Krause BBS

Diunggah oleh

Gabriel FeresHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Krause BBS

Diunggah oleh

Gabriel FeresHak Cipta:

Format Tersedia

SYMPOSIUM SERIES No.

148

2001 IChemE

MOVING TO THE 2ND GENERATION IN BEHAVIOUR-BASED

SAFETY

Thomas R. Krause *, Gordon Sellers # and Chris Horn

* Behavioral Science Technology, Ojai CA, USA

#

Behavioural Science Technology International, Bracknell RG12 1JB, UK

Gordon.Sellers@bstsolutions.com

GlaxoSmithKline, Worthing, West Sussex BN14 8QH, UK

Behaviour-Based Safety has moved from being a curiosity to becoming an

established part of many companies safety programmes. But what is the right

perspective on it is it a passing fad that will soon die away or, as we saw with

HAZOP, is it a foundation methodology for the future? The answer depends on how

we see the field of safety and what next steps we take. We discuss typical

shortcomings in what some people call behaviour-based safety. We then discuss

strategies for maintaining the strengths while addressing the weaknesses, before

suggesting two next steps: rethink the old concepts, making the radical proposal that

we should take away the emphasis from behaviours and focus instead on the

working interface; and use behaviour-based safety methodology as a foundation for

organisational change. The paper ends with a case study from a pharmaceutical

company that is implementing most features of the 2nd generation of behaviourbased safety.

Keywords: safety, behaviour, second generation, case study, pharmaceuticals

ESTABLISHING THE NEXT STEP IN BEHAVIOUR-BASED SAFETY

Behaviour-based safety (BBS), pioneered in the early 1980s, has attracted so many imitators

that the BBS label no longer means very much. It is time to take stock of the current scene

and to draw lessons for the future of behaviour-based safety. We discuss: the origins of BBS;

report on current confusions about it; sketch the evolution of an integrated model of BBS;

make suggestions for where BBS should move in the future; and close with a case study.

THE ORIGINS OF BBS

BBS came into being as the result of three currents of work done separately with a small

degree of overlap. The first was the applied behaviour analysis work of psychologist Judi

Komaki, then at the Georgia Institute of Technology in the United States. Komaki was one of

a small group of academic applied behavioural analysts working on industrial performance.

Her interest was not solely in safety; she was interested in the use of applied behaviour

analysis techniques in industry in general. However safety became the focus of her study

when one of her students proposed to use behavioural techniques to design a performance

improvement at his familys 200-employee food processing plant. As it happened, safety was

the area in which the plant most wanted to see performance improvement. Komaki and her

associates published an academic paper on their findings in 19781.

In 1979, John Hidley and one of us (Tom Krause) were asked by an offshore oil-drilling

company in California to help them find innovative ways of improving safety performance.

Based on our preliminary analysis of the situation facing this employer, we recommended the

use of applied behaviour analysis as an improvement methodology2. This was the beginning

of BST.

During this same period Gene Earnest and Jim Palmer at Proctor and Gamble were

developing a methodology drawn from the behavioural sciences. To our knowledge, Earnest

and Palmer were the first to use the phrase behavior-based safety.

731

SYMPOSIUM SERIES No. 148

2001 IChemE

Although similar work in the UK began rather later than in the US, by the late 1980s

extensive university research had been applied in industry and a strong body of experience

developed through the 1990s, as described by Cooper3.

CURRENT CONFUSIONS ABOUT BBS

Twenty years later, BBS means many different things to different people. The ambiguity or

fuzziness of the term is so far advanced that BBS has lost its power to describe anything

clearly. For example, some organisations call what they are doing BBS even though they

admit they have no involvement of shop-floor personnel in the effort, no operational

definitions of critical behaviours, and no continuous improvement mechanism. What they do

have is the traditional manager/supervisor audit programme focussed on disciplinary action.

The proponents of that approach lose no opportunity to refer to it as behaviour-based safety.

This is just part of the trend in which all kinds of techniques, including the use of

incentives related to accident rates, are labelled BBS in an apparent effort to make them

more popular. This presents enormous difficulties in communication. One end of the

continuum of confusion is the idea that anything to do with behaviour, attitude, culture, the

worker, etc. is BBS. The next level of confusion is represented by the idea that, to implement

BBS, all you have to do is identify some behaviours on a check list, get people to go out and

start observing them, apply a lot of reinforcement (including tangible incentives) and then sit

back to watch your incident rate fall.

This drastic oversimplification about BBS is troublesome even where the effort is

supplemented by standard safety activities. However, this minimalist, by-the-numbers

version of BBS becomes even more problematic when people offer it as the primary

component of a safety effort, instead of as part of an integrated approach that strengthens and

supports existing safety systems.

It is hardly surprising that some trade union representatives raise a number of valid

concerns about BBS based on what they have seen labelled as BBS in various organisations

for example:

THE BLAME GAME

Because behaviour-based safety tracks shopfloor behaviour, they predict that it will

necessarily turn into fault-finding and blaming.

REDUCED HAZARD MITIGATION

They worry that managers will think that, once they have implemented behaviour-based

safety, they can stop pursuing engineering controls for hazard mitigation so resources will

be taken away from facilities, design and maintenance.

DRIVING DATA UNDERGROUND

They believe that, if managers set ambitious targets for the numbers coming out of

behaviour-based safety, then they will get the numbers they want but they may bear little

resemblance to reality.

IGNORING SAFETY SPECIALISTS

They also express concern that, because behaviour-based safety encourages the involvement

of people who are not safety specialists, this approach bypasses a sites safety specialists and

de-skills the safety function.

732

SYMPOSIUM SERIES No. 148

2001 IChemE

THE EVOLUTION OF BSTS APPROACH TO BEHAVIOUR-BASED SAFETY

Since 1980, BST has helped organisations to implement BBS at more than 1,400 sites around

the world. Over that period, like any organisation that is committed to continuous

improvement, BST has significantly evolved its Behavioural Accident Prevention Process or

BAPP technology.

1980 1985. In these early years, the method used by BST was management-driven

from the top down. BST completed about 15 projects using that supervisor-driven model.

1986 1997. From 1986 until about 1995, Krause and his colleagues changed the model

to one that was employee-driven. BST integrated Total Quality Management and

Organisation Development principles with those of applied behaviour analysis in developing

BAPP technology. BST also developed software to store and analyse data generated during

behavioural observations, and emphasised feedback as an improvement mechanism and as a

type of reinforcement. During this period, BST completed about 200 projects.

1997 present. Since 1997 the BAPP model has evolved to include more completely

the engagement of all employees. This occurred in response to the need to address more

directly the contradiction that some organisations perceived between an employee-driven

process and management accountability. The contradiction does not exist, but failing

explicitly to address it allowed misinterpretations to occur.

In spite of warnings to the contrary, some companies implementing BAPP left out the

manager and the supervisor. In those companies it was as though people thought that to

involve front-line personnel it was necessary to exclude the managers and supervisors. As a

result, they put in place change efforts that had strong employee involvement and support, but

weak support and commitment from supervisors and managers. It did not take long for

organisations to realise that, in order to make a BAPP initiative work over the long run,

managers and supervisors had to be involved in appropriate ways.

Some of those ways include: involving some managers and supervisors as equal

members of a BAPP steering team, along with front-line employees; training managers and

supervisors as observers; developing a datasheet for the management behaviours that support

safety (walking the talk, which is not always easy for managers who are increasingly faced

with intense production and financial pressures); using the behavioural safety process to

gather before and after data to assist other initiatives; using existing departmental

continuous improvement teams to develop behavioural action plans to remove intransigent

barriers to safe behaviour that have been identified by the observation process; and extending

the scope of the behavioural safety process to address other important matters such as product

or service quality.

The significance is that the behavioural safety process becomes a method for

continuously improving facilities, equipment, design and management system issues. Of

BSTs current total of implementations, over 1,000 are based on this most current model.

IS BEHAVIOUR-BASED SAFETY STILL THE CORRECT LABEL?

For many years BSTs research and development department has analysed hundreds of site

data sets containing barriers to safe behaviour. The pie chart in Figure 1 is an analysis of

13,264 behaviours observed at 13 sites.

The pattern of distribution across barriers is similar at these sites to many other sites.

Namely, facilities & equipment and hazard recognition & response make up the largest

categories, comprising a majority of the barriers to safe behaviours. It is worth noting that this

kind of data would not be available if it were not for a behaviour-based methodology that

allows it to be gathered. Examining and thinking about these data in consultation with many

733

SYMPOSIUM SERIES No. 148

2001 IChemE

different organisations has caused BST to take a fresh look at the relationship among causal

factors that contribute to injury.

As we now know that barriers to safe behaviour are primarily related to conditions,

equipment and management systems, rather than to personal choice, it no longer seems

reasonable to state that:

80 to 95% of injuries are caused by unsafe acts

However carefully we phrase it, many people still read that as requiring us to make a

choice between behaviours and facilities and implying blame for the worker if he or she

acted unsafely.

The focus of our safety improvement efforts has to change from the worker to the

systems that enable safe behaviour.

HELPING ORGANISATIONS REDUCE EXPOSURE TO INCIDENTS BY

IMPROVING THE WORKING INTERFACE

If we analyse injuries exhaustively, looking at a variety of organisations across industries over

a period of several years, what we find is that the actual cause of the great majority of injuries

is an interaction between the worker and the facility. We describe this interaction as the

Working Interface. Furthermore, we believe that improvement in safety consists of

systematically defining and improving this critically important working interface (Figure 2)

and we can now change our definition to:

Incidents are caused by multiple factors which are seen in the working interface.

Many exposures are likely to occur before an injury. The specific relationship between

exposure and injury varies with type of industry and type of injury.

In spite of much confusion about the essence and the applications of behaviour-based

safety, it remains an effective tool for performance improvement, and it is growing stronger

and more flexible as more companies adapt it to their unique needs. For companies to succeed

with BBS, it is important for them to look beyond the label and understand what constitutes

an effective system. And for BBS to continue to thrive, it must continue to evolve, retaining

those characteristics that are effective, while addressing perceived weaknesses.

GOING BEYOND SAFETY

Most companies are looking for ways to:

Engage their employees in problem solving;

Develop their employees capacity to respond to challenges; and

Use data-based tools to make improvements.

We are now demonstrating that behaviour-based safety methodology is a model for

organisational change by applying it to such diverse issues as:

Improving quality in manufacturing processes;

Improving student life on a college campus;

Medical error reduction; and

Improving quality and customer service in a business service company.

734

SYMPOSIUM SERIES No. 148

2001 IChemE

CASE STUDY OF BBS AT A UK PHARMACEUTICALS PLANT

Within BST, the change in focus from the worker to the systems that enable safe

behaviour has not occurred overnight, but has been an evolution over several years. This can

be seen in the experience of the major multinational pharmaceuticals company SmithKline

Beecham (now GlaxoSmithKline) that in 1998 launched pilot implementations of BSTs

BAPP technology at two of its sites one at Worthing UK and the other at Clifton, NJ, USA.

Since then, BAPP implementations have begun at three more of the companys sites in

Ireland, Kenya and Argentina. This brief case study reports on safety gains at the UK site.

Following its August 1998 launch of behaviour-based safety, the Worthing sites twelvemonth moving average for lost time accidents (LTAs) has improved steadily (Figure 3). An

important factor of this success is the contribution of the sites trained BAPP observers who

consistently meet or exceed their targets in 2000 they completed 3,309 observations against

their target of 3,114 (based on one observation per observer per week).

ACTIVE STEERING TEAMS AND OBSERVERS

The site comprises both primary and secondary production. Using reactors, filters, dryers and

pumps, primary operations include large-scale fermentation, extraction and fine chemical

processing. Secondary operations include bulk powder processing, producing finished tablets

and capsules, and product packaging using high speed machinery. Using two steering

committees, one for primary production and one for secondary production, the site

implemented the process in seven production units out of a total of ten business units.

A BST consultant began training the two steering committees together in July 1998. The

committee members in turn trained many of their colleagues as observers. The observers use

the data sheets to record the rates at which their colleagues are using the identified safe or atrisk behaviours. After an observation, the observers use two-way feedback to reinforce the

safe behaviours they have seen. They then talk about any at-risk behaviour they may have

seen. When it is within the control of the observed personnel to avoid an at-risk behaviour,

one of the aims of the feedback discussion is for them to agree that in future they will use the

identified safe behaviour.

When existing procedures or conditions prevent this change from being within the

control of the worker, the observers record that information along with their colleagues

thoughts on how to remove barriers to safe behaviour. Problem-solving teams then use this

observation data to make improvements. (This is what BST would now describe as

improving the working interface).

FACING UP TO THE COMMUNICATION CHALLENGES

The first challenge was a need for communication across seven business units using many

different work patterns. There was also a need for good communication through all levels of

the organisation, including team leaders and managers. In addition, the observers needed

ongoing feedback to remind them of the value of their work, to motivate them, and to keep

them calibrated with emerging observation targets.

The first site-wide BAPP co-ordinator was especially effective at promoting the process

and grabbing peoples attention. For a Worthing site open day in May 1998, just before the

BBS process was launched, he set up an exhibition stand featuring literature and videos on the

BAPP approach to safety. He and the BST consultant were on hand to chat informally about

the process and implementation. He then developed a briefing pack for other presenters to use

and, to achieve continuity across all seven business units, this pack reproduced the slides and

handouts from the exhibition stand. The steering committees used this pack to conduct

735

SYMPOSIUM SERIES No. 148

2001 IChemE

approximately five presentations per work area covering every shift, totalling 40 to 50

presentations over the entire site.

In addition, the BAPP team produced and published a double-page introductory article in

the sites quarterly magazine and have since gone on to launch a very readable behaviourbased safety newsletter.

UNION INVOLVEMENT

The AEEU and TGWU are both represented at the site, and members of the unions were

appointed to positions on the steering committees. The site-wide co-ordinator comments that,

A conscious effort was made to involve the unions from the start and because of that we

have a very good relationship with them over behaviour-based safety. The co-ordinator of

the secondary area steering committee has been a TGWU safety representative for several

years and she notes that, Before we had behaviour-based safety, everyone in my department

expected me to solve all their safety problems. Now I have a group of observers and steering

team members who help to spread the load and get better involvement.

ADDRESSING OBSERVER CONCERNS

To keep observers in the loop, the steering committees issue reports and conduct regular

meetings that are keyed to observer concerns. These communications emphasise the gains the

site has made based on observation data.

To remove some of the time pressure on observers, the site is using an alternative

feedback method that they call hindsight feedback. When they observe colleagues

performing some high priority production jobs, instead of directly engaging in two-way

feedback the observers return after the job is completed to conduct a feedback session. This

procedure lets the observers conduct observations when they have time to do so and when the

observed person is actively engaged; then it lets the observed personnel receive the feedback

after the priority job is complete.

CELEBRATING THE GAINS

GlaxoSmithKline Worthing sees its success in various ways. Its lost time accident rate shows

continuous improvement. The sites observers are meeting and beating their targets. In March

and April of 1999, for the first time in 10 years the site had zero reportable injuries for two

consecutive months. According to the current site-wide co-ordinator, beyond those numbers

the sites safety culture is improving as more people understand the connection between using

the identified critical safe behaviours and reducing their exposure to injury.

REFERENCES

1.

Komaki, J., Barwick, K.D. and Scott, L.R., 1978, A Behavioral Approach to

Occupational Safety, Journal of Applied Psychology, 63(4): 434-445

2.

Krause, T.R., Hidley, J.H. and Lareau, W, 1984 (July), Behavioral Science Applied to

Industrial Accident Prevention, Professional Safety

3.

