - 9087A - 198Th Street, Langley, BC Canada V1M 3B1AdeelBelum ada peringkat

- Haier Placa ElDokumen57 halamanHaier Placa ElRadoi RaduBelum ada peringkat

- Search GPS 2Dokumen25 halamanSearch GPS 2HENRY DJOHNSONBelum ada peringkat

- E CTCDokumen1 halamanE CTCjanechuacruzBelum ada peringkat

- GE Fanuc Series One PlusDokumen300 halamanGE Fanuc Series One PlusRubén SánchezBelum ada peringkat

- 06 EasyIO FC20 Sedona Kitsv1.2 PDFDokumen63 halaman06 EasyIO FC20 Sedona Kitsv1.2 PDFnguyendinhphuc22008Belum ada peringkat

- Siemenss 7200 PLC 1Dokumen26 halamanSiemenss 7200 PLC 1Handi KsciBelum ada peringkat

- Weekly Programmable Electronic Timer: Technical DataDokumen2 halamanWeekly Programmable Electronic Timer: Technical DataCsaba VargaBelum ada peringkat

- Deep Sea 5510 ManualDokumen78 halamanDeep Sea 5510 Manualruizaco745586% (7)

- jk50 GBDokumen5 halamanjk50 GBInaamBelum ada peringkat

- Fluke PM6666 Freq CounterDokumen46 halamanFluke PM6666 Freq CounterKang OyonBelum ada peringkat

- UNIT 5 MechatronicsDokumen16 halamanUNIT 5 MechatronicsMuthuvel M85% (27)

- An865a Sia 1Dokumen32 halamanAn865a Sia 1felixsafar3243Belum ada peringkat

- Tempo Riz AdoresDokumen40 halamanTempo Riz AdoresNelson AlvesBelum ada peringkat

- PLC ProgramDokumen5 halamanPLC ProgramMOUSIN PASHABelum ada peringkat

- Hat220 V1Dokumen6 halamanHat220 V1Avilio CastellanoBelum ada peringkat

- NEED Manual Ver. 1.7 enDokumen297 halamanNEED Manual Ver. 1.7 enradhoinezerellyBelum ada peringkat

- Manual JulaboDokumen28 halamanManual JulaboJosep Folguera GarciaBelum ada peringkat

- Getting Started With Timer/Counter Type A (Tca) : View The Atmega4809 Code Example On GithubDokumen23 halamanGetting Started With Timer/Counter Type A (Tca) : View The Atmega4809 Code Example On GithubGion AndrásBelum ada peringkat

- Architecture and Programming of 8051 MCU's: 1.1 What Are Microcontrollers and What Are They Used For?Dokumen11 halamanArchitecture and Programming of 8051 MCU's: 1.1 What Are Microcontrollers and What Are They Used For?JosephPaulBelum ada peringkat

- Dse55xx PC Software ManualDokumen142 halamanDse55xx PC Software ManualcarlosrmtzBelum ada peringkat

- Garmin Swim: Owner's ManualDokumen12 halamanGarmin Swim: Owner's ManualCiureanu CristianBelum ada peringkat

- Casio Stopwatch HS80TWDokumen1 halamanCasio Stopwatch HS80TWVicente_scridbBelum ada peringkat

- Basic Electricity 3Dokumen52 halamanBasic Electricity 3Jon Yingst100% (1)

- MB90F337Dokumen85 halamanMB90F337Bin WangBelum ada peringkat

- Service Manual: Air ConditionersDokumen51 halamanService Manual: Air ConditionersM8R-hauss31Belum ada peringkat

- Cateye Mity 8Dokumen2 halamanCateye Mity 8Chad GlendeBelum ada peringkat

- Models 69NT40-511-310, 344 & 359: Operation & ServiceDokumen4 halamanModels 69NT40-511-310, 344 & 359: Operation & ServiceRodrigo Ribeiro ArnholdBelum ada peringkat

- Microprocessors & Interfacing: Interrupts (II)Dokumen9 halamanMicroprocessors & Interfacing: Interrupts (II)Daisy Paola Rodriguez SuarezBelum ada peringkat

- The Internet Con: How to Seize the Means of ComputationDari EverandThe Internet Con: How to Seize the Means of ComputationPenilaian: 5 dari 5 bintang5/5 (6)

- How to Do Nothing: Resisting the Attention EconomyDari EverandHow to Do Nothing: Resisting the Attention EconomyPenilaian: 4 dari 5 bintang4/5 (421)

- NFT per Creators: La guida pratica per creare, investire e vendere token non fungibili ed arte digitale nella blockchain: Guide sul metaverso e l'arte digitale con le criptovaluteDari EverandNFT per Creators: La guida pratica per creare, investire e vendere token non fungibili ed arte digitale nella blockchain: Guide sul metaverso e l'arte digitale con le criptovalutePenilaian: 5 dari 5 bintang5/5 (15)

- How to Create Cpn Numbers the Right way: A Step by Step Guide to Creating cpn Numbers LegallyDari EverandHow to Create Cpn Numbers the Right way: A Step by Step Guide to Creating cpn Numbers LegallyPenilaian: 4 dari 5 bintang4/5 (27)

- TikTok Algorithms 2024 $15,000/Month Guide To Escape Your Job And Build an Successful Social Media Marketing Business From Home Using Your Personal Account, Branding, SEO, InfluencerDari EverandTikTok Algorithms 2024 $15,000/Month Guide To Escape Your Job And Build an Successful Social Media Marketing Business From Home Using Your Personal Account, Branding, SEO, InfluencerPenilaian: 4 dari 5 bintang4/5 (4)

- Ten Arguments for Deleting Your Social Media Accounts Right NowDari EverandTen Arguments for Deleting Your Social Media Accounts Right NowPenilaian: 4 dari 5 bintang4/5 (388)

- Your Network Is Your Net Worth: Unlock the Hidden Power of Connections for Wealth, Success, and Happiness in the Digital AgeDari EverandYour Network Is Your Net Worth: Unlock the Hidden Power of Connections for Wealth, Success, and Happiness in the Digital AgePenilaian: 3.5 dari 5 bintang3.5/5 (43)

- Blender 3D for Jobseekers: Learn professional 3D creation skills using Blender 3D (English Edition)Dari EverandBlender 3D for Jobseekers: Learn professional 3D creation skills using Blender 3D (English Edition)Belum ada peringkat

- Kill All Normies: Online Culture Wars From 4Chan And Tumblr To Trump And The Alt-RightDari EverandKill All Normies: Online Culture Wars From 4Chan And Tumblr To Trump And The Alt-RightPenilaian: 3.5 dari 5 bintang3.5/5 (240)

- Narrative Design for Indies: Getting StartedDari EverandNarrative Design for Indies: Getting StartedPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Ultimate Guide to YouTube for BusinessDari EverandUltimate Guide to YouTube for BusinessPenilaian: 5 dari 5 bintang5/5 (1)

- The YouTube Formula: How Anyone Can Unlock the Algorithm to Drive Views, Build an Audience, and Grow RevenueDari EverandThe YouTube Formula: How Anyone Can Unlock the Algorithm to Drive Views, Build an Audience, and Grow RevenuePenilaian: 5 dari 5 bintang5/5 (33)

- Social Media Marketing 2024, 2025: Build Your Business, Skyrocket in Passive Income, Stop Working a 9-5 Lifestyle, True Online Working from HomeDari EverandSocial Media Marketing 2024, 2025: Build Your Business, Skyrocket in Passive Income, Stop Working a 9-5 Lifestyle, True Online Working from HomeBelum ada peringkat

- Viralnomics: The Ultimate Guide on How to Go Viral! Learn All About Viral Marketing and the Elements of a Successful Viral CampaignDari EverandViralnomics: The Ultimate Guide on How to Go Viral! Learn All About Viral Marketing and the Elements of a Successful Viral CampaignPenilaian: 5 dari 5 bintang5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDari EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosPenilaian: 5 dari 5 bintang5/5 (1)

- The Social Media Bible: Tactics, Tools, and Strategies for Business SuccessDari EverandThe Social Media Bible: Tactics, Tools, and Strategies for Business SuccessPenilaian: 3.5 dari 5 bintang3.5/5 (19)

- Computer Science: A Concise IntroductionDari EverandComputer Science: A Concise IntroductionPenilaian: 4.5 dari 5 bintang4.5/5 (14)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsDari EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsPenilaian: 5 dari 5 bintang5/5 (1)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDari EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperiencePenilaian: 4 dari 5 bintang4/5 (19)

- Laws of UX: Using Psychology to Design Better Products & ServicesDari EverandLaws of UX: Using Psychology to Design Better Products & ServicesPenilaian: 5 dari 5 bintang5/5 (9)

- Branding: What You Need to Know About Building a Personal Brand and Growing Your Small Business Using Social Media Marketing and Offline Guerrilla TacticsDari EverandBranding: What You Need to Know About Building a Personal Brand and Growing Your Small Business Using Social Media Marketing and Offline Guerrilla TacticsPenilaian: 5 dari 5 bintang5/5 (32)

- The Ultimate LinkedIn Sales Guide: How to Use Digital and Social Selling to Turn LinkedIn into a Lead, Sales and Revenue Generating MachineDari EverandThe Ultimate LinkedIn Sales Guide: How to Use Digital and Social Selling to Turn LinkedIn into a Lead, Sales and Revenue Generating MachineBelum ada peringkat