Addition of Limestone 2

Diunggah oleh

yinglvHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Addition of Limestone 2

Diunggah oleh

yinglvHak Cipta:

Format Tersedia

Original papers

ADDITION OF LIMESTONE

IN THE LOW HEAT PORTLAND CEMENT

Part 2.

HAMDY EL-DIDAMONY, EL-SAYED EL-ALFI*

Faculty of Science, Zagazig University,

Zagazig, Egypt

*National Research Centre,

Dokki, Cairo, Egypt

Submitted August 9, 1999; accepted June 17, 2000.

The influence of substitution of clinker by fine limestone on the properties of the low heat Portland cement pastes up to 90 days

was studied. The results show that the substitution of 4-6 wt.% of clinker by fine limestone (76 m) improves the rate of

hydration up to 90 days. In addition, as the amount of limestone increases the heat of hydration and the free lime content slightly

enhance, while the total porosity decreases and the compressive strength enhances at early ages.

INTRODUCTION

The rise in temperature in the interior of a large

concrete bodies due to the heat developed by the

hydration of cement can lead to serious cracking. For

this reason, it is necessary to limit the rate of heat

evolution of the cement paste by using the low heat

Portland cement (Type IV). In some application, a very

low early strength of this cement may be a disadvantage. Therefore, the substitution of clinker by fine

limestone in the low heat Portland cement with the aim

to improve its physicomechanical properties was

studied.

Many authors have been tried to explain the

influence of finely ground limestone on the physicomechanical properties of filled cement [1 - 3]. Most

common hypotheses are the filler effect of fine particles,

the increase of rate of hydration of the clinker, the

formation of monocarboaluminate and the modification

of microstructure of hardened cement paste.

The addition amount of filler to Portland cement

reduces the rate and total heat released as well as the

heat evolution time [4]. Increasing filler content

therefore reduces the temperature rise in the concrete

body. The acceleration of hydration due to the action of

calcite on the aluminates and C3S becomes evident from

the microcalorimetry. Barker and Mattheus [4] found

that the increase amount of limestone filler in Portland

cements progressively decreases the rate of heat

evolved during the first 72 hours.

The effect of calcium and magnesium carbonate

addition on the hydration of Portland cement is reported

to the rate of hydration and compressive strength [5, 6].

The higher strength was attributed to the formation of a

dense structure and to the crystallization of a highly

polymerized calcium silicate hydrate.

146

The addition of limestone to cement paste affects

the activation of hydration and crystallization of CSH,

which ultimately affects the physicomechanical

properties of the cement [7]. The effect of -C2S and

C3S contents on compressive strength, Ca(OH)2 and

water contents are described.

The characterization of high-strength concrete

using low heat Portland cement was studied [8]. The

workability of the concrete is inferior to that of concrete

with ordinary Portland cement due to low water to

cement ratio. Moreover, there are concerns about

thermal cracking as the high strength concrete contains

a great amount of cement. To solve this problem, the

application of low heat Portland cement with the

addition of limestone to high strength concrete was

examined. The slump and long-term compressive

strength of low heat Portland cement concrete was

higher than that of ordinary Portland cement concrete.

The aim of the present work is to study the

influence of substitution of cement clinker by limestone

up to 10 wt.% on the physicomechanical properties and

the kinetics of hydration of laboratory prepared low heat

Portland cement pastes.

EXPERIMENTAL PART

The material used in this study, namely limestone,

clay, pyrite ash and gypsum were provided by Suez

Portland Cement Company, Egypt. Table 1 shows the

chemical analysis of these materials. The materials were

ground in laboratory steel ball mill to pass through a

200-mesh sieve. To prepare the low heat Portland

cement [9], the ingredient were homogenized, mixed

with water, moulded into a compact mass and fired at

1200 C for two hours, then ground, remoulded with

CCl4 and refired at 1450 C for two hours. The clinker

Ceramics Silikty 44 (4) 146-150 (2000)

Addition of limestone in the low heat Portland cement - Part 2.

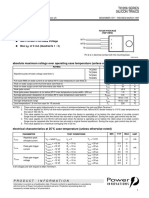

Table 1. Chemical composition of starting materials (wt.%).

limestone

clay

pyrite ash

SiO2

Al2O3

Fe2O3

CaO

MgO

SO3

2.61

69.96

7.92

0.93

9.17

11.45

0.38

3.91

66.15

52.58

4.50

3.92

0.05

1.09

2.05

0.12

1.61

0.95

ignition loss

43.03

4.55

5.17

Table 2. Chemical and phase composition of the prepared low heat Portland cement.

chemical composition (wt.%)

mineralogical composition (wt.%)

SiO2

Al2O3

Fe2O3

CaO

MgO

SO3

alite

belite

aluminate ferrite

23.20

4.39

5.86

61.39

1.15

1.68

35.80

39.62

1.78

was tested by determining the insoluble residue and free

lime contents.

The chemical and mineralogical composition

(using Bogue equation) of the prepared low heat

Portland cement [ASTM C150-92] Type IV are given in

table 2.

The prepared clinker (specific surface area

3150 g cm-2) was substituted with 0, 2, 4, 8 and 10 wt.%

of fine limestone (76m) with constant amount of

gypsum (5 wt.%). The water of consistency [10] and the

setting time [11] were determined. The pastes were

mixed with the water of consistency, moulded in 0.5inch cubic moulds for 24 hours, demoulded then

immersed in tap-water up to 90 days. The kinetic of

hydration were followed by the determination of heat of

hydration [12], free lime [13] and combined water

contents after firing at 1000 C for 30 minutes minus the

weight of water in Ca(OH)2.

The total porosity, bulk density and compressive

strength were also measured up to 90 days. The mixing,

moulding, curing and stopping of hydration were

described elsewhere [14].

RESULTS AND DISCUSSION

The water of consistency as well as initial and final

setting time of the cement pastes are presented in figure

1. The results show that the water of consistency as well

as setting time of all cement pastes slightly decrease

with limestone content. This is because the limestone

increases the number of precipitation sites for

deposition of C-S-H gel and calcium hydroxide from

solution. In addition, the limestone forms monocarboaluminate hydrate, which needs less water amount than

that of ettringite.

The heat of hydration of cement pastes cured up to

90-days is presented in figure 2. The heat of hydration

increases with curing time for all hardened cement

pastes due to the continuous hydration of the cement

paste accompanied by the heat liberation. In addition, it

can be seen that the heat of hydration enhances at early

ages up to 90 days when the amount of the limestone

Ceramics Silikty 44 (4) 146-150 (2000)

17.81

Figure 1. Water of consistency , initial and final setting times of

low heat Portland cement pastes with different amounts of

limestone.

U - water of consistency,

- initial setting time,

- final

setting time

content increases. The addition of limestone accelerates

the hydration of C3S especially at the early ages. This

accelerating effect may be related to a modification of

the hydrating C3S surface and its nucleating effect

[1 - 3]. The low heat Portland cement without limestone

shows sharp increase of heat up to 7 days, slight

increase from 7 - 28 day and then sharp increase up to

90 days. The first sharp increase is mainly due to the

hydration of alite in the early ages. The slow and then

rapid increase within 7-90 day is mainly attributed to

the hydration of belite.

The addition of limestone increases the rate of

hydration and then the amount of heat liberated at early

ages up to 28-days. This is because the limestone

activates the hydration reaction of the alite and maybe

the belite. The cement with 6 wt.% limestone gives the

147

H. El-Didamony, El-Sayed El-Alfi

Figure 2. Heat of hydration of low heat Portland cement pastes

with different ratios of limestone.

- 0 wt.%,

- 2 wt.%, S - 4 wt.%, U - 6wt.%, 8 wt.%, -10 wt.% limestone

highest rate of hydration as well as the amount of heat

liberated than the others at later ages (90 day). The

addition of limestone also increases the rate of

hydration and the amount of liberated heat at later ages

7 - 90 day. The increased of limestone content is

accompanied by a decrease in the clinker content of the

cement and, therefore, the rate of hydration is slightly

increases.

