Optimization of Constrained Layer Damping For Strain Energy Minimization of Vibrating Pads

Diunggah oleh

Ivan GrujicDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Optimization of Constrained Layer Damping For Strain Energy Minimization of Vibrating Pads

Diunggah oleh

Ivan GrujicHak Cipta:

Format Tersedia

Songklanakarin J. Sci. Technol.

34 (2), 179-187, Mar. - Apr. 2012

http://www.sjst.psu.ac.th

Original Article

Optimization of constrained layer damping

for strain energy minimization of vibrating pads

Supachai Lakkam1* and Saiprasit Koetniyom2

1

Department of Mechanical Engineering

Rajamankara University of Technology Pranakhon, Dusit, Bangkok, 10300 Thailand.

2

The Sirindhorn International Thai-German Graduate School of Engineering

King Mongkuts University of Technology North Bangkok, Bang Sue, Bangkok, 10800 Thailand.

Received 1 April 2011; Accepted 20 February 2012

Abstract

An optimization study for brake squeals aims to minimize the strain energy of vibrating pads with constrained layer

damping. To achieve this, using finite element method and experiments were operated and assumed-coupling mode method

was used to solve it. The integrated global strain energy of the pad over a frequency range of interesting mode was calculated.

Parametric studies were then performed to identify those dominant parameters on the vibration response of the damped pad.

Moreover, the proposed methodology was employed to search for the optimum of the position/geometry of the constrained

layer damping patch. Optimal solutions are given and discussed for different cases where the strain energy of the pad over a

frequency range is covering the first bending mode and with the inclusion of the restriction of minimum damping material

utilization. As a result, the integrated strain energy is then performed to identify and optimize the position and geometry of the

damping shim. The optimization of the constrained layer damping for strain energy minimization of vibrating pads depend on

the position of the shape of the damping patch. These data can guide to specify the position of the constrained layer damping

patch under pressure conditions.

Keywords: disc brake noise, friction coefficient, damping shim

1. Introduction

It is principally accepted that noise and vibration have

become key issues in the intention of automotive braking

systems. Typically, the vibration of a brake system cause

brake noise phenomena. There are several methods to reduce

brake noise phenomena. One of the brake noise reduction

methods is the addition of a constrained layer material to the

brake pads (Triches et al., 2004 and Zheng et al., 2004). For

the control strategy of vibration, there are many parameters

to indicate the degree of vibration. Displacement/acceleration of deformation, loss factor/damping ratio, vibration

* Corresponding author.

Email address: bus_supachai@hotmail.com

energy and strain energy are examples for controlling strategies. In mechanical engineering aspects, the global strain

energy is simply used as an indicator for vibration of the

brake system in order to optimize the constrained layer

damping.

2. Literature survey

2.1 Experimental works

Generally, the experimental works focus on how to

reduce brake noise behavior which can be classified based on

the approaching procedure. The first approach is the active

or direct method that is used to prevent the source of sound

vibration in the brake system. Secondly, it is called passive

or indirect method, which is mainly to minimize the sound

180

S. Lakkam & S. Koetniyom / Songklanakarin J. Sci. Technol. 34 (2), 179-187, 2012

vibration.

In direct methods, the characteristic of disc brake

squeal was investigated (Eriksson et al., 2000). The onset and

suppression of such vibration have been controlled using a

surface improvement of the brake disc with a grit-blasted

sector. In this way, the whole pads can slide through the

untreated and treated disc surface alternatively. Normally the

untreated surface can generate squeal while the pad is passing. In the other method, the treated or grit-blasted surface

can deactivate the vibration in the vertical plane of the brake

disc. Thus, brake squeal can be eliminated with an improvement of the disc surface. However, the squeal can occur if

the treated surface is wear out under long term usage.

Additionally, the basic mechanism of instability of the

disc brake system was presented by Fieldhouse (2000). The

propensity of brake noise generation is investigated over a

range of temperatures and pressures under specific conditions through the brake disc configuration. A mechanically

induced offset centre of pressure between the pad and rotor

can be varied in order to investigate disc brake squeal. Consequently, the offset centre of pressure can be used to diminish

disc brake squeal.

Likewise, brake squeal was reduced by the design of

the friction interface between the piston and the damping

shim with holes (Heppes, 2000). In this interface, the geometry

of the insulator is modified to shift the center of pressure.

However, the brake disc geometry is also sensitive to the

center of pressure at the friction interface. With an adequate

interface design, it is possible to minimize the brake squeal.

Nevertheless, as both techniques are using modified interface and surface treatment they are complicated and costly

during the manufacturing process.

2.2 Analytical and numerical methods

The friction material model which is able to describe

the onset of self-excited vibrations from a dry friction

material was suggested by Shin et al. (2002). The model,

based on this assumption, can produce self-excited vibrations

in the case of a onedegree of freedom. Consequently, only

horizontal vibration of variously planar material model plays

a dominant role in the case of brake squeal. Furthermore, the

damping material and friction force are the key for vibration

behavior. However, the model was created in one direction,

which does not describe the other degrees of freedom, i.e.

vertical direction. Nevertheless, the technique is typical for

describing self-excited vibrations based on a dry friction

model.

Additionally, the friction-induced vibration of an

elastic slider was studied using a rotating disc (Ouyang et al.,

1999). All models were created with an elastic material behavior in both vertical and horizontal direction. However, the

slider model against the disc model has flexibility and damping in the circumferential (in-plane) and transverse directions.

In the boundary conditions, the static and dynamic friction

coefficients were taken into this analysis. In addition, two

coupled equations of the motion between the slider and the

disc models were used to obtain vibration characteristics.

A specialized mathematical modeling technique was

applied for high frequency disc brake squeal analysis (Flint,

2000). This technique is used for modeling two rigid caliper

parts, two lumped mass piston, two flexible pads, and disc.

The complex vibration behavior of continuous elements in

the model system with limited number of degrees of freedom

is represented. Therefore, the damping between piston and

caliper can be investigated. However, the results do not represent the responses from the disc model in circumferential

direction.

