Calculation

Diunggah oleh

Tohid KarimiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Calculation

Diunggah oleh

Tohid KarimiHak Cipta:

Format Tersedia

PROJECT : KERMANSHAH OIL STORAGE FARM

ENGINEERING - CONSTRUCTION

COMPANY

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

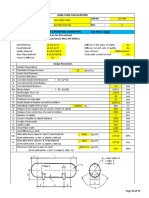

8- ANCHOR CHAIR DESIGN

STRESS DUE TO ANCHOR FORCE IN TANK SHELL AT POINT WHERE THE ANCHORES ATTACHED SHOULD BE

CHECKED PER PART VII,VOLUME II,AISI E-1,"ANCHOR BOLT CHAIRS" ACC. TO PARA E6-1

8-1) GENERAL DATA :

FROM SEISMIC DESIGN,SEC. 6-4 , P=

1052

188

197930

(N)

44585

(Lb)

(P IS BOLT FORCE DUE TO WIND OR SEISMIC WICHEVER IS GREATER)

FROM STD. DWG. NO. STD.TK.GEN.7314 :

a=

350

mm = 13.78 in

d=

45

mm = 1.772 in

h=

200

mm = 7.874 in

f=

50

mm = 1.969 in

g=

100

mm = 3.937 in

e=

98

mm = 3.858 in

(SHELL THK) t =

mm = 0.354 in

(BOTTOM THK) m =

mm = 0.276 in

112

mm = 4.409 in

R=

C=

12500 mm = 492.1 in

30

mm = 1.181 in

(AVERAGE LENGTH) L =

DESIGNED

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

Document Subject

ENGINEERING - CONSTRUCTION

COMPANY

Doc No

Date

Page of Page

N.I.O.P.D.C.

Mechanical Calculation Book

8-2) STRESS IN SHELL :

Pe

S=

x[

t2

1.43ah2

Rt

1

Z=

0.177 a m ( m / t )2

+

( R t )0.5

1.32 Z

+

+

( 4 ah2).333

=

0.31

( R t )0.5

111,816

PSI

0.97

SHELL ALOWABLE STRESS IN SEISMIC = 0.8 * YIELD STRESS = 0.8 x205 = 164 Mpa (24000 PSI).

THEN PAD SHOULD BE USED IN SHELL CONTACT POINT.

USING PAD WITH 12mm THK.

t = 9 + 12=

S=

21 mm =

Pe

t2

x[

:

0.827 in

h =

200 mm =

1.32 Z

1.43ah

Rt

Z=

+

( 4 ah2).333

0.177 a m ( m / t )2

7.874 in

0.31

( R t )0.5

e=

]

98

=

mm =

3.86

22230

0.996

( R t )0.5

8-3) TOP RING THICKNESS :

MAX STRESS IN TOP PLATE THAT ACCURES BETWEEN HOLE & FREE EDGE OF THE PLATE IS EQUAL :

S=

S=

P

fC2

(O.375 g - 0.22 d )

17642

PSI < 0.8 x YIELD STRESS = 24000 PSI

8-4) GUSSET THICKNESS :

THICKNESS REQUIRED :

tg min.=1/2" or 0.04(h-c)

0.04(200-30)=6.8 mm

tg=14 mm is selected.

jk> p/25

2.43 >

DESIGNED

1.8

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

in

PSI

PROJECT : KERMANSHAH OIL STORAGE FARM

ENGINEERING - CONSTRUCTION

COMPANY

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

7-WIND LOAD (PARA 3-11)

7-1) WIND SHEAR & MOMENT(PARA 3-11-1) :

WIND PRESSURE ON TANK SHELL , Pw =

860.0 Pa

(ON PROJECTED AREA)

WIND PRESSURE ON TANK ROOF , Pw =

720.0 Pa

(ON PROJECTED AREA)

WIND FORCE ON TANK SHELL =

215000

CENTER OF AREA =

5.3

WIND FORCE ON TANK ROOF =

7078

CENTER OF AREA =

10.76

RESULT :

WIND FORCE ON TANK =

222078

WIND MOMENT ON TANK =

1204921

N.m

7-2) FOR TANK STABILITY AGAINST WIND MOMENT :

M< =

2

3

W.D

2

(PARA. 3.11.2)

W = SHELL WEIGHT AVAILABLE TO RESIST UPLIFT LESS ANY CORROSION ALLOWANCE

PLUS DEAD WEIGHT SUPPORTED BY SHELL =

2

3

W.D

2

5,765,623

N.m

>

70599

Kg

1,204,921

THEN TANK IS STABLE AGAINST WIND OVERTURNING.

DESIGNED

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

Document Subject

ENGINEERING - CONSTRUCTION

COMPANY

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

6- SEISMIC DESIGN (APP. E)

6-1) SHEAR & OVERTURNING MOMENT(PARA. E-3-1) :

M = Z . I ( C1WSXS + C1WrHt + C1W1X1 + C2W2X2 )

V = Z . I ( C1WS + C1Wr + C1W1 + C2W2 )

Z

=ZONE FACTOR

0.4

=IMPORTANCE. FACTOR

1.25

= SHELL WEIGHT +2700 Kg ACC.

75758

Kg

50887

Kg

WS

WEIGHT

Wr

= ROOF WEIGHT+20000 Kg ACC.&STRUC.

WEIGHT

XS

= SHELL C.G.

4.59

Ht

=SHELL HEIGHT

10.5

=PARA. E.3.3.1

0.6

= ACCORDING TO FIGURE (E.4)

0.61

= NOMINAL DIAMETER

25000

5.5

0.17

C1

T

C2

= NATURAL PERIOD OF FIRST SLOSHING

=1.8 K( D0.5)

= 3.375 S / T ^2 =

mm

>

4.5

(BASED ON E.3..3.2)

= SITE COEFF.

1.5

= LIQUID LEVEL

10

WT

=WEIGHT OF CONTENT

4.91E+06

kg

tb

= BOTTOM PLATE THK .

mm

=MIN. YIELD STRENGTH OF BOTTOM PL

205

Mpa

Fby

DESIGNED

J.GH.

CHECKEDED:

M.GH.

(PARA E-4-2)

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

ENGINEERING - CONSTRUCTION

COMPANY

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

6-2) EFFECTIVE MASS OF TANK CONTENTS :

W1

WEIGHT OF EFFECTIVE MASS OF CONTENTS THAT MOVE IN

UNISON WITH TANK SHELL.

W2

WEIGHT OF EFFECTIVE MASS OF CONTENTS THAT MOVE IN

FIRST SLOSHING MODE.

X1

DISTANCE TO CENTROID OF LATERAL FORCE APPLIED TO W 1.

X2

DISTANCE TO CENTROID OF LATERAL FORCE APPLIED TO W 2.

W1 / WT =

0.480

W1 =

2.36E+06

Kg

W2 / W T =

0.480

W2 =

2.36E+06

Kg

X1 / H =

0.378

X1 =

3.78E+00

X2 / H =

0.580

X2 =

5.80E+00

FIG. E.2 :

FIG. E.3 :

RESULT :

OVER TURNING MOMENT & SHEAR :

DESIGNED

J.GH.

M~

4.08E+06

Kg-m

V~

9.43E+05

Kg

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

Document Subject

ENGINEERING - CONSTRUCTION

COMPANY

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

6-3) CHECKING STABILITY OF UNANCHORED TANK (PARA. E.4 & E.5) :

FOR STABLITY AGAINST SEISMIC OVERTURNING WITHOUT ANCHORAGE :

M

<

1.57

D ( Wt + Wl )

2

Wt :

SHELL WEIGHT AND PORTION OF FIXED ROOF SUPPORTED BY SHELL PER

SHELL CIRCUMFERENCE

Wt =

75758

16962

xp

25

SHELL WEIGHT ~

75758

1180.6

Kg / m

Kg

ROOF WEIGHT SUPPORTED BY SHELL ~

WL :

16962

Kg

MAXIMUM CONTENT WEIGHT THAT RESIST THE SHELL OVERTURNING

WL = 99 tb (Fby x G x H)0.5 THAT SHALL NOT EXCEED 196GHD (PARA. E-4-1)

WL =

31377

N / m (PER SHELL CIRCUMFERENCE)

196xGHD=

49000

N/m

WL =

31377

N/m

>

WL

THEN :

M

D2 ( Wt + Wl )

1.49

(BASED ON E.4.1)

>

1.57

TANK IS STABLE AND SHOULD NOT BE ANCHORED.

DESIGNED

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

ENGINEERING - CONSTRUCTION

COMPANY

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

6-4) MINIMUM ANCHORAGE, (PARA. E-6-1) :

MIN ANCHORAGE RESISTANCE :

BOLT NUMBER :

B.C.D =

BOLT YIELD STRESS :

- Wt

D2

28

25.22

BOLT SPACING

1.273 M

69950.0

N/m

m

25.22 x p

28

2400

2.83

(ACCEPTABLE PER CODE PARA. E-6-2-2)

Kg / Cm2

BOLT ALLOWABLE STRESS : 0.8 x YEILD STRESS PER PARA. E-6-2-3:

REQUIRED AREA FOR EACH BOLT=

69950.0

188.2

188.2

2.83

1052

MPa

mm2

ANCHOR BOLT SIZE SHALL NOT BE LESS THAN 1 in PER PARA. E6.2.2.

NOTE:

CONSIDERING 1.5 mm C.A. THEN A=

USING

DESIGNED

28

NO.

J.GH.

M 45

CHECKEDED:

1231

mm2

WITH 1262 mm2 ROOT AREA WITH 2400 Kg / Cm2 YIELD STRESS

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

ENGINEERING - CONSTRUCTION

COMPANY

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

6-5) CHECKING MAX. COMPRESSION ON SHELL(PARA.E-5-2) :

b=

1.273 M

D2

+ Wt

93089

N/m

b : MAX. LONGITUDINAL COMPRESSIVE FORCE AT THE BOTTOM SHELL COURSE CIRCUMFERENCE.

MAX. LONG. COMP. STRESS ON BOTTOM SHELL COURSE = b / 1000 t =

t = BOTTOM SHELL COURSE EXCLUDING ANY C.A. =

12

7.8

Mpa

mm

b / 1000 t SHOULD BE LESS THAN ALLOWABLE COMP. STRESS WHICH IS CALCULATED PER PARA. E-5-3.

6-6) FINDING MAX. COMPRESSION STRESS ON SHELL(PARA.E-5-3) :

FINDING "Fa " :

GHD2

t2

Fa = 83 t / D

39.8

43.4

>

44

Mpa

Fa SHALL NOT EXCEED 0.5 Fty(=0.5 x 205 = 102.5 MPa)

Fty = MINIMUM YIELD STRENGTH OF BOTTOM SHELL COURSE = 205 Mpa

b / 1000 t =

7.8

Mpa IS LESS THAN ALLOWABLE COMP. STRESS =

39.8

Mpa

.THEN IT IS NOT

REQUIRED TO INCREASE THICKNESS OF BOTTOM SHELL COURSE.

DESIGNED

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

ENGINEERING - CONSTRUCTION

COMPANY

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

5- TANK STABILITY AGAINST WIND LOAD, PARA. 3-9-7

5-1) UNSTIFFENED SHELL HEIGHT:

MAX. HEIGHT OF UNSTIFFENED SHELL SHALL NOT BE GREATER THAN H1:

H1 = 9.47t ( t / D )1.5 x (160/V)2

(PARA. 3-9-7-1)

t = THICKNESS OF TOP COURSE (uncorroded condition) =

D = NOMINAL TANK DIAMETER =

V=WIND VELOCITY = 160

H1=

6.681

25

mm

Km/hr

5-1) UNSTIFFENED SHELL HEIGHT, PARA. 3.9.7.2 :

COURSE NO.

7

6

5

4

3

2

1

ttop

tcourse

H1

(mm) (m) (mm)

6

6.681

6

6

6.681

6

6

6.681

8

6

6.681

8

6

6.681

10

6

6.681

12

6

6.681

12

W

(m)

1.5

1.5

1.5

1.5

1.5

1.5

1.5

W tr

SW tr

(m)

1.50

1.50

0.73

0.73

0.42

0.27

0.27

(m)

1.50

3.00

3.73

4.46

4.88

5.14

5.41

WIND GIRDER

REQUIRED

POSITION FROM

TOP (M)

NO

NO

NO

NO

NO

NO

NO

--------

Wtr = TRANSPOSED WIDTH OF EACH SHELL COURSE

Ttop = TOP SHELL COURSE

W = EACH COURSE HEIGHT

RESULT:

NO WIND GIRDER IS REQUIRED.

DESIGNED

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

Document Subject

ENGINEERING - CONSTRUCTION

COMPANY

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

4-ROOF DESIGN, PARA 3-10-4:(FOR CARRING LIVE & DEAD LOAD)

THE ROOF IS CONSIDERED SUPPORTED CONE ROOF AS DESCRIBED IN CODE, PARA 3-10-1 & 3-10-4.FOR ROOF

STRUCTURE, RAFTERS AND GIRDERS WITH COLUMN IS CONSIDERED.THEN TOP ANGLE SHALL BE CHECKED

WITH STRUCTURES, TOO. SIZING TOP ANGLE AND STRUCTURES ARE SPECIFIED IN SEC. 10.

THE SLOPE OF ROOF IS EQUAL TO ( 3/4" IN 12" ) THEN CONE ROOF ANGLE.( PER PARA. 3-10-4) IS 3.6 o

MINIMUM SIZE OF ROOF PLATE & TOP ANGLE IS AS FOLLOW:

ROOF PLATE THICKNESS :

5+C.A. mm, MIN. OF CODE PER PARA 3-10-2-2

MIN TOP ANGLE SIZING PER PARA.3-1-5-9-e : : 150X150X15

RESULT;

ROOF PLATE THICKNESS :

: ROOF SLOPE :

3.6

mm

ROOF PLATE WEIGHT =

30887

Kg

ROOF PLATE WEUGHT (CORRODED)=

19304

Kg

DESIGNED

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

Document Subject

ENGINEERING - CONSTRUCTION

COMPANY

Doc No

Date

Page of Page

Mechanical Calculation Book for

N.I.O.P.D.C.

3- SHELL PLATE DESIGN

3-1 ) CALCULATION :

THICKNESS OF SHELL COURSES IS CALCULATED BY "ONE FOOT METHOD" ACCORDING

TO PARA 3-6-3 . THE REQUIRED SHELL THICKNESS SHALL BE GREATER OF VALUES

COMPUTED BY THE FOLLOWING FORMULAS BUT NOT LESS THAN TABLE OF PARA 3-6-1-1 :

DESIGN SHELL THICKNESS:

HYDROSTATIC SHELL THICKNESS:

td =

4.9 D ( H - 0.3 ) G

Sd

tt =

4.9 D ( H - 0.3 )

St

+C.A.

D = INSIDE DIAMETER

SELECTED MATERIAL FOR SHELL :

A-283 Gr. C

Sd = PRODUCT DESIGN STRESS OF SHELL PLATE =

137 MPA

St = ALLOWABLE STRESS FOR HYDROTEST PRESSURE =

154 MPA

G = SPECIFIC GRAVITY =

1.000

H = DESIGN LIQUID LEVEL , FROM BOTTOM OF THE COURSE UNDER CONSIDERATION TO MAX. LIQUID LEVEL

(SHELL HEIGHT FOR HYDROTEST CONDITION)

DESIGNED

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book for Fire

Water Storage Tank

618-ME-CAL-001-1

Dec.19,2005

6 of 25

ENGINEERING - CONSTRUCTION

COMPANY

N.I.O.P.D.C.

3-2) SHELL THICKNESS :

11.67

10.33

8.99

7.65

6.31

4.97

3.63

7.72

6.52

5.33

4.14

2.94

1.75

0.56

WEIGHT(Kg)

(CRRODED)

13872

12947

11097

11097

9248

7398

7398

11097.3

10172.6

8323.0

8323.0

6473.5

4623.9

4623.9

IAL

HK

M)

3

3

3

3

3

3

3

R

TE

MA

(M

HK

M)

10

8.5

7

5.5

4

2.5

1

T

AL

TU

AC M )

(M

T

ST

TE

(M

HK

)

mm

HT

HT

1.5

1.5

1.5

1.5

1.5

1.5

1.5

.T

LC

CA

A(

C.

IG

HE

EIG

EH

UID

LI Q )

(M

S

UR

CO )

(M

L

EL E

SH URS

CO

1

2

3

4

5

6

7

WEIGHT(Kg)

15

14

12

12

10

8

8

A-283 Gr. C

A-283 Gr. C

A-283 Gr. C

A-283 Gr. C

A-283 Gr. C

A-283 Gr. C

A-283 Gr. C

NOTE :

SHELL THICKNESS SHOULD NOT BE LESS THAN 5mm PER CODE ,PARA 3-6-1-1.

SHELL PLATE

WEIGHT (Kg) :

73057.55

SHELL PLATE

WEIGHT (Kg) :

(CORRODED)

SHELL CENTER OF GRAVITY =

4.59

53637.19

3-3) FINDING M.D.M.T :

MAX THK. =

15

FOR

M.D.M.T. FROM FIGURE 2-1 :

DESIGNED

J.GH.

A-283 Gr. C

-4

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

ENGINEERING - CONSTRUCTION

COMPANY

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

2- BOTTOM PLATE DESIGN

2-1) BOTTOM CENTERAL PLATES (PARA. 3-4-1) :

BOTTOM TYPE

BOTTOM MATERIAL :

CENTER UP

A-283 Gr. C

BOTTOM THK

MIN. THK = 6 + C.A.=

ACC TO PARA. 3.4.1

RESULT:

10

mm PLATE FOR BOTTOMPLATE IS USED.

2-2) ANNULAR BOTTOM PLATE : (PARA. 3-5)

ANNULAR MATERIAL :

A-283 Gr. C

ANNULAR THK. ACC TO TABLE 3-1:

Shyd FOR RST-37-2=22500 PSI <= 27000 PSI

&

ANNULAR PL. THK.

6 +C.A. = 6 + 3 =

TBOTTOM COURSE < 0.75"

THEN:

mm

USE 10mm THK. PLATE SAME AS BOTTOM PLATE FOR ANNULAR PLATE.

ANNULAR MIN. WIDTH:

MIN. REDIAL WIDTH OF ANNULAR PLATE ACC TO PARA 3.5.1 :

G=

215 tb / (GH)0.5

679.9

mm

H =LIQUID LEVEL=

10

t =ANULLAR PLATE THICKNESS =

10

mm

RESULT:

USE 10 mm PLATE FOR ANULAR PLATE WITH 680 MIN WIDTH

DESIGNED

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH OIL STORAGE FARM

Document Subject

ENGINEERING - CONSTRUCTION

COMPANY

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

1- GENERAL

DESIGN DATA

DATA

UNIT

TAG NO.

SERVICE

LOCATION

PURCHASER

CONTRACTOR

CODE

EDITION

OPERATING

DESIGN

APPENDIX(S)

DIMENSIONS

LIQUID LEVEL

CAPACITY

CONTENT

PUMP RATE FOR

BLEEDER VENT

SEISMIC

WIND VELOCITY

DESIGN METHODE

ROOF TYPE

MATERIAL

TEMP

PRESSURE

TEMP

PRESSURE

C

mbar

o

C

mbar

DIAxHEIGHT

MAX.

MIN.

GEOMETRIC

WORKING

SERVICE

S.G.

IN

OUT

ZONE

IMP. FACTOR

SOIL FACTOR

@ 15m

(m)

(mm)

(mm)

m3

m3

M3/Hr

M3/Hr

Km/hr

SHELL

BOTTOM

ANNULAR

ROOF

STRUCTURAL

ANCHOR BOLT

CORROSION

ALLOWANCE

DESIGNED

J.GH.

SHELL

BOTTOM

ROOF

CHECKEDED:

(mm)

(mm)

(mm)

M.GH.

TK 1029 & TK1030

GL/KR

KEMANSHAH

N.I.O.P.D.C.

JALKEH Co.

API-650

10th , Add. 2 ,2001

50

ATM.

90

ATM.

E

25

x

10.5

10000

200

5,154

4,908

GL/KR

1.000

HOLD

640

UBC-4

1.25

1.5

160

ONE FOOT METHOD

SUPPORTED CONE ROOF

A-283 Gr. C

A-283 Gr. C

A-283 Gr. C

A-283 Gr. C

ST37 OR EQUAL

YIELD : 2400 Kg/Cm2 (AI)

3

3

3

APPROVED

JALKEH CO.

