Steel Column Design

Diunggah oleh

Wazini D. IzaniJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Steel Column Design

Diunggah oleh

Wazini D. IzaniHak Cipta:

Format Tersedia

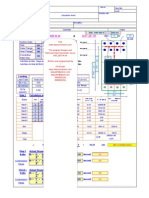

STRUCTURA

AL STEELWORK & TIMBER DESIGN

N - ECS328

STEEL COLU

UMN DESIGN

NOV13 MAC14

M

C

Clause

R

Remarks

Example

E

of Pinned Co

olumn w/o Intermediatte Restrain

The

T

column

n shown in figure

f

below

w is pin-end

ded about both axes

was design

and

a

has no

o intermedia

ate restraintt. Column w

n using S355

5

steel

s

and design comp

pression forrce, NEd = 3

3500 kN

NEd = 3500 kN

1.

1 SELECTION OF SECTION

Required

R

Area, A = NEdd / (fy / MO )

6.1

1 (1)

Partial

P

facto

or for partic

cular resista

ance, M

Resistance

R

of cross-sec

ctions whattever the c lass, MO = 1

1.0

Ta

able 3.1

Assume

A

the

e nominal th

hk. of flange

e and web

b is less than

n 40mm and

d

2

advance

a

UKB S355 to be used, .: yield streng

gth, fy = 355

5N/mm

.:

. Required Gross Area

a , A = NEd / (fy / MO )

3

=3500

=

x 10 / (355 / 1.0

0)

=98.60

=

cm2

From

F

Table of Propertie

es, select 356 x 368 x 1

129 UKC in SS355 steel

2

provided

p

16

64 cm of Area

A

356 x 368 x 129

UKC

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

From section property tables, section properties for 356 x 368 x 129

UKC:

Depth ,h

Width, b

Web thickness, tw

Flange thickness, tf

Root radius, r

Depth between fillets, d

Ratio for Local Buckling (flange), cf/tf

Ratio for Local Buckling (web), cw/tw

Radius of gyration y axis, iy

Radius of gyration z axis, iz

Torsional constant, IT

Warping constant, Iw

Area, A

Modulus of elasticity, E

Shear modulus, G

= 355.6 mm

= 368.6 mm

= 10.4 mm

= 17.5 mm

= 15.2 mm

= 290.2 mm

= 9.4

= 27.9

= 15.6 cm

= 9.43 cm

= 153 cm4

= 4.18 dm6

= 164 cm2

= 210 000 N/mm2

81 000 N/mm2

2. CLASIFICATION OF SECTION

Table 3.1

Take steel grade as S355 and tw = 10.4 mm < 40 mm

.: fyw = 355 N/mm2

fyw = 355N/mm2

Web

Table

5.2(1)

= 0.81 and cw/tw = 27.9 < 38

.: Web section was Class 2

Table 3.1

Take steel grade as S355 and tf = 17.5 mm < 40 mm

.: fyf = 355 N/mm2

fyf = 355 N/mm2

Flange

Table

5.2(2)

= 0.81 and cf/tf = 9.4 < 14

.: Flange section was Class 3

.: Section was Class 3 under compression

Section was Class

3 under

compression

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

3.RESISTANCE OF CROSS- SECTION SUBJECT TO COMPRESSION

6.2.4

Compression

6.2.4(1)

The design value of the compression force NEd at each cross-section

shall satisfy:

NEd /Nc,Rd 1 (eq. 6.9)

6.2.4(2)

Nc,Rd = A fy / MO (eq 6.10)

= 164 x 102 (355) / 1.0

= 5,822kN

Nc,Rd = 5,822kN

NEd /Nc,Rd = 3,500kN/5,822kN

= 0.6 <1

.: Cross-section is adequate for compression resistance

6.3

Buckling resistance of members

6.3.1

Uniform Members in Compression

6.3.1.1

Buckling resistance

6.3.1.1(1)

A compression member should be verified against buckling as

follows:

NEd /Nb,Rd 1 (eq. 6.46)

6.3.1.1(3)

The design buckling resistance of a compression member should be

taken as:

Nb,Rd = (X A fy ) / M1 (eq. 6.47)

where X is the reduction factor for the relevant buckling mode

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

6.3.1.2

Buckling Curves

For axial compression in members the value of X for the appropriate

non-dimensional slenderness should be determined from the

relevant buckling curve according to:

6.3.1.2(1)

Reduction factor, X = 1 / ( + 2 - 2 ) but X 1 (eq.6.49)

Where:

6.3.1.3(1)

= Afy / Ncr = (Lcr / i) x (1 / 1) (eq. 6.50) for class 1,2,3 cross section

1 = 93.9

= 93.9 (0.81)

= 76.06

Lcr = 6000mm

Lcr = 6000mm (see additional notes)

.: z = (Lcr / iz) x (1 / 1)

= (6000/94.3) x (1/76.06)

= 0.84

z = 0.84

= 0.5 ( 1 + ( 0.2) + )

6.3.1.2(2)

Where imperfection factor, corresponding to the appropriate

buckling curve should be obtained from

Table 6.1 and Table 6.2.

h/b = 355.6/368.6

= 0.96

Table 6.2

For rolled section grade S355 with h/b < 1.2 and tf 100mm, buckling

about z-z axis .: buckling curve c

Table 6.1

For buckling curve c .: Imperfection factor , = 0.49

2

.: = 0.5 (1 + ( 0.2) + )

= 0.5 (1 + 0.49 (0.84 -0.2) + 0.842)

= 1.01

.: Reduction factor, X = 1 / ( + 2 - 2 )

= 1 / (1.01 + 1.012 - 0.842)

= 0.64 < 1

X =0.64

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

.: Buckling resistance Nb,Rd = (X A fy ) / M1 (eq. 6.47)

= (0.64 x 16400 x 355) / 1.0

= 3726.08 kN

Nb,Rd = 3726.08 kN

NEd /Nb,Rd 1 (eq. 6.46)

3500 / 3726.08 = 0.94 < 1 .: section is satisfactory for buckling

resistance

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

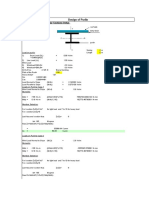

Example of Pinned Column with Intermediate Restrained

The column shown in figure below is pin-ended about both axes

and has a tie at mid-height providing restraint about the z-z axis.

Column was used S355 steel and design compression force, NEd =

3,500 kN

NEd = 3,500 kN

1. SELECTION OF SECTION

Required Area, A = NEd / (fy / MO )

6.1 (1)

Partial factor for particular resistance, M

Resistance of cross-sections whatever the class, MO = 1.0

Table 3.1

Assume the nominal thk. of flange and web is less than 40mm and

advance UKB S355 to be used, .: yield strength, fy = 355N/mm2

.: Required Plastic Modulus , A = NEd / (fy / MO )

=3500 x 103 / (355 / 1.0)

=98.60 cm2

From Table of Properties, select 356 x 368 x 129 UKC in S355 steel

provided 164 cm2 of Area

356 x 368 x 129

UKC

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

From section property tables, section properties for 356 x 368 x 129

UKC:

Depth ,h

Width, b

Web thickness, tw

Flange thickness, tf

Root radius, r

Depth between fillets, d

Ratio for Local Buckling (flange), cf/tf

Ratio for Local Buckling (web), cw/tw

Radius of gyration y axis, iy

Radius of gyration z axis, iz

Torsional constant, IT

Warping constant, Iw

Area, A

Modulus of elasticity, E

Shear modulus, G

= 355.6 mm

= 368.6 mm

= 10.4 mm

= 17.5 mm

= 15.2 mm

= 290.2 mm

= 9.4

= 27.9

= 15.6 cm

= 9.43 cm

= 153 cm4

= 4.18 dm6

= 164 cm2

= 210 000 N/mm2

81 000 N/mm2

2. CLASIFICATION OF SECTION

Table 3.1

Take steel grade as S355 and tw = 10.4 mm < 40 mm

.: fyw = 355 N/mm2

fyw = 355N/mm2

Web

Table

5.2(1)

= 0.81 and cw/tw = 27.9 < 38

.: Web section was Class 2

Table 3.1

Take steel grade as S355 and tf = 17.5 mm < 40 mm

.: fyf = 355 N/mm2

fyf = 355 N/mm2

Flange

Table

5.2(2)

= 0.81 and cf/tf = 9.4 < 14

.: Flange section was Class 3

.: Section was Class 3 under compression

Section was Class

3 under

compression

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

3.RESISTANCE OF CROSS- SECTION SUBJECT TO COMPRESSION

6.2.4

Compression

6.2.4(1)

The design value of the compression force NEd at each cross-section

shall satisfy:

NEd /Nc,Rd 1 (eq. 6.9)

6.2.4(2)

Nc,Rd = A fy / MO (eq 6.10)

= 164 x 102 (355) / 1.0

= 5,822kN

Nc,Rd = 5,822kN

NEd /Nc,Rd = 3,500kN/5,822kN

= 0.6 <1

.: Cross-section is adequate for compression resistance

6.3

Buckling resistance of members

6.3.1

Uniform Members in Compression

6.3.1.1

Buckling resistance

6.3.1.1(1)

A compression member should be verified against buckling as

follows:

NEd /Nb,Rd 1 (eq. 6.46)

6.3.1.1(3)

The design buckling resistance of a compression member should be

taken as:

Nb,Rd = (X A fy ) / M1 (eq. 6.47)

where X is the reduction factor for the relevant buckling mode

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

6.3.1.2

Buckling Curves

For axial compression in members the value of X for the appropriate

non-dimensional slenderness should be determined from the

relevant buckling curve according to:

6.3.1.2(1)

Reduction factor, X = 1 / ( + 2 - 2 ) but X 1 (eq.6.49)

Where:

6.3.1.3(1)

= Afy / Ncr = (Lcr / i) x (1 / 1) (eq. 6.50) for class 1,2,3 cross section

1 = 93.9

= 93.9 (0.81)

= 76.06

1 = 76.06

The member is effectively held in position at both ends, but not

restrained in direction at either end. The tie provides restraint in

position only for buckling about the z-z axis (i.e. the member is not

restrained in direction by the tie. Therefore the buckling lengths are:

About the y-y axis Lcr,y= 6000 mm

About the z-z axis Lcr,z = 3000 mm

.: y = (Lcr,y / iy) x (1 / 1)

= (6000/156) x (1/76.06)

= 0.51

Lcr,y= 6000 mm

Lcr,z = 3000 mm

.: z = (Lcr,z/ iz) x (1 / 1)

= (3000/94.3) x (1/76.06)

= 0.42

y = 0.51

z = 0.42

= 0.5 ( 1 + ( 0.2) + )

6.3.1.2(2)

Where imperfection factor, corresponding to the appropriate

buckling curve should be obtained from

Table 6.1 and Table 6.2.

h/b = 355.6/368.6

= 0.96

Table 6.2

h/b = 0.96

For rolled section grade S355 with h/b < 1.2 and tf 100mm, buckling

about y-y axis .: buckling curve b

For rolled section grade S355 with h/b < 1.2 and tf 100mm, buckling

about z-z axis .: buckling curve c

MAT

STRUCTURAL STEELWORK & TIMBER DESIGN - ECS328

STEEL COLUMN DESIGN

NOV13 MAC14

Table 6.1

For buckling curve b .: Imperfection factor , y = 0.34

For buckling curve c .: Imperfection factor , z = 0.49

2

y= 0.5 (1 + ( 0.2) + )

= 0.5(1+0.34(0.51-0.2)+0.512)

= 0.68

y = 0.34

z = 0.49

2

z= 0.5 (1 + ( 0.2) + )

= 0.5(1+0.49(0.42-0.2)+0.422)

= 0.64

y = 0.68

z = 0.64

.: Reduction factor, X = 1 / ( + 2 - 2 )

Xy= 1 / ( + 2 - 2 )

= 1 / (0.68 + 0.682 - 0.512)

= 0.8851

Xz = 1 / ( + 2 - 2 )

= 1 / (0.64 + 0.642 - 0.422)

= 0.8905

Xy= 0.8851

Xz = 0.8905

In case of different value of reduction factor, take the more onerous

effect.

.: Buckling resistance Nb,Rd = (X A fy ) / M1 (eq. 6.47)

= (0.8851 x 16400 x 355) / 1.0

= 5,153.05 kN

Nb,Rd = 5,153.05 kN

NEd /Nb,Rd 1 (eq. 6.46)

3,500 / 5,153.05 = 0.68 < 1 .: section is satisfactory for buckling

resistance

10

MAT

Anda mungkin juga menyukai

- Steel Design SpreadsheetDokumen53 halamanSteel Design SpreadsheetJan Alexis Monsalud100% (3)

- Crane Girder DesignDokumen6 halamanCrane Girder DesignAya Montes100% (3)

- Magnetic Circuits - Full NotesDokumen14 halamanMagnetic Circuits - Full NotesiJordanScribd90% (21)

- Steel Column DesignDokumen15 halamanSteel Column DesignNitesh Singh100% (6)

- Anchor Bolt DesignDokumen26 halamanAnchor Bolt Designdwicahyo_as100% (1)

- Design of Pedestal FoundationDokumen4 halamanDesign of Pedestal FoundationARUNKUMAR KBelum ada peringkat

- Lec 10 Combinational Logic CircuitsDokumen59 halamanLec 10 Combinational Logic CircuitsNaim UddinBelum ada peringkat

- Steel Column DesignDokumen4 halamanSteel Column Designanshutomar7915100% (2)

- P 5.0.1 Loading Condition For Columns: 5.0 Analysis of ColumnDokumen6 halamanP 5.0.1 Loading Condition For Columns: 5.0 Analysis of Columnanimesh91Belum ada peringkat

- Bolted ConnectionDokumen86 halamanBolted ConnectionPooja MistryBelum ada peringkat

- Steel ColumnDokumen2 halamanSteel ColumnNikki Roberts100% (2)

- Axially Loaded Columns - SteelDokumen1 halamanAxially Loaded Columns - SteelHari Amudhan IlanchezhianBelum ada peringkat

- Splice Connection 200Dokumen19 halamanSplice Connection 200Gheorghe IonicaBelum ada peringkat

- Crane Beam DesignDokumen7 halamanCrane Beam DesignTharanga Pradeep100% (2)

- Steel Beam DesignDokumen4 halamanSteel Beam Designanshutomar7915100% (1)

- DESIGN CALCULATION SHEET FOR SUPPORTING BEAMDokumen29 halamanDESIGN CALCULATION SHEET FOR SUPPORTING BEAMTamkwokkwong86% (7)

- Moment Connection - Flush End Plate-19.01.06Dokumen48 halamanMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Weld ConnectionDokumen70 halamanWeld ConnectionSudhakar KrishnamurthyBelum ada peringkat

- Moment Connection Calculation TypeDokumen17 halamanMoment Connection Calculation TypesamBelum ada peringkat

- Design of MonorailDokumen9 halamanDesign of MonorailAnonymous Q8XIGqHyCBelum ada peringkat

- Connection Design SheetDokumen47 halamanConnection Design SheetStephen James100% (1)

- Design Procedure For ColumnDokumen102 halamanDesign Procedure For ColumnPerarasan M100% (2)

- Design of C and I Shape Weld GroupDokumen4 halamanDesign of C and I Shape Weld GroupkarthicksipBelum ada peringkat

- Rafter DesignDokumen12 halamanRafter DesignsetakBelum ada peringkat

- Baseplate Design Input DataDokumen166 halamanBaseplate Design Input DataAnonymous ciKyr0t86% (7)

- Splice 03Dokumen15 halamanSplice 03LexBelum ada peringkat

- Shear Connection - Beam - Steel Column - Fin PlateDokumen30 halamanShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Bridge Load Calculation SheetDokumen8 halamanBridge Load Calculation SheetNats DizonBelum ada peringkat

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDokumen1 halamanCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- 11 Steel Connection Design As Per AISC 23052014Dokumen2 halaman11 Steel Connection Design As Per AISC 23052014Ahmad Badsha Quadri50% (2)

- Base Plate CalculationDokumen6 halamanBase Plate CalculationbuildconBelum ada peringkat

- Gantry Beam DesignDokumen5 halamanGantry Beam DesignSanjeev Kumar Pillai100% (9)

- DESIGN CALCULATION Report PDFDokumen61 halamanDESIGN CALCULATION Report PDFShaikh Muhammad Ateeq100% (1)

- Bolts For Base PlateDokumen12 halamanBolts For Base Platehemantkle2u50% (2)

- Monorail Beam Design 3TDokumen22 halamanMonorail Beam Design 3Tdeepak_dce_me100% (3)

- Stair Hand Rail Connection Design Calculation-WPCDokumen12 halamanStair Hand Rail Connection Design Calculation-WPCUmesh ChamaraBelum ada peringkat

- Torsion 9Dokumen13 halamanTorsion 9EngDbtBelum ada peringkat

- End Plate DesignDokumen26 halamanEnd Plate DesignNitesh SinghBelum ada peringkat

- Design of FoundationDokumen66 halamanDesign of FoundationShaikh Muhammad Ateeq100% (2)

- ETABS Software Verifies BS 5950-2000 Steel Frame ExampleDokumen5 halamanETABS Software Verifies BS 5950-2000 Steel Frame ExampleAnitha Hassan KabeerBelum ada peringkat

- Trash Rack Design of Compression Member As Per Is 800-2007Dokumen12 halamanTrash Rack Design of Compression Member As Per Is 800-2007D SRINIVASBelum ada peringkat

- Base Plate Design SummaryDokumen3 halamanBase Plate Design SummarySơn Nguyễn-LêBelum ada peringkat

- Beam DesignDokumen30 halamanBeam DesignSarat Srinivas BeesettiBelum ada peringkat

- Brace DesignDokumen457 halamanBrace DesignRyan Goh Chuang HongBelum ada peringkat

- Moment Connection Portal FrameDokumen18 halamanMoment Connection Portal Frametmssorin100% (1)

- Design of Purlin (Rectangular Sections Only)Dokumen3 halamanDesign of Purlin (Rectangular Sections Only)Amit Parikh100% (1)

- Steel Beam DesignDokumen26 halamanSteel Beam DesignWazini D. Izani100% (1)

- Vežbe Br. 8 - Primeri: Specijalne Metalne Konstrukcije Aluminijum - Stabilnost - NastavakDokumen15 halamanVežbe Br. 8 - Primeri: Specijalne Metalne Konstrukcije Aluminijum - Stabilnost - NastavakDJordje JovanovicBelum ada peringkat

- Steel TextbookDokumen41 halamanSteel TextbookRutu RajBelum ada peringkat

- Design of Steel ColumnDokumen22 halamanDesign of Steel ColumnN.S.M.RAVI KUMARBelum ada peringkat

- Extracts From Ec3 For Students 2012Dokumen6 halamanExtracts From Ec3 For Students 2012Alexandru MarincuBelum ada peringkat

- EC3EXT200102 Steel Reference in EC3Dokumen6 halamanEC3EXT200102 Steel Reference in EC3mileBelum ada peringkat

- Column Steel DesignDokumen37 halamanColumn Steel DesignIlya Joohari100% (1)

- Steel member design EN1993 (40Dokumen8 halamanSteel member design EN1993 (40vsnsfbBelum ada peringkat

- Ec9 Ex94 Beam Column HAZDokumen5 halamanEc9 Ex94 Beam Column HAZimotalpBelum ada peringkat

- Eccentric loading and combined stresses design problemsDokumen133 halamanEccentric loading and combined stresses design problemsGlënnLibönTäbiölö100% (1)

- Steel Joint Design (Fin Plate)Dokumen8 halamanSteel Joint Design (Fin Plate)Wazini D. IzaniBelum ada peringkat

- Shear Check To Eurocode 2Dokumen4 halamanShear Check To Eurocode 2smkumar121Belum ada peringkat

- Proiect Om2Dokumen20 halamanProiect Om2Gabriel CimpeanBelum ada peringkat

- Beam-Column Using Double Angle CleatDokumen7 halamanBeam-Column Using Double Angle CleatNur Syahira100% (1)

- Compression MembersDokumen172 halamanCompression Membersbsitler100% (1)

- Lecture 2 Beams - Concrete CenterDokumen99 halamanLecture 2 Beams - Concrete Centerwanksta67Belum ada peringkat

- 1Dokumen2 halaman1Wazini D. IzaniBelum ada peringkat

- Steel Joint Design (Flexible End Plate)Dokumen6 halamanSteel Joint Design (Flexible End Plate)Wazini D. IzaniBelum ada peringkat

- BaruDokumen4 halamanBaruWazini D. IzaniBelum ada peringkat

- RARBGDokumen1 halamanRARBGWazini D. IzaniBelum ada peringkat

- First Draft AlbinismDokumen5 halamanFirst Draft AlbinismWazini D. IzaniBelum ada peringkat

- Steel Joint Design (Fin Plate)Dokumen8 halamanSteel Joint Design (Fin Plate)Wazini D. IzaniBelum ada peringkat

- Steel Joint Design (Tension Splices)Dokumen5 halamanSteel Joint Design (Tension Splices)Wazini D. IzaniBelum ada peringkat

- Structural Steel Beam to Column Connection DesignDokumen7 halamanStructural Steel Beam to Column Connection DesignWazini D. IzaniBelum ada peringkat

- Tutorial 3 Ecs208 - Basic Solid MechanicsDokumen1 halamanTutorial 3 Ecs208 - Basic Solid MechanicsWazini D. IzaniBelum ada peringkat

- Steel Beam DesignDokumen26 halamanSteel Beam DesignWazini D. Izani100% (1)

- WWork ConditionsDokumen8 halamanWWork ConditionsWazini D. IzaniBelum ada peringkat

- Maurice Nicoll The Mark PDFDokumen4 halamanMaurice Nicoll The Mark PDFErwin KroonBelum ada peringkat

- Steam Install AgreementDokumen2 halamanSteam Install Agreementkoi9Belum ada peringkat

- FB SCDokumen1 halamanFB SCPraveen MekalaBelum ada peringkat

- Homework & Practice: Another Look!Dokumen2 halamanHomework & Practice: Another Look!MONAE MAPPBelum ada peringkat

- Arvind Sir Tutorials - Maths Formula Book 22 April 2018Dokumen8 halamanArvind Sir Tutorials - Maths Formula Book 22 April 2018Kumar ArvindBelum ada peringkat

- MELSEC iQ-R Structured Text (ST) Programming Guide BookDokumen106 halamanMELSEC iQ-R Structured Text (ST) Programming Guide BookyounesBelum ada peringkat

- Brownian MotionDokumen76 halamanBrownian MotionPraveen KumarBelum ada peringkat

- Maximum Efficiency and Output of Class-F Power AmplifiersDokumen5 halamanMaximum Efficiency and Output of Class-F Power AmplifierscemshitBelum ada peringkat

- INTRODUCTION To Construction RatesDokumen91 halamanINTRODUCTION To Construction RatesIzo SeremBelum ada peringkat

- 11-1 Graphing Linear EquationsDokumen10 halaman11-1 Graphing Linear Equationsapi-26014607Belum ada peringkat

- Stacks and QueuesDokumen21 halamanStacks and QueuesDhivya NBelum ada peringkat

- Understanding Attribute Acceptance Sampling: Dan O'Leary Cba, Cqa, Cqe, Cre, SSBB, Cirm President Ombu Enterprises, LLCDokumen72 halamanUnderstanding Attribute Acceptance Sampling: Dan O'Leary Cba, Cqa, Cqe, Cre, SSBB, Cirm President Ombu Enterprises, LLCDarren TanBelum ada peringkat

- AC Interference On Pipeline ThesisDokumen133 halamanAC Interference On Pipeline ThesisMn HjhjjBelum ada peringkat

- ProposalDokumen9 halamanProposalAsaad iqbalBelum ada peringkat

- Checkpoint 2016 - P2Dokumen15 halamanCheckpoint 2016 - P2seetBelum ada peringkat

- Syllabus B Tech 1 Year PDFDokumen36 halamanSyllabus B Tech 1 Year PDFPcm Aryan AnkitBelum ada peringkat

- Cel 2106 SCL Worksheet Week 1Dokumen9 halamanCel 2106 SCL Worksheet Week 1Abdul Qhouyyum AiedilBelum ada peringkat

- Quarter 1 - Week 8: Learning Activity Sheet 1 Representing Real-Life Situations Using Logarithmic FunctionsDokumen16 halamanQuarter 1 - Week 8: Learning Activity Sheet 1 Representing Real-Life Situations Using Logarithmic FunctionsJiwon ParkBelum ada peringkat

- Belt Weigher Technical PDFDokumen4 halamanBelt Weigher Technical PDFKEERTHI INDUSTRIESBelum ada peringkat

- Decimal GlossaryDokumen4 halamanDecimal Glossaryshahul488Belum ada peringkat

- MINI Wind TurbineDokumen14 halamanMINI Wind TurbineahdabmkBelum ada peringkat

- DR. BABASAHEB AMBEDKAR TECHNOLOGICAL UNIVERSITY, LONERE EQUIVALENCE REPORTDokumen22 halamanDR. BABASAHEB AMBEDKAR TECHNOLOGICAL UNIVERSITY, LONERE EQUIVALENCE REPORTRajnikant NarwadeBelum ada peringkat

- Mpc12 ExamDokumen8 halamanMpc12 Examamir12345678Belum ada peringkat

- FFJM Semi-Finals March 21st 2015 rankingsDokumen2 halamanFFJM Semi-Finals March 21st 2015 rankingsTapas HiraBelum ada peringkat

- A Tutorial On Combinatorics An Enumeration in Music TheoryDokumen22 halamanA Tutorial On Combinatorics An Enumeration in Music TheoryGrandeBoiBelum ada peringkat

- DM Unit 1Dokumen15 halamanDM Unit 1Rushikesh ShindeBelum ada peringkat

- ArrayList WorksheetDokumen1 halamanArrayList Worksheetfreddy the gamerBelum ada peringkat

- Investigation on Pole-Slot Combinations for PM Machines with Concentrated WindingsDokumen6 halamanInvestigation on Pole-Slot Combinations for PM Machines with Concentrated WindingsAnna DrKiss SzűcsnéBelum ada peringkat

- Quantiacs Reading ListDokumen7 halamanQuantiacs Reading Listdesikudi9000Belum ada peringkat

- Gumbel DistributionDokumen5 halamanGumbel DistributionAdrian IosifBelum ada peringkat

- Algorithmic Differentiation in Finance Explained-Henrard, Marc, Palgrave Macmillan (2017) PDFDokumen112 halamanAlgorithmic Differentiation in Finance Explained-Henrard, Marc, Palgrave Macmillan (2017) PDFdata100% (3)