The combined water content of cement pastes is

plotted as a function of curing time in figure 3. The

combined water content increases with curing time for

all hardened cement pastes. As the amount of limestone

increases the combined water content enhances at early

ages. On the other side, the low heat cement without

limestone gives a lower amount of combined water up

to 28-days than those containing limestone. This

indicates that the limestone plays an important role in

the hydration of low heat Portland cement. In addition,

cements with 4 and 6 wt.% limestone give a higher

amounts of combined water at 28-90 days than the other

cement pastes. The increase of limestone is accompanied by a decrease in the clinker content. Therefore, the

cements with 8 and 10 wt.% limestone give a higher

amount of combined water at 3-days and a lower

amount at 90 days. This shows the role of limestone in

activation of C3S and maybe -C2S at early ages of

hydration. The addition of a small amount of limestone

(4 - 6 wt.%) also increases the combined water content

with curing time up to 90 days.

The free lime contents of hardened cement pastes

are plotted as a function of curing time in figure 4. The

free lime content increases with curing time for all

cement pastes due to the continuous hydration of

silicate phases that liberate free Ca(OH)2. The most of

free lime was liberated at early ages (3-days) while a

148

Figure 3. Combined water content of low heat Portland cement

pastes with limestone in relation to curing time.

- 0 wt.%,

- 2 wt.%, S - 4 wt.%, U - 6wt.%, - 8 wt.%,

-10 wt.% limestone

Figure 4. Free lime content of low heat Portland cement pastes

as a function of curing time as well as limestone content.

- 0 wt.%,

- 2 wt.%, S - 4 wt.%, U - 6wt.%, - 8 wt.%,

-10 wt.% limestone

slight increase was obtained at later ages up to 90-days

for all cement pastes. This is mainly due to the fact that

the low heat Portland cement contains lower amounts of

alite liberating more Ca(OH)2 and having a higher rate

of hydration at early ages than the belite, which amount

is increasing at later ages. Also, as the amount of limestone increases the free lime content sharply enhances

at early ages up to 3 days and then slightly up to 90

days. This is attributed to the activated alite that liberates more Ca(OH)2 than belite during the hydration

Ceramics Silikty 44 (4) 146-150 (2000)

Addition of limestone in the low heat Portland cement - Part 2.

Figure 5. Total porosity of low heat Portland cement pastes

with limestone additions.

- 0 wt.%,

- 2 wt.%, S - 4 wt.%, U - 6wt.%, - 8 wt.%,

-10 wt.% limestone

Figure 7. DTA thermograms of low heat Portland cement pastes

with various proportions of limestone.

- 0 wt.%,

- 2 wt.%, S - 4 wt.%, U - 6wt.%, - 8 wt.%,

-10 wt.% limestone

Figure 6. Compressive strength of low heat Portland cement

pastes with different proportions of limestone.

- 0 wt.%,

- 2 wt.%, S - 4 wt.%, U - 6wt.%, - 8 wt.%,

-10 wt.% limestone

The total porosity of the hardened cement pastes

cured up to 90 days is illustrated in figure 5. The total

porosity of all hardened cement pastes decreases with

curing time due to the filling up of a part of the available

Ceramics Silikty 44 (4) 146-150 (2000)

pores with the hydration products. The low heat

Portland cement pastes without limestone exhibit higher

values of porosity than those with limestone up to 90

days. On the other hand, as the limestone content

increases, the total porosity decreases, especially at

early ages. Soroka [15-17] illustrated that the strength

increase at a later age is similar for all fillers; while at

early ages the effect of calcareous fillers is greater than

the others. The author suggests that the limestone filler

act as an accelerator and the filler effect is brought

about by the increased rate of hydration associated with

their incorporation in Portland cement mixes. The filler

effect on strength is primarily an accelerating effect on

the cement hydration with the filler serving as

crystallization nuclei, and it increases with the fineness

and content of the filler.

The compressive strength of the hardened cement

pastes cured for 3, 7, 28 and 90 days is graphically

plotted in figure 6. The compressive strength increases

with curing time for all hardened cement pastes. This is

attributed to the increasing amount of hydrated products

(especially tobermorite gel) leading to an increase in the

compressive strength of cement paste. The cement paste

149

H. El-Didamony, El-Sayed El-Alfi

without limestone has lower values of compressive

strength at all ages than those containing limestone. In

addition, as the limestone content increases, the

hardening enhances especially at early ages up to 28days. This is attributed to the higher degree of hydration

of cement with limestone than those without limestone.

