Recognized Worldwide For Dependability: Features / Benefits

Diunggah oleh

Sii UnchuJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Recognized Worldwide For Dependability: Features / Benefits

Diunggah oleh

Sii UnchuHak Cipta:

Format Tersedia

Warman 5000 vertical sump pump

Recognized worldwide for dependability

Warman centrifugal slurry pumps is pleased to offer the Galigher

5000 Series pump, featuring heavy duty construction, long service

life and easy maintenance. They are offered in a variety of materials

to match your requirements, combining flexibility and dependability in

abrasive/corrosive applications.

FEATURES / BENEFITS

Cantilevered shaft design

Double suction, semi-open impeller

Elastomer or abrasion resistant metal construction

Agitator option keeps solids in suspension

Optional suction extension

Universal motor bracket accomodates several motor sizes

Optional length to 5.6m with water lubricated intermediate bearings to drain deep

sumps

Dual casing balances radial loads on shaft and bearings

SHW-R Submersible slurry pump

The design process of the Warman SHW-R made extensive use of

state of the art solids modeling to ensure rugged, dependable solids

handling capability at lowest possible cost.

A heavy duty all chrome wet end coupled with a motor designed and

built by Weir Minerals for the most demanding applications makes

the Warman SHW-R the most dependable, long lasting, submersible

pump you can buy.

FEATURES

Size range (discharge)

2 to 6

50 mm to 150 mm

Capacities

to 2,000 gpm

to 455 m3/hr

Heads

to 175 ft

to 53 m

BENEFITS

Vortex design allows the SHW-R to pump any solids that pass through the pump

suction, even stringy, fibrous or tramp material

Recessed impeller provides long wear life on heavy slurry applications

The SHW-R handles much higher concentrations of air than centrifugal pumps

Particle degradation is greatly reduced since pumped solids do not pass through the

impeller

Temperature Sensor Over-temperature sensors protect the motor by sounding an

alarm or shutting down the unit if internal temperatures exceed safe operating limits

Moisture detector A twin electrode system provides double protection by detecting

moisture intrusion in either the motor housing or the mechanical seal chamber

Mechanical seals The SHW-R incorporates Warmans proven balanced doubleseal arrangement in which both sets of seal springs are enclosed in the oil reservoir.

Silicon carbide seal faces are subject to submergence pressure only for greatly

extended wear life

Heavy-duty water end Standard high chrome iron construction coupled with heavy

section thickness provides the ultimate in protection against abrasive wear in heavy

slurries

Easy maintenance access T-bolt construction allows rapid disassembly of the

pump end for maintenance access. The heavy-duty impeller is not screwed on, but

keyed to the shaft for easy removal and protection against movement

OPTIONAL FEATURES

Cooling jacket

quick disconnect

Discharge elbow

Sparger ring

Slide bracket

General purpose slurry pump

Warman centrifugal slurry pumps is pleased to offer

the Galigher Series 1000 pump -- a long proven horizontal end

suction centrifugal pump that will reliably and economically handle

abrasive and corrosive medium duty services.

Several unique features make the 1000 series ideal for handling

stringy/fibrous slurries, low NPSHA applications and services that

require minimum dilution due to gland seal water.

FEATURES

Size range (discharge)

1.5 to 12

40 mm to 300 mm

Capacities

to 6,500 gpm

to 1,480 m3/hr

Heads

to 140 ft

to 43 m

Pressures

to 232 psi

to 1,600 kPa

BENEFITS

Heavy duty construction with through-bolt casing design provides ease of

maintenance and results in less down time

Erosion and corrosion resistant elastomers or metal alloy liners are available to

handle solids laden and/or corrosive slurries

Semi-open impeller easily passes large or stringy particles and is well suited for froth

laden slurries.

Unique impeller hydraulic design allows operation

in systems with low NPSHA

Cartridge-style bearing assemblies offer compact reliable design that reduces

shaft/impeller overhang decreasing deflection for improved packing life and allows for

easy rebuilds

Multiple shaft sealing configurations are available

to best suit application requirements including standard wet and dry glands as well as

mechanical seals

Effective expeller prolongs packing life while reducing or eliminating flush water

requirement

Casing drain plug allows for component wear inspection as well as draining slurry

from the pump to prevent freezing or corrosion after flushing

Grease or oil lubricated bearing assemblies offer ease of maintenance and reduce

down time

Formerly marketed under the Vacseal and Galigher nameplates.

