Superlon Technical Specification

Diunggah oleh

Sam Wing HongHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Superlon Technical Specification

Diunggah oleh

Sam Wing HongHak Cipta:

Format Tersedia

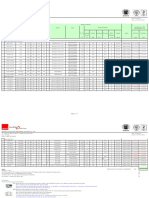

Quality NBR Insulation

Thickness Guide for Condensation Control

Recommended Thickness (mm) for Condensate, Chilled Water and Refrigeration Systems

Ambient Temperature

Relative Humidity

26 oC

30 oC

35 oC

75% 80% 85% 90% 75% 80% 85% 90% 75% 80% 85% 90%

Condensate +18 oC

Pipe Up to 38 mm OD

Pipe 42 89 mm OD

Pipe above 102 mm OD

6

6

10

10

10

10

10

10

13

19

19

25

10

10

10

10

13

13

13

19

19

25

25

32

10

10

13

13

19

19

19

25

25

32

38

38

Chilled Water +5 oC

Pipe Up to 38 mm OD

Pipe 42 89 mm OD

Pipe above 102 mm OD

13

19

19

19

19

25

25

32

32

38

51

51

19

19

19

19

25

25

32

32

32

51

51

51

19

19

25

25

25

32

32

38

38

51

64

64

Refrigeration 0 oC

Pipe Up to 38 mm OD

Pipe 42 89 mm OD

Pipe above 102 mm OD

19

19

25

25

25

25

32

32

38

51

51

64

19

25

25

25

32

32

32

38

38

51

64

64

25

25

25

25

32

32

38

38

50

64

64

76

Refrigeration -15 oC

Pipe Up to 38 mm OD

Pipe 42 89 mm OD

Pipe above 102 mm OD

25

32

32

32

38

38

51

51

51

64

76

89

25

32

32

32

38

51

51

51

64

76

89

89

32

32

38

38

51

51

51

64

64

76

89

102

Recommended Thickness (mm) for ducting

Ambient Temperature

Relative Humidity

Air Ducting +15 oC

26 oC

30 oC

35 oC

75% 80% 85% 90% 75% 80% 85% 90% 75% 80% 85% 90%

6

10

16

32

10

16

25

38

13

19

32

51

At Superlon condensation prevention

is our utmost priority. As a safety to prevent condensation, calculated figures are based on dew

o

point temperature adding +0.5 C with a external surface coefficient of 9 W/M2-K. Thickness should be recalculated if there is any use

of jacketing such as aluminium as the external surface coefficient will be changed.

Note: Recommended thickness are to be used as a guide. Results are obtained under typical conditions. Superlon does not guarantee

it will be prevent condensation. Other factors such as proper installation is crucial in condensation prevention. Please consult with our

technical staff for more precise calculations.

SUPERLON WORLDWIDE SDN. BHD. (252355-U)

Lot 2736, Jalan Raja Nong, 41200 Klang, Selangor, Malaysia.

Tel: +60 3 5161 7778 Fax: +60 3 5162 7778

Email: inquiry@superlon.com.my

Website: www.superlon.com.my

Quality NBR Insulation

Superlon Insulation R-Values

R value or thermal resistance is a measure of the ability of a material to retard heat flow. The higher the

R-value the higher the insulating value. The R-value is generally calculated by dividing the insulation by its

K-value.

Nominal ID

Inches

mm

1/4

3/8

1/2

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2"

1 5/8

1 7/8

2

2 1/8

2 3/8

2 5/8

2 7/8

3

3 1/8

3 1/2"

4

6

10

13

16

19

22

25

28

32

35

38

42

47

51

54

60

67

73

76

80

89

101

3/8

10

0.462

0.400

0.374

0.356

0.342

0.332

0.324

0.317

0.310

0.305

0.302

0.297

0.293

0.290

0.288

0.284

0.281

0.279

0.278

0.276

0.274

0.271

1/2"

13

0.744

0.640

0.595

0.563

0.539

0.520

0.505

0.493

0.479

0.471

0.463

0.455

0.446

0.441

0.437

0.430

0.424

0.419

0.417

0.414

0.409

0.404

Pipe Insulation

Insulation Wall Thickness

3/4"

1

1 1/4"

19

25

32

1.218

1.737

1.046

1.493

0.968

1.381

0.912

1.299

1.788

0.870

1.236

1.700

0.836

1.186

1.628

0.809

1.144

1.570

0.786

1.110

1.520

0.761

1.072

1.465

0.745

1.048

1.430

0.732

1.026

1.399

0.716

1.002

1.363

0.699

0.976

1.325

0.688

0.959

1.299

0.681

0.947

1.281

0.668

0.926

1.250

0.655

0.906

1.220

0.646

0.891

1.198

0.642

0.885

1.188

0.637

0.877

1.176

0.627

0.861

1.151

0.617

0.843

-

1 1/2"

38

2.235

2.124

2.033

1.959

1.895

1.825

1.779

1.739

1.693

1.643

1.609

1.586

1.546

1.506

1.477

1.463

1.447

1.415

-

2

50

3.192

3.032

2.903

2.794

2.702

2.598

2.531

2.472

2.402

2.328

2.276

2.241

2.180

2.118

-

Sheet Insulation

Thickness

R-Value

Inches

mm

1/8

3

0.083

1/4"

6

0.167

3/8

10

0.278

1/2"

13

0.361

5/8

16

0.444

3/4"

19

0.528

1

25

0.694

1 1/4

32

0.889

1 1/2"

38

1.056

2

50

1.417

SUPERLON WORLDWIDE SDN. BHD. (252355-U)

Lot 2736, Jalan Raja Nong, 41200 Klang, Selangor, Malaysia.

Tel: +60 3 5161 7778 Fax: +60 3 5162 7778

Email: inquiry@superlon.com.my

Website: www.superlon.com.my

Quality NBR Insulation

Condensation Control

Condensation or sweating on the insulation is a big problem for installers. Upon condensation, the cost of repair and

replacement of water damaged ceiling and spoilt goods is considerably higher than actual cost of the insulation. This is

why the correct thickness, proper installation and good understanding of the relationship between ambient temperature,

relative humidity (RH) and dew point are extremely important to prevent condensation.

Insulating Environment

Knowing what sort of environment the insulation will be installed at is very important in determining the thickness of

your insulation. This greatly depends on the temperature and humidity of the environment and how close the dew point

is to the ambient temperature.

Air can only hold a certain amount of water vapors. In general, the hotter it is (higher temperature) the more water

vapor the air can hold. If the water vapors exceed the amount that the air can hold, condensation occurs. This is where

understanding the dew point is important. At the given temperature and humidity, the dew point is the temperature

where humidity is 100%. Therefore when the surface temperature of the insulating pipe reaches its dew point

temperature or below, condensation occurs. The diagram below explains this:

o

Temperature: 30 C

Relative Humidity: 70%

o

Dew Point: 24 C

1.

Temperature: 25 C

Relative HUmiduty: 97%

o

Dew Point: 24 C

Temperature: 24 C

Relative Humidity: 100%

o

Dew Point: 24 C

3.

2.

This is why knowing the dew point of the installation environment is

extremely important. The higher the humidity, the closer the ambient

temperature is to its dew point temperature.

o

An example of a mild environment temperature of 25 C with a RH 60%

o

would have a dew point of 17 C. When the dew point is further away

from the ambient temperature the less likely condensation will occur.

Another example but an extreme environment with ambient

o

o

temperature 35 C and RH 85% the dew point would be 32 C. The

ambient temperature and dew point is very close, the likelihood of

sweating is very high. This is why at high humidity environments

Superlon always recommends to size up and use a greater thickness of

insulation.

Dew Point Calculation:

TD =

f

100

1/8

(112 + 0.9T) + 0.1T 112

Where:

F = Relative Humidity

T = Ambient Temperature

TD = Dew Point Temperature

SUPERLON WORLDWIDE SDN. BHD. (252355-U)

Lot 2736, Jalan Raja Nong, 41200 Klang, Selangor, Malaysia.

Tel: +60 3 5161 7778 Fax: +60 3 5162 7778

Email: inquiry@superlon.com.my

Website: www.superlon.com.my

Quality NBR Insulation

Insulation Thickness

Choosing the right insulation thickness is critical in preventing condensation. There are many things to

consider when choosing the right insulation thickness. The following listed below is important for calculating

the insulation thickness:

Maximum ambient temperature

Pipe line temperature

Maximum relative temperature

Pipe line outer diameter (OD)

As a basic rule the higher the humidity, the

thicker the insulation is required. This is because

when the humidity is high, the closer it is to its

dew point. This is why for any installation

environment,

the

maximum

ambient

temperature and the maximum relative humidity

is crucial in the prevention of condensation.

Figure 2 demonstrates the comparison between

insulation thickness and humidity. As the

humidity increases, the insulation thickness

required also increases with it. As shown, at a

high humidity of 95%, an insulation thickness of

2 or 50 mm is required to prevent condensation.

Figure 2: Thickness and humidity comparison example of a typical

o

environment with ambient temperature of 30 C and line

o

temperature of 10 C

Line temperature is also an important factor in

determining the thickness of the insulation

required. As a rule of thumb, the lower the

pipe line temperature, thicker the insulation

needs to be used. This is because when the line

temperature decreases, it will be easier to

penetrate the walls of the insulation. This

means that the insulating surface will near or

reach its dew point quicker causing it to

condensate. Figure 3 is an example where the

insulating thickness needs to be 1 1/4 (32 mm)

at a line temperature of -10 oC compared to

3/4 (19 mm) at a line temperature of 10 oC.

Figure 3: Thickness and line temperature comparison example of

o

a typical environment with ambient temperature of 30 C and

humidity of 80%

SUPERLON WORLDWIDE SDN. BHD. (252355-U)

Lot 2736, Jalan Raja Nong, 41200 Klang, Selangor, Malaysia.

Tel: +60 3 5161 7778 Fax: +60 3 5162 7778

Email: inquiry@superlon.com.my

Website: www.superlon.com.my

Quality NBR Insulation

Common Causes of Condensation

Insulation thickness is the main reason why condensation occurs. Condensation could occur from high

humidity environments where the thickness of the insulation used was not thick enough. There are many

other reasons why, more specifically from installation.

Installers must remember that condensation occurs when the INSULATION SURFACE TEMPERATURE

REACHES ITS DEW POINT. Installers can seal it very tightly without any air getting in but if the thickness is not

enough the surface temperature WILL reach its dew point, which will result in condensation.

1. PVC Tape

Many installers use PVC tape to try and seal joints for

insulation materials together. The main reasons for this is that

installers feel that since PVC tape is water proof it can protect

joints without the use of glue. Usually installers will wrap the

PVC tape very tightly to try and make the joints air tight and

secure from outside environments. This actually makes things

worse as the insulation thickness is severely compressed.

Condensation will occur since the insulation thickness is now

less than actual thickness.

2. Two Copper Pipes for one tube

Some installers and contractors try to save time and the cost

of insulation by inserting two copper pipes into one insulation

tube. This method stretches the insulation tube which could

result in the reduction of thickness.

Copper tubes may also damage due to friction. Since there is

much more air inside the internal diameter of the insulation,

this could cause the pipes to lose temperature and shorten

the life span of the air conditioners.

PVC tape wrapped around joints without

glue

One copper

pipe per

insulation

tube does

not deform

the

insulation

Two copper

pipes per

insulation

deforms and

stretches the

insulation

To the right is a picture of a bad installation job using PVC tape to

improperly join the insulation tubes and also using two copper

pipes for one insulation tube. Joints are easily exposed as it has

not been glued using Superlon Insulation Glue, and the tightly

wrapped PVC tape has made the insulation thickness much less

than its prior thickness.

SUPERLON WORLDWIDE SDN. BHD. (252355-U)

Lot 2736, Jalan Raja Nong, 41200 Klang, Selangor, Malaysia.

Tel: +60 3 5161 7778 Fax: +60 3 5162 7778

Email: inquiry@superlon.com.my

Website: www.superlon.com.my

Quality NBR Insulation

3. Pipe Supports and Hangers

Improper use of pipe supports is also one of the major causes

of condensation. Pipe supports are usually made to support

hard and solid tubes and pipes and were not meant to use for

foamed insulation materials as it could press against the

insulation resulting in insulation thickness reduction. The

reduction of thickness causes the insulation pipe to

condensate as it is not suitable to the particular temperatures

and humidity. The photos below are examples of how pipe

supports could affect the insulation thickness.

Example of pipe support reducing thickness and crowded pipes

thickness

Pipe support reducing insulation

4. Pipe Crowding

Too many insulation tubes crowded together can

cause condensation. Crowding of pipes prevents air

circulation which is critical in preventing condensation.

Lack of air circulation increases the pipes humidity

which can cause condensation. Examples of this are

pictured above and to the right.

Example of crowded pipes

5. Outdoor use

Installing outdoors without the use of Superlon

Weather Paint or Superlon Aluminium Jacketing can

damage the insulation pipe. Prolonged exposures to

the sun can cause the insulation material to crack.

SUPERLON WORLDWIDE SDN. BHD. (252355-U)

Prolonged exposure to the sun

and environment causes cracks

Lot 2736, Jalan Raja Nong, 41200 Klang, Selangor, Malaysia.

Tel: +60 3 5161 7778 Fax: +60 3 5162 7778

Email: inquiry@superlon.com.my

Website: www.superlon.com.my

Quality NBR Insulation

Installation

Whilst choosing the correct thickness is critical, one of the most important aspects in preventing

condensation is having a proper and sound installation. Before installing please take note of the

points below:

Before installing make sure that the Superlon insulation and the surface of pipes are dry

and clean. The surface to be insulated must be free of debris and rust.

Superlon insulation must never stretched, instead use a piece of insulation longer than the

pipe itself. It is better to compress the insulation slightly than stretched as this can lose the

insulations thickness.

Always use a proper size insulation ID to fit the OD of the pipe. Never put two pipes into

one insulation tube as this can result the insulation being stretched and have the

insulation lose its thickness and shape. The additional air inside the insulation tube can

cause condensation.

Do not crowd pipes together. Crowding pipes together prevents air circulation which

results in surface condensation. Instead spacing out the pipes allows air movement in the

pipes which is critical in areas with high temperatures and humidity.

Proper sealing of all pipe insulation is the key to minimizing heat loss and control surface

condensation. Cold pipe lines which are exposed due to poor installation can allow

formation of condensation and may contribute to pipe corrosion. All joints should be

properly coated with Superlon insulation glue and Superlon foam tape to properly seal the

joints together.

For outdoor applications, Superlon insulation pipes must be coated with two layers of

weather paint. Falling to do so may result in surface cracking and erosion with time, which

can lead to heat loss and condensation. Superlon recommends aluminium jacketing for

high UV applications.

SUPERLON WORLDWIDE SDN. BHD. (252355-U)

Lot 2736, Jalan Raja Nong, 41200 Klang, Selangor, Malaysia.

Tel: +60 3 5161 7778 Fax: +60 3 5162 7778

Email: inquiry@superlon.com.my

Website: www.superlon.com.my

Quality NBR Insulation

Thickness Recommendation

Using the correct thickness in a particular operating environment can prevent condensation from

occurring. Below are some typical conditions that are based in a more hot and humid environment.

Please make sure that the conditions do not go over its maximum severity to ensure proper

condensation control. Thickness recommended within the specified temperature and humidity range

will control condensation if installed correctly.

o

15 C

Piping Line Surface Temperature

5 oC

-18 oC

Normal Conditions

Based on the weather conditions

experienced in tropical regions

1/2 (13 mm)

1 (25 mm)

1 1/2 (32 mm)

1 (25 mm)

1 1/2" (38 mm)

2 (50 mm)

3/8 (10 mm)

1/2 (13 mm)

1 (25 mm)

Maximum severity of 29 oC and

RH of 78%

Severe Conditions

Confined and poorly ventilated

areas with excessive moisture

o

Maximum severity of 35 C and

RH of 85%

Mild Conditions

Well ventilated, low humidity

conditions

o

Maximum severity of 26 C and

RH of 70%

For a more accurate calculation, Superlons specially designed computer software can help calculate

the specific insulation thickness in a particular environment. The following needs to be known for an

accurate calculation: maximum temperature, maximum humidity, line temperature and pipe line size.

Please refer to your local distributors for more information.

Superlon recommends sizing up thickness for pipe sizes above 3 (76 mm) IPS.

SUPERLON WORLDWIDE SDN. BHD. (252355-U)

Lot 2736, Jalan Raja Nong, 41200 Klang, Selangor, Malaysia.

Tel: +60 3 5161 7778 Fax: +60 3 5162 7778

Email: inquiry@superlon.com.my

Website: www.superlon.com.my

Anda mungkin juga menyukai

- Catalogue Air Cooled Chiller Uaa-St3m (R134) PDFDokumen9 halamanCatalogue Air Cooled Chiller Uaa-St3m (R134) PDFNanda AulianaBelum ada peringkat

- F 1090 - 87 R97 - Rjewota - PDFDokumen4 halamanF 1090 - 87 R97 - Rjewota - PDFFreddy AlmeidaBelum ada peringkat

- Sealant - 1st Acrylic A-700 MSDSDokumen6 halamanSealant - 1st Acrylic A-700 MSDSBozow BongBelum ada peringkat

- YORK PackageDokumen28 halamanYORK PackageSreekumarBelum ada peringkat

- Natural Ventilation Openings Calculation ToolDokumen9 halamanNatural Ventilation Openings Calculation ToolSamved PatelBelum ada peringkat

- Ahu 1Dokumen1 halamanAhu 1quynhanh2603Belum ada peringkat

- Clarke 100e Mig WelderDokumen18 halamanClarke 100e Mig WelderplainmanBelum ada peringkat

- LN Electrical DataDokumen7 halamanLN Electrical DataBen MusimaneBelum ada peringkat

- TA Balancing Valve-STAFDokumen12 halamanTA Balancing Valve-STAFAnonymous FZs3yBHh7Belum ada peringkat

- DBV 5 Pro - R410A - 50Hz - 27.10.2021Dokumen48 halamanDBV 5 Pro - R410A - 50Hz - 27.10.2021MIk AzizBelum ada peringkat

- BOSS™ Pressurisation Units and Expansion Vessels PDFDokumen16 halamanBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASBelum ada peringkat

- Technical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)Dokumen32 halamanTechnical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)yusuf mohd sallehBelum ada peringkat

- H23A383DBEADokumen1 halamanH23A383DBEABruno Monteiro0% (1)

- Water in Air CalculatorDokumen7 halamanWater in Air CalculatorBhramandhikaNalendraGhuptaBelum ada peringkat

- All in One HVAC Calculation 1Dokumen51 halamanAll in One HVAC Calculation 1Youssry Elsayed MohamedBelum ada peringkat

- Esp Calculation StudioDokumen8 halamanEsp Calculation StudioMohsin ShaikhBelum ada peringkat

- 40LX Ceiling Concealed CCAC InstallationDokumen17 halaman40LX Ceiling Concealed CCAC Installationjeferson binayBelum ada peringkat

- Fans Static Head Calculation SheetDokumen1 halamanFans Static Head Calculation SheetraifaisalBelum ada peringkat

- 21A Solenoid Valves Series DatasheetDokumen40 halaman21A Solenoid Valves Series Datasheetportusan2000Belum ada peringkat

- Catalog VRV IV - 2016Dokumen62 halamanCatalog VRV IV - 2016VietHienBelum ada peringkat

- Daikin Packaged Unit UAYQ-C Series Engineering DataDokumen58 halamanDaikin Packaged Unit UAYQ-C Series Engineering DataMichaelBelum ada peringkat

- Karnataka Electrical Inspectorate) Rules, 2018Dokumen38 halamanKarnataka Electrical Inspectorate) Rules, 2018Babu BabuBelum ada peringkat

- Yazd-System Description For Clean Drain System PDFDokumen7 halamanYazd-System Description For Clean Drain System PDFace-winnieBelum ada peringkat

- The Good Ventilation of Switchgear and Transformer RoomsDokumen8 halamanThe Good Ventilation of Switchgear and Transformer RoomsjayamenggalaBelum ada peringkat

- Beijer Ref Service Support Handbook 19 Web 2Dokumen60 halamanBeijer Ref Service Support Handbook 19 Web 2xfvnjhkwrtjBelum ada peringkat

- Panasonic - Industrial Use PAC (Packaged AC)Dokumen2 halamanPanasonic - Industrial Use PAC (Packaged AC)Combox Black100% (1)

- Dual Fuel Genset - Heat Recovery-1-2Dokumen2 halamanDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- Babcock & Wilcox Steam TablesDokumen5 halamanBabcock & Wilcox Steam Tablesnum0067Belum ada peringkat

- RTP 3 25 TR For Rooftoppackage 1Dokumen52 halamanRTP 3 25 TR For Rooftoppackage 1GeorgeBelum ada peringkat

- Psychrometrics FormulaeDokumen5 halamanPsychrometrics Formulaetmy3dataBelum ada peringkat

- Ref Pipe Sizing Ver 02 21 11Dokumen12 halamanRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- 1.ChillerTechnicalData 1 1Dokumen2 halaman1.ChillerTechnicalData 1 1Nguyên Trịnh CaoBelum ada peringkat

- Duct CalculationsDokumen38 halamanDuct CalculationsDilnesa EjiguBelum ada peringkat

- Data Sheet of Bronze Ferrule ValvesDokumen1 halamanData Sheet of Bronze Ferrule ValvesAfzalBelum ada peringkat

- Mechanical Heat Pump-2 PDFDokumen9 halamanMechanical Heat Pump-2 PDFRushikesh PatilBelum ada peringkat

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDokumen3 halamanGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarBelum ada peringkat

- Water-Cooled Series R (TM) RTHD Product Report PDFDokumen2 halamanWater-Cooled Series R (TM) RTHD Product Report PDFMajho CanilangBelum ada peringkat

- MAKRO MYANMAR ACMV PDF DWG PDFDokumen21 halamanMAKRO MYANMAR ACMV PDF DWG PDFHnin Pwint100% (1)

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenDokumen9 halamanNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenrakamechBelum ada peringkat

- Oxycom IntrCool Brochure (2019) enDokumen20 halamanOxycom IntrCool Brochure (2019) enAnkit JainBelum ada peringkat

- Refrigeration Dryer 250 M3/mminDokumen2 halamanRefrigeration Dryer 250 M3/mminAriep Rachman100% (1)

- ASLI 02 Supply Air Grilles Set - AIR ConditioningDokumen21 halamanASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)

- VTS FAHU Selected Model - Fin PDFDokumen2 halamanVTS FAHU Selected Model - Fin PDFDuxToyBelum ada peringkat