In addition, when the limestone content increases,

calcium hydroxide crystallizing in large crystals is

concentrated in some areas to form bridge between the

calcareous grains. The increased binding capacity of

carboaluminate as compared to other C3A hydrates is

probably affected by its compact structure [18]. On the

other side, the cements containing 4 and 6 wt.%

limestone give the highest values of compressive

strength at 90 days. This is because the small amount of

limestone (< 5 wt.%) enhances the strength at early

ages. This is attributed to the formation of a dense

structure and crystallization of a highly polymerized

calcium silicate hydrate [5, 6].

Figure 7 illustrates the DTA thermograms of the

low heat Portland cement pastes containing 0, 4, 6 and

10 wt.% limestone hydrated up to 90 days. It is clear

that the endothermic peak of the dissociation of

Ca(OH)2 slightly increases with limestone content as

revealed also from the results of the chemical analysis.

In addition, as the amount of limestone increases up to

6 wt.% the dehydration of interlayer water of calcium

silicate hydrate enhances. On the other side, the sample

containing 10 wt.% limestone gives a lower amount of

dehydration peak. An elevated content of limestone is

accompanied by a decrease in the clinker content. Therefore, the cement containing 10 wt.% limestone gives a

lower amount of interlayer water of hydrated products

than the other cements at 90 days due to the decrease of

the amount of clinker. These results are confirmed by

the results of combined water content and the compressive strength, where as the limestone increases up to 6

wt.%, the low heat Portland cement is more activated

and the amount of hydration product increases. The

endothermic peak at 780 C is mainly attributed to the

decomposition of limestone. The intensity of the peak

increases with the amount of CaCO3 added.

CONCLUSION

The development of new process and better quality

control will lead to a more active clinker, i.e. a clinker,

which can be used in high performance concrete, but

will need to be spread for the more common uses. The

addition of filler is a possibility to achieve this in the

most satisfactory way. The main results obtained from

this investigation are summarized as follows:

The substitution of clinker by limestone slightly

decreases the water of consistency as well as the setting

time of cement paste.

The addition of 2-10 wt.% limestone to low heat

Portland cements enhances the heat of hydration up to

90 days.

The combined water content increases with the limestone content at early ages and up to 6 wt.% at later ages.

150

The filled cement shows lower values of porosity

and higher compressive strength than the pure low heat

Portland cement especially at early ages. This suggests

that the limestone acts as an accelerator and filler.

Till now there is no publication for the activation

of belite by the addition of limestone. Therefore, the

following studies will focus on the hydration

characteristics of -C2S by the addition of limestone.

References

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

Lu P., Lu S.: Guisuanyan Xuebo 15, 289 (1987).

Ramachandran V.S., Zhang C. : il cemento 83, 129 (1986).

Ramachandran R., Chun-Mei Z.: Durability of Building

Material 4, 45 (1986).

Barkers A.P., Matthews J.P.: BRE Sem. Performance of

Limestone, Filled Cements 1989.

Timsasheu V.V., Kozhemyakin P.G. : Tr. Mask. Khim,

Tekhnol. Inst. im . D-I Mendeleva 118, 70 (1981).

Kamenic N., Bezjak A.: Cement (Zagreb) 22, 128 (1981).

Piasta J., Kraywoblocka-laurow R., Owsiak Z., Knizinice

abd. Ved. Spisu, Vys. Ucemi Tech., Brne, Bl, 78, B 80, 7

(1980).

Tokemura H., Ohtsuks A., Horiguchi K., Sumitomo T. :

Char Semento, Konkurite Ronbnshu Japan 47, 690

(1993).

9-ASTM Standards, ASTM Designation C 150-92

(1992).

ASTM Standards, ASTM Designation C 187- 92 (1992).

ASTM Standards, ASTM Designation C 191- 92 (1992).

ASTM Standards, ASTM Designation C 186- 92 (1992).

Kondo R., Abo-El-Enein S.A., Diamon A.: Bull. Chem.

Soc. Japan 8, 222 (1975).

El-Didamony H., Haggag M.Y., Abo El-Enein S.A.: Cem.

Concr. Res. 8, 351 (1978).