Cooper, D., 1998, Improving Safety Culture: A Practical Guide, John Wiley & Sons

736

SYMPOSIUM SERIES No. 148

2001 IChemE

Proportion of Barriers for

13264 At-Risk Behaviours

Rewards / Recognition 3%

Business Systems 4%

Culture 7%

Personal Factors 5%

Disagreement on

Safe Practices

9%

Personal Choice

17%

Hazard Recognition and

Response 22%

Facility and Equipment 33%

Figure 1. Analysis of at-risk behaviours at 13 sites

Injury

Behaviour

Working

Interface

Facilities

The Interaction Between Worker and Technology

Should be the Focus of Safety Improvement Efforts

Figure 2. Injuries occur at the working interface

737

SYMPOSIUM SERIES No. 148

2001 IChemE

LTAs:Production Business Units

BBS Launch

8

7

6

5

12 month moving average

LTA

12 per. Mov. Avg. (LTA)

4

3

2

1

Jan'97

April'97

July'97

Oct'97

Jan'98

April'98

July'98

Oct'98

Jan'99

April'99

July'99

Oct'99

Jan'00

April'00

July'00

Figure 3. Lost Time Accidents have fallen since the launch of BBS

738

Anda mungkin juga menyukai

- Behavior-Based Safety: All in The FamilyDokumen2 halamanBehavior-Based Safety: All in The FamilyPipat Singha-inBelum ada peringkat

- Safety AspectsDokumen14 halamanSafety AspectsGanga DaranBelum ada peringkat

- Fall FR Height English tag-FW PDFDokumen31 halamanFall FR Height English tag-FW PDFNosh AnbreenBelum ada peringkat

- Iso 45001:2018Dokumen1 halamanIso 45001:2018Unokhogie EmmanuelBelum ada peringkat

- Environmental Health and Safety Electrical Safety Program and PermitDokumen25 halamanEnvironmental Health and Safety Electrical Safety Program and PermitDanielSombeBelum ada peringkat

- PHD Thesis - Breaking The Safety BarrierDokumen270 halamanPHD Thesis - Breaking The Safety BarrierdileshBelum ada peringkat

- PGD in Occupational Safety Engineering and Risk ManagementDokumen1 halamanPGD in Occupational Safety Engineering and Risk ManagementRichard BaileyBelum ada peringkat

- Nebosh Diploma FlyerDokumen5 halamanNebosh Diploma Flyerhsecouncil100% (1)

- The Iaq Investigator's GuideDokumen86 halamanThe Iaq Investigator's GuideatenguezBelum ada peringkat

- Safety CultureDokumen4 halamanSafety CultureTunaivashBelum ada peringkat

- Unit GC2 Revision NotesDokumen65 halamanUnit GC2 Revision NotesBobBelum ada peringkat

- Guide Safety and Lean Trends 2022Dokumen32 halamanGuide Safety and Lean Trends 2022JOSEPH RIŇOSBelum ada peringkat

- Safety Park BungeDokumen37 halamanSafety Park BungeRavi Sankar VenkatesanBelum ada peringkat

- Noise and Hearing Conservation TrainingDokumen1 halamanNoise and Hearing Conservation TrainingRabialtu SulihahBelum ada peringkat

- Dhi-Ehs-Hsm-028 Work Over Water Rev0Dokumen5 halamanDhi-Ehs-Hsm-028 Work Over Water Rev0Phạm Đình NghĩaBelum ada peringkat

- American National Standard Criteria For Accepted Practices in Safety, Health, and Environmental TrainingDokumen32 halamanAmerican National Standard Criteria For Accepted Practices in Safety, Health, and Environmental TrainingOSHTECH LATAMBelum ada peringkat

- Part VI (J) - Mechanical Plant & Machinery Safety (Day 6)Dokumen23 halamanPart VI (J) - Mechanical Plant & Machinery Safety (Day 6)kwong siongBelum ada peringkat