http://www.weirminerals.com/products__services/warman.aspx

Anda mungkin juga menyukai

- Warman AH Pump PDFDokumen4 halamanWarman AH Pump PDFEdwarPGBelum ada peringkat

- Equipment:: Figure 1: Vertical Turbine PumpDokumen8 halamanEquipment:: Figure 1: Vertical Turbine PumphamizanBelum ada peringkat

- Heavy Duty Wastewater Pumps: Performance OverviewDokumen1 halamanHeavy Duty Wastewater Pumps: Performance OverviewbayuBelum ada peringkat

- ESP System ApplicationsDokumen13 halamanESP System Applicationssindy amaliaBelum ada peringkat

- 1190E 2007 BrochureDokumen6 halaman1190E 2007 BrochureChinita_287Belum ada peringkat

- 02 02 Wirbelrad EnglischDokumen4 halaman02 02 Wirbelrad EnglischOsama TahaBelum ada peringkat

- b5860 For Slurry ApplicationDokumen6 halamanb5860 For Slurry Applicationpeach5Belum ada peringkat

- Goulds PUMPSDokumen10 halamanGoulds PUMPSMoustafa ElsadanyBelum ada peringkat

- Goulds Vertical Turbine PumpDokumen16 halamanGoulds Vertical Turbine PumpAnanto Veryadesa100% (2)

- 01 Chemical ProcessDokumen333 halaman01 Chemical ProcessDavid ValladaresBelum ada peringkat

- General Catalogue - Waterfalls Manufacturing - 2022 EditionDokumen16 halamanGeneral Catalogue - Waterfalls Manufacturing - 2022 Editionmuhammad nurochmanBelum ada peringkat

- Dorrco BrochureDokumen8 halamanDorrco BrochureJonathan Cornejo SuañaBelum ada peringkat

- Hidrostal Submersible Immersible PDFDokumen8 halamanHidrostal Submersible Immersible PDFariyamanjulaBelum ada peringkat

- Hidrolik SilindirlerDokumen20 halamanHidrolik SilindirlerEnver AtamanBelum ada peringkat

- Double Flap Gate ValvesDokumen16 halamanDouble Flap Gate ValvesMatias MancillaBelum ada peringkat

- Catalogo Tecnico Iso9001Dokumen5 halamanCatalogo Tecnico Iso9001daniela100% (1)

- VHDP AsmallDokumen76 halamanVHDP AsmalljnmanivannanBelum ada peringkat

- Coiled Tubing Workover ApplicationsDokumen60 halamanCoiled Tubing Workover Applicationsak_adamBelum ada peringkat

- Volvo Hydraulic Hammer PDFDokumen6 halamanVolvo Hydraulic Hammer PDFrammysi100% (1)

- Aturia Process Api610 092012low1Dokumen4 halamanAturia Process Api610 092012low1Goce VasilevskiBelum ada peringkat

- Grundfosliterature 425618Dokumen3 halamanGrundfosliterature 425618jasamnajBelum ada peringkat

- Pump Sales WebDokumen7 halamanPump Sales WebGermán Soledad MolinaBelum ada peringkat

- Goulds 3910 BulletinDokumen12 halamanGoulds 3910 BulletinLuevandresBelum ada peringkat

- TechSpec MistralDokumen4 halamanTechSpec MistralScarab SweepersBelum ada peringkat

- Vertical Turbine AND Propeller PumpsDokumen10 halamanVertical Turbine AND Propeller PumpsHamed Hamed100% (1)

- Product Range: Gate Valve / Sluice ValveDokumen6 halamanProduct Range: Gate Valve / Sluice ValveTanmoy DuttaBelum ada peringkat

- DR460 2008 BrochureDokumen8 halamanDR460 2008 Brochuredeath666dark100% (1)

- Liqua-Blaster 100 Series BrochureDokumen4 halamanLiqua-Blaster 100 Series BrochurejleonosBelum ada peringkat

- Literatura Tehnica - 22Dokumen16 halamanLiteratura Tehnica - 22roco_3213Belum ada peringkat

- AHR Brochure PDFDokumen6 halamanAHR Brochure PDFjraulpdBelum ada peringkat

- PDF 5000 Series Vertical Pumps Elastomer Lined or All Metal Abrasion Corrosion Resistant - CompressDokumen4 halamanPDF 5000 Series Vertical Pumps Elastomer Lined or All Metal Abrasion Corrosion Resistant - CompressPepe CarrBelum ada peringkat