Apart from the analytical model, the disc brake squeal

was investigated using the finite element (FE) software

named ABAQUS version 6.4 (Liu et al., 2007). This method

uses nonlinear static analysis to calculate the friction coupling based on the complex Eigenvalue method. Therefore,

the effects of system parameters can be investigated, such as

the hydraulic pressure, the rotational velocity of the disc, the

friction coefficient of the contact interactions between the

pads and the disc, and the stiffness of the disc and the back

plates.

Moreover, the geometric nonlinear solution was

studied using MSC/NASTRAN software for friction stiffness

matrix to model the contact between the pad and rotor (Nack,

1999). This technique also introduces frictional dependent

pressure of brake system but the method is insensitive to the

variable pressure and velocity. Consequently, this simulation

performed a guideline to reduce the squeal noise of the brake

disc system

On the other hand, the influence of the tribological

properties of the friction material on the vibration levels in

a brake disc was investigated using a mathematical model

(El-Butch, 2000). Two friction models with the variation of

the friction coefficient from applied load, temperature, and

velocity are modeled. As a result, the effect of pressure,

temperature and sliding velocity on the friction coefficient

depends on the choice of the friction material. For this reason,

this method can be used to avoid vibration for friction. It can

also be used during the early stage of design in order to

minimize brake noise characteristics.

3. Characterization of the Dynamics of Brake Components

Brake noise occurs only when components of the

brake system demonstrate resonance vibrations. Therefore,

it is very important to determine the modal behavior of the

components to understand the problem. In the following

different analyses to obtain vibration behavior of a brake

system are presented.

3.1 Modal simulation of brake disc

The modal analysis of the rotor is likely the most

important process to find and understand solutions for the

disc brake noise problem. The 3D rotor model, using a tetra-

S. Lakkam & S. Koetniyom / Songklanakarin J. Sci. Technol. 34 (2), 179-187, 2012

181

bending modes along the longer edge occur first. From the

modal coupling point of view, the bending modes are more

important than the twisting modes. In most cases, the modal

coupling occurs between pad and rotor bending modes. The

bending mode shapes for the brake pads are shown in Figure 4 and Table 2 presents their natural frequencies. In comparison to the response frequency of the rotor, maximum

response frequency of pad is less.

Figure 1. Fixed-free boundary conditions of brake disc

3.3 Analysis for coupled mode between rotor and pad

hedron element type, which consists of 20,061 nodes and

12,683 elements, is created and assumed to be constrained

with bolts at the brake knuckle in order to simulate a fixedfree boundary condition as shown in Figure 1. The condition

for free vibration allows the structure to vibrate without interference from other parts, making the visualization easier to

locate mode shapes associated with each natural frequency.

For the simulation data of the brake disc, OEM material

properties of the overall brake system from Toyota PPV are

used, such as the elastic modulus of 220 GPa, a Poissons

ratio of 0.3, and a density of 8,000 kg/m3.

The simulation results of brake disc as shown in Table

1 represent its natural frequencies and degree of mode shape.

Such mode shape characteristic can be seen in different

frequencies between 2 and 23 kHz, which is in the range of

squeal brake frequency. It also found that the degree of bending mode is proportional to the degree of response frequency.

Contours of the mode shape and its frequency response for

the rotor in bending modes are shown in Figure 2.

Squeal noise usually occurs whenever the interaction

between pad and disc starts to vibrate together, creating a

coupled system mode (Triches et al., 2004). Considering the

bending modes coupling, when the components have the

same wavelength and frequency, they will be geometrically

matched and will vibrate in the same phase. In this case, the

damping characteristic of the pad is minimal. Consequently,

3.2 Modal analysis of brake pads

In the same way as that for the rotor model, the modal

analysis of the brake pad was simulated. The 3D brake pad

model using a tetrahedron element type, which consisted of

4,861 nodes and 2,541 elements, is created and supported by

two slender cables in order to simulate a free-free boundary

condition as shown in Figure 3. For the simulation data of the

brake pad, the Compact Internationals material properties

for a Toyota PPV are used, such as the elastic modulus of

3 GPa, a Poissons ratio of 0.23 and a density of 2,750 kg/m3.

The mode shapes for the brake pad are very similar to

the bending modes of the beams. As a consequence, the

Table 1. Model parameter obtained for brake disc

Figure 2. Various mode shapes for the rotor

Mode Shape

nd

2 bending

3rdbending

4thbending

5thbending

6thbending

7thbending

8thbending

9thbending

Resonance Frequency(Hz)

2,542

4,433

6,879

9,796

13,049

16,532

20,177

23,942

Figure 3. Free-free boundary conditions of the brake pad.

182

S. Lakkam & S. Koetniyom / Songklanakarin J. Sci. Technol. 34 (2), 179-187, 2012

the possibility of a coupled mode in the brake system. The

first bending mode of the pad has a resonance frequency

around 1,790 Hz, while the rotor resonance occurs at 13,049

Hz for the sixth bending mode.

3.4 Analysis for coupled mode under pressure condition

during brake application

Figure 4. Mode shape for brake pad

Table 2. Model parameter obtained for brake pad

Mode Shape

Resonance Frequency(Hz)

1stbending

2ndbending

3rdbending

1790

4953

8828

the brake system works as a loudspeaker, which can generate

a sound pressure during coupling mode between pad and

rotor. Therefore, the mode shape of the 3D rotor model is

compared with the model shape of the 3D pad model in order

to identify the coupling conditions. Classically, the resonance

frequencies of both rotor and brake pad are significantly difference. The relation of the two modes between rotor and

pad occurs when the brake system works under pressure and

temperature. In this situation, the stiffness of the pad is

increased moving the resonance to higher frequencies as

shown in Figure 5.

To analyze for coupled modes between rotor and pad

model with their geometry, it can be noticed that the first

bending mode of the brake pad and the sixth bending mode

of the rotor can be coupled. This coupling mode is based on

the same wave length at 120 and 138 mm in both pad and

rotor, respectively (see Figure 6). Thus, there is a wavelength

coincidence between pad and disc in this situation, leading to

In previous analysis, the bending modes of pad and

rotor are possible to vibrate together under pressure condition. Therefore, in a simulation the pad model should be

excited under pressure and constrained on the friction surface

area. In this case, it is possible for the rotor to vibrate and

transfer the vibration to the pad. At higher pressure conditions, the rotor and pad modes start vibrating in the same

phase. In this situation, nodes of elements in both pad and

rotor models are assumed not to be rotated during analysis.

But they remained in the same position along the rotor diameter. For this reason, the boundary and load conditions are

shown as Figure 7 in which pad surface is constrained and

the back plate is applied with a pressure of 1 MPa under 30C

reference temperature. As a consequence, the friction mechanism was not taken into account. Thus, the input energy

introduced by the friction between pad and rotor is replaced

by the excitation from frequency response of the brake

system.

3.5 Analysis for coupled mode with the damping patch under

pressure condition during brake application

The simplest pad model covered with a damping patch

is schematically shown in Figure 8. The model includes the

back pad and the damping patch which consists of the constraining layer and the viscoelastic layer. Both constraining

layer and viscoelastic core layer have the same width as the

back pad. The contact model between the back pad and

Figure 6. Wave length coincidence between disc and pad

Figure 5. Influence of pressure on modes of pad and disc (Triches

et al., 2004).

Figure 7. Conditions of simulation under pressure

S. Lakkam & S. Koetniyom / Songklanakarin J. Sci. Technol. 34 (2), 179-187, 2012

Figure 8. Constrained layer damping

viscoelastic layer should be unilateral. Thus, normal pressure

equals zero if nodes of contact between the back pad and

viscoelastic layer model is separated. In addition, gaps

between them are load-dependent. Consequently, this analysis has a nonlinear load condition and the area of contact also

depends on the applying load. The integrated global strain

energy of the pad can also be investigated from its deformed

shape of model.

4. Conceptual study

4.1 Strain energy

For the rectangular coordinate system, evaluating the

work done by stresses in x direction x on either side of the

element, it noted that each stress acts through a different

displacement. The net work done on the element by forcing

all of stresses in the rectangular coordinate system (dx dy

dz) is

dU x d x dxdydz

(1)

In the case in which x, y and z act simultaneously,

the total work done by these normal stresses is simple. Thus,

the total strain energy per volume is

1

(2)

y y

z z

2 x x

Because the work done by shear stress, xy accompanying perpendicular strains yz and xz is zero, the total strain

energy density attributable to shear alone is found by superposition of three terms identical in form with Equation 2:

u

1

yz yz

xz xz

2 xy xy

(3)

As mentioned in a general state of stress, the strain

energy density is found by adding Equation 2 and 3 (Ugural

et al., 1995)

u

1

y y

z z

xy xy

yz yz

xz xz

2 x x

(4)

4.2 Influence of strain energy to damping ratio for the brake

pad system

To achieve optimization of the constrained layer damp-

183

ing patch position, only strain energy from simulation can be

used in order to investigate vibration behavior for the brake

pad system. This is because damping cannot be obtained from

the computational results. But, it can be taken from the modal

testing. Therefore, correlation between strain energy from

simulation and damping ratio from experiment should be

investigated in order to optimize vibration of the brake pad

from strain energy using only simulation.

To find out the damping ratio of brake pad with damping patch, the vibration of the constrained layer damping

patch position is performed by using a vibration test. Four

different types of geometry with the constrained layer damping patch position such as no damping patch, full damping

patch, two-side damping patch and three-part damping patch

are illustrated in Table 3.

From testing, the experimental result reveals that these

resonances from the first bending mode are slightly the same

around 2.2 kHz with a damping ratio ranging from 0.0054 to

0.0189, respectively as shown in Table 4. For the simulation

result using FEM, there are 1.20104 to 4.29104 nodes and

5.79103 to 1.85103 elements using a tetrahedron element

type and the four different types of pad geometry are modeled

as shown in Table 5.

As a result of the simulation, it reveals that the bending mode is dominated by shear strain from viscoelastic

materials. The comparison of the shear strain density (in the

y-z and x-z planes) of the viscoelastic layer from different

positions of the constrained layer damping patch is shown in

Figure 9. These results are related to the global strain energy

of the pad system (see Figure 10). Nevertheless, strain energy

density per damping area indicates that three-part geometry

can reduce strain energy more than the two-side geometry as

shown in Figure 11. This is because the shear strain energy at

the middle area is more than that of other areas with a less

amount of vibration.

Table 3. Position of the constrained layer damping patch for

modal testing

184

S. Lakkam & S. Koetniyom / Songklanakarin J. Sci. Technol. 34 (2), 179-187, 2012

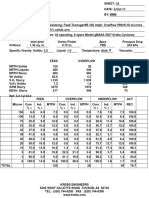

Table 4. Experimental results of the constrained layer damping patch

for vibration testing

No.

1

2

3

4

Constrained Layer

Damping Patch

No Damping Patch

Full Geometry

Two-side Geometry

Three-part Geometry

Natural Frequency,

fn (Hz)

Damping Ratio,

D

2,264

2,258

2,233

2,233

0.0054

0.0189

0.0055

0.0109

Table 5. Position of the constrained layer damping patch for

simulation

Figure 9. Simulation results for shear elastic strain of viscoelastic

layer (in y-z and x-z planes)

Figure 10. Simulation results for integrated global strain energy density of the viscoelastic layer

From the experimental results in Table 4 and simulation results in Figure 9, 10, and 11 it can be concluded that

damping ratios are in-proportional to the strain energy of the

viscoelastic layer. Thus, these techniques can be used as

basic knowledge for the optimization of the constrained layer

damping patch in the next step in order to minimize strain

energy for vibration and noise of the brake system.

5. Investigation of vibration properties and geometry for

constrained layer damping

In the following, vibration properties and parameters

of the geometry from the simple pad model under viscoelas-

Figure 11. Simulation results for strain energy density per damping

area (calculated by global strain energy divided by area)

of the viscoelastic layer

185

S. Lakkam & S. Koetniyom / Songklanakarin J. Sci. Technol. 34 (2), 179-187, 2012

tically damped systems are desirable to carry out parametric

investigations, which dominate on the vibration response of

the pad structure. The strain energy density equation of the

simple pad model, Equation 4, is calculated from deformation

results. The basis simulation results, the deformation of the

pad are investigated. OEM material properties of the overall

brake system from a Toyota PPV are used for the simulations

as shown in Table 6.

5.1 Variation in the elastic modulus of the viscoelastic system

The integrated global strain energies of the pad from

the variation in the elastic moduli, Ev, of the viscoelastic

system between 0.3, 1.3, 2.3 and 3.3 MPa are displayed in

Figure 12. In this parametric study, the thicknesses of both

constraining layer and damping layer are kept constant at hv

= 0.03 mm and hc = 0.3 mm, respectively. It can be demonstrated that viscoelastic elastic modulus plays a much more

crucial role, not only in the strain energy density, but also in

the resonant frequency of the brake pad system. A lower

elastic modulus tends to reduce the resonant frequency and

the optimization of viscoelastic strain energy is 2.3 of the

viscoelastic elastic modulus. However, this is due to the fact

that pad manufacturers are unable to produce lower elastic

moduli of the pad. It is then estimated from the results that

there is an optimal value of the elastic modulus for the

viscoelastic layer to maintain a minimization strain energy

density on the pad system.

5.2 Variation of viscoelastic layer thickness

The comparison of the integrated global strain energy

density of the pad using different thicknesses for the viscoelastic layer is given in Figure 13. It can be seen that lower

strain energy density can be achieved in a system by increasing the thickness of viscoelastic layer. However, it is also

evident that this decrease in strain energy density is not a

linear function of thickness. If the viscoelastic layer thickness

is too high the strain energy density can be raised. For the

variation of the viscoelastic thickness no significant change

of the resonant frequency of the pad is expected. It is then

estimated that an optimal value of the viscoelastic layer thickness exists for a minimial strain energy density on pad system.

5.3 Variation of the constrained layer damping patch position

The position of the constrained layer damping patch

is divided into six patterns based on the propensity of the

strain energy, such as no damping patch, full damping patch,

Table 6. OEM part specifications

Part name

Rotor

Friction material Back plate Viscoelastic layer Constraining layer

Mechanical Properties

Elastic modulus(Pa)

Poissons ratio

Density(kg/m3)

220109

0.3

8000

3109

0.23

2750

210109

0.3

7800

1.361106

0.39

1000

200109

0.3

7000

Thermal properties

Thermal expansion(/K)

Thermal conductivity(W/mK)

Specific heat (J/kgK)

1.210-5

45

510

2.06

749

1.210-5

52

486

0.189

1535

1.1710-5

51.9

486

12

0.03

0.3

Geometry

Thickness(mm)

Figure 12. Integrated global strain energy density of the viscoelastic

layer with various the viscoelastics elastic modulus

Figure 13. Integrated global strain energy density of the viscoelastic

layer with a variation of the viscoelastic layer thickness

186

S. Lakkam & S. Koetniyom / Songklanakarin J. Sci. Technol. 34 (2), 179-187, 2012

hole damping patch, finned damping patch, two-side damping patch, and a middle geometry, which are 1.20104 to

5.90104 nodes and 5.79103 to 29.12103 elements, using a

tetrahedron element type as shown in Table 7.

A comparison of the shear strain densities (in y-z

plane, x-z plane) of the viscoelastic layer from different positions of the constrained layer damping patch under pressure

conditions is show in Figure 14. These results are related to

the global strain energy under pressure conditions of the pad

system (see Figure 15). Nevertheless, Figure 16 shows the

same area for different patterns of the hole, two-side and

middle geometry. It can be seen that the smallest strain energy

density can be achieved by a full geometry of the constrained

layer damping patch in the system. Furthermore, a comparison between patterns with an equal area damping reveals

that the middle geometry provides the lowest strain energy

density or high area efficiency that induces mode shape in the

pad. This is because the cutoff area at the hole in the pad is

pressed by the piston which has a small amount of vibration.

Since the strain energy density of the viscoelastic layer

can be calculated through the integration for constituting the

deformation shape, the broadband displacement of the pad

is related to the physical and geometrical parameters of the

pad itself and the viscoelastic and constraining layers. Parametric studies are preformed to recognize the important

parameters of the constrained layer damping, which affect significantly the strain energy density of the damped pad. The

results show that the strain energy density of the viscoelas-

Table 7. Various position of the constrained layer damping

patch

Figure 14. Shear elastic strain of the viscoelastic layer (in y-z and

x-z planes) with various positions of the constrained

layer damping patch

Figure 15. Integrated global strain energy density of viscoelastic

layer with various positions of the constrained layer

damping patch

Figure 16. Area efficiency (calculated by strain energy divided by

area) of the constrained layer damping patch position

S. Lakkam & S. Koetniyom / Songklanakarin J. Sci. Technol. 34 (2), 179-187, 2012

tically damped pad is sensitive to the position/geometry of

the constrained layer damping patch and the viscoelastic

elastic modulus more than to other parameters. Thus, these

techniques can be used as a basic knowledge for the optimization of the constrained layer damping treatment for strain

energy minimization of vibration and noise of the brake

system.

6. Conclusion

This research reveals the overall results of the experimental work and simulation. For experimental analysis from

modal testing, it can be found that the influence of the strain

energy to the damping ratio of a brake pad system is represented in a brake noise reduction method. According to

the simulation results, the strain energy density of the viscoelastically damped pad is sensitive to the position/geometry

of the constrained layer damping patch and the viscoelastic

elastic modulus more than to other parameters. The optimization of the constrained layer damping for strain energy minimization of vibrating pads depends on the position of the

shape of the damping patch. These data can guide to specify

the position of the constrained layer damping patch under

pressure conditions.

Acknowledgments

The authors are grateful for the financially support

for the experimental work from Compact International (1994)

Co., Ltd. and appreciative instrument support from King

Mongkuts University of Technology North Bangkok. Also,

the authors would like to thank the organizing committee of

Songklanakarin J Sci Technol for providing the opportunity

to present this work.

References

El-Butch, A.M.A. 2000. Evaluation of friction materials tribological properties and their effect on the dynamic

response of disc-brake systems. Proceedings of the

International Conference on Brakes 2000 Automotive

Braking-Technologies for the 21th Century, Leeds,

UK, July 11-12, 2000, 51-60.

Eriksson, M., Bergman, P. and Jacobson, S. 2000. A study of

inhibition of disc-brake squeal. Proceedings of the

International Conference on Brakes 2000 Automotive

Braking-Technologies for the 21th Century, Leeds,

UK, July 11-12, 2000, 29-37.

187

Fieldhouse, J.D. 2000. A study of the interface pressure distribution between pad and rotor, the co-efficient of

friction and caliper mounting geometry with regard to

brake noise. Proceedings of the International Conference on Brakes 2000 Automotive Braking-Technologies for the 21th Century, Leeds, UK, July 11-12, 2000,

3-18.

Flint, J. 2000. Modeling of high frequency disc-brake squeal.

Proceedings of The International Conference on

Brakes 2000 Automotive Braking-Technologies for the

21th Century, Leeds, UK, July 11-12, 2000, 39-50.

Heppes, P. 2000. Brake squeal reduction by the design of the

interface caliper-friction pads-brake shoe holder. Proceedings of The International Conference on Brakes

2000 Automotive Braking-Technologies for the 21th

Century, Leeds, UK, July 11-12, 2000, 29-38.

Liu, P., Zheng, H., Cai, C., Wang, Y.Y., Lu, C., Ang, K.H. and

Liu, G.R. 2007. Analysis of disc brake squeal using the

complex eigenvalue method. Applied Acoustics. 68,

603615.

Nack, W.V. 1999. Brake squeal analysis by finite elements and

comparisons to dyno results. Proceedings of the 1999

American Society of Mechanical Engineers (ASME)

Design Engineering Technical Conference, Las Vegas,

Nevada, U.S.A., Sep. 12-15, 1999, DETC99/DFM-8923.

Ouyang, H., Mottershead, J.E., Cartmell, M.P. and Brookfield,

D.J. 1999. Friction-induced vibration of an elastic slider

on a vibrating disc. International Journal of Mechanical Sciences. 41, 325-336.

Shin, K., Brennan, M.J., Oh, J.-E. and Harris, C.J. 2002. Analysis of disk brake noise using a two-degree-of-freedom

model. Journal of Sound and Vibration. 254, 837848.

Triches, M., Gerges, N.Y. and Jordan, R. 2004. Reduction of

squeal noise from disc brake systems using constrained

layer damping. Journal of the Brazilian Society of

Mechanical Sciences and Engineering. 26, 476-498.

Ugural, A.C. and Fenster, S.K. 1995. Advanced Strength and

Applied Elasticity, Prentice-Hall PTR, New York,

U.S.A., pp. 77-79.

Zhen, H., Cai, C. and Tan, X.M. 2004. Optimization of partial

constrained layer damping treatment for vibrational

energy minimization of vibrating beams. Computers

and Structures. 82, 2493-2507.

Anda mungkin juga menyukai

- Irjet-V8i12267 2Dokumen7 halamanIrjet-V8i12267 2Om SinghBelum ada peringkat

- BI31199203Dokumen5 halamanBI31199203Dr-Nouby Mahdy GhazalyBelum ada peringkat

- The Influence of Pad'S Thickness On Contact Pressure Distribution in Disc Brake SystemDokumen12 halamanThe Influence of Pad'S Thickness On Contact Pressure Distribution in Disc Brake SystemOday IbraheemBelum ada peringkat

- A11v26n3 PDFDokumen9 halamanA11v26n3 PDFLoredana MagdaBelum ada peringkat

- Brake Squeal PaperDokumen7 halamanBrake Squeal PaperjoshibecBelum ada peringkat

- Parametricstudiesofdiscbrakesquealusing PDFDokumen16 halamanParametricstudiesofdiscbrakesquealusing PDFRajiv SarkarBelum ada peringkat

- Tyre Cavity ResonanceDokumen11 halamanTyre Cavity ResonanceArjunBelum ada peringkat

- Determination of Heat Transfer Coefficient of Brake Rotor Disc Using CFD SimulationDokumen9 halamanDetermination of Heat Transfer Coefficient of Brake Rotor Disc Using CFD SimulationIAEME PublicationBelum ada peringkat

- Brake Disc Modal Behaviour: January 2018Dokumen8 halamanBrake Disc Modal Behaviour: January 2018Ashwin KumarBelum ada peringkat

- Optimization Design and Performance Analysis of Vehicle Powertrain Mounting SystemDokumen13 halamanOptimization Design and Performance Analysis of Vehicle Powertrain Mounting SystemAbdurahman MuhammadBelum ada peringkat

- Reduction of Squeal Noise From Disc Brake Systems Using Constrained Layer DampingDokumen9 halamanReduction of Squeal Noise From Disc Brake Systems Using Constrained Layer DampingMuhammad M ElhafidBelum ada peringkat

- Thermal Deformation Analysis of Automotive Disc Brake SquealDokumen26 halamanThermal Deformation Analysis of Automotive Disc Brake SquealNg Guo LiangBelum ada peringkat

- Rolling Ressistance of Truck TireDokumen8 halamanRolling Ressistance of Truck TiregdanonBelum ada peringkat

- Budak tmt07Dokumen29 halamanBudak tmt07abdollahzadehBelum ada peringkat

- 2 Design and Optimisation of Disc Brake RotorDokumen12 halaman2 Design and Optimisation of Disc Brake Rotorankush belkarBelum ada peringkat

- Operational Modal Analysis of Tyre Road Interaction Using Abaqus Explicit and Operational Modal AnalysisDokumen14 halamanOperational Modal Analysis of Tyre Road Interaction Using Abaqus Explicit and Operational Modal AnalysismatmeanBelum ada peringkat

- Tribology in Industry: Aliyaa Q. Mohammed, Ihsan Y. Hussain, Oday I. AbdullahDokumen9 halamanTribology in Industry: Aliyaa Q. Mohammed, Ihsan Y. Hussain, Oday I. AbdullahOday Ibraheem ABdullahBelum ada peringkat

- A Brief Review On Modeling Approaches of Friction Dampers Used in TurbomachineryDokumen13 halamanA Brief Review On Modeling Approaches of Friction Dampers Used in TurbomachineryUtku Arda TöreBelum ada peringkat

- Dymenic DesignDokumen15 halamanDymenic DesignBipin PatelBelum ada peringkat

- A Reduced-Scale Brake Dynamometer For Friction Characterization PDFDokumen7 halamanA Reduced-Scale Brake Dynamometer For Friction Characterization PDFashwaniBelum ada peringkat

- 10 11770954407019845723 PDFDokumen11 halaman10 11770954407019845723 PDFfoufouaBelum ada peringkat

- Review PaperDokumen24 halamanReview Papergamas141200Belum ada peringkat

- (Disque) A Note On Safety-Relevant Vibrations Induced by Brake SquealDokumen6 halaman(Disque) A Note On Safety-Relevant Vibrations Induced by Brake SquealAhmed GHORBELBelum ada peringkat

- Study of Thermal Analysis of Disc Brake Rotor For Different DISC BrakesDokumen9 halamanStudy of Thermal Analysis of Disc Brake Rotor For Different DISC Brakes刘牛Belum ada peringkat

- Friction Behavior of Clutch Facing Using Pin On-Disk TestDokumen6 halamanFriction Behavior of Clutch Facing Using Pin On-Disk TestAbisha JeffrinBelum ada peringkat

- Automotive Chapter OneDokumen8 halamanAutomotive Chapter OneGabriel AgyemangBelum ada peringkat

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDokumen12 halamanIjesrt: International Journal of Engineering Sciences & Research Technologyatika kabouyaBelum ada peringkat

- Finite Element ModellingDokumen15 halamanFinite Element ModellingsiritapeBelum ada peringkat

- Pengaruh Bahan Kampas Rem Terhadap Respon Getaran Pada Sistem Rem CakramDokumen7 halamanPengaruh Bahan Kampas Rem Terhadap Respon Getaran Pada Sistem Rem CakramReynold RezaBelum ada peringkat

- Abolhasan Giashi-PaperDokumen11 halamanAbolhasan Giashi-Paperf20202281Belum ada peringkat

- Measurements Lip TreadDokumen12 halamanMeasurements Lip TreadsiritapeBelum ada peringkat

- Vibration Isolation With Clutch Disk Pre-Damper Mechanism For The Idle Rattle PhenomenonDokumen18 halamanVibration Isolation With Clutch Disk Pre-Damper Mechanism For The Idle Rattle PhenomenonTuna RefaioğluBelum ada peringkat

- 2006 Degenstein Fisita PDFDokumen12 halaman2006 Degenstein Fisita PDFamir8100Belum ada peringkat

- Zhou Et Al 2019 Vibration and Noise Characteristics of A Gear Reducer Under Different Operation ConditionsDokumen18 halamanZhou Et Al 2019 Vibration and Noise Characteristics of A Gear Reducer Under Different Operation ConditionsGanesh KCBelum ada peringkat

- LECTURA 2 Bortoleto2013Dokumen8 halamanLECTURA 2 Bortoleto2013Victor Manuel CastañedaBelum ada peringkat

- SPE/IADC 163420 Drillstring Mechanics Model For Surveillance, Root Cause Analysis, and Mitigation of Torsional and Axial VibrationsDokumen14 halamanSPE/IADC 163420 Drillstring Mechanics Model For Surveillance, Root Cause Analysis, and Mitigation of Torsional and Axial Vibrationscarloszapata1Belum ada peringkat

- Tribology International: M. Amarnath, I.R. Praveen KrishnaDokumen11 halamanTribology International: M. Amarnath, I.R. Praveen KrishnaM.ThirunavukkarasuBelum ada peringkat

- Structural and Thermal Analysis of Brake Disc Rotor Using Different MaterialsDokumen10 halamanStructural and Thermal Analysis of Brake Disc Rotor Using Different MaterialsIJRASETPublicationsBelum ada peringkat

- Brake SquealDokumen10 halamanBrake Squealsharanmit2039Belum ada peringkat

- Influence of The Steel Plate On The Friction Behavior of Automotive Wet Disk ClutchesDokumen14 halamanInfluence of The Steel Plate On The Friction Behavior of Automotive Wet Disk ClutchesIdris EpBelum ada peringkat

- Design and Analysis of Disc BrakDokumen54 halamanDesign and Analysis of Disc Braksrivc1988Belum ada peringkat

- Measurement 2015 PDFDokumen13 halamanMeasurement 2015 PDFM.ThirunavukkarasuBelum ada peringkat

- Vibration Mechanism of A Mistuned Bladed-Disk: Y.J. Yan, P.L. Cui, H.N. HaoDokumen14 halamanVibration Mechanism of A Mistuned Bladed-Disk: Y.J. Yan, P.L. Cui, H.N. HaoZain Ul Islam ButtBelum ada peringkat

- Mathematical Model For Torsional Vibration Analysis in Internal Combustion EnginesDokumen6 halamanMathematical Model For Torsional Vibration Analysis in Internal Combustion Enginesstefanovicana1Belum ada peringkat

- 1989 - Griffin - NASAreviewDokumen22 halaman1989 - Griffin - NASAreviewChiara GastaldiBelum ada peringkat

- Lubricants 06 00107Dokumen17 halamanLubricants 06 00107Tomas DanelonBelum ada peringkat

- Effects of Disk Geometry On Strength of A Centrifugal Compressor Impeller For A High Pressure Ratio TurbochargerDokumen8 halamanEffects of Disk Geometry On Strength of A Centrifugal Compressor Impeller For A High Pressure Ratio TurbochargerjswxieBelum ada peringkat

- Wes 6 367 2021Dokumen10 halamanWes 6 367 202122143141Belum ada peringkat

- 2008 - A Finite Element Approach For The Simulation of Tire Rolling NoiseDokumen20 halaman2008 - A Finite Element Approach For The Simulation of Tire Rolling NoiseGuilherme Henrique GodoiBelum ada peringkat

- Tribology in Industry: H.P. Khairnar, V.M. Phalle, S.S. ManthaDokumen13 halamanTribology in Industry: H.P. Khairnar, V.M. Phalle, S.S. ManthaBrunoBelum ada peringkat

- Damping in A Rolling Bearing Arrangement-SkfDokumen7 halamanDamping in A Rolling Bearing Arrangement-Skfmick.pride81Belum ada peringkat

- Introduction To CNCDokumen8 halamanIntroduction To CNCharshBelum ada peringkat

- Stability Analysis With An NVH Minimal Model For BDokumen22 halamanStability Analysis With An NVH Minimal Model For Bdamienky.2024Belum ada peringkat

- Damage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingDokumen8 halamanDamage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingMa RcoBelum ada peringkat

- 12 Steady PDFDokumen12 halaman12 Steady PDFMichael ZhaoBelum ada peringkat

- Topological Optimization of Automobile Rotor Disk Brake: Vipul Matariya, Hiren PatelDokumen5 halamanTopological Optimization of Automobile Rotor Disk Brake: Vipul Matariya, Hiren PatelEmir EsimBelum ada peringkat

- Static/dynamic Contact FEA and Experimental Study For Tooth Profile Modification of Helical GearsDokumen9 halamanStatic/dynamic Contact FEA and Experimental Study For Tooth Profile Modification of Helical Gearsanmol6237Belum ada peringkat

- Vibrational Analysis of Flexible Coupling by Considering UnbalanceDokumen11 halamanVibrational Analysis of Flexible Coupling by Considering UnbalanceMuhammad TabishBelum ada peringkat

- Automotive Brake Squeal Analysis Using A Complex Modes Approach 2005Dokumen1 halamanAutomotive Brake Squeal Analysis Using A Complex Modes Approach 2005SIMULIACorpBelum ada peringkat

- Engine Modeling A KeromnesDokumen42 halamanEngine Modeling A KeromnesIvan GrujicBelum ada peringkat

- Coupled Thermal Stress Analysis SeminarDokumen30 halamanCoupled Thermal Stress Analysis Seminarmanjunathbagali100% (1)

- Citroen DS3 Owner HandbookDokumen233 halamanCitroen DS3 Owner HandbookIvan GrujicBelum ada peringkat

- HevDokumen14 halamanHevjungdjudfBelum ada peringkat

- Wood& ArmerDokumen9 halamanWood& ArmerthirumalaichettiarBelum ada peringkat

- Circular Motion SolDokumen47 halamanCircular Motion SolABCABCBelum ada peringkat

- Base Plate Design - HiltiDokumen38 halamanBase Plate Design - HiltiVictor IkeBelum ada peringkat

- ASME PTC 30-1991 Air Cooled Heat ExchangersDokumen19 halamanASME PTC 30-1991 Air Cooled Heat ExchangersShanBelum ada peringkat

- Chapter 4-Lateral Earth Pressure-09Dokumen14 halamanChapter 4-Lateral Earth Pressure-09Alexander AlexanderBelum ada peringkat

- Punching Shear PDFDokumen13 halamanPunching Shear PDFmohamedadel100Belum ada peringkat

- Point-to-Point Trajectory Generation Under Joint Constraints For Industrial RobotsDokumen9 halamanPoint-to-Point Trajectory Generation Under Joint Constraints For Industrial RobotsInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- IK CAPE Equations PDFDokumen41 halamanIK CAPE Equations PDFJoseCastilhoBelum ada peringkat

- Geomechanical Characterisation of Unconventional Reservoir 1669547621Dokumen7 halamanGeomechanical Characterisation of Unconventional Reservoir 1669547621Mohamed AbbasBelum ada peringkat

- Erdenet Concentrate Desliming - Alternate gMAX4 Simulation PDFDokumen1 halamanErdenet Concentrate Desliming - Alternate gMAX4 Simulation PDFolziitulga batboldBelum ada peringkat

- Fluid Properties 1Dokumen37 halamanFluid Properties 1Hamza AslamBelum ada peringkat

- Cambridge International Advanced Subsidiary and Advanced LevelDokumen16 halamanCambridge International Advanced Subsidiary and Advanced LevelCallie Jia LiBelum ada peringkat

- 08 - Bottom Stability AnalysisDokumen7 halaman08 - Bottom Stability AnalysisDang Dinh ChiBelum ada peringkat

- MECH 343 Lab 3 ReportDokumen32 halamanMECH 343 Lab 3 ReportYousef MeguidBelum ada peringkat

- Definition of Head and Its Units - Kinetic Head - Potential Head - Pressure Head - Total Head - Civil Engineering TermsDokumen1 halamanDefinition of Head and Its Units - Kinetic Head - Potential Head - Pressure Head - Total Head - Civil Engineering TermsMalik Hamid50% (2)

- First Semester Engineering Degree Examination: Subject Title 21PHY12/22Dokumen3 halamanFirst Semester Engineering Degree Examination: Subject Title 21PHY12/22Nanditha OBelum ada peringkat

- Physics Class XII Formula All in One (Formula SH - Pfapasu5sj7gorhmns7qDokumen41 halamanPhysics Class XII Formula All in One (Formula SH - Pfapasu5sj7gorhmns7qSaurav singh MohantaBelum ada peringkat

- P P W V: MEEN 310-Thermodynamics II Exam 1 Equation SheetDokumen5 halamanP P W V: MEEN 310-Thermodynamics II Exam 1 Equation SheetmikemcchezzBelum ada peringkat

- Assignment Physics 01 012022Dokumen2 halamanAssignment Physics 01 012022Trương Đức HiếuBelum ada peringkat

- Ca4682 Chapter02 PDFDokumen32 halamanCa4682 Chapter02 PDFMk2Belum ada peringkat

- Design and Analysis of Al-6081 T6 PistonDokumen9 halamanDesign and Analysis of Al-6081 T6 PistonIJIRSTBelum ada peringkat

- STRUKTUR GABLE FRAME BAJA OKDokumen26 halamanSTRUKTUR GABLE FRAME BAJA OKpriyadiBelum ada peringkat

- Eccentric Beam Column Connections Ci 2004 138Dokumen5 halamanEccentric Beam Column Connections Ci 2004 138kp21100% (2)

- Concrete Compressive StrengthDokumen4 halamanConcrete Compressive StrengthklynchelleBelum ada peringkat

- Rcp2Cr-Rt Rcp2W-Rt: Cleanroom Dust-proof/Splash-proofDokumen16 halamanRcp2Cr-Rt Rcp2W-Rt: Cleanroom Dust-proof/Splash-proofhoangnuceBelum ada peringkat

- Kinematics - HW 1Dokumen5 halamanKinematics - HW 1Julie MaBelum ada peringkat

- CM1Dokumen16 halamanCM1WASHIPONG LONGKUMER 2147327Belum ada peringkat

- Soil-Pile-Bridge Seismic Interaction KinematicDokumen24 halamanSoil-Pile-Bridge Seismic Interaction KinematicJustine NewmanBelum ada peringkat

- PENG 219 - Production Engineering: Vahid AtashbariDokumen45 halamanPENG 219 - Production Engineering: Vahid AtashbariGilbertBelum ada peringkat

- General Physics1: Quarter 1 - Module 1: Title: Inertial Frame of ReferenceDokumen24 halamanGeneral Physics1: Quarter 1 - Module 1: Title: Inertial Frame of ReferenceDiana Silva HernandezBelum ada peringkat

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDari EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindBelum ada peringkat

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveDari EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveBelum ada peringkat

- Cyber War: The Next Threat to National Security and What to Do About ItDari EverandCyber War: The Next Threat to National Security and What to Do About ItPenilaian: 3.5 dari 5 bintang3.5/5 (66)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityDari EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityPenilaian: 5 dari 5 bintang5/5 (1)

- Algorithms to Live By: The Computer Science of Human DecisionsDari EverandAlgorithms to Live By: The Computer Science of Human DecisionsPenilaian: 4.5 dari 5 bintang4.5/5 (722)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldDari EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldPenilaian: 4.5 dari 5 bintang4.5/5 (55)

- Alibaba: The House That Jack Ma BuiltDari EverandAlibaba: The House That Jack Ma BuiltPenilaian: 3.5 dari 5 bintang3.5/5 (29)

- Generative AI: The Insights You Need from Harvard Business ReviewDari EverandGenerative AI: The Insights You Need from Harvard Business ReviewPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyDari EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyPenilaian: 3.5 dari 5 bintang3.5/5 (111)

- Solutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesDari EverandSolutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesBelum ada peringkat

- The AI Advantage: How to Put the Artificial Intelligence Revolution to WorkDari EverandThe AI Advantage: How to Put the Artificial Intelligence Revolution to WorkPenilaian: 4 dari 5 bintang4/5 (7)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyDari EverandChip War: The Quest to Dominate the World's Most Critical TechnologyPenilaian: 4.5 dari 5 bintang4.5/5 (228)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceDari EverandFour Battlegrounds: Power in the Age of Artificial IntelligencePenilaian: 5 dari 5 bintang5/5 (5)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldDari EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldPenilaian: 4.5 dari 5 bintang4.5/5 (107)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessDari EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessBelum ada peringkat

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewDari EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewPenilaian: 4.5 dari 5 bintang4.5/5 (104)

- Python for Beginners: A Crash Course Guide to Learn Python in 1 WeekDari EverandPython for Beginners: A Crash Course Guide to Learn Python in 1 WeekPenilaian: 4.5 dari 5 bintang4.5/5 (7)

- 100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziDari Everand100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziBelum ada peringkat

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesDari EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesPenilaian: 4.5 dari 5 bintang4.5/5 (13)

- AI Prompting Mastery: Strategies and Techniques for Effective PromptingDari EverandAI Prompting Mastery: Strategies and Techniques for Effective PromptingBelum ada peringkat

- The Digital Marketing Handbook: A Step-By-Step Guide to Creating Websites That SellDari EverandThe Digital Marketing Handbook: A Step-By-Step Guide to Creating Websites That SellPenilaian: 5 dari 5 bintang5/5 (6)

- Working with AI: Real Stories of Human-Machine Collaboration (Management on the Cutting Edge)Dari EverandWorking with AI: Real Stories of Human-Machine Collaboration (Management on the Cutting Edge)Penilaian: 5 dari 5 bintang5/5 (5)

- Architects of Intelligence: The truth about AI from the people building itDari EverandArchitects of Intelligence: The truth about AI from the people building itPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Dark Data: Why What You Don’t Know MattersDari EverandDark Data: Why What You Don’t Know MattersPenilaian: 4.5 dari 5 bintang4.5/5 (3)