- Hunter GP100 08-2003 PDFDokumen1 halamanHunter GP100 08-2003 PDFaymanmkBelum ada peringkat

- DCDokumen25 halamanDCaries26marchBelum ada peringkat

- Hourly Load Profile of District Cooling System With Thermal Energy StorageDokumen3 halamanHourly Load Profile of District Cooling System With Thermal Energy StorageBalasundaramSrinivasaRajkumarBelum ada peringkat

- Flexidoor High Speed DoorsDokumen20 halamanFlexidoor High Speed DoorsDentobiasBelum ada peringkat

- ASHRAE Table9 Hot Water DemandDokumen1 halamanASHRAE Table9 Hot Water DemandTerrence Redd100% (1)

- F ChartDokumen7 halamanF Charthemal4379Belum ada peringkat

- Cooling Towers Certified by CTIDokumen7 halamanCooling Towers Certified by CTIvsrajguruBelum ada peringkat

- 1Dokumen3 halaman1ntt_121987Belum ada peringkat

- Carriage Bolts and Nuts DIN 603 (Bolt) DIN 934 (Nut)Dokumen1 halamanCarriage Bolts and Nuts DIN 603 (Bolt) DIN 934 (Nut)Srinivasa TemkarBelum ada peringkat

- Product Range Kruger Fan PDFDokumen4 halamanProduct Range Kruger Fan PDFBenny S Putra100% (2)

- Pressure Volume Calculator 02Dokumen6 halamanPressure Volume Calculator 02Jenny Cecilia Ureña ZuriBelum ada peringkat

- Blue Star AHU DetailsDokumen5 halamanBlue Star AHU DetailsdheerajdorlikarBelum ada peringkat

- Superlon1 PDFDokumen4 halamanSuperlon1 PDFmohd aliffBelum ada peringkat

- Kaiflex Specification DomesticDokumen5 halamanKaiflex Specification Domesticnaseema1Belum ada peringkat

- Kooltherm PipeDokumen8 halamanKooltherm Pipenaseema1Belum ada peringkat

- Sellos para Vacio Criterio de DiseñoDokumen8 halamanSellos para Vacio Criterio de Diseñogabinho755416Belum ada peringkat

- Insulation GuidanceDokumen55 halamanInsulation Guidancesiva_nagesh_2Belum ada peringkat

- Cag I Air Compressor HPDokumen24 halamanCag I Air Compressor HPcamenitaBelum ada peringkat

- CodeconductDokumen12 halamanCodeconductJude FrancisBelum ada peringkat

- Superlon Technical SpecificationDokumen8 halamanSuperlon Technical SpecificationSam Wing HongBelum ada peringkat

- DH 6 IDokumen1 halamanDH 6 Ikan_chan_01Belum ada peringkat

- Designing Your Compressed Air System - KAESER Compressor PDFDokumen8 halamanDesigning Your Compressed Air System - KAESER Compressor PDFhugoBelum ada peringkat

- REA2015 REG2015 (Final) PDFDokumen92 halamanREA2015 REG2015 (Final) PDFAuYongTheanSengBelum ada peringkat

- Daikin Download Link (070915)Dokumen6 halamanDaikin Download Link (070915)Sam Wing HongBelum ada peringkat

- Examples of Fire Safety Engineering Calculations.Dokumen18 halamanExamples of Fire Safety Engineering Calculations.Sam Wing HongBelum ada peringkat

- Room Aircon Heat Load Estimate FormDokumen3 halamanRoom Aircon Heat Load Estimate FormMena G. El NimrBelum ada peringkat

- Bomba UBBL 1984 (Amendment 2012) HighlightDokumen11 halamanBomba UBBL 1984 (Amendment 2012) HighlightSam Wing HongBelum ada peringkat

- HR T&CDokumen29 halamanHR T&CSam Wing HongBelum ada peringkat

- HVAC Handbook HVAC Design Brief (Singapore)Dokumen26 halamanHVAC Handbook HVAC Design Brief (Singapore)Sam Wing Hong50% (2)

- Duct Pressure Loss CalculationDokumen24 halamanDuct Pressure Loss CalculationbernardsilvanoBelum ada peringkat

- Draft SCA Guidance On Smoke Control in Apartment BuildingsDokumen67 halamanDraft SCA Guidance On Smoke Control in Apartment BuildingsSam Wing HongBelum ada peringkat

- Typical SMATV For Condo-ApartmentDokumen3 halamanTypical SMATV For Condo-ApartmentSam Wing HongBelum ada peringkat

- TOLCO Pipe HangersDokumen26 halamanTOLCO Pipe HangersPaulo VeríssimoBelum ada peringkat

