Resume of Dianagarcia

Diunggah oleh

api-23512047Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Resume of Dianagarcia

Diunggah oleh

api-23512047Hak Cipta:

Format Tersedia

Diana R. Garcia 18328 W. Beryl Ct.

● Waddell, AZ 85355

480-580-8035 ● diana.garcia@ asu.edu

OBJECTIVE

Seeking a challenging mechanical engineering position with a company which will utilize my skills,

abilities and experience to contribute to the company’s success

EDUCATION

Bachelors of Science in Engineering, Mechanical Engineering December 2009

Ira A. Fulton Schools of Engineering, Arizona State University Tempe, AZ

• Structural Mechanics • Mechanical Design • Thermodynamics

• Internal Combustion Engines • Polymer & Composites • Energy System Design

SKILLS

Tools: SolidWorks, ANSYS, LabVIEW, PSpice, FieldView

Applications: MS Office Suite, MATLAB

Languages: Fluent in English and Spanish.

Machine Shop Experience: Lathe, vertical mill, drill press, horizontal band saw

PROJECTS

Unmanned Ground Vehicle Fall 2008-Spring 2009

• Worked with team-members in the development of the suspension, control system, drive-train,

and chassis.

• Documented all progress and built to meet functionality, feasibility, reliability, manufacturability,

and safety metrics.

• Validated design by analyzing component strength and vehicle dynamics, devising experiments to

identify potential issues and implementing changes to improve the vehicle’s form and function.

Energy Assessment Spring 2009

• Conducted facility inspections, wrote proposals, and organized client meetings to address and

resolve issues.

• Created a plan that could reduce utility costs by more that $67,000/yr.

Product Testing Machine Spring 2008

• Engineered a machine which simulates walking that was used to test military boots.

• Prototype was a remote controlled, four-bar linkage with a crank rocker mechanism and a spring

shock absorber.

EXPERIENCE

Office Manager LG Auto Body, Phoenix, AZ July 2008-Present

• Manage invoices, inventory control, and provide customer service.

• Prepare and maintain profit/loss statements.

Accounts Payable Leggett & Platt, Phoenix, AZ December 2004-January 2008

• Calculated machine production efficiencies and forecasted monthly production for production

reports.

• Created work instructions for process improvement, saving time and money.

Parts Supervisor Leggett & Platt, Phoenix, AZ November 2005 – May 2006

• Decreased manufacturing costs by researching different vendors and reducing unnecessary

inventory by over 25%.

• Participated in Total Productive Manufacturing and Continuous Improvement teams that reduced

maintenance and machine downtime which contributed to a 20% decrease in maintenance costs.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Listening - Homework 2: Brushes 285 RamdhanieDokumen4 halamanListening - Homework 2: Brushes 285 RamdhanieBao Tran NguyenBelum ada peringkat

- Zest O CorporationDokumen21 halamanZest O CorporationJhamane Chan53% (15)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 39ED3050CT - RT49S - AP Service ManualDokumen31 halaman39ED3050CT - RT49S - AP Service Manualبوند بوند100% (1)

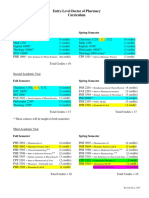

- Pharmd CurriculumDokumen18 halamanPharmd Curriculum5377773Belum ada peringkat

- Action Analysis For Animators by Chris WebsterDokumen409 halamanAction Analysis For Animators by Chris WebsterThomas Yandex100% (8)

- Course Structure and Content For Mechatronics, Systems and CDokumen32 halamanCourse Structure and Content For Mechatronics, Systems and CAnimonga HajimeBelum ada peringkat

- 1.1 The Prescription of Blood ComponentsDokumen9 halaman1.1 The Prescription of Blood ComponentsagurtovicBelum ada peringkat

- Antoine Constants PDFDokumen3 halamanAntoine Constants PDFsofiaBelum ada peringkat

- Engineering Structures: C.X. Dong, A.K.H. Kwan, J.C.M. HoDokumen14 halamanEngineering Structures: C.X. Dong, A.K.H. Kwan, J.C.M. HoElieser SinagaBelum ada peringkat

- ReviewerDokumen3 halamanReviewerKristine SantominBelum ada peringkat

- Mpfic54 PDFDokumen201 halamanMpfic54 PDFAmy100% (1)

- Chemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsDokumen5 halamanChemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsSevinc NuriyevaBelum ada peringkat

- Communication Guide: For Vita 62 Compliant VPX Power SuppliesDokumen8 halamanCommunication Guide: For Vita 62 Compliant VPX Power Suppliesk.saikumarBelum ada peringkat

- Properties of Matter ReviewDokumen8 halamanProperties of Matter Reviewapi-290100812Belum ada peringkat

- Crashing Is A Schedule Compression Technique Used To Reduce or Shorten The Project ScheduleDokumen1 halamanCrashing Is A Schedule Compression Technique Used To Reduce or Shorten The Project ScheduleRaymart BulagsacBelum ada peringkat

- Five Star Hotel and ResortDokumen9 halamanFive Star Hotel and ResortAISHBelum ada peringkat

- Future AncestorsDokumen44 halamanFuture AncestorsAlex100% (1)

- Of The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestDokumen4 halamanOf The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestBaydaa QaidyBelum ada peringkat

- Salem RPGDokumen16 halamanSalem RPGabstockingBelum ada peringkat

- Pineapple in JohorDokumen6 halamanPineapple in JohorHaiqal AzizBelum ada peringkat

- Opex and CapexDokumen5 halamanOpex and CapexATM Shafiq Ul AlamBelum ada peringkat

- Serving North Central Idaho & Southeastern WashingtonDokumen12 halamanServing North Central Idaho & Southeastern WashingtonDavid Arndt100% (3)

- By This Axe I Rule!Dokumen15 halamanBy This Axe I Rule!storm0% (1)

- Reactive Dyes For Digital Textile Printing InksDokumen4 halamanReactive Dyes For Digital Textile Printing InksDHRUVBelum ada peringkat

- Book BindingDokumen14 halamanBook Bindingpesticu100% (2)

- Shell Gadus: Designed To Do More. Just Like Our Greases - Shell GadusDokumen2 halamanShell Gadus: Designed To Do More. Just Like Our Greases - Shell Gadusperi irawanBelum ada peringkat

- Sw34 Religion, Secularism and The Environment by NasrDokumen19 halamanSw34 Religion, Secularism and The Environment by Nasrbawah61455Belum ada peringkat

- Apcotide 1000 pc2782Dokumen1 halamanApcotide 1000 pc2782hellmanyaBelum ada peringkat

- The Unofficial Aterlife GuideDokumen33 halamanThe Unofficial Aterlife GuideIsrael Teixeira de AndradeBelum ada peringkat