- Promoting A Positive Health and Safety CultureDokumen12 halamanPromoting A Positive Health and Safety CultureDhana RajuBelum ada peringkat

- Topic C - S&H Committee, TBM & So Basic RolesDokumen33 halamanTopic C - S&H Committee, TBM & So Basic RolesConnor WalshBelum ada peringkat

- HSE Alert 105-21 Welder Finger InjuryDokumen2 halamanHSE Alert 105-21 Welder Finger InjuryAlecs NedeaBelum ada peringkat

- Oshas 18000Dokumen10 halamanOshas 18000JanaBelum ada peringkat

- EHSS Risk Management System - DraftDokumen17 halamanEHSS Risk Management System - DraftMd Rafat ArefinBelum ada peringkat

- 1.procedure For Envi Aspect and Impact AssessmentDokumen15 halaman1.procedure For Envi Aspect and Impact AssessmentDendi Pradeep ReddyBelum ada peringkat

- Employee Wwelfare ProjectDokumen11 halamanEmployee Wwelfare ProjectVijay KishanBelum ada peringkat

- Combined Fall and Rescue Plan TemplatesDokumen14 halamanCombined Fall and Rescue Plan TemplatesOsama ShaalanBelum ada peringkat

- Is 14489 1998Dokumen19 halamanIs 14489 1998Imran Bagwan100% (1)

- IOSHCPD Export 2021-09-07 03 58 43Dokumen1 halamanIOSHCPD Export 2021-09-07 03 58 43besongBelum ada peringkat

- 28.0 - Hot Work Operations (Eg Welding and Cutting) v3.0 EnglishDokumen16 halaman28.0 - Hot Work Operations (Eg Welding and Cutting) v3.0 EnglishSantosh Gudadinni100% (1)

- Achieving a Safety Culture with Employee EngagementDokumen44 halamanAchieving a Safety Culture with Employee Engagementasep100% (1)

- Ergonomics Principles and GuidelinesDokumen18 halamanErgonomics Principles and GuidelinesArpan Gautam100% (1)

- Prof Krishna's 5A Way to Workplace SafetyDokumen26 halamanProf Krishna's 5A Way to Workplace SafetyEPOUBelum ada peringkat

- Behaviour-Based Safety in Organizations: Saving Life Before The Accident, 2/eDokumen2 halamanBehaviour-Based Safety in Organizations: Saving Life Before The Accident, 2/ePampanagouda YadavBelum ada peringkat

- Aim Vision Safety - Brochure-new-Safety First Is Safety Always. PDFDokumen7 halamanAim Vision Safety - Brochure-new-Safety First Is Safety Always. PDFGurji SirajBelum ada peringkat

- Elemnt 2 IbDokumen1 halamanElemnt 2 IbManiMadishettyBelum ada peringkat

- Blueprint References: Book Title Auxilliary InformationDokumen2 halamanBlueprint References: Book Title Auxilliary InformationsafetydmrcBelum ada peringkat

- Construction Project Public Protection ANSI StandardDokumen49 halamanConstruction Project Public Protection ANSI StandardJeerawatBelum ada peringkat

- NEBOSH International Diploma inDokumen4 halamanNEBOSH International Diploma inNazir AhmadBelum ada peringkat

- Topic 3 Motivating Safety and Health1 PDFDokumen17 halamanTopic 3 Motivating Safety and Health1 PDFDiyana Osman100% (1)

- Workers' Participation in ManagementDokumen37 halamanWorkers' Participation in ManagementPiyush ParmarBelum ada peringkat

- Global Ehs Micron Construction Safety GuidebookDokumen164 halamanGlobal Ehs Micron Construction Safety GuidebookJinchang ZhangBelum ada peringkat

- Safety Culture Survey ReportDokumen43 halamanSafety Culture Survey ReportClaireBelum ada peringkat

- EHS Culture Road Map - LFSSDokumen27 halamanEHS Culture Road Map - LFSSSebastian IacopiBelum ada peringkat