- Papaya Pipe HangerDokumen2 halamanPapaya Pipe HangerSam Wing HongBelum ada peringkat

- Domestic Hot Water RecirculationDokumen2 halamanDomestic Hot Water RecirculationSam Wing HongBelum ada peringkat

- Superlon Technical SpecificationDokumen8 halamanSuperlon Technical SpecificationSam Wing HongBelum ada peringkat

- Lift Traffic Design Spreadsheet - All PeaksDokumen8 halamanLift Traffic Design Spreadsheet - All PeaksSam Wing HongBelum ada peringkat

- Typical MSW SchematicDokumen9 halamanTypical MSW SchematicSam Wing HongBelum ada peringkat

- Soil Pipe (Timplas)Dokumen9 halamanSoil Pipe (Timplas)Sam Wing HongBelum ada peringkat

- Choosing Soft Starter or Variable Frequency DriveDokumen4 halamanChoosing Soft Starter or Variable Frequency Drivesiva_nagesh_2Belum ada peringkat

- Engineering Sump Design Guide PDFDokumen8 halamanEngineering Sump Design Guide PDFHaimwant DhanieBelum ada peringkat

- Paper-on-Swimming Pool Circulation-Systems PDFDokumen5 halamanPaper-on-Swimming Pool Circulation-Systems PDFIlyas AhmedBelum ada peringkat

- Pyrochem Operation ManualDokumen82 halamanPyrochem Operation ManualSam Wing Hong100% (2)

- Hot Water Supply (Apprentice) M2 U10Dokumen39 halamanHot Water Supply (Apprentice) M2 U10Sam Wing HongBelum ada peringkat

- Surge ControlDokumen14 halamanSurge Control31jamesBelum ada peringkat

- Preliminary Calculation On Sizing of Surge VesselDokumen3 halamanPreliminary Calculation On Sizing of Surge VesselSam Wing Hong100% (3)

- Casette YorkDokumen4 halamanCasette YorkWilliam RuizBelum ada peringkat

- Fes EngDokumen4 halamanFes EngErdinc KlimaBelum ada peringkat

- Vrfahupau2018 PDFDokumen16 halamanVrfahupau2018 PDFPrasath SBelum ada peringkat

- TRICKLE VENT TECHNICAL BROCHURE - 2021 - WebDokumen2 halamanTRICKLE VENT TECHNICAL BROCHURE - 2021 - WeblabanBelum ada peringkat

- Final - District Cooling System Design MENA - July2021Dokumen220 halamanFinal - District Cooling System Design MENA - July2021Mubashir Khan100% (2)

- Fujitsu-ASYG24LFCC Περιγραφή PDFDokumen2 halamanFujitsu-ASYG24LFCC Περιγραφή PDFStrato 'stratari' KyriazidisBelum ada peringkat

- Catalog Mitsubishi Electric Lossnay LGH RVX 2019Dokumen28 halamanCatalog Mitsubishi Electric Lossnay LGH RVX 2019tachetBelum ada peringkat

- HVAC Brochure PDFDokumen16 halamanHVAC Brochure PDFCarlos Benavides AlvarezBelum ada peringkat

- Ulei Pentru RefrigerantiDokumen2 halamanUlei Pentru RefrigerantiMarian MarianBelum ada peringkat

- Samsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business IndiaDokumen4 halamanSamsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business Indiachandravadiyaketan1504Belum ada peringkat

- LG - Catalogue - Scroll Compressor (20201204 - 165426)Dokumen17 halamanLG - Catalogue - Scroll Compressor (20201204 - 165426)Thanh NguyễnBelum ada peringkat

- ESG Service Information: BackgroundDokumen6 halamanESG Service Information: BackgroundAbdulSattarBelum ada peringkat

- Scroll Compressors: R410A // HermeticDokumen12 halamanScroll Compressors: R410A // HermeticMechanical PowerBelum ada peringkat

- Perdele Economic B 2VVDokumen4 halamanPerdele Economic B 2VVakitainupufBelum ada peringkat

- SODECA. Manufacturer of Fans and Industrial ExtractorsDokumen3 halamanSODECA. Manufacturer of Fans and Industrial Extractorsmohsen_267Belum ada peringkat

- RXYQ-U EEDEN19 Data Books EnglishDokumen65 halamanRXYQ-U EEDEN19 Data Books EnglishvukBelum ada peringkat

- Chapter 3. Central Cooling and Heating PlantsDokumen21 halamanChapter 3. Central Cooling and Heating PlantsRolando Valdez GutierrezBelum ada peringkat

- 08ts Ta26 070103Dokumen2 halaman08ts Ta26 070103Ashraf Adel Nashed ZakiBelum ada peringkat

