V4i2 Ijertv4is020814

Diunggah oleh

hari0118Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

V4i2 Ijertv4is020814

Diunggah oleh

hari0118Hak Cipta:

Format Tersedia

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 02, February-2015

Experimental Study to Investigate of Effects of

Cutting tools on Surface Roughness and MRR of

EN31 (Alloy Steel) Turning Operation on CNC

Machine-Research Review

Delvadiya Parth 1, Prof. Ankit Darji2

1

P.G student,

Assistant Professor, LDRP-ITRGandhinagar, Gujarat (India)

Abstract-- The main purpose of this review paper is to check

whether quality lies within desired tolerance level which can be

accepted by the customers. Surface roughness relative using

various CNC machining parameters including spindle speed (N),

feed rate (f) and depth of cut (d) and cutting tolls. In

experimental study to investigate the surface roughness relatives

using various CNC machining parameters like spindle speed,

feed and depth of cut and cutting tools on surface finish on EN31.The evaluation of influence of cutting conditions in facing

operation of EN-31 in this paper. Machining was done using

cemented carbide insert.

Keywords: CNC turning operation, EN-31, Surface roughness,

Material removal rate.

INTRODUCTION

The challenge of modern machining industries is mainly

focused on the achievement of high quality in term of work

piece dimensional accuracy, surface finish, high production

rate, less wear on the cutting tools, economy of machining in

terms of cost saving and increase of the performance of the

product with reduced environmental .The mechanism behind

the formation of surface roughness in CNC Lathe turning

process is very dynamic, complicated, and process

dependent. Several factors will influence the final surface

roughness in CNC Lathe operations such as controllable

factors (spindle speed, feed rate and depth of cut) and

uncontrollable factors (tool geometry and material properties

of both tool and workpiece).

Surface finish is one of the most important requirements in

machining process, as it is considered an index of product

quality. It measures the finer irregularities of the surface

texture. Achieving the desired surface quality is critical for

the functional behavior of a part.

Fig. 1 Parameters affects the surface roughness

The factors that influence surface finish are machining

parameters, tool and work piece material properties and

cutting conditions. For example, in Turning operation the

surface finish depends on cutting speed, feed rate, depth of

cut, cutting fluid, tool nose radius lubrication of the cutting

tool, machine vibrations, tool wear and on the mechanical

and other properties of the material being machined. CNC

turning process parameters are -classified according to Tool,

IJERTV4IS020814

www.ijert.org

( This work is licensed under a Creative Commons Attribution 4.0 International License.)

1121

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 02, February-2015

Machining parameters, Work piece, machine tool and cutting

process parameters as shown in below Figure (1).

. EXPERIMENTAL CONDITIONS AND PROCEDURES

1. Test specimen: The experiment was conducted using one

work piece material EN-31. The tests work piece relative

dimension was a length 200 MM and diameter 32 MM. The

basic used of EN-31material as Ball and Roller Bearings,

Spinning tools, Beading Rolls, Punches and Dies. By its

character this type of steel has high resisting nature against

wear and can be used for components which are subjected to

severe abrasion, wear or high surface loading.

The chemical composition and mechanical properties of the

selected work piece is shown as in table 1 and table 2

respectively.

C%

Si%

Mn%

S%

P%

0.30 0.10 0.040

0.040

0.90 - 1.20

0.75

0.35

Table1. Chemical composition of EN 31 Alloy Steel

Bulk

Modulus

Shear

modulus

Elastic

modulus

Poisson's

ratio

Hardness

Rockwell

C

140 Gpa

80 Gpa

190 GPa

0.30

0.20

Table2. Mechanical Properties of EN 31 Alloy Steel

2. Machine tool: Machining experiment has been performed

on a high rigid CNC lathe (JOBBER XL, AMS, India)

equipped with variable spindle speed from 50 to 3500 rpm

and 16KW maximum spindle power with Control System

Fanuc 0i-Mate-TD shown in Fig. 2) under dry environment.

Fig.2 Photograph of CNC Lathe.

IJERTV4IS020814

3. Cutting inserts: In tests, two types of carbide inserts use.

A) chemical vapor deposition (CVD) multilayer coated

carbide inserts coated with four layers of (TiN, TiCN, Al2O3

and TiN), the outermost being TiN designated as TN 2000

grade and other is CVD coated (TiN, TiCN, Al2O3 and

ZrCN), the outer most being ZrCN designated as TN 7015

grade respectively. Grade TN 2000, a CVD coated cobalt

enriched substrate has required bulk toughness added with

multilayer MT CVD coating which gives the wear resistance

and crater resistance required in steel machining. It provides

required chip impact resistance and well balanced toughness

and wear resistance properties. Grade TN 7015, a CVD

coated with tough surface zone and thick TiCN and ZrCN

coating gives excellent wear and heat resistant properties.

Grade TTS is ideally considered as universal uncoated grade

for steel machining. Inserts are mounted on a tool holder

designated by ISO as PCLNR2525 M12

B) Physical vapor deposited (PVD) coated carbide tools

tungsten carbide substrate material is used in order to

increase wear resistance and reduce insert chip-ping. Tool

wear, cutting force, surface roughness and cutting power are

relative responses. Tool wear results in changes in tool

geometry that affect cutting forces, cutting power, and

surface finish. It is the main factor that determines the

economics in metal cutting. A lower rate of tool wear means

increased tool life, better surface finish, reduced tooling cost

and lower cost of production. In case of PVD TiAlN coating,

the improvement in the cutting performance is due to the

oxidation resistance of TiAlN properties at higher

temperature. High wear resistance even at high temperatures

is the outstanding property of TiAlN, a characteristic that

makes this coating appropriate to cut abrasive work piece

material such as cast iron, aluminum silicon alloys and

composite materials at high speeds.

4. Cutting conditions: The cutting condition for finish hard

turning under higher parametric condition is shown in

Table3.

www.ijert.org

( This work is licensed under a Creative Commons Attribution 4.0 International License.)

1122

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 4 Issue 02, February-2015

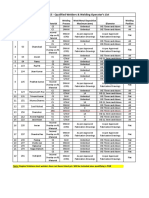

Process Parameters With Their Values At Three Levels

Factor

Process parameters

Level 1

Level 2

Level 3

Cutting speed

(m/min)

100

150

200

Feed rate (mm/rev.)

0.125

0.150

0.175

Depth of cut (mm)

0.2

0.3

0.4

Table3. Process Parameters of CNC Machine

5. Material removal rate (MRR): has been calculated from

the difference of weight of work

piece before and after experiment.

. REFERENCES

1.

D.I. Lalwani, N.K. Mehta, P.K. Jain, Experimental

investigations of cutting parameters influence on cutting

forces and surface roughness in finish hard turning of

MDN250 steel, J. Mater. Process. Technol. 206 (2008) 167

179.

2. Y.W. Park, Tool material dependence of hard turning on the

surface quality, Int. J. Korean Soc. f Prec. Eng. 3 (1) (2002)

76 82.

3. T. Ozel, Y. Karpat, L. Figueira, J.P. Davim, Modelling of

surface finish and tool flank wear in turning of AISI D2 steel

with ceramic wiper inserts,J. Mater. Process. Technol. 189

(2007) 192198.

4.

Y. Sahin, A.R. Motorcu, Surface roughness model in

machining hardened steel with cubic boron nitride cutting tool,

Int. J. Refract. Metals Hard Mater. 26 (2008) 8490.

MRR =

Where, Wi is the initial weight of work piece in g ; W f is the

final weight of work piece in g ; t is the machining time in

minutes; s is the density of alloy steel. The weight of the

work piece has been measured in a high precision digital

balance meter (Model: DHD 200 Macro single pan

DIGITAL reading electrically operated analytical balance),

which can measure up to the accuracy of 10-4 g and thus

eliminates the possibility of large error while calculating

material removal rate (MRR) in straight turning operation.

6. Surface roughness measurements: The arithmetic average

surface roughness (Ra) of the work piece is measured by

SURFTEST SJ 201P surface roughness tester (shown in Fig.

3), where the cutoff length and assessment length was fixed

as 0.8 mm and 4 mm respectively. The instrument was

calibrated using a standard calibration block prior to the

measurements. The measurement was taken at four locations

(90_apart) around the circumference of the workpieces and

repeated twice at each point on the face of the machined

surface and the average values reported for the response.

Fig 3. Surface roughness tester (MITUTOYO SURFTEST SJ 201P).

IJERTV4IS020814

www.ijert.org

( This work is licensed under a Creative Commons Attribution 4.0 International License.)

1123

Anda mungkin juga menyukai

- 2 67 1588079784 14ijmperdjun202014Dokumen12 halaman2 67 1588079784 14ijmperdjun202014TJPRC PublicationsBelum ada peringkat

- Effect of Cutting Parameters On MRR and Surface Roughness in Turning EN-8Dokumen5 halamanEffect of Cutting Parameters On MRR and Surface Roughness in Turning EN-8PranowoBelum ada peringkat

- 1 s2.0 S2212017314001030 Main PDFDokumen7 halaman1 s2.0 S2212017314001030 Main PDFDrRoja A RBelum ada peringkat

- 79IJMPERDJUN201979Dokumen8 halaman79IJMPERDJUN201979TJPRC PublicationsBelum ada peringkat

- Rugozitatea SuprafetelorDokumen7 halamanRugozitatea SuprafetelorcristinaBelum ada peringkat

- Tool Wear Characterization of Carbide Cutting Tool Insert Coated With Titanium Nitride TIN in A Single Point Turning Operation of Aisi D2 Steel - Muhammad Farouq B. Muhammad Faisal - TJ1186.M42 2008Dokumen27 halamanTool Wear Characterization of Carbide Cutting Tool Insert Coated With Titanium Nitride TIN in A Single Point Turning Operation of Aisi D2 Steel - Muhammad Farouq B. Muhammad Faisal - TJ1186.M42 2008hari0118Belum ada peringkat

- 1 PDFDokumen11 halaman1 PDFmahendraBelum ada peringkat

- Evalution of Surface Finish On Machining of Mild Steel Using High Speed Steel Tool in Lathe With Normal Coolant (Or) Nano Material Added CoolantDokumen9 halamanEvalution of Surface Finish On Machining of Mild Steel Using High Speed Steel Tool in Lathe With Normal Coolant (Or) Nano Material Added CoolantInternational Organization of Scientific Research (IOSR)Belum ada peringkat

- Matecconf Imanee2018Dokumen6 halamanMatecconf Imanee2018Irina BesliuBelum ada peringkat

- Interncionalparametros de CorteDokumen7 halamanInterncionalparametros de CorteFernando Michelon MarquesBelum ada peringkat

- A Review On Optimization of Turningparameter For Aisi 4140 by Grey Relation AnalysisDokumen10 halamanA Review On Optimization of Turningparameter For Aisi 4140 by Grey Relation AnalysisRavi TiwariBelum ada peringkat

- Feed RateDokumen14 halamanFeed RateAbdallah Irfaan RamjanBelum ada peringkat

- Nano World Journal TemplateDokumen10 halamanNano World Journal TemplatejabbarbookeditorBelum ada peringkat

- CNC TurningDokumen5 halamanCNC TurningJournalNX - a Multidisciplinary Peer Reviewed JournalBelum ada peringkat

- Microdureza 3Dokumen5 halamanMicrodureza 3cortelinirosaBelum ada peringkat

- Performance Analysis of Coated Single Point Cutting Tool in Turning OperationDokumen10 halamanPerformance Analysis of Coated Single Point Cutting Tool in Turning OperationViraj GaonkarBelum ada peringkat

- H Demir-E NasVolume13-11Dokumen8 halamanH Demir-E NasVolume13-11Ahmad BaihaqiBelum ada peringkat

- Effect of Process Parameters On Surface Roughness of Cylindrical Grinding Process On Ohns (Aisi 0-1) Steel Rounds Using ANOVADokumen6 halamanEffect of Process Parameters On Surface Roughness of Cylindrical Grinding Process On Ohns (Aisi 0-1) Steel Rounds Using ANOVAsureshkumarBelum ada peringkat

- High Speed Hard Turning of Aisi S1 (60Wcrv8) Cold Work Tool SteelDokumen18 halamanHigh Speed Hard Turning of Aisi S1 (60Wcrv8) Cold Work Tool Steelnovkovic1984Belum ada peringkat

- Performance Evaluation of Tin Coated and Uncoated Carbide Tools in Turning Aisi 4140 SteelDokumen6 halamanPerformance Evaluation of Tin Coated and Uncoated Carbide Tools in Turning Aisi 4140 SteelRizal FahrezaBelum ada peringkat

- Ranjan Das 2018Dokumen10 halamanRanjan Das 2018nishatBelum ada peringkat

- Improvement of Machinability of Mild Steel During Turning Operation by Magnetic CuttingDokumen5 halamanImprovement of Machinability of Mild Steel During Turning Operation by Magnetic CuttingIzzah HzmhBelum ada peringkat

- Effects of Single Point Cutting Tool Materials On PDFDokumen20 halamanEffects of Single Point Cutting Tool Materials On PDFAyush UpadhyayBelum ada peringkat

- Influence of Cutting-Edge Modifications On The Inconel 718Dokumen9 halamanInfluence of Cutting-Edge Modifications On The Inconel 718Jo marBelum ada peringkat

- Experimental Investigation of Machining PDFDokumen8 halamanExperimental Investigation of Machining PDFJeyapragash RBelum ada peringkat

- Conceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. RamegoudaDokumen4 halamanConceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. Ramegoudaaravindan476Belum ada peringkat

- Investigation On Influence of Cutting Parameters oDokumen6 halamanInvestigation On Influence of Cutting Parameters oDuy TrầnBelum ada peringkat

- A Review Paper On Latest Trend On Face Milling Tool-41282Dokumen3 halamanA Review Paper On Latest Trend On Face Milling Tool-41282ajayBelum ada peringkat

- An Experimental Investigation of Hot Machining Performance Parameters Using Oxy-Acetylene Gas SetupDokumen6 halamanAn Experimental Investigation of Hot Machining Performance Parameters Using Oxy-Acetylene Gas SetupSagar MohanBelum ada peringkat

- Effect of Machining Parameters and Coating On Wear Mechanisms in Dry Drilling of Aluminium AlloysDokumen7 halamanEffect of Machining Parameters and Coating On Wear Mechanisms in Dry Drilling of Aluminium AlloysgudukumarBelum ada peringkat

- En 9paper1Dokumen6 halamanEn 9paper1Stuart BroadBelum ada peringkat

- Optimization of Machining Parameter For Turning of en 16 SteelDokumen5 halamanOptimization of Machining Parameter For Turning of en 16 SteelShivam SharmaBelum ada peringkat

- Surface Roughness and Cutting Forces For Optimization of Machining Condition in Finish HardDokumen10 halamanSurface Roughness and Cutting Forces For Optimization of Machining Condition in Finish HardHeri SetiawanBelum ada peringkat

- Rdme 51Dokumen6 halamanRdme 51adarshgitamBelum ada peringkat

- HTL - 17-4-PH - Optimization of Machining Parameters in Turning 17-4 PH Stainless SteelDokumen9 halamanHTL - 17-4-PH - Optimization of Machining Parameters in Turning 17-4 PH Stainless SteelSridhar AtlaBelum ada peringkat

- Optimization of Machining Parameters For Turning Different Alloy Steel Using CNC - ReviewDokumen8 halamanOptimization of Machining Parameters For Turning Different Alloy Steel Using CNC - Reviewsreejith2786Belum ada peringkat

- 2 67 1587621735 6ijmperdjun20206Dokumen10 halaman2 67 1587621735 6ijmperdjun20206TJPRC PublicationsBelum ada peringkat

- Analyzing The Effect of Cutting Parameters On Surface Roughness and Tool Wear When Machining Nickel Based Hastelloy - 276Dokumen11 halamanAnalyzing The Effect of Cutting Parameters On Surface Roughness and Tool Wear When Machining Nickel Based Hastelloy - 276Antonius Adi Hendra SaputraBelum ada peringkat

- Evaluation of Cutting Tool Vibration andDokumen8 halamanEvaluation of Cutting Tool Vibration andchaib boudabBelum ada peringkat

- Twist DrillDokumen10 halamanTwist DrillIAEME PublicationBelum ada peringkat

- Optimization of Surface Roughness and Material Removal Rate in Turning of Aisi D2Dokumen3 halamanOptimization of Surface Roughness and Material Removal Rate in Turning of Aisi D2Fikri SiplhoBelum ada peringkat

- Materials Today: Proceedings: C. Veera Ajay, V. VinothDokumen7 halamanMaterials Today: Proceedings: C. Veera Ajay, V. VinothSREEJITH S NAIRBelum ada peringkat

- Optimization of Surface Roughness and Flank Wear Using The Taguchi Method in Milling of Hadfield Steel With PVD and CVD Coated InsertsDokumen10 halamanOptimization of Surface Roughness and Flank Wear Using The Taguchi Method in Milling of Hadfield Steel With PVD and CVD Coated InsertsMohamedKamalBelum ada peringkat

- Optimization of Machining Parameters of 20MnCr5 Steel in Turning Operation Using Taguchi TechniqueDokumen11 halamanOptimization of Machining Parameters of 20MnCr5 Steel in Turning Operation Using Taguchi TechniqueIJMERBelum ada peringkat

- Experimental Investigation of Tool Life and Surface Roughness During CNC Turning Using Single Point Cutting ToolDokumen7 halamanExperimental Investigation of Tool Life and Surface Roughness During CNC Turning Using Single Point Cutting ToolIJRASETPublicationsBelum ada peringkat

- Experimental Investigation of Surface Roughness and Tool Wear of Machining Rolled AA7075 Aluminium Alloy Using Advanced Cutting ToolsDokumen5 halamanExperimental Investigation of Surface Roughness and Tool Wear of Machining Rolled AA7075 Aluminium Alloy Using Advanced Cutting ToolsInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Theory of Metal Cutting, Metal FormingDokumen181 halamanTheory of Metal Cutting, Metal Formingprabhjotbhangal100% (1)

- Estimation of Tool Life by Industrial Method and TDokumen8 halamanEstimation of Tool Life by Industrial Method and TKamesh JaiBelum ada peringkat

- JT 34 1 11Dokumen11 halamanJT 34 1 11Grey MouseBelum ada peringkat

- Jaser4001 PDFDokumen10 halamanJaser4001 PDFFikri SiplhoBelum ada peringkat

- Parametric Optimization of Cutting Force and Temperature During Hard Turning of Inconel 625-A ReviewDokumen4 halamanParametric Optimization of Cutting Force and Temperature During Hard Turning of Inconel 625-A ReviewGopala Rao ThellaputtaBelum ada peringkat

- Tool Wear and Surface Finish Investigation of Hard Turning Using Tool ImagingDokumen4 halamanTool Wear and Surface Finish Investigation of Hard Turning Using Tool ImagingM JefriantoBelum ada peringkat

- Cutting ToolDokumen9 halamanCutting ToolRay Live To RaceBelum ada peringkat

- Optimization of Cutting Parameters in Turning Operation of Mild SteelDokumen6 halamanOptimization of Cutting Parameters in Turning Operation of Mild SteelIzzah HzmhBelum ada peringkat

- Investigation of Surface Textured Cutting Tools For Sustainable MachiningDokumen7 halamanInvestigation of Surface Textured Cutting Tools For Sustainable MachiningnarenBelum ada peringkat

- MC FCD500Dokumen6 halamanMC FCD500Ashok KhannaBelum ada peringkat

- Machining Performance Enhancement of Brass C360 Alloy Using Taguchi Based Grey Relational Analysis MethodDokumen10 halamanMachining Performance Enhancement of Brass C360 Alloy Using Taguchi Based Grey Relational Analysis MethodTJPRC PublicationsBelum ada peringkat

- 10 5267@j Ijiec 2017 8 002Dokumen20 halaman10 5267@j Ijiec 2017 8 002chaib boudabBelum ada peringkat

- The Effects of Cutting Tool Coating On The Surface Roughness of AISI 1015 Steel Depending On Cutting ParametersDokumen11 halamanThe Effects of Cutting Tool Coating On The Surface Roughness of AISI 1015 Steel Depending On Cutting ParametersRohit RamchandaniBelum ada peringkat

- Module 1 FundamentalsDokumen90 halamanModule 1 Fundamentalshari0118Belum ada peringkat

- Development of An Intelligent System For Tool Wear Monitoring Applying Neural NetworksDokumen6 halamanDevelopment of An Intelligent System For Tool Wear Monitoring Applying Neural Networkshari0118Belum ada peringkat

- Chapter 3.Cnc Part ProgrammingDokumen61 halamanChapter 3.Cnc Part Programminghari0118Belum ada peringkat

- Cad Cam QBDokumen10 halamanCad Cam QBhari0118Belum ada peringkat

- Ucmp Crouse FileDokumen37 halamanUcmp Crouse Filehari0118Belum ada peringkat

- Lecture 3-Tool Life, Tools, Machine Parts-F-19!8!14Dokumen20 halamanLecture 3-Tool Life, Tools, Machine Parts-F-19!8!14hari0118Belum ada peringkat

- Tool Wear Characterization of Carbide Cutting Tool Insert Coated With Titanium Nitride TIN in A Single Point Turning Operation of Aisi D2 Steel - Muhammad Farouq B. Muhammad Faisal - TJ1186.M42 2008Dokumen27 halamanTool Wear Characterization of Carbide Cutting Tool Insert Coated With Titanium Nitride TIN in A Single Point Turning Operation of Aisi D2 Steel - Muhammad Farouq B. Muhammad Faisal - TJ1186.M42 2008hari0118Belum ada peringkat

- Nbnfi Fe200903191248Dokumen98 halamanNbnfi Fe200903191248hari0118Belum ada peringkat

- Sreyas Education Society: CompanyDokumen3 halamanSreyas Education Society: Companyhari0118Belum ada peringkat

- Company:: Sreyas Education SocietyDokumen6 halamanCompany:: Sreyas Education Societyhari0118Belum ada peringkat

- 52214-mt - Embedded SystemsDokumen2 halaman52214-mt - Embedded SystemsSRINIVASA RAO GANTABelum ada peringkat

- 1 Year R13Dokumen4 halaman1 Year R13hari0118Belum ada peringkat

- Sreyas Education Society: CompanyDokumen3 halamanSreyas Education Society: Companyhari0118Belum ada peringkat

- Challenging Success Business PowerPoint TemplatesDokumen47 halamanChallenging Success Business PowerPoint Templatesika dunggioBelum ada peringkat

- 2 Connector Technology Shelf SupportsDokumen76 halaman2 Connector Technology Shelf SupportsRanel P. JamarolinBelum ada peringkat