- A Short Guide To Leading and Lagging Indicators of Safety PerformanceDokumen9 halamanA Short Guide To Leading and Lagging Indicators of Safety Performancebobobo22Belum ada peringkat

- Introduction to Employee Welfare FacilitiesDokumen44 halamanIntroduction to Employee Welfare FacilitiesL. V B ReddyBelum ada peringkat

- Occupational Health and Safety Program: How To Implement A FormalDokumen52 halamanOccupational Health and Safety Program: How To Implement A Formaldnzk dnzkBelum ada peringkat

- REd Hat Safety BrochureDokumen3 halamanREd Hat Safety BrochureAmal JagadiBelum ada peringkat

- Overview of Work at Height Safety EngDokumen32 halamanOverview of Work at Height Safety EngJacky LeongBelum ada peringkat

- Behavioural Safety Application GuideDokumen52 halamanBehavioural Safety Application GuideBobby IM SibaraniBelum ada peringkat

- Safety ProgramDokumen21 halamanSafety ProgramSits RdddBelum ada peringkat

- POL4112 Coaching For Safety 234x156 v3spDokumen24 halamanPOL4112 Coaching For Safety 234x156 v3spAndres Lucero LeivaBelum ada peringkat

- BSBWHS302 PowerPoint Slides V1.1Dokumen47 halamanBSBWHS302 PowerPoint Slides V1.1Natti NonglekBelum ada peringkat

- Road Safety Management InsightsDokumen38 halamanRoad Safety Management InsightsPtn DhavalBelum ada peringkat

- Design and Implement Behavioural Safety Programme (SOH CHEE SENG)Dokumen95 halamanDesign and Implement Behavioural Safety Programme (SOH CHEE SENG)Chauhan VineetBelum ada peringkat

- Lifting Machine Entity Registration - IonDokumen5 halamanLifting Machine Entity Registration - IonJason Fourie100% (1)

- Safety Leadership Survey key factorsDokumen4 halamanSafety Leadership Survey key factorslooking99Belum ada peringkat

- Crisis Management Plan: Revised - March 7, 2012Dokumen214 halamanCrisis Management Plan: Revised - March 7, 2012Exa HeydemansBelum ada peringkat

- Training Needs AssessmentDokumen5 halamanTraining Needs AssessmentahmadBelum ada peringkat

- Occupational Health and Safety Training Knowledge PDFDokumen14 halamanOccupational Health and Safety Training Knowledge PDFTalha AfzalBelum ada peringkat

- Reversing ReadicideDokumen7 halamanReversing Readicidedeldobuss100% (1)

- Data Sovereignty and The Opportunity For Glo Calization: InsightsDokumen1 halamanData Sovereignty and The Opportunity For Glo Calization: InsightsOtuya OkechaBelum ada peringkat

- Angela Valdez Ramos National High School: Advantages and Disadvantages of Social MediaDokumen23 halamanAngela Valdez Ramos National High School: Advantages and Disadvantages of Social MediaRogelyn Tabin-Pagador Alcover-SabadoBelum ada peringkat

- Southern Mindanao Colleges Pagadian City: Jeep Accel 2Dokumen8 halamanSouthern Mindanao Colleges Pagadian City: Jeep Accel 2Gennyse Balmadres-Selaras Pantorilla-FernandezBelum ada peringkat

- Reading reveals origins and types of popular hobbiesDokumen5 halamanReading reveals origins and types of popular hobbiesMilagrosVelasquezMoralesBelum ada peringkat

- Vocabulary Through Morphemes Suffixes PRDokumen16 halamanVocabulary Through Morphemes Suffixes PRsiavash_fouladi0% (1)

- Competency Based TNA TrainingDokumen3 halamanCompetency Based TNA TrainingThangamany SadasivanBelum ada peringkat

- Model Course 7.02 Chief Engineer Officer & Second Engineer OfficerDokumen218 halamanModel Course 7.02 Chief Engineer Officer & Second Engineer OfficerkemimeBelum ada peringkat