- Low Level Return or Exhaust Air Grilles Are Usually PreferredDokumen3 halamanLow Level Return or Exhaust Air Grilles Are Usually PreferredNadya Putri Dwi YanariBelum ada peringkat

- LG MultiV III - CatalogueDokumen13 halamanLG MultiV III - CatalogueMuhidin KozicaBelum ada peringkat

- DezumidificatorDokumen12 halamanDezumidificatordeselnicuBelum ada peringkat

- Duct Size Duct Size Velocity Duct Loss Pressure Pressure Length Width (Equiv Round) Airflow Velocity Pressure Length Coeff. Loss Per 100ft LossDokumen1 halamanDuct Size Duct Size Velocity Duct Loss Pressure Pressure Length Width (Equiv Round) Airflow Velocity Pressure Length Coeff. Loss Per 100ft LossAzher ABelum ada peringkat

- Manual Load CalculationDokumen6 halamanManual Load Calculationganesh gundBelum ada peringkat

- BH 5 en 15251 Indoor AirDokumen13 halamanBH 5 en 15251 Indoor AirmelvinBelum ada peringkat

- Applied Thermodynamics - Refrigeration CycleDokumen59 halamanApplied Thermodynamics - Refrigeration CycleSHREYASIBelum ada peringkat

- Simple Dew Point Control With Propane Loop For Chilling (HYSYS V8.6)Dokumen32 halamanSimple Dew Point Control With Propane Loop For Chilling (HYSYS V8.6)JesusBelum ada peringkat

- Parameters - Manual-Air-Compresor-Atlas Copco-GA75-2Dokumen3 halamanParameters - Manual-Air-Compresor-Atlas Copco-GA75-2Tolias EgwBelum ada peringkat

- Cooltech Prsentation - May 2016Dokumen12 halamanCooltech Prsentation - May 2016Cooltech ApplicationsBelum ada peringkat

- Numerical Investigation of Air Cooled Condensers Using Different RefrigerantsDokumen4 halamanNumerical Investigation of Air Cooled Condensers Using Different RefrigerantsEditor IJTSRDBelum ada peringkat

- Karlsson Capacity Control Residential HP Heating Systems TESIDokumen115 halamanKarlsson Capacity Control Residential HP Heating Systems TESIGiovanniCuocoBelum ada peringkat

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDari EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincPenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeDari EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifePenilaian: 4 dari 5 bintang4/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDari EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifePenilaian: 5 dari 5 bintang5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsDari EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsPenilaian: 4 dari 5 bintang4/5 (146)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDari EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsPenilaian: 5 dari 5 bintang5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDari EverandChemistry for Breakfast: The Amazing Science of Everyday LifePenilaian: 4.5 dari 5 bintang4.5/5 (90)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDari EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolBelum ada peringkat

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableDari EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TablePenilaian: 3.5 dari 5 bintang3.5/5 (22)

- Transformer: The Deep Chemistry of Life and DeathDari EverandTransformer: The Deep Chemistry of Life and DeathPenilaian: 4.5 dari 5 bintang4.5/5 (13)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilDari EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilPenilaian: 5 dari 5 bintang5/5 (1)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsDari EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsBelum ada peringkat

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookDari EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookBelum ada peringkat

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideDari EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideBelum ada peringkat

- Taste: Surprising Stories and Science About Why Food Tastes GoodDari EverandTaste: Surprising Stories and Science About Why Food Tastes GoodPenilaian: 3 dari 5 bintang3/5 (20)

- Bioplastics: A Home Inventors HandbookDari EverandBioplastics: A Home Inventors HandbookPenilaian: 4 dari 5 bintang4/5 (2)

- Chemistry: a QuickStudy Laminated Reference GuideDari EverandChemistry: a QuickStudy Laminated Reference GuidePenilaian: 5 dari 5 bintang5/5 (1)

- Tribology: Friction and Wear of Engineering MaterialsDari EverandTribology: Friction and Wear of Engineering MaterialsPenilaian: 5 dari 5 bintang5/5 (1)

- Phase Equilibria in Chemical EngineeringDari EverandPhase Equilibria in Chemical EngineeringPenilaian: 4 dari 5 bintang4/5 (11)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeDari EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifePenilaian: 5 dari 5 bintang5/5 (1)

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireDari EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesirePenilaian: 4 dari 5 bintang4/5 (129)

- Gas-Liquid And Liquid-Liquid SeparatorsDari EverandGas-Liquid And Liquid-Liquid SeparatorsPenilaian: 3.5 dari 5 bintang3.5/5 (3)