Soroka I., Stern N.: Cem. Concr. Res. 6, 367 (1976).

Soroka I., Stern, N.: Am. Ceram. Soc. Bull. 55, 594 (1976).

Soroka I., Stern N.: Cem. Concr. Res. 7, 449 (1977).

Ingram K.D., Poslusny M., Daugherty K., Rowe W.:

ASTM STP 1064, p.14, (Eds.P.Kieger and R.D.Hooton),

ASTM, Philadelphia 1990.

Submitted in English by the authors.

PDAVEK VPENCE K PORTLANDSKMU

CEMENTU S NZKM HYDRATANM TEPLEM

ST 2

HAMDY EL-DIDAMONY, EL-SAYED EL-ALFI*

Faculty of science, Zagazig University, Zagazig, Egypt

*National Research Centre, Dokki, Cairo, Egypt

Byl studovn vliv nhrady slnku vpencem na

vlastnosti past portlandskho cementu s nzkm hydratanm teplem bhem 90 dn. Vsledky ukazuj, e

nhrada 4 - 6 hmotn.% slnku jemn mletm vpencem

(76 m) zvyuje hydratan rychlost po dobu 90 dn.

Dle roste s obsahem vpence hydratan teplo a obsah

volnho vpna, zatmco celkov porozita kles a zvyuje se pevnost v tlaku v potench stdich tuhnut.

Ceramics Silikty 44 (4) 146-150 (2000)

Anda mungkin juga menyukai

- VANCOUVER Reference Style Guide: NotesDokumen6 halamanVANCOUVER Reference Style Guide: NotesMuhammad MoazzamBelum ada peringkat

- Hexavalent Chromium in Portland CementDokumen5 halamanHexavalent Chromium in Portland Cementyinglv100% (1)

- Volume Stability of Calcium Sulfoaluminate Phases PDFDokumen6 halamanVolume Stability of Calcium Sulfoaluminate Phases PDFyinglvBelum ada peringkat

- Physico Mechanical Characteristics of Hydrating Tetracalcium Aluminoferrite System at Low Water - Solid Ratio PDFDokumen7 halamanPhysico Mechanical Characteristics of Hydrating Tetracalcium Aluminoferrite System at Low Water - Solid Ratio PDFyinglvBelum ada peringkat

- The Special Features of Cement Standards in China PDFDokumen5 halamanThe Special Features of Cement Standards in China PDFyinglvBelum ada peringkat

- Sustainable Infrastructure Materials - Challenges and Opportunities PDFDokumen9 halamanSustainable Infrastructure Materials - Challenges and Opportunities PDFyinglvBelum ada peringkat

- Long-Term Leaching of Toxic Trace Metals From Portland Cement ConcreteDokumen7 halamanLong-Term Leaching of Toxic Trace Metals From Portland Cement ConcreteyinglvBelum ada peringkat

- Accurate Rapid Analysis of Alkali Contents in Portland CementDokumen4 halamanAccurate Rapid Analysis of Alkali Contents in Portland CementyinglvBelum ada peringkat

- Sewage Sludge Quality Standards Required by Polish Cement PlantsDokumen3 halamanSewage Sludge Quality Standards Required by Polish Cement PlantsyinglvBelum ada peringkat

- Assessment of Pollution Potentialities of Some Portland Cement PDFDokumen3 halamanAssessment of Pollution Potentialities of Some Portland Cement PDFyinglvBelum ada peringkat

- Raman Spectroscopy of Anhydrous and Hydrated Calcium Aluminates and Sulfoaluminates PDFDokumen7 halamanRaman Spectroscopy of Anhydrous and Hydrated Calcium Aluminates and Sulfoaluminates PDFyinglvBelum ada peringkat

- The Composition and Crystallography of An Anhydrous Calcium Aluminosulphate Occurring in Expanding Cement PDFDokumen5 halamanThe Composition and Crystallography of An Anhydrous Calcium Aluminosulphate Occurring in Expanding Cement PDFyinglvBelum ada peringkat

- Formation of Ettringite from Monosulfate and GypsumDokumen6 halamanFormation of Ettringite from Monosulfate and GypsumyinglvBelum ada peringkat