- LW5926 Flame Stitch Bag Free Crochet PatternDokumen3 halamanLW5926 Flame Stitch Bag Free Crochet PatternzagyvacsekBelum ada peringkat

- 02 Spring Crochet Along - Jumbo Ice Cream Elephant Truck - ENDokumen3 halaman02 Spring Crochet Along - Jumbo Ice Cream Elephant Truck - ENKatherine Lyra Luiz100% (2)

- Tech Mill FormulasDokumen5 halamanTech Mill FormulaspchakkrapaniBelum ada peringkat

- Sheet Metal Gauge Size ChartDokumen2 halamanSheet Metal Gauge Size ChartaselabollegalaBelum ada peringkat

- Dollhouse PurseDokumen2 halamanDollhouse PurseJill Krahling100% (1)

- Leo Moon: by Nat RaedwulfDokumen4 halamanLeo Moon: by Nat RaedwulfRoganBelum ada peringkat

- 3 in 1 DIY Sharpening Jig PLANS: 1. Knife SharpenerDokumen22 halaman3 in 1 DIY Sharpening Jig PLANS: 1. Knife SharpenerΔΗΜΗΤΡΗΣ ΠΑΠΑΕΥΣΤΑΘΙΟΥBelum ada peringkat

- Wooden Mallet Plans 2 - WoodArchivistDokumen4 halamanWooden Mallet Plans 2 - WoodArchivistEricsBelum ada peringkat

- English KnottyDokumen2 halamanEnglish Knottynehiltas2013Belum ada peringkat

- CNC Lathe ProgrammingDokumen11 halamanCNC Lathe ProgrammingKevin Wang100% (2)

- Hes A3003-03 Chamfer of Thread EndDokumen5 halamanHes A3003-03 Chamfer of Thread EndPreetam Kumar100% (1)

- Aisii 1045Dokumen6 halamanAisii 1045Edho AristiantoBelum ada peringkat

- 1990 08 CBDokumen12 halaman1990 08 CBRedirecting DecoyBelum ada peringkat

- Forging: ObjectivesDokumen5 halamanForging: ObjectivesLeeladhar SharmaBelum ada peringkat

- Crochet Sampler AfghanDokumen8 halamanCrochet Sampler Afghanandiscrbd100% (1)

- Manual Display Panel - Timber - Cersanit - enDokumen13 halamanManual Display Panel - Timber - Cersanit - enCsibi ErvinBelum ada peringkat

- Three Legged Stool PDFDokumen5 halamanThree Legged Stool PDFFeng Shu jiBelum ada peringkat

- 1255 - Qualified Welder ListDokumen1 halaman1255 - Qualified Welder ListattaullaBelum ada peringkat

- Machining OperationsDokumen7 halamanMachining OperationsbazilBelum ada peringkat

- Die Process Check SheetDokumen83 halamanDie Process Check SheetMURALIDHRABelum ada peringkat

- Manpower Deployment Plan Ot2499Dokumen1 halamanManpower Deployment Plan Ot2499becemBelum ada peringkat

- Catalogo Die Cast DMEDokumen24 halamanCatalogo Die Cast DMEkontacBelum ada peringkat

- JIS Material ComparisonDokumen1 halamanJIS Material ComparisonasritaipBelum ada peringkat

- Machine Tools: Lecture Notes 1Dokumen38 halamanMachine Tools: Lecture Notes 1muhammet çalım100% (1)

- CounterSink Holes ChartDokumen3 halamanCounterSink Holes Chartmohdazlan hassanBelum ada peringkat

- Ridgid Pipe ThreaderDokumen2 halamanRidgid Pipe Threaderhammondm3Belum ada peringkat

- Knuth Ecoturn 650-1000Dokumen2 halamanKnuth Ecoturn 650-1000Iacob CornelBelum ada peringkat

- Step by Step Sweater V1Dokumen7 halamanStep by Step Sweater V1KKK VBelum ada peringkat