- Auditors Code of ConductDokumen33 halamanAuditors Code of ConductSherwin MosomosBelum ada peringkat

- The Grey Book by Snoek, Johan Martinus, 1920Dokumen264 halamanThe Grey Book by Snoek, Johan Martinus, 1920Gutenberg.orgBelum ada peringkat

- Starting a Business Risks and RequirementsDokumen2 halamanStarting a Business Risks and RequirementsK58 Hoa Trần Quỳnh TrangBelum ada peringkat

- Noc18 mg42 Assignment10Dokumen3 halamanNoc18 mg42 Assignment10GangadharBelum ada peringkat

- Assessing The Level of Tourist Satisfaction and Its Effect On Future Behavior Intentions in The Province of Ilocos NorteDokumen16 halamanAssessing The Level of Tourist Satisfaction and Its Effect On Future Behavior Intentions in The Province of Ilocos NorteMacquen Balucio100% (2)

- Similes and Metaphors: Creative Writing ComparisonsDokumen2 halamanSimiles and Metaphors: Creative Writing ComparisonsRose YulasBelum ada peringkat

- Objectives:: Canianido, Riendl Kizer GDokumen5 halamanObjectives:: Canianido, Riendl Kizer GPJ FloresBelum ada peringkat

- Ms. Jigya Yadav (Minor) Vs CBSE-WP (C) 3774 of 2010Dokumen11 halamanMs. Jigya Yadav (Minor) Vs CBSE-WP (C) 3774 of 2010Umesh KaisthaBelum ada peringkat

- Strategy at Zara: © Clegg, Schweitzer, Whittle & Pitelis 2017Dokumen2 halamanStrategy at Zara: © Clegg, Schweitzer, Whittle & Pitelis 2017Fiza Wahla342Belum ada peringkat

- Conflict ManagementDokumen21 halamanConflict ManagementimadBelum ada peringkat

- 1200 TỪ VỰNG HỌC THUẬT THƯỜNG XUẤT HIỆN NHẤT TRONG IELTS READINGDokumen3 halaman1200 TỪ VỰNG HỌC THUẬT THƯỜNG XUẤT HIỆN NHẤT TRONG IELTS READINGLong LưBelum ada peringkat

- GD 4 (A) - Application Form For Approval To Install (ATI)Dokumen7 halamanGD 4 (A) - Application Form For Approval To Install (ATI)Usup AwangBelum ada peringkat

- Master of Science in Computer Science: ConcentrationsDokumen2 halamanMaster of Science in Computer Science: ConcentrationsDeept MahendirattaBelum ada peringkat

- essayDokumen2 halamanessayDavid SparksBelum ada peringkat

- Y5L Open EveningDokumen27 halamanY5L Open Eveningjamiestark427Belum ada peringkat

- Course Information: Handbook For Additional InformationDokumen11 halamanCourse Information: Handbook For Additional InformationSean F-WBelum ada peringkat

- PPC All Solved Open Book PapersDokumen366 halamanPPC All Solved Open Book PapersGrd GrdBelum ada peringkat

- Top Notch 1 Page 7Dokumen1 halamanTop Notch 1 Page 7Diana Carolina Figueroa MendezBelum ada peringkat

- Ionut - Unit 8 - ICDokumen17 halamanIonut - Unit 8 - ICComsec JonBelum ada peringkat

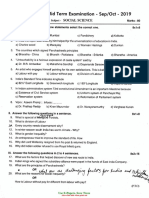

- 10th Standard Midterm Social Science ExamDokumen2 halaman10th Standard Midterm Social Science ExamPriya DarshiniBelum ada peringkat

- Blank's Questions Guide to Developing Reading SkillsDokumen2 halamanBlank's Questions Guide to Developing Reading SkillsdfBelum ada peringkat

- Sanctions Against Member States Under Article 260 Tfeu: Alive, But Not Kicking?Dokumen31 halamanSanctions Against Member States Under Article 260 Tfeu: Alive, But Not Kicking?Peroshnah T. DevBelum ada peringkat