Test 1with Solution

Diunggah oleh

Aakash GoelDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Test 1with Solution

Diunggah oleh

Aakash GoelHak Cipta:

Format Tersedia

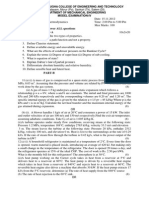

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, PILANI

HYDERABAD CAMPUS

SECOND SEMESTER 2010-2011

APPLIED THERMODYNAMICS (ME C211)

Feb. 07, 2011 (Monday)

11:00 11:50 AM

TEST - 1 (Open Book)

Max. Marks: 60

1. A binary vapour cycle operates with potassium cycle and reheat-regenerative steam cycle. Potassium enters

potassium turbine at 6 atm and 1325 K and leaves the potassium condenser at 950 K. The heat rejected in the

condenser of the potassium cycle is used only for the latent heat gain in the boiler of the steam cycle. Steam at 6

MPa and 5500 C enters the high pressure steam turbine and expands to 500 KPa where a fraction of steam is

extracted to heat the feed water in an open feed water heater and the remainder is supplied to the reheater. The

reheated steam enters the low pressure steam turbine at 500 KPa and 5000 C and expands to the condenser

pressure of 7.5 KPa. For all calculation purposes, all pump works can be assumed negligible and hence equal to

zero. (Note: 1 atm = 101.325 KPa).

(Total = 35 M)

a) Draw the T-s diagram

(7 M)

(2 M)

b) Calculate heat added in potassium cycle (QP1)

(2 M)

c) Heat rejected in potassium cycle (QP2)

(2 M)

d) Work output in potassium cycle (WP)

(3 M)

e) Work output of HP turbine (WS1)

(3 M)

f) Work output in LP turbine (WS2)

(2 M)

g) Heat input in Economizer (QS1)

(2 M)

h) Heat input in Super heater (QS2)

(2 M)

i) Heat input in Reheater (QS3)

(2 M)

j) Mass of potassium circulated per kg of steam (mp)

(3 M)

k) Mass fraction bled off in feed water heater (m1)

l) Net work output (W)

(2 M)

m) Net heat input (Q)

(2 M)

n) Efficiency of the binary cycle

(1 M)

From superheated potassium table at 6 atm and 1325 K

h = 2873.7 kJ/kg

s = 4.4162 kJ/kg.K

v = 0.000411 m3/kg

From saturated potassium tables

T (K) P (atm) vf (m3/kg) hf (kJ/kg) hfg (kJ/kg) hg (kJ/kg) sf (kJ/kg.K) sfg (kJ/kg.K) sg (kJ/kg.K)

950

0.447

0.001462

771.4

1979

2750.4

2.7313

2.0816

4.8129

2. Consider a cogeneration plant where steam enters the turbine at 7 MPa and 5000 C. Some steam is extracted from

the turbine at 500 kPa for process heating. The remaining steam continues to expand to 5 kPa. Steam is then

condensed at constant pressure and pumped to the boiler pressure of 7 MPa. At times of high demand for process

heat, some steam leaving the boiler is throttled to 500 kPa and is routed to the process heater. The extraction

fractions are adjusted so that the steam leaves the process heater as a saturated liquid at 500 kPa. It is

subsequently pumped to 7 MPa and mixed with the remaining steam before being supplied to the boiler. Draw the

appropriate T-s and schematic diagrams for the cogeneration plant.

(5+5 = 10 M)

3. A refrigerator using R-22 operates on an ideal vapour compression cycle between 250 C and 400 C. The mass

flow rate of refrigerant is 0.05 kg/s. Draw the suitable T-s and p-h diagrams. Determine (a) the rate of heat

removal from the refrigerated space, (b) the isentropic discharge temperature using R-22 superheated tables, (c)

the power input to the compressor, (d) the heat rejection to the environment and (e) the COP. (2+4*3+1= 15 M)

Anda mungkin juga menyukai

- Steam ProblemsDokumen10 halamanSteam ProblemsCaro Kan LopezBelum ada peringkat

- Coal-Fired Powerplant Problem Set: Name: Gamboa, Ariel C. SN: 20151157958Dokumen30 halamanCoal-Fired Powerplant Problem Set: Name: Gamboa, Ariel C. SN: 20151157958Ariel GamboaBelum ada peringkat

- Introduction To Chemical Engineering ThermodynamicDokumen3 halamanIntroduction To Chemical Engineering ThermodynamicR SuyaoBelum ada peringkat

- Tugas 2 MS2230 Sem II 18-19 PDFDokumen1 halamanTugas 2 MS2230 Sem II 18-19 PDFHanif MuhammadBelum ada peringkat

- Sheet (3) Regenerative Rankine Cycle A. Review QuestionsDokumen6 halamanSheet (3) Regenerative Rankine Cycle A. Review QuestionsHamadaMohassabBelum ada peringkat

- Availability Analysis: Tutorial QuestionsDokumen2 halamanAvailability Analysis: Tutorial QuestionsJackson TeohBelum ada peringkat

- Addis Ababa UniversityDokumen2 halamanAddis Ababa Universitydeni ebit nugroho100% (1)

- Steam CycleDokumen11 halamanSteam CycleRowin Mark SabornidoBelum ada peringkat

- Sheet 2Dokumen2 halamanSheet 2Ahmed Rabie Abd Elazeem100% (1)

- A1 4Dokumen6 halamanA1 4Mohit PassiBelum ada peringkat

- Tutorial Sheet 6Dokumen2 halamanTutorial Sheet 6Syed YousufuddinBelum ada peringkat

- Problem Set IDokumen2 halamanProblem Set Iİbrahim KaraoğlanBelum ada peringkat

- AEE 4 Basic Thermodynamics Final ExamDokumen2 halamanAEE 4 Basic Thermodynamics Final ExamClint Jefferon C. ActubBelum ada peringkat

- Steam and Rankine Cycle OtDokumen5 halamanSteam and Rankine Cycle OtRegineil JavierBelum ada peringkat

- SP5 Problems SET A B PDFDokumen4 halamanSP5 Problems SET A B PDFNicah Dela Viña BuhiaBelum ada peringkat

- Thermodynamics ProblemsDokumen2 halamanThermodynamics ProblemsAlexander Salado IbrahimBelum ada peringkat

- Applied Thermodynamics Question Bank Unit - 1Dokumen7 halamanApplied Thermodynamics Question Bank Unit - 1Shivansh SudhaBelum ada peringkat

- Assignment 2Dokumen1 halamanAssignment 2Ankit OlaBelum ada peringkat

- Thermo I Set of Questions 2022Dokumen6 halamanThermo I Set of Questions 2022Paa Kwesi ArhinfulBelum ada peringkat

- ETD Model IV QPDokumen2 halamanETD Model IV QPtagoreboopathyBelum ada peringkat

- Coaching Problems 1Dokumen103 halamanCoaching Problems 1nathaniel villanuevaBelum ada peringkat

- Problemario MFCDokumen31 halamanProblemario MFCPonce MrlnBelum ada peringkat

- Thermodynamics Review ProblemsDokumen3 halamanThermodynamics Review ProblemssayanBelum ada peringkat

- Tutorial 1Dokumen4 halamanTutorial 1Anonymous lV8E5mEOBelum ada peringkat

- Tutorial Chapter 1 BoilerDokumen3 halamanTutorial Chapter 1 Boilershresthasamir743Belum ada peringkat

- MPD 2012 - Sheet 3 - Binary and Combined CyclesDokumen3 halamanMPD 2012 - Sheet 3 - Binary and Combined CyclesPeter Raouf100% (1)

- