Preparation of Calcite Thin Films

Diunggah oleh

jc0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

33 tayangan3 halamanThis document describes the synthesis of carboxylate-terminated poly(amidoamine)-type polyhedral oligosilsesquioxane (POSS)-core dendrimer (POSS-COOH) in multiple steps. It first involves synthesizing POSS-NH3+ and then converting it to the t-butyl ester terminated POSS-CO2But using ion exchange resin. POSS-CO2But is then hydrolyzed to the carboxylic acid terminated POSS-COOH. POSS-COOH is used to prepare vaterite composite particles by precipitation in aqueous solutions. Finally, the document describes fabricating free-standing calcite thin films by sequentially depositing layers of CaCO3 and poly

Deskripsi Asli:

calcite thin films derived from

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document describes the synthesis of carboxylate-terminated poly(amidoamine)-type polyhedral oligosilsesquioxane (POSS)-core dendrimer (POSS-COOH) in multiple steps. It first involves synthesizing POSS-NH3+ and then converting it to the t-butyl ester terminated POSS-CO2But using ion exchange resin. POSS-CO2But is then hydrolyzed to the carboxylic acid terminated POSS-COOH. POSS-COOH is used to prepare vaterite composite particles by precipitation in aqueous solutions. Finally, the document describes fabricating free-standing calcite thin films by sequentially depositing layers of CaCO3 and poly

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

33 tayangan3 halamanPreparation of Calcite Thin Films

Diunggah oleh

jcThis document describes the synthesis of carboxylate-terminated poly(amidoamine)-type polyhedral oligosilsesquioxane (POSS)-core dendrimer (POSS-COOH) in multiple steps. It first involves synthesizing POSS-NH3+ and then converting it to the t-butyl ester terminated POSS-CO2But using ion exchange resin. POSS-CO2But is then hydrolyzed to the carboxylic acid terminated POSS-COOH. POSS-COOH is used to prepare vaterite composite particles by precipitation in aqueous solutions. Finally, the document describes fabricating free-standing calcite thin films by sequentially depositing layers of CaCO3 and poly

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

Preparation of Carboxylate-terminated poly(amidoamine)-type polyhedral

oligosilsesquioxane (POSS)-core dendrimer (POSS-COOH)

All reactions are done under a nitrogen atmosphere.

Synthesis of POSS-NH3+ [2]

Schlenk flask with magnetic stirrer and nitrogen purge

800 mL MeOH placed into flask

100 mL of (3-Aminopropyl)triethoxysilane drop wise into flask

135 mL of 12 M HCl quickly into flask

Close flask once fume production has stopped (takes about ~5 minutes)

Stir mixture under nitrogen until white powder has precipitated (~ 5 10 days)

Wash powder with cold DRY MeOH

Dry under vacuum

Recrystallization using hot MeOH

t-Butyl Ester-Terminated POSS-Core Dendrimer (POSS-CO2But)[1]

Preparation of Amberlite IRA-400 ion exchange resin (30g)

4 x 150 mL rinses with H2O

3 x 150 mL rinses with 1 M NaOH

6 x 150 mL rinses with H2O

6 x 150 mL rinses with MeOH

Chill the resin in -10 C for 2 hours in MeOH before use

Load 15g of resin beads into a 3.5 cm diameter column

Use other 15g to dissolve suspension of neutralized POSS-NH3+ (1.43 g, 1.22 mmol) in

minimum amount of solvent below 0 C

Elution across column produces MeOH solution of neutralized POSS-NH3

70 mL t-butyl acrylate immediately via syringe

Heat mixture for 48 hours at 80 C

Crude POSS-CO2But (oil like substance) purified by size exclusion chromatography

Carboxylic Acid-Terminated POSS-Core Dendrimer (POSS-COOH)