- Orthosilicate Analyses - A Measure of Hydration in Pastes of Alite and Portland Cement PDFDokumen2 halamanOrthosilicate Analyses - A Measure of Hydration in Pastes of Alite and Portland Cement PDFyinglvBelum ada peringkat

- Opportunities For Use of Bauxite Residue in Special CementsDokumen46 halamanOpportunities For Use of Bauxite Residue in Special CementsyinglvBelum ada peringkat

- Stability of Ettringite On Heating PDFDokumen2 halamanStability of Ettringite On Heating PDFyinglvBelum ada peringkat

- Utilization of Coal Combustion Ashes For The Synthesis of Ordinary and Special Cements PDFDokumen14 halamanUtilization of Coal Combustion Ashes For The Synthesis of Ordinary and Special Cements PDFyinglvBelum ada peringkat

- Formation of Ettringite by Hydration of A System Containing An Anhydrous Calcium Sulfoaluminate PDFDokumen2 halamanFormation of Ettringite by Hydration of A System Containing An Anhydrous Calcium Sulfoaluminate PDFyinglvBelum ada peringkat

- Concrete Construction Article PDF - Special Cements and Their Uses PDFDokumen5 halamanConcrete Construction Article PDF - Special Cements and Their Uses PDFyinglvBelum ada peringkat

- Li Walentaand Gartner ICCCMontreal 2007Dokumen12 halamanLi Walentaand Gartner ICCCMontreal 2007Nabila NabilaBelum ada peringkat

- Sustainable Concrete by Mehta ArticleDokumen10 halamanSustainable Concrete by Mehta ArticleAnonymous LcR6ykPBT100% (1)

- Role of Phosphogypsum in The Hydration of Calcium Sulphoaluminate PDFDokumen8 halamanRole of Phosphogypsum in The Hydration of Calcium Sulphoaluminate PDFyinglvBelum ada peringkat

- Generalized Bogue Computations To Forecast The Mineralogical Composition of Sulfoaluminate Cements Based On Fly Ashes PDFDokumen8 halamanGeneralized Bogue Computations To Forecast The Mineralogical Composition of Sulfoaluminate Cements Based On Fly Ashes PDFyinglvBelum ada peringkat

- The Formation of Calcium Sulfoaluminate Hydrate Compounds 2 PDFDokumen8 halamanThe Formation of Calcium Sulfoaluminate Hydrate Compounds 2 PDFyinglvBelum ada peringkat

- Ettringite and Calcium Sulfoaluminate Cement Investigation of Water Content by Near-Infrared Spectros PDFDokumen7 halamanEttringite and Calcium Sulfoaluminate Cement Investigation of Water Content by Near-Infrared Spectros PDFyinglvBelum ada peringkat

- Performance of Belite-Sulfoaluminate Cements PDFDokumen9 halamanPerformance of Belite-Sulfoaluminate Cements PDFyinglvBelum ada peringkat

- Relationship Between Raw Mixture and Mineralogical Composition of Sulphoaluminate Belite Clinkers in The System CaO SiO2 Al2O3 Fe2O3 SO3 PDFDokumen6 halamanRelationship Between Raw Mixture and Mineralogical Composition of Sulphoaluminate Belite Clinkers in The System CaO SiO2 Al2O3 Fe2O3 SO3 PDFyinglvBelum ada peringkat

- Thermodynamic Data of Ye'elimite (C4A3$) For Cement Clinker Equilibrium PDFDokumen7 halamanThermodynamic Data of Ye'elimite (C4A3$) For Cement Clinker Equilibrium PDFyinglvBelum ada peringkat

- Gartner. Cem Concr Res 2004Dokumen10 halamanGartner. Cem Concr Res 2004Smeetha KaurBelum ada peringkat

- Studies On The Stability of The Calcium Sulfoaluminate Hydrates, Part Iii The Monophases PDFDokumen9 halamanStudies On The Stability of The Calcium Sulfoaluminate Hydrates, Part Iii The Monophases PDFyinglvBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Bayer Process Diagram ExplainedDokumen6 halamanBayer Process Diagram ExplainednatsmdBelum ada peringkat

- Adsorption of Surfactants On Sand SurfacDokumen13 halamanAdsorption of Surfactants On Sand SurfacBihag Shukla100% (1)

