Satr-P-3101 Rev 3

Diunggah oleh

mahdi_gJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Satr-P-3101 Rev 3

Diunggah oleh

mahdi_gHak Cipta:

Format Tersedia

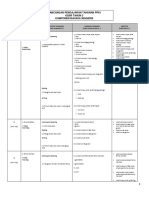

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAUDI ARAMCO TEST REPORT

SATR NUMBER

UPS/DC Electrochemical Battery, Storage and Preservation

Testing

PROJECT TITLE

SATR-P-3101

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED TEST DATE & TIME

ACTUAL TEST DATE & TIME

ELECTCONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

REFERENCE

A. TEST PROCEDURE AND CHECKLIST

A1

Batteries of different types and capacities shall not be mixed unless

authorized by the UPS manufacturer.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.9)

SAES-P-103

Sec. 3.2

A2

Terminals should be kept clean and free of chemical deposits that may

form on the interface between the battery terminal and the battery

connector.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.10)

SAES-P-103

Sec. 3.2

A3

All post-to-post and terminal connections should be tested for proper

resistance after all terminal connections are completed and prior to use

of the battery.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.10)

SAES-P-103

Sec. 3.2

A4

Batteries should be handled with extreme care or they may cause

severe injury. Spilled electrolyte may destroy clothing, burn skin, or

cause blindness. CAUTION- Always wear goggles and rubber gloves

when working with batteries.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.11)

SAES-P-103

Sec. 3.2

A5

Always wear eye protection, and never smoke when in the vicinity of

vented lead-acid batteries. The gases vented are hydrogen and oxygen,

a potentially explosive mixture. If electrolyte gets into the eyes, flush with

copious amounts of water and seek medical help immediately.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.11)

SAES-P-103

Sec. 3.2

A6

Batteries shall be used and stored in an upright position unless they

have been designed for all altitude use.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.11)

SAES-P-103

Sec. 3.2

A7

Insure that lead acid batteries are stored in a charge condition.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.12)

SAES-P-103

Sec. 3.2

A8

Verify that storage temperature range is 0 degree Centigrade to 25

degrees Centigrade or in accordance with the manufacturer's

recommendations.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.12)

SAES-P-103

Sec. 3.2

A9

Insure that when stored in a long period of time, it is advisable to keep

them on a very low rate of trickle charge in accordance with

manufacturer's recommendations.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.12)

SAES-P-103

Sec. 3.2

A10

Insure that when such trickle charging is impractical, batteries may be

charged periodically.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.12)

SAES-P-103

Sec. 3.2

A11

Check that battery operation monitoring system shall be implemented for

each bank of batteries to obtain history of the operation of the battery

system and to assist in battery evaluation.

(NFPA 70, NEC 110.3B, NEMA PE 1 Sec. 2.5.13)

SAES-P-103

Sec. 3.2

Page 1 of 8

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO ACTIVITY NUMBER

TEST PROCEDURE ACCEPTANCE CRITERIA

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

SAUDI ARAMCO TIP NUMBER

ITEM

No.

30-Jun-08

DATE APPROVED

QR NUMBER

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-TEST DATE

A12

The cells and monoblocks shall be interconnected using standard

connector used in actual battery installations. The cell opening shall be

closed with the appropriate electrolyte level indicators, vent plugs, flame

barriers or similar.

(NFPA 70, NEC 110.3B)

Page 2 of 8

SAES-P-103

Sec. 3.2

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAUDI ARAMCO TEST REPORT

SATR NUMBER

UPS/DC Electrochemical Battery, Storage and Preservation

Testing

PROJECT TITLE

ITEM

No.

SATR-P-3101

WBS / BI / JO NUMBER

TEST RESULTS ACCEPTANCE CRITERIA

REFERENCE

A13

Purified water shall be added to the cells if the electrolyte level

approaches the minimum mark.

(NFPA 70, NEC 110.3B)

SAES-P-103

Sec. 3.2

A14

The cells or batteries shall be allowed to remain without a connected

circuit for a period of 90 days, during which time the average

temperature of the electrolyte shall be maintained at (20 2) C. During

this time, the maximum electrolyte temperature shall not exceed 25 C,

and the minimum shall be not less than 15 C.