20 mL of HCOOH to 0.144 g of POSS-CO2But

Heat mixture for 24 hours at 80 C

Remove HCOOH by azerotropic distillation with water under reduced pressure

POSS-COOH should be a white powder

Precipitation of Vaterite Composite Particles

Prepare stock solution of POSS-COOH (2.5 x 10-2 mmol) in DI Water

Add dilute NaOH to adjust pH to 11

Prepare 0.1 M CaCl2

Add aqueous NH3 to adjust pH to 8.5

Add 0.5 mL of CaCl2 to 4.5 mL of the stock solution

Stir gently at 30 C for 1 hour

Prepare 0.1 M (NH4)2CO3

Add aqueous NH3 to adjust pH to 10.0

Add 0.5 mL of (NH4)2CO3 solution to mixture

Stir gently at 30 C for 1 hour

Collect precipitated CaCO3 product using a 0.1 um pore sized membrane filter

Wash product with multiple portions of water

Dry at RT with reduced pressure

Fabricating Free-Standing Calcite Thin Films

Sonicate glass slide in acetone for 30 minutes

Rinse with water

Sonicate in wash solution (1% KOH + 39% Water + 60% EtOH) for 30 minutes

Rinse with water

Dry with N2 stream

Immerse glass slide in PDDA solution (5 mg/ mL) for 15 minutes

Rinse with DI Water in three different vials

Dry with gentle air stream

Immerse glass slide in ethanol dispersion of precipitated CaCO3 (4 mg/ mL pH= 11) for 15

minutes

Immerse glass slide in ethanol solution of PDDA (1 mg/ mL) for 15 minutes

Rinse glass slide with ethanol for 1 minute x 3

Dry with gentle air stream

Repeat bolded section sequentially 10 x

Coat top layer with PDDA (vaterite)10/ PDDA

Immerse glass slide in DI Water in 30 C for 5 days (calcite)1

Immerse glass slide in aqueous PDDA (3 mg / 3 mL) for 15 minutes

Rinse with DI Water in three different vials

Dry with N2 stream

Immerse glass slides in ethanol dispersion of CaCO3 for 15 minutes

Immerse glass slide in ethanol solution of PDDA for 15 minutes

Rinse glass slide with ethanol for 1 minutes x 3

Dry with gentle air stream

Repeat bolded section sequentially 10 x

Coat top layer with PDDA (calcite)1/ (vaterite)10/ PDDA

Immerse glass slide in DI water in 30 C for 5 days (calcite)2

References:

[1] Feher, FrankJ, and Kevin D Wyndham. "Amine and ester-substituted silsesquioxanes:

synthesis, characterization and use as a core for starburst dendrimers." Chemical

communications 3 (1998): 323-324.

[2] Gravel, M-C., et al. "Octa (3-chloroammoniumpropyl) octasilsesquioxane." (1999).

Anda mungkin juga menyukai

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1091)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- 1233zd Honeywell Solstice LBA Technical BrochureDokumen8 halaman1233zd Honeywell Solstice LBA Technical BrochureAB DevilierBelum ada peringkat

- Orca Share Media1567258117004Dokumen10 halamanOrca Share Media1567258117004Monique Eloise GualizaBelum ada peringkat

- Metal Casting Process Unit - 1Dokumen146 halamanMetal Casting Process Unit - 1sudhakarBelum ada peringkat

- Sri Bhagawan Mahaveer Jain Collge Chemistry: Mock Paper 1 Part A IDokumen4 halamanSri Bhagawan Mahaveer Jain Collge Chemistry: Mock Paper 1 Part A IChiranjivi ChiruBelum ada peringkat

- MSDS - Hydrochloric Acid 28-30%Dokumen12 halamanMSDS - Hydrochloric Acid 28-30%Sayed SalahBelum ada peringkat

- Reading2D Spectrum PDFDokumen6 halamanReading2D Spectrum PDFRaihan Uchiha100% (1)

- Tutorial Questions On Free Radical Reactions PDFDokumen3 halamanTutorial Questions On Free Radical Reactions PDFHarry ZgamboBelum ada peringkat

- Extraction and Distribution CoefficientDokumen3 halamanExtraction and Distribution CoefficientSaeed KhawamBelum ada peringkat

- Binder PitchDokumen10 halamanBinder PitchSudipta RoyBelum ada peringkat

- Salt Analysis Cheat SheetDokumen3 halamanSalt Analysis Cheat Sheetgsg171869Belum ada peringkat

- 12088600Dokumen9 halaman12088600deni.sttnBelum ada peringkat

- Radel PPSU Veradel PESU Acudel PPSU Design Guide enDokumen68 halamanRadel PPSU Veradel PESU Acudel PPSU Design Guide enzaeem73Belum ada peringkat

- Ms Ultra Clear Structural Adhesive: Art - No. 0892 412901Dokumen2 halamanMs Ultra Clear Structural Adhesive: Art - No. 0892 412901Wurth JordanBelum ada peringkat

- L7.8.9.Cell BiologyDokumen81 halamanL7.8.9.Cell BiologyGeethanjali SivakumarBelum ada peringkat

- MatWeb - The Online Materials Information ResourceDokumen3 halamanMatWeb - The Online Materials Information ResourceVignesh AnbazhaganBelum ada peringkat

- Assays by Precipitation.Dokumen3 halamanAssays by Precipitation.Subhash DhungelBelum ada peringkat

- Ionic Liquid: Green Chemistry PresentationDokumen29 halamanIonic Liquid: Green Chemistry PresentationBaloch SamBelum ada peringkat

- Dke345 Sec1Dokumen92 halamanDke345 Sec1IAMANDU COSTABelum ada peringkat

- Liu - Hydrogenation of Acrylonitrile-Butadiene Copolymer Latex Using Water-Soluble Rhodium Catalysts, 2013 +Dokumen10 halamanLiu - Hydrogenation of Acrylonitrile-Butadiene Copolymer Latex Using Water-Soluble Rhodium Catalysts, 2013 +oreamigBelum ada peringkat

- PA-PAC Eutectic MixturesDokumen4 halamanPA-PAC Eutectic MixturesRajeshBelum ada peringkat

- Activated Carbon VRS SYstemDokumen2 halamanActivated Carbon VRS SYstemThamilselvan VengatasalamBelum ada peringkat

- Alcohols 1 QPDokumen10 halamanAlcohols 1 QPHailey WongBelum ada peringkat

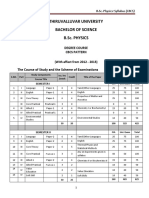

- B.sc. PhysicsDokumen70 halamanB.sc. PhysicsGurnehmat SinghBelum ada peringkat

- Productcatalog Eastman Com Tds ProdDatasheet Aspx Product 71049470 PN EndexDokumen2 halamanProductcatalog Eastman Com Tds ProdDatasheet Aspx Product 71049470 PN EndexsigitBelum ada peringkat

- Solutions of Himanshu Pandey Probllems in General Organic ChemistryDokumen144 halamanSolutions of Himanshu Pandey Probllems in General Organic ChemistryParth Patel71% (208)

- Oc02 Alkenesalkynesandcyclichydrocarbons Worksheet PDFDokumen5 halamanOc02 Alkenesalkynesandcyclichydrocarbons Worksheet PDFGil Anthony AbañoBelum ada peringkat

- C1.3 PhotosynthesisDokumen42 halamanC1.3 PhotosynthesisteddyenBelum ada peringkat

- IMPORT01012010Dokumen7 halamanIMPORT01012010Yakshit JainBelum ada peringkat

- Everything You Need To Know About Solvent DyesDokumen2 halamanEverything You Need To Know About Solvent DyesRoyceintlBelum ada peringkat

- Jurnal Urea Formaldehyde 1Dokumen9 halamanJurnal Urea Formaldehyde 1Afriyanti RosmadianaBelum ada peringkat