PROJECT : KERMANSHAH TANK FARM

ENGINEERING - CONSTRUCTION

COMPANY

Document Subject

Doc No

Date

Page of Page

Mechanical Calculation Book

N.I.O.P.D.C.

CONTENTS:

DESIGNED

1- GENERAL

2- BOTTOM PLATE DESIGN

3- SHELL PLATE DESIGN

4-ROOF DESIGN, PARA 3-10-4(FOR CARRING LIVE & DEAD LOAD)

5- TANK STABILITY AGAINST WIND LOAD , PARA. 3-9-7

6- SEISMIC DESIGN (APP.E)

7- WIND LOAD (PARA 3-11)

14

8-ANCHORE CHAIR DESIGN

15

9-STRUCTURE SIZING

17

J.GH.

CHECKEDED:

M.GH.

APPROVED

JALKEH CO.

Anda mungkin juga menyukai

- Expansion Loop Flexibility Analysis (Weaver)Dokumen3 halamanExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- Tailing Lug - 173004-05Dokumen1 halamanTailing Lug - 173004-05shazan100% (1)

- Welding Calculations For Base PlateDokumen116 halamanWelding Calculations For Base PlateSyedZainAli100% (2)

- Calculation of left and right saddle supports for offshore tankerDokumen12 halamanCalculation of left and right saddle supports for offshore tankerrustamriyadiBelum ada peringkat

- Calculation of DavitDokumen2 halamanCalculation of DavitpiziyuBelum ada peringkat

- Saddle Baseplate Joint Weld Strength CalculationDokumen58 halamanSaddle Baseplate Joint Weld Strength CalculationSyedZainAliBelum ada peringkat

- LIFTING LUG CALCULATIONDokumen2 halamanLIFTING LUG CALCULATIONhuangjlBelum ada peringkat

- Saddle Support Calculation PD 5500,2000 Annex.G)Dokumen26 halamanSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- PFS FWKO Tank EvaluationDokumen12 halamanPFS FWKO Tank EvaluationkoyahassanBelum ada peringkat

- Pipe Saddle Support CalculationsDokumen1 halamanPipe Saddle Support CalculationsAbir Baran HandaBelum ada peringkat

- Saddle Design at Operating ConditionDokumen17 halamanSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- Design of Flanges - Full-Face Gasket 2010Dokumen29 halamanDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- LIFTING LUG Weld Check KGDokumen4 halamanLIFTING LUG Weld Check KGjoerijiBelum ada peringkat

- Pipe Clamp CalculationDokumen3 halamanPipe Clamp CalculationmohdrashidBelum ada peringkat

- Teto Api620Dokumen3 halamanTeto Api620viniciuskurtBelum ada peringkat

- Nozzle ReinforcementDokumen8 halamanNozzle ReinforcementHafizi HZnumismatic0% (1)

- Lift Lug SpreadsheetDokumen2 halamanLift Lug Spreadsheetpgarrett775814233100% (1)

- Bolt TorqueDokumen2 halamanBolt TorqueAzwan Shah100% (1)

- Weldment Strength Excel CalculationsDokumen33 halamanWeldment Strength Excel CalculationsYl WongBelum ada peringkat

- Welded PipeDokumen2 halamanWelded PipeНемања КараклајићBelum ada peringkat

- Godrej & Boyce calculations for weld strength and size of RIL equipmentDokumen10 halamanGodrej & Boyce calculations for weld strength and size of RIL equipmentSajal KulshresthaBelum ada peringkat

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDokumen25 halamanRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- Base Plate - FixedDokumen4 halamanBase Plate - Fixedbhaskardharani80% (5)

- Weight CalculatorDokumen12 halamanWeight CalculatorShafqat AfridiBelum ada peringkat

- Support CalculationDokumen16 halamanSupport Calculationhosny1987Belum ada peringkat

- (For Base Plate - BP1) : Weld Design For Stiffeners Vertical WeldDokumen10 halaman(For Base Plate - BP1) : Weld Design For Stiffeners Vertical Weldasvenk309Belum ada peringkat

- Baseplate Design Input DataDokumen166 halamanBaseplate Design Input DataAnonymous ciKyr0t86% (7)

- Saddle CalcDokumen26 halamanSaddle CalcVamsi S100% (2)

- Flange From Plate - Asme 16.5Dokumen1 halamanFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- FRP RF CalcDokumen1 halamanFRP RF CalcmukeshBelum ada peringkat

- Platform Cleat CalculationDokumen1 halamanPlatform Cleat Calculationmiteshpatel191Belum ada peringkat

- Base Plate CalculationDokumen8 halamanBase Plate Calculationanbuaed100% (1)

- Design Calculations For Pressure VesselsDokumen54 halamanDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozBelum ada peringkat

- Shell Type Boiler CalculationsDokumen17 halamanShell Type Boiler Calculations9913489806Belum ada peringkat

- WF, Unp, Angle, Pipe Steel Profile CalculationDokumen24 halamanWF, Unp, Angle, Pipe Steel Profile CalculationFian ArdiyanaBelum ada peringkat

- Calculating saddle dimensions for pipesDokumen2 halamanCalculating saddle dimensions for pipesrinabiswas50% (2)

- Design Calculation For Diesel TankDokumen17 halamanDesign Calculation For Diesel Tankויליאם סן מרמיגיוס100% (1)

- Lifting Lug CapacityDokumen1 halamanLifting Lug CapacityfutzbubbleBelum ada peringkat

- Imperial Piping Weight Load Calculation WorkbookDokumen13 halamanImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- SEISMIC ANALYSIS KazzincDokumen14 halamanSEISMIC ANALYSIS KazzincArees KhambattaBelum ada peringkat

- Pressure Vessel Lifting Lug CalculationDokumen2 halamanPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Plate CalculationDokumen7 halamanPlate CalculationminhthanhmosBelum ada peringkat

- Insert Plate DesignDokumen8 halamanInsert Plate Designvrajan1988Belum ada peringkat

- Chequered PlateDokumen23 halamanChequered Platesaravanan428680% (10)

- Total Middle East New Bitumen Terminal in TlbuDokumen25 halamanTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Skid CalcDokumen8 halamanSkid CalcRyan Fadhli50% (2)

- Calculation Storage Tank1000 KL PDFDokumen58 halamanCalculation Storage Tank1000 KL PDFemre gedikli100% (1)

- E4.5 Flange Cover CalcDokumen10 halamanE4.5 Flange Cover CalcTanCM100% (1)

- Design of Beam to Column ConnectionDokumen13 halamanDesign of Beam to Column ConnectionGautam SharmaBelum ada peringkat

- Design Calculation R1 PDFDokumen14 halamanDesign Calculation R1 PDFJagankumarBelum ada peringkat

- DRILL JIG (Final One)Dokumen21 halamanDRILL JIG (Final One)Varshasonawane962Belum ada peringkat

- Raw Water Storage Tank Design CalculationDokumen32 halamanRaw Water Storage Tank Design Calculationtanmaymajhi09_796764Belum ada peringkat

- 35 KL DesignDokumen10 halaman35 KL DesigneduardoambientalBelum ada peringkat

- Pump Foundation DesignDokumen18 halamanPump Foundation DesignSourav92% (12)

- UEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPDokumen8 halamanUEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPmkchy12100% (1)

- Thickness Cal. Fo DM Water Storage Tank-API 650Dokumen15 halamanThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- Purlin Cleat 220908Dokumen24 halamanPurlin Cleat 220908kalpanaadhi100% (2)

- Steam Drum, Water Wall & Evaporator - VWHA054Dokumen36 halamanSteam Drum, Water Wall & Evaporator - VWHA054Mani SunBelum ada peringkat

- Machine Design Elements and AssembliesDari EverandMachine Design Elements and AssembliesPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsDari EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsBelum ada peringkat

- QP (2016) 2Dokumen1 halamanQP (2016) 2pedro carrapicoBelum ada peringkat

- Final Decision W - Cover Letter, 7-14-22Dokumen19 halamanFinal Decision W - Cover Letter, 7-14-22Helen BennettBelum ada peringkat

- T9001 T9002 T9003 T9004: Tecn# Originator Title Aging Status of TecnDokumen2 halamanT9001 T9002 T9003 T9004: Tecn# Originator Title Aging Status of TecnThanalachmy GopiBelum ada peringkat

- 40 26Dokumen3 halaman40 26Maxi452Belum ada peringkat

- Thermal BurnsDokumen50 halamanThermal BurnsPooya WindyBelum ada peringkat

- Guidance Notes Blow Out PreventerDokumen6 halamanGuidance Notes Blow Out PreventerasadqhseBelum ada peringkat

- Sri Radhakrishna SwamijiDokumen43 halamanSri Radhakrishna SwamijiNarayana IyengarBelum ada peringkat

- Chapter 16 - Energy Transfers: I) Answer The FollowingDokumen3 halamanChapter 16 - Energy Transfers: I) Answer The FollowingPauline Kezia P Gr 6 B1Belum ada peringkat

- Swami Rama's demonstration of voluntary control over autonomic functionsDokumen17 halamanSwami Rama's demonstration of voluntary control over autonomic functionsyunjana100% (1)

- Smart Note Taker Saves Time With Air WritingDokumen17 halamanSmart Note Taker Saves Time With Air WritingNagarjuna LokkuBelum ada peringkat

- The Simple PendulumDokumen5 halamanThe Simple PendulumDexter TorringtonBelum ada peringkat

- Ultrasonic Weld Examination ProcedureDokumen16 halamanUltrasonic Weld Examination ProcedureramalingamBelum ada peringkat

- Are Hypomineralized Primary Molars and Canines Associated With Molar-Incisor HypomineralizationDokumen5 halamanAre Hypomineralized Primary Molars and Canines Associated With Molar-Incisor HypomineralizationDr Chevyndra100% (1)

- ADDRESSABLE 51.HI 60854 G Contoller GuideDokumen76 halamanADDRESSABLE 51.HI 60854 G Contoller Guidemohinfo88Belum ada peringkat

- Emerson EPC48150 1800 FA1EPC48300 3200 FA1 V PDFDokumen26 halamanEmerson EPC48150 1800 FA1EPC48300 3200 FA1 V PDFRicardo Andrés Soto Salinas RassBelum ada peringkat

- Retaining Wall-Masonry Design and Calculation SpreadsheetDokumen6 halamanRetaining Wall-Masonry Design and Calculation SpreadsheetfarrukhBelum ada peringkat

- Problem SolutionsDokumen5 halamanProblem SolutionskkappaBelum ada peringkat

- ROMUS 2012 Flooring CatalogueDokumen20 halamanROMUS 2012 Flooring CatalogueDan George IIIBelum ada peringkat

- Conjoint Analysis Basic PrincipleDokumen16 halamanConjoint Analysis Basic PrinciplePAglu JohnBelum ada peringkat

- Internal Audit ChecklistDokumen18 halamanInternal Audit ChecklistAkhilesh Kumar75% (4)

- Virchow TriadDokumen6 halamanVirchow Triadarif 2006Belum ada peringkat

- PDFViewer - JSP 3Dokumen46 halamanPDFViewer - JSP 3Kartik ChaudharyBelum ada peringkat

- WL 318 PDFDokumen199 halamanWL 318 PDFBeckty Ahmad100% (1)

- An Online ECG QRS Detection TechniqueDokumen6 halamanAn Online ECG QRS Detection TechniqueIDESBelum ada peringkat

- Sto - Cristo Proper Integrated School 1 Grading Grade 9 Science Table of SpecializationDokumen2 halamanSto - Cristo Proper Integrated School 1 Grading Grade 9 Science Table of Specializationinah jessica valerianoBelum ada peringkat

- Religion in Space Science FictionDokumen23 halamanReligion in Space Science FictionjasonbattBelum ada peringkat

- Clausius TheoremDokumen3 halamanClausius TheoremNitish KumarBelum ada peringkat

- 1989 GMC Light Duty Truck Fuel and Emissions Including Driveability PDFDokumen274 halaman1989 GMC Light Duty Truck Fuel and Emissions Including Driveability PDFRobert Klitzing100% (1)

- Validation Master PlanDokumen27 halamanValidation Master PlanPrashansa Shrestha85% (13)

- Ancient MesopotamiaDokumen69 halamanAncient MesopotamiaAlma CayapBelum ada peringkat