(IEC 60896-11 Sec. 18.2)

SAES-P-103

Sec. 3.2

A15

After 90 days of storage without a circuit, the cells or batteries shall

undergo a capacity test and the measured capacity shall be corrected.

IEC 60896-11 Sec. 18.3

SAES-P-103

Sec. 3.2

A16

Protective equipment:

The following minimum set of protective equipment for safe handling of

battery and protection of personnel shall be available:

a) Safety glasses with side shields, goggles or face shields

b) Electrically insulated gloves

c) Protective aprons and safety shoes

d) Portable or stationary water facilities for rinsing eyes and skin in case

of contact with electrolyte

e) Class C fire extinguisher

f) Bicarbonate of soda, mixed 0.1 kg to 1 L (1 lb to 1 gal) of water, to

neutralize acid spillage

g) Adequately insulated tools

SAES-P-103

Sec. 3.2

h) lifting device of adequate capacity, when required

NOTE- Some battery manufacturers do not recommend the use of CO2

Class C fire extinguishers due to the potential of thermal shock.

IEEE Std 1188-2005 Sec. 4.2

A17

A18

The following protective procedures shall be observed:

a) Use caution when working on batteries since they present a shock

hazard.

b) Check the voltage to ground (ac and dc) before working around the

battery

c) Prohibit smoking and open flames, and avoid arcing in the immediate

vicinity of the battery.

d) Provide adequate ventilation; follow manufacturer's instruction during

charging

e) Ensure unobstructed egress from the battery work area

f) Avoid wearing of metallic objects

such as jewelry

g) Ensure that work area is suitably illuminated

h) Follow manufacturer's recommendation regarding cell orientation

i) Follow manufacturer's recommendation regarding lifting and handling

of cells

(IEEE Std 1188-2005 Sec 4.3)

When cell temperatures deviate more than 3 C (5 F) from each other

during a single inspection, determine the cause and correct. If sufficient

correction cannot be made, contact the manufacturer for allowances that

must be taken.

IEEE Std 1188-2005 Sec. 5.3.2 b

Page 3 of 8

30-Jun-08

DATE APPROVED

QR NUMBER

SAES-P-103

Sec. 3.2

SAES-P-103

Sec. 3.2

ELECTCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-TEST DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAUDI ARAMCO TEST REPORT

SATR NUMBER

UPS/DC Electrochemical Battery, Storage and Preservation

Testing

PROJECT TITLE

ITEM

No.

A19

A20

A21

B.

SATR-P-3101

WBS / BI / JO NUMBER

TEST RESULTS ACCEPTANCE CRITERIA

A continuity test will determine the physical integrity of the battery

system, but not necessarily the performance of the battery. This test is

done with the semiannual maintenance, in accordance with the

manufacturer's recommendations, or when internal ohmic

measurements cannot be performed.

IEEE Std 1188-2005 Sec. 6.3

Connection resistance

It is good practice to read and record intercell and terminal connection

detail resistances as a baseline upon installation. It is very important that

the procedure be consistent so as to detect upward changes that could

be caused by corrosion or loose connections. Increased resistance is a

cause for concern and may require corrective action.

Normal

installation resistances vary greatly as a function of the size of the

installation, e.g., from less than 10 W for a large battery to as much as

100 W or more for a smaller battery. The manufacturer should be

contacted for the expected values.

IEEE Std 1188-2005 Annex D.1 & D.2

Pretest requirements:

The following defines the activities and data required prior to initiating a

discharge test.

a) If an equalizing charge is specifically recommended by the

manufacturer, verify that it has been completed more than three days

and less than thirty days prior to the start of the test.

b) Check all battery connections and ensure that all resistance readings

are correct for the system.

c) Read and record the float voltage of each cell/unit just prior to the test.

d) Read and record the temperature of the battery cell/unit to determine

an average battery temperature (suggest 10% or more cells/units).

e) Read and record the battery terminal float voltage.

f) Measure and record individual cell/unit internal ohmic values prior to

the test.

g) Take adequate precautions (such as isolating the battery to be tested

from other batteries and critical loads) to ensure that a failure will not

jeopardize other systems or equipment.

IEEE Std 1188-2005 Sec. 7.2

30-Jun-08

DATE APPROVED

QR NUMBER

REFERENCE

ELECTCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-TEST DATE

SAES-P-103

Sec. 3.2

SAES-P-103

Sec. 3.2

SAES-P-103

Sec. 3.2

TEST EQUIPMENT AND MATERIALS CRITERIA

1. When working on the electrical connections to the batteries, insulated tools should be used. (PE 1-2003 Sec. 2.5.10)

2. The instruments used for voltage measurement shall be voltmeters of an accuracy class equal to 0,5 or better. The resistance of the voltmeters

used shall be at least 1 k/V (see IEC 60051 or IEC 60485).

3. The instruments used for current measurement shall be ammeters of an accuracy class equal to 0,5 or better. The entire assembly of ammeter,

shunt and leads shall be of an accuracy class of 0,5 or better (see IEC 60051 or refer to IEC 60359).

4. For measuring temperature, thermometers shall be used having a suitable measuring range in which the value of each graduated division is not in

excess of 1 C. The absolute accuracy of the instruments shall be at least 1 C.

5. For measuring electrolyte densities, hydrometers or other instruments shall be used with scales so graduated that the value of each division is not

in excess of 5 kg/m3. The absolute accuracy of the instruments shall be at least 5 kg/m3.

Page 4 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAUDI ARAMCO TEST REPORT

SATR NUMBER

UPS/DC Electrochemical Battery, Storage and Preservation

Testing

PROJECT TITLE

ITEM

No.

SATR-P-3101

WBS / BI / JO NUMBER

TEST RESULTS ACCEPTANCE CRITERIA

6. For measurement of time, the instruments accuracy shall be 1% or better.

7. The test equipment calibration cycle shall not exceed twelve months.

Schedule Q, Att. IV, Sec. 7

Page 5 of 8

30-Jun-08

DATE APPROVED

QR NUMBER

REFERENCE

ELECTCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-TEST DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAUDI ARAMCO TEST REPORT

SATR NUMBER

UPS/DC Electrochemical Battery, Storage and Preservation

Testing

PROJECT TITLE

ITEM

No.

30-Jun-08

DATE APPROVED

QR NUMBER

SATR-P-3101

ELECT-

WBS / BI / JO NUMBER

CONTRACTOR / SUBCONTRACTOR

TEST RESULTS ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-TEST DATE

TEST RESULTS ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-TEST DATE

C. TEST RESULTS

D. CONCLUSIONS

ITEM

No.

D1

Specific gravity shall be in accordance with manufacturer's

recommended values.

NETA ATS 2007

7.18.1.1.1.6

D2

Electrolyte level shall be at the manufacturer's recommended reference

point.

NETA ATS 2007

7.18.1.1.1.6

D3

Cell voltage shall be in accordance with manufacturer's published data.

NETA ATS 2007

7.18.1.1.3.2.4

D4

Consult the battery manufacturer for cell internal ohmic values in excess

of 25% between identical cell that are in fully charge state.

NETA ATS 2007

7.18.1.1.3.2.6

D5

Test results are acceptable and in accordance with Saudi Aramco

Engineering Standards and contractual requirements.

Schedule Q

Att. II

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule Q Quality Requirements (Pro Forma Contract), February 2008

2. Acceptance Testing Specifications - NETA (2007)

3. IEEE Std 1188-2005 Valve-Regulated Lead-Acid (VRLA) Batteries for Stationary Applications, 2005

4. IEC 60896-11 Stationary Lead-acid batteries- Part 11: Vented type - General requirements and methods of tests, 2002

5. SAES-P-103, UPS and DC Systems, 02 June 2008

6. NEMA PE 1 Uninterruptible Power Systems (UPS) - Specification and Performance Verification (1-2003)

ATTACHMENT(S):

1. Attachment - 1 IEC-60896-11, Table A.1 and A.2 Test recommendation for stationary batteries

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

Page 6 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAUDI ARAMCO TEST REPORT

SATR NUMBER

UPS/DC Electrochemical Battery, Storage and Preservation

Testing

PROJECT TITLE

SATR-P-3101

WBS / BI / JO NUMBER

ITEM

No.

TEST RESULTS ACCEPTANCE CRITERIA

30-Jun-08

DATE APPROVED

QR NUMBER

REFERENCE

ELECTCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-TEST DATE

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer

indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party

Saudi Aramco

Technician Performing Test*

Name, Title, Department,

Company, Initials and

Date:

PMT Representative

Test Performed Successfully and Results are Acceptable:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Witnessed Test

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results

Y = YES

Page 7 of 8

N = NO F = FAILED

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAUDI ARAMCO TEST REPORT

SATR NUMBER

UPS/DC Electrochemical Battery, Storage and Preservation

Testing

SATR-P-3101

Attachment 1 -IEC 60896-11

Page 8 of 8

30-Jun-08

DATE APPROVED

QR NUMBER

ELECT-

Anda mungkin juga menyukai

- SATR-X-3201 Rev 3Dokumen4 halamanSATR-X-3201 Rev 3mahdi_gBelum ada peringkat

- 03 11 4297Dokumen3 halaman03 11 4297mahdi_gBelum ada peringkat

- SAIC-X-3102 Rev 3Dokumen5 halamanSAIC-X-3102 Rev 3mahdi_gBelum ada peringkat

- EKL-QC-F-0121 QC Monthly Report R 2.0Dokumen2 halamanEKL-QC-F-0121 QC Monthly Report R 2.0mahdi_gBelum ada peringkat

- SATR-X-3101 Rev 3Dokumen3 halamanSATR-X-3101 Rev 3mahdi_gBelum ada peringkat

- EKL-QC-F-0106-C Post Weld Heat Treatment ReportDokumen1 halamanEKL-QC-F-0106-C Post Weld Heat Treatment Reportmahdi_gBelum ada peringkat

- Sa P 070Dokumen3 halamanSa P 070mahdi_gBelum ada peringkat

- Satr S 4001Dokumen1 halamanSatr S 4001mahdi_gBelum ada peringkat

- Saic S 4006Dokumen2 halamanSaic S 4006mahdi_gBelum ada peringkat

- Saudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 15-Dec-09 PlumbDokumen2 halamanSaudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 15-Dec-09 Plumbmahdi_gBelum ada peringkat

- Saudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 15-Dec-09 PlumbDokumen1 halamanSaudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 15-Dec-09 Plumbmahdi_gBelum ada peringkat

- Sa F 001Dokumen13 halamanSa F 001mahdi_gBelum ada peringkat

- Satr B 4001Dokumen3 halamanSatr B 4001mahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & DateDokumen2 halamanSaudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & Datemahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning FormDokumen1 halamanSaudi Aramco Pre-Commissioning Formmahdi_gBelum ada peringkat

- Sa J 001Dokumen2 halamanSa J 001mahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning Form: MeteringDokumen1 halamanSaudi Aramco Pre-Commissioning Form: Meteringmahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning FormDokumen1 halamanSaudi Aramco Pre-Commissioning Formmahdi_gBelum ada peringkat

- Sa J 001Dokumen2 halamanSa J 001mahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning Form: FORM # J-011 (5/19/15) SHT 1 of 2Dokumen2 halamanSaudi Aramco Pre-Commissioning Form: FORM # J-011 (5/19/15) SHT 1 of 2mahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning Form: Positive Displacement Pumps (Reciprocating)Dokumen1 halamanSaudi Aramco Pre-Commissioning Form: Positive Displacement Pumps (Reciprocating)mahdi_gBelum ada peringkat

- Sa G 005Dokumen1 halamanSa G 005mahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning FormDokumen1 halamanSaudi Aramco Pre-Commissioning Formmahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning FormDokumen2 halamanSaudi Aramco Pre-Commissioning Formmahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning FormDokumen2 halamanSaudi Aramco Pre-Commissioning Formmahdi_gBelum ada peringkat

- Sa e 001aDokumen7 halamanSa e 001amahdi_gBelum ada peringkat

- Saudi Aramco Pre-Commissioning FormDokumen2 halamanSaudi Aramco Pre-Commissioning Formmahdi_gBelum ada peringkat

- Saer 5711Dokumen161 halamanSaer 5711sethu1091100% (1)

- Saer 5895Dokumen18 halamanSaer 5895sethu1091Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Session 27 Sales PromotionDokumen27 halamanSession 27 Sales PromotionNarayana ReddyBelum ada peringkat

- Weights & Measurement Charts - How To Guides - Cooking TipsDokumen6 halamanWeights & Measurement Charts - How To Guides - Cooking Tipsshalupappi22Belum ada peringkat

- The Marketing FunctionsDokumen21 halamanThe Marketing FunctionsGhani Thapa0% (1)

- New Dope & Dapper Catalog DDGIDokumen89 halamanNew Dope & Dapper Catalog DDGIDharmaDwiBelum ada peringkat

- I SUCK AT GIRLS by Justin HalpernDokumen8 halamanI SUCK AT GIRLS by Justin HalpernDey Street Books17% (69)

- Logistics Supply Chain ManagementDokumen62 halamanLogistics Supply Chain ManagementSyed Tauseef ChowdhuryBelum ada peringkat

- Top Textile Exporters and ImpotersDokumen8 halamanTop Textile Exporters and Impotersaskmeamol0% (1)

- I Change Training Book Phase 1 & 2Dokumen15 halamanI Change Training Book Phase 1 & 2刘世尉Belum ada peringkat

- Conveyor Belt Manual PDFDokumen74 halamanConveyor Belt Manual PDFawfahBelum ada peringkat

- All The Questions From Part B Are Compulsory (5marks Each)Dokumen2 halamanAll The Questions From Part B Are Compulsory (5marks Each)PuneetKaushik33% (3)

- Tutorial Martha DahligDokumen3 halamanTutorial Martha DahligalfredovidyBelum ada peringkat

- Bangalore Nift CasestudyDokumen100 halamanBangalore Nift Casestudysravya upadrastaBelum ada peringkat

- Service BlueprintDokumen3 halamanService BlueprintFelipe YbarraBelum ada peringkat

- At The Clothes ShopDokumen2 halamanAt The Clothes ShopRicardo Rentería AlvídrezBelum ada peringkat

- Husqvarna/Viking Victoria Sewing Machine Instruction ManualDokumen42 halamanHusqvarna/Viking Victoria Sewing Machine Instruction ManualiliiexpugnansBelum ada peringkat

- Hazir IsaretlerDokumen64 halamanHazir IsaretlerbulentbulutBelum ada peringkat

- Janome M7100 Sewing Machine Instruction Book enDokumen60 halamanJanome M7100 Sewing Machine Instruction Book enTerrence JonesBelum ada peringkat

- AmazonDokumen18 halamanAmazonmashurBelum ada peringkat

- Five Nights at Freddy's - The Silver Eyes (Excerpt)Dokumen34 halamanFive Nights at Freddy's - The Silver Eyes (Excerpt)I Read YA50% (4)

- Floods 11: Disasterchef by Colin ThompsonDokumen22 halamanFloods 11: Disasterchef by Colin ThompsonRandomHouseAU50% (2)

- Jamba Juice Case StudyDokumen4 halamanJamba Juice Case StudyMollie GreenBelum ada peringkat

- CM735Dokumen2 halamanCM735Haitsam MaulanaBelum ada peringkat

- How Green Are YouDokumen14 halamanHow Green Are YouCami Inthesky WithDiamondsBelum ada peringkat

- Portafolio Smart Unit 5-6Dokumen2 halamanPortafolio Smart Unit 5-6KAROLL DAYANNA ORTIZ MARTINEZBelum ada peringkat

- Stitching Techniques For Historic Costume ReproductionDokumen4 halamanStitching Techniques For Historic Costume ReproductionScott Patten100% (1)

- Konoike OPL - 11 - Standard PPE For Packer End of LineDokumen1 halamanKonoike OPL - 11 - Standard PPE For Packer End of LineAtif AlBelum ada peringkat

- Amul Marketing ProjectDokumen57 halamanAmul Marketing ProjectShivamSrivastava100% (1)

- Press Fit bb92 B30060-BDokumen1 halamanPress Fit bb92 B30060-BjlmreisBelum ada peringkat

- History of LingerieDokumen3 halamanHistory of LingerieRemyaBelum ada peringkat

- Rancangan Pengajaran Tahunan Ppki KSSR Tahun 2 Komponen Bahasa InggerisDokumen12 halamanRancangan Pengajaran Tahunan Ppki KSSR Tahun 2 Komponen Bahasa InggerishanyjamalBelum ada peringkat