- Road Project Steps and Interview QuestionsDokumen54 halamanRoad Project Steps and Interview QuestionsaamirBelum ada peringkat

- Textile Apparel Ecological Safety Quality V9 - 3Dokumen21 halamanTextile Apparel Ecological Safety Quality V9 - 3mmbBelum ada peringkat

- Assignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsDokumen61 halamanAssignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsHarshil JainBelum ada peringkat

- Safety Data Sheet for Penguard HB - Comp. ADokumen5 halamanSafety Data Sheet for Penguard HB - Comp. ABalasubramanian AnanthBelum ada peringkat

- Route 34 PlansDokumen1 halamanRoute 34 PlansThe Valley IndyBelum ada peringkat

- WRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionDokumen5 halamanWRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionmsmrizhwanBelum ada peringkat

- Heraklith CatalogueDokumen54 halamanHeraklith CatalogueN P SrinivasaraoBelum ada peringkat

- AP Chemistry Summer Assignment 2017Dokumen44 halamanAP Chemistry Summer Assignment 2017John SmithBelum ada peringkat

- ME206 Lecture 3 - Key concepts in metal casting flowDokumen28 halamanME206 Lecture 3 - Key concepts in metal casting flowHarsh ShahBelum ada peringkat

- 27 PsychrometryDokumen16 halaman27 PsychrometryPRASAD326100% (1)

- Duct Tape and Insulation Tape GuideDokumen2 halamanDuct Tape and Insulation Tape GuideDhanish AhsenBelum ada peringkat

- Arches: Theory of StructuresDokumen20 halamanArches: Theory of StructuresAravind BhashyamBelum ada peringkat

- Hazardous Waste Management TechniquesDokumen12 halamanHazardous Waste Management TechniquesSyed YousufuddinBelum ada peringkat

- Microchip Drug Delivery - New Era of Drug Delivery SystemDokumen8 halamanMicrochip Drug Delivery - New Era of Drug Delivery SystemDV65Belum ada peringkat

- Mechanical SealDokumen64 halamanMechanical SealKhoh Kai ShengBelum ada peringkat

- Advanced Lab Course 50: PhotovoltaicsDokumen18 halamanAdvanced Lab Course 50: PhotovoltaicsHamza OuerfelliBelum ada peringkat

- Geotechnical Engineering QuantumDokumen274 halamanGeotechnical Engineering QuantumRitik SinghBelum ada peringkat

- Basics of Reinforced Concrete Design: OutlineDokumen10 halamanBasics of Reinforced Concrete Design: OutlineariBelum ada peringkat

- Astm C361M-14Dokumen26 halamanAstm C361M-14diego rodriguez100% (1)

- Equilibrium Constants and Le Chatelier's PrincipleDokumen20 halamanEquilibrium Constants and Le Chatelier's Principlekrishna100% (1)

- Tic206 Series Silicon TriacsDokumen6 halamanTic206 Series Silicon TriacsIgorCostaCorreiaBelum ada peringkat

- A Study of The Effect of Magnetite Additions To Shell Molds On THDokumen106 halamanA Study of The Effect of Magnetite Additions To Shell Molds On THneel gajBelum ada peringkat

- VMC-Haj House - Final Estimate 09.01.19Dokumen787 halamanVMC-Haj House - Final Estimate 09.01.19Patan Abdul Mehmood Khan100% (1)

- Materials: Current Status and Future Prospects of Copper Oxide Heterojunction Solar CellsDokumen21 halamanMaterials: Current Status and Future Prospects of Copper Oxide Heterojunction Solar CellsMurat YilmazBelum ada peringkat

- Retrofit Guidelines For Dupont Isceon 9 Series RefrigerantsDokumen20 halamanRetrofit Guidelines For Dupont Isceon 9 Series RefrigerantsaBelum ada peringkat

- Housekeeping & Accommodation StudiesDokumen15 halamanHousekeeping & Accommodation StudiesCaleb MukaviBelum ada peringkat

- FME-2021-0403 Proof HiDokumen41 halamanFME-2021-0403 Proof HiAsif EqubalBelum ada peringkat

- 3rd Summative TestDokumen8 halaman3rd Summative TestAngelica ValdezBelum ada peringkat