High Strength Pumpable Non-Shrink Cement Grout

Diunggah oleh

Lukman ZakariyahDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

High Strength Pumpable Non-Shrink Cement Grout

Diunggah oleh

Lukman ZakariyahHak Cipta:

Format Tersedia

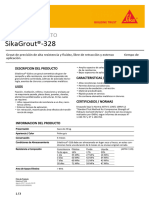

STARGROUT 2400

High Strength Pumpable Non-Shrink Cementitious Grout

SPECIFICATION OF DATA :

Form

: Powder

Colour

: Grey

Trowellable

12.0

Min. Gap width

Max. Thickness

Expansion

Bleeding

Mixed Up Density, 30

( flowable consistency )

Setting Time

- Initial Setting Time

- Final Setting Time

Approximate Yield at Various Consistency,

Litres per 25 kg/bag

Pourable

12.7

Flowable

13.3

Flowable Consistency

Age

Strength

1 days

3.5

3 days

5.1

7 days

6.8

28 days

8.6

: 10 mm

: 125 mm

: 0.30 1.40 %

: Nil

: ~ 2190 kg/m3

:

: 2 h 15 minutes

: 4 h 30 minutes

Water Demand at Various Consistency

Litres per 25 kg/bag

Trowellable

Pourable

FlowableFlowable Consistency

(1)

(1)

( 3 )Age

Strength

2.50

3.25

428 days

4.3

Tensile Strength ( Mpa )

(1) Flowability ~ 40 70% on flow table ( 5 drops )

(2) Flowability ~ 80 110% on a flow table

(3) Flowability ~ 6 12 second by Mod. J. Cone

Compressive Strength ( Mpa )

Age

1 days

3 days

7 days

28 days

Adhesive Strength ( Mpa ) at 28 days

Flowable

Consistency

Consistency

Trowellable

Pourable

Flowable

On Concrete

On Star Grout 2400

34

26

20

55

48

3.4 35

4.2

60

52

45

72

64

55

STARGROUT 2400

High Strength Pumpable Non-Shrink Cementitious Grout

Description

StarGrout 2400 is a non shrink, cementitious premixed grout with extended

working time to suit local ambient temperatures. StarGrout 2400 is based on a

blend cements, carefully selected and graded aggregates and Star Admixtures. This

precise blend of materials produces a grout which achieves high strength rapidly

and is suitable for a wide range applications.

Uses

StarGrout 2400 are used for grouting over a wide range of applications :

- Machine bedding/base plates

- Supporting bridge bearing pads

- Precast Concrete Sections

- Cavities, gaps and recesses

- Dry pack application

Advantages

Packaging

StarGrout 2400 are supplied in 25 kg/bag

Excellent flowability

No metallic iron contents to cause staining

Chloride free ( Non Corrosive )

Good dimensional stability

Easy to mix and apply

No bleeding or segregation

Final strengths > 57 Mpa

Instruction for use

Surface Preparation

Surface must be clean, sound and free from dust, oil, grease, cement laitance and

any loose materials. For maximum bond, surfaces should be roughned. All surfaces

must be well saturated clean water orior to application of StarGrout 2400.

Mixing

Put measured quantity of water ( depend on the required consistency ) into an

empty pail/drum. Slowly add the total contents of Star Grout 2400 while mixing.

Mix continuously for 5 7 minutes to achieve an even consistency. A mechanical

powered low speed grout mixer should be used for the best result ( may be area of

places are biggest ), StarGrout 2400 can be added aggregates ( bauxite 0 2 mm or

calcined silica ) 20% weight of grouting.

Placing

Pour StarGrout 2400 from one side only to avoid air entrapment. Do not vibrate.

Use suitable head box of 150 200 mm and maintain to grout head at all times to

ensure a continuous flow. Twenty five minutes are considered as the ideal placing

time.

Curing

On completion of the grouting operation all exposed areas which are not to be

throughty cured. This should be done after the initial hardening of the grout by

continuous application of water and / or wet hessian, or by application of suitable

curing membrane such as Concure P.

Anda mungkin juga menyukai

- Stargrout 2400: High Strength Pumpable Non-Shrink Cementitious GroutDokumen1 halamanStargrout 2400: High Strength Pumpable Non-Shrink Cementitious GroutLukman ZakariyahBelum ada peringkat

- Grouting Materials - Shortcut - LNKDokumen4 halamanGrouting Materials - Shortcut - LNKLaxmana Prasad100% (1)

- Admix TS 500Dokumen2 halamanAdmix TS 500betopagoadaBelum ada peringkat

- Sikagrout®-215: Product Data SheetDokumen4 halamanSikagrout®-215: Product Data SheetMarvin MartinezBelum ada peringkat

- Sikagrout®-215: Product Data SheetDokumen4 halamanSikagrout®-215: Product Data Sheeterdilyn PradoBelum ada peringkat

- Ultra High Strength Non-Shrink Cementitious GroutDokumen2 halamanUltra High Strength Non-Shrink Cementitious Groutmail2meanwar7865Belum ada peringkat

- Sikagrout 215 M: Non-Shrink Cementitious Grout For Marine Structure and Concrete RepairDokumen2 halamanSikagrout 215 M: Non-Shrink Cementitious Grout For Marine Structure and Concrete RepairDani LerviBelum ada peringkat

- SikaGrout® - 114 - PDS PDFDokumen4 halamanSikaGrout® - 114 - PDS PDFSheraz BashirBelum ada peringkat

- Sikagrout - 214 11Dokumen3 halamanSikagrout - 214 11Thắng HoàngBelum ada peringkat

- TEC - TA-550 - Power Grout Spec SheetDokumen2 halamanTEC - TA-550 - Power Grout Spec SheetMark MehnerBelum ada peringkat

- SikaGrout 214-11 - English VerDokumen3 halamanSikaGrout 214-11 - English VerTrưng Quỳnh HoàngBelum ada peringkat

- Sikagrout - 228Dokumen3 halamanSikagrout - 228Anonymous T7zEN6iLHBelum ada peringkat

- Ul Tra Co Lor: UltracolorDokumen6 halamanUl Tra Co Lor: UltracolorKim ChanthanBelum ada peringkat

- Relative Air Humidity and Condensation RiskDokumen6 halamanRelative Air Humidity and Condensation RiskAnonymous v1blzDsEWABelum ada peringkat

- Description: LLCMS119 Rev01Dokumen3 halamanDescription: LLCMS119 Rev01beto pagoadaBelum ada peringkat

- Sikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedDokumen6 halamanSikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedhvduylinhBelum ada peringkat

- DS 730 HS-Super GroutDokumen2 halamanDS 730 HS-Super GroutJignessh JoshiBelum ada peringkat

- Everlast Floor: Physical/Chemical CharacteristicsDokumen2 halamanEverlast Floor: Physical/Chemical CharacteristicsnlusardoBelum ada peringkat

- Flexane 80 CompoundDokumen3 halamanFlexane 80 Compoundabh_omegaBelum ada peringkat

- Sikagrout®-114 Ae: Product Data SheetDokumen3 halamanSikagrout®-114 Ae: Product Data SheetAlexander Jonas Zach ValdrizBelum ada peringkat

- Sikadur®-42 (Au) : Product Data SheetDokumen3 halamanSikadur®-42 (Au) : Product Data SheetPramuditha SuraweeraBelum ada peringkat

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDokumen3 halamanMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolBelum ada peringkat

- SdadsadasDokumen3 halamanSdadsadasTwink Arcane 9Belum ada peringkat

- Conbextra GP2Dokumen4 halamanConbextra GP2Sikander GirgoukarBelum ada peringkat

- Proposal - Ayush ParkDokumen25 halamanProposal - Ayush ParkAvinash PhaseBelum ada peringkat

- Sikadur®-53: Product Data SheetDokumen3 halamanSikadur®-53: Product Data Sheetjet toledoBelum ada peringkat

- Sikadur®-42 Grout Pak LE: Pre-Proportioned, Precision Epoxy Grouting SystemDokumen2 halamanSikadur®-42 Grout Pak LE: Pre-Proportioned, Precision Epoxy Grouting Systemraunak upadhyayaBelum ada peringkat

- Screed Concentrate: FeaturesDokumen3 halamanScreed Concentrate: FeaturesParashuram ChauhanBelum ada peringkat

- Standard Grout PDFDokumen3 halamanStandard Grout PDFFrancois-Belum ada peringkat

- ShaliGrout 73Dokumen3 halamanShaliGrout 73Anupam ShilBelum ada peringkat

- Rainbow Tile Mate Epoxy GroutDokumen3 halamanRainbow Tile Mate Epoxy Grouthunky11Belum ada peringkat

- Ultr Afle X LFTDokumen4 halamanUltr Afle X LFTjon_doh1Belum ada peringkat

- Conbextra GP2 (T)Dokumen4 halamanConbextra GP2 (T)Vikas Singh ChandelBelum ada peringkat

- Flo-Grout BP800Dokumen26 halamanFlo-Grout BP800qasim078100% (1)

- 2801 Ultracolor Plus GB NoRestrictionDokumen6 halaman2801 Ultracolor Plus GB NoRestrictionFloorkitBelum ada peringkat

- Non-Shrink Cement Grout for Filling Voids and Bonding ConcreteDokumen3 halamanNon-Shrink Cement Grout for Filling Voids and Bonding ConcreteGeneiroseJaspeBelum ada peringkat

- Sikagrout 428 FS: Fast-Setting and High-Strength, Cementitious Precision GroutDokumen4 halamanSikagrout 428 FS: Fast-Setting and High-Strength, Cementitious Precision GroutGeorge MarinBelum ada peringkat

- Sikagrout 215: General Purpose Non-Shrink Cementitious GroutDokumen3 halamanSikagrout 215: General Purpose Non-Shrink Cementitious GroutDani LerviBelum ada peringkat

- Mixing Instructions For Castables and Dry MortarsDokumen5 halamanMixing Instructions For Castables and Dry MortarsWael IsmaelBelum ada peringkat

- Sikagrout® GP: Product Data SheetDokumen4 halamanSikagrout® GP: Product Data SheetCatherine Fatima Mae LeynoBelum ada peringkat

- Sikagrout Deep PourDokumen3 halamanSikagrout Deep PourLuis Andrade InsúaBelum ada peringkat

- Screed Concentrate: FeaturesDokumen3 halamanScreed Concentrate: FeaturesMohzin KmBelum ada peringkat

- T01 New Construction Tile Adhesive (NCA) : Crack Resistant and Waterproof TilingDokumen2 halamanT01 New Construction Tile Adhesive (NCA) : Crack Resistant and Waterproof Tilingvijayasarathy2013253Belum ada peringkat

- Cico Grout-Gpls: Non-Shrink Ready To Use Cementitious GroutDokumen2 halamanCico Grout-Gpls: Non-Shrink Ready To Use Cementitious GroutAmanulla KhanBelum ada peringkat

- Masterflow 96 PDS ASEAN 180310Dokumen2 halamanMasterflow 96 PDS ASEAN 180310Ryan Aldy HutagalungBelum ada peringkat

- Estogrout MP70 PremixDokumen2 halamanEstogrout MP70 PremixElias Jaya PerkasaBelum ada peringkat

- TBL Spec 1548147068 174562 P 4653732Dokumen3 halamanTBL Spec 1548147068 174562 P 4653732Shailendra SharmaBelum ada peringkat

- Sikagrout - 328Dokumen3 halamanSikagrout - 328Javier TapiaBelum ada peringkat

- Heavy Duty Stone Tile Adhesive (STADokumen2 halamanHeavy Duty Stone Tile Adhesive (STA1am17ec014 ashnal ahmedBelum ada peringkat

- PDS SikaGrout-215P PDFDokumen3 halamanPDS SikaGrout-215P PDFDeny PutraBelum ada peringkat

- TL-Sika Level 100Dokumen6 halamanTL-Sika Level 100BronjaEmrahBelum ada peringkat

- Masterflow 980 Tds PDFDokumen4 halamanMasterflow 980 Tds PDFAdamo Absalome MulocheBelum ada peringkat

- Brosur Deltagrout CG - REV - 20100725MTDokumen2 halamanBrosur Deltagrout CG - REV - 20100725MTjimdabrondBelum ada peringkat

- Fosroc Conbextra GP2Dokumen4 halamanFosroc Conbextra GP2awsdhnjkklmBelum ada peringkat

- Sikafloor 144Dokumen8 halamanSikafloor 144Jessica CaldwellBelum ada peringkat

- Ardex Eg 15: High Performance Epoxy GroutDokumen4 halamanArdex Eg 15: High Performance Epoxy GroutPhong NguyenBelum ada peringkat

- en-GB - Flo-Grout 2.03012016065544 PDFDokumen2 halamanen-GB - Flo-Grout 2.03012016065544 PDFHassan SleemBelum ada peringkat

- Sikagrout 214-11 PdsDokumen2 halamanSikagrout 214-11 PdscharlessimoBelum ada peringkat

- Epir 20SDokumen3 halamanEpir 20SBobbie RuckBelum ada peringkat

- Brick HouseDokumen1 halamanBrick HouseLukman ZakariyahBelum ada peringkat

- Butt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Dokumen3 halamanButt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Reginaldo Matias NunesBelum ada peringkat

- Perogress Report S Curve PPCDokumen302 halamanPerogress Report S Curve PPCLukman ZakariyahBelum ada peringkat

- Tools List InsulationDokumen1 halamanTools List InsulationLukman ZakariyahBelum ada peringkat

- 2.5 Insulation & RefractoriesDokumen23 halaman2.5 Insulation & RefractoriesImhoudu Ben100% (1)

- Butt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Dokumen3 halamanButt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Reginaldo Matias NunesBelum ada peringkat

- Title of CD or DVD: Left Side Text Field Right Side Text FieldDokumen1 halamanTitle of CD or DVD: Left Side Text Field Right Side Text FieldLukman ZakariyahBelum ada peringkat

- NPTF Thread Sizes and DimensionsDokumen1 halamanNPTF Thread Sizes and DimensionsLukman ZakariyahBelum ada peringkat

- Viking 062293Dokumen8 halamanViking 062293Lukman ZakariyahBelum ada peringkat

- Constrution SiteDokumen20 halamanConstrution Site101arBelum ada peringkat

- Spec Polyuretahne PDFDokumen1 halamanSpec Polyuretahne PDFLukman ZakariyahBelum ada peringkat

- High Strength Pumpable Non-Shrink Cement GroutDokumen2 halamanHigh Strength Pumpable Non-Shrink Cement GroutLukman ZakariyahBelum ada peringkat

- NPTF Thread Sizes and DimensionsDokumen1 halamanNPTF Thread Sizes and DimensionsLukman ZakariyahBelum ada peringkat

- Absensi Proyek: Kamis Jumat Senin Selasa RabuDokumen1 halamanAbsensi Proyek: Kamis Jumat Senin Selasa RabuLukman ZakariyahBelum ada peringkat

- Application Instructions for Ballast Tank CoatingsDokumen5 halamanApplication Instructions for Ballast Tank CoatingsLukman ZakariyahBelum ada peringkat

- 7 20130802 2026075Dokumen4 halaman7 20130802 2026075Rizky Aprianto SetiawanBelum ada peringkat

- 2009 - Perlite General BrochureDokumen1 halaman2009 - Perlite General BrochureIPILITEBelum ada peringkat

- Claims PolicyDokumen3 halamanClaims PolicyLukman ZakariyahBelum ada peringkat

- ANMAN CatalogueDokumen5 halamanANMAN CatalogueLukman ZakariyahBelum ada peringkat

- Liquid Fuel Measurements and ConversionsDokumen4 halamanLiquid Fuel Measurements and ConversionsrhazoorBelum ada peringkat

- Standard Rab (Publish)Dokumen222 halamanStandard Rab (Publish)Lukman ZakariyahBelum ada peringkat

- SH Conf HIRA HandoutDokumen19 halamanSH Conf HIRA HandoutLukman ZakariyahBelum ada peringkat

- Csms PQ Emp Group PublicDokumen16 halamanCsms PQ Emp Group PublicAfif Said Hadjin100% (2)

- Is 6073Dokumen19 halamanIs 6073Vivek GaurBelum ada peringkat

- Construction Offer at 750 Per SFT.: ChohanDokumen2 halamanConstruction Offer at 750 Per SFT.: Chohanalkamran98137Belum ada peringkat

- Astm-C 150Dokumen5 halamanAstm-C 150iknis_592100% (1)

- Iron ProductionDokumen7 halamanIron ProductionVij_78Belum ada peringkat

- Condulet Serie 5, 7, 8 y 9 Crouse-HindsDokumen1 halamanCondulet Serie 5, 7, 8 y 9 Crouse-HindsArmando GarcíaBelum ada peringkat

- Deltron Systems Guide PDFDokumen2 halamanDeltron Systems Guide PDFAlberto CamejoBelum ada peringkat

- Aluminium Alloy Sheet / Plate - Aa: (H32) Astm B209 / Ams 4016Dokumen25 halamanAluminium Alloy Sheet / Plate - Aa: (H32) Astm B209 / Ams 4016Rahmat AnpsBelum ada peringkat

- 1600 LR Wall - A PDFDokumen32 halaman1600 LR Wall - A PDFPrunici IonBelum ada peringkat

- Paper 032 Durability Guidelines For Materials in SWRO Brine - FinalDokumen13 halamanPaper 032 Durability Guidelines For Materials in SWRO Brine - FinalMaqsood Ibn Shaikhul ArfeenBelum ada peringkat

- High Performance Torch Applied Waterproofing MembraneDokumen3 halamanHigh Performance Torch Applied Waterproofing Membraneaskmewhy18Belum ada peringkat

- POUR CARD and Foundation FormatsDokumen16 halamanPOUR CARD and Foundation Formatsshanmugam.s100% (1)

- Art & Graphic Artists Products and Their UsesDokumen36 halamanArt & Graphic Artists Products and Their Usespatvindewr100% (1)

- Bonding of TimberDokumen92 halamanBonding of Timberamino2220% (1)

- All-Purpose Contact AdhesiveDokumen3 halamanAll-Purpose Contact AdhesiveBerno Muishond KohlmeyerBelum ada peringkat

- Cervac Board HS&HS PlusDokumen2 halamanCervac Board HS&HS PlusCynthia MillerBelum ada peringkat

- Building Materials: Waterproofing and DamproofingDokumen11 halamanBuilding Materials: Waterproofing and DamproofingarchitectjeyBelum ada peringkat

- GB STD Steel PDFDokumen7 halamanGB STD Steel PDFBapu612345100% (1)

- DTEI Pavement Design Supplement 31oct 2014 V4Dokumen52 halamanDTEI Pavement Design Supplement 31oct 2014 V4Oladunni AfolabiBelum ada peringkat

- Prefabrication Concrete ShellsDokumen202 halamanPrefabrication Concrete ShellsGabriel Riso100% (1)

- Metal or Alloy Kg/cu.m: Unit Conversion Tool - DownloadDokumen3 halamanMetal or Alloy Kg/cu.m: Unit Conversion Tool - DownloadRam AravindBelum ada peringkat

- Construction Chemicals Conference Success StoryDokumen45 halamanConstruction Chemicals Conference Success StoryShikhin GargBelum ada peringkat

- File 40 - Doors and WindowsDokumen44 halamanFile 40 - Doors and WindowsdvduronBelum ada peringkat

- Rap 8 PDFDokumen6 halamanRap 8 PDFd'Hell CaesarBelum ada peringkat

- GulfSea Hyperbar LCM2 PDFDokumen2 halamanGulfSea Hyperbar LCM2 PDFObydur RahmanBelum ada peringkat

- Cloverdale EcosheetDokumen2 halamanCloverdale EcosheetJennyBelum ada peringkat

- The Complete Guide To Roofing Siding & TrimDokumen272 halamanThe Complete Guide To Roofing Siding & TrimHao LinKinyao92% (13)

- Test On BricksDokumen17 halamanTest On BricksRuthra Manickam100% (4)

- FRP Composites Grating ManualDokumen10 halamanFRP Composites Grating ManualCasey Ryback33% (3)

- Civil Green ConcreteDokumen18 halamanCivil Green ConcreteShreekant KeraiBelum ada peringkat

- Aluminium Honeycomb Seminar ReportDokumen28 halamanAluminium Honeycomb Seminar Report123CineWorld Com0% (1)