- Atuador Rotativo - Série MDokumen16 halamanAtuador Rotativo - Série MTedson BragaBelum ada peringkat

- Mma 1210-Uk PDFDokumen24 halamanMma 1210-Uk PDFArnaldo BenitezBelum ada peringkat

- Steering StabilisationDokumen24 halamanSteering StabilisationRooftop Gardener100% (1)

- Paper Fan PumpsDokumen8 halamanPaper Fan PumpsnazeerBelum ada peringkat

- Centrifugal Slurry Pump RangeDokumen16 halamanCentrifugal Slurry Pump Rangecitramuara100% (4)

- Slurrymax Camur Pompasi 3 PDFDokumen8 halamanSlurrymax Camur Pompasi 3 PDFTecnologia Fabricación MetalmecanicaBelum ada peringkat

- Boletin Non ClogDokumen12 halamanBoletin Non ClogulisesgeBelum ada peringkat

- Taco 1400Dokumen4 halamanTaco 1400sas999333Belum ada peringkat

- NLB 225 Series F PumpDokumen2 halamanNLB 225 Series F Pumpjromero_rpgBelum ada peringkat

- Brochure BEGEMANN PA Pumps-Low ResolutionDokumen6 halamanBrochure BEGEMANN PA Pumps-Low ResolutionIsaac RubioBelum ada peringkat

- AHLSTAR - UP Process PumpsDokumen16 halamanAHLSTAR - UP Process PumpsSandi ApriandiBelum ada peringkat

- V4 SUBMERSIBLE PUMPSET - cUuTUtdDokumen8 halamanV4 SUBMERSIBLE PUMPSET - cUuTUtdtayadeyadhneshBelum ada peringkat

- Homa A Series BrochureDokumen8 halamanHoma A Series BrochureΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥBelum ada peringkat

- AG 3.1 End Suction DS Series 3422 Sterling SPA034 HR2Dokumen12 halamanAG 3.1 End Suction DS Series 3422 Sterling SPA034 HR2KhalidBelum ada peringkat

- 2018-05 KRAL Z Series En-UsDokumen16 halaman2018-05 KRAL Z Series En-UsartyyBelum ada peringkat

- E SV Series Promo Brochure BroesvDokumen16 halamanE SV Series Promo Brochure BroesvNelson CatucuagoBelum ada peringkat

- Flowserve Multiphase PumpsDokumen8 halamanFlowserve Multiphase PumpsveronrazvyBelum ada peringkat

- Double Flap Gate ValvesDokumen16 halamanDouble Flap Gate Valveskselvan_1Belum ada peringkat

- Slurrymax Pump: Split Casing Design For Multiple ApplicationsDokumen8 halamanSlurrymax Pump: Split Casing Design For Multiple Applicationssergio.manuel ovandoBelum ada peringkat

- Ps 70 1 eDokumen8 halamanPs 70 1 eMochamad Mujib Faozi NasirBelum ada peringkat

- 50 Pu 001 Wilfley PDFDokumen15 halaman50 Pu 001 Wilfley PDFMaju Palomino ChahuaBelum ada peringkat

- Valve Automation BrochureDokumen8 halamanValve Automation Brochuredarkchess76Belum ada peringkat

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDari EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingPenilaian: 5 dari 5 bintang5/5 (3)

- High-Performance GM LS-Series Cylinder Head GuideDari EverandHigh-Performance GM LS-Series Cylinder Head GuidePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Column Webs in Steel Beam-To-Column Connexions Part I-Formulation and VerificationDokumen27 halamanColumn Webs in Steel Beam-To-Column Connexions Part I-Formulation and VerificationSabra SABRABelum ada peringkat

- Mass Spectrometry Assignment-4Dokumen2 halamanMass Spectrometry Assignment-4Gouri PrinceBelum ada peringkat

- Science9 Q4 SLM9Dokumen11 halamanScience9 Q4 SLM9Soliel RiegoBelum ada peringkat

- ATC 34 Critical Review of Current Approaches To Earthquake Design - TOC ONLYDokumen6 halamanATC 34 Critical Review of Current Approaches To Earthquake Design - TOC ONLYNoahBelum ada peringkat

- Damping Dissipation AbsorbtionDokumen3 halamanDamping Dissipation AbsorbtionLia MatiasBelum ada peringkat

- C - 15 - 58 Project ProposalDokumen35 halamanC - 15 - 58 Project ProposalklklklBelum ada peringkat

- Lab 12 Specific Heat Garcia VersionDokumen3 halamanLab 12 Specific Heat Garcia VersionKimberly Suzanne TecsonBelum ada peringkat

- Buku Introduction To Oceanography PDFDokumen276 halamanBuku Introduction To Oceanography PDFmuhammad gilang ramadhanBelum ada peringkat

- Introduction To Seismic Interpretation El AmalDokumen33 halamanIntroduction To Seismic Interpretation El AmalFredrick Oshogbunu Ovakporaye100% (1)

- Why Kinetics Is Very Important in PharmacyDokumen13 halamanWhy Kinetics Is Very Important in PharmacyRavi KantBelum ada peringkat

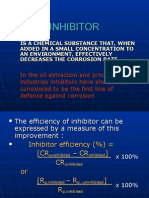

- Inhibitor CorrosionDokumen21 halamanInhibitor CorrosionDiego Pabon100% (2)

- MEC-307 Design of Machine Element 6 Semester (3 Year) : Name: Chirag Shetty Urn No: 2020-B-26101996Dokumen18 halamanMEC-307 Design of Machine Element 6 Semester (3 Year) : Name: Chirag Shetty Urn No: 2020-B-26101996Siddharth SinghBelum ada peringkat

- Metal Dusting in A Laboratory Environment - Alloying Addition EffectsDokumen15 halamanMetal Dusting in A Laboratory Environment - Alloying Addition EffectsClaudia MmsBelum ada peringkat

- Biosci 106: The Chemical Basis of LifeDokumen30 halamanBiosci 106: The Chemical Basis of LifeChengBelum ada peringkat

- Bom Lay Mau BuiDokumen2 halamanBom Lay Mau Buitranminhphuc2010Belum ada peringkat

- Variational Principle For A Particle in A BoxDokumen4 halamanVariational Principle For A Particle in A BoxajparnaibaBelum ada peringkat

- Tugas Strategi Rencana ProsesDokumen3 halamanTugas Strategi Rencana ProsesgeafitriaBelum ada peringkat

- HDG Steel Combined With Al-AlloyDokumen9 halamanHDG Steel Combined With Al-AlloySreedhar Patnaik.MBelum ada peringkat

- Thermochemical Properties Estimation For Biodiesel Related MixturesDokumen11 halamanThermochemical Properties Estimation For Biodiesel Related Mixturesalberth_carantónBelum ada peringkat

- Multiple Choice Question Material ScienceDokumen2 halamanMultiple Choice Question Material Sciencemanish_agr8567% (3)

- Insulated Glass Unit: Why Window Techs Insulated BlindDokumen2 halamanInsulated Glass Unit: Why Window Techs Insulated BlindSuruthi DasanBelum ada peringkat

- Ball Joint Failure DocumentDokumen2 halamanBall Joint Failure DocumentAbeer Darhous100% (1)

- Copra: RF SoftwareDokumen44 halamanCopra: RF Softwareabhimanyu alwaniBelum ada peringkat

- Clopidogrel TabletDokumen2 halamanClopidogrel Tabletgrace_febiantyBelum ada peringkat

- Vapor-Liquid Equilibria of Nonideal Solutions: Harrison C. Carlson, and Allan P. ColburnDokumen10 halamanVapor-Liquid Equilibria of Nonideal Solutions: Harrison C. Carlson, and Allan P. ColburnAlfonso Dominguez GonzalezBelum ada peringkat

- Motion in A Plane DPP 02 (Of Lec 05) Arjuna JEE 2024Dokumen3 halamanMotion in A Plane DPP 02 (Of Lec 05) Arjuna JEE 2024PriyanshuBelum ada peringkat

- MicroscopeDokumen4 halamanMicroscopeBryan PaulBelum ada peringkat

- E201: Work, Energy and Power POLICIOUS, Mark Angelo FDokumen5 halamanE201: Work, Energy and Power POLICIOUS, Mark Angelo FMark Angelo PoliciosBelum ada peringkat

- Beniston (2006) Mountain Weather and Climate A General Overview and A Focus On Climatic Change in The AlpsDokumen14 halamanBeniston (2006) Mountain Weather and Climate A General Overview and A Focus On Climatic Change in The AlpspierinaBelum ada peringkat

- Coh FRANC2D Tutorial PCDokumen0 halamanCoh FRANC2D Tutorial PCthegreatest0888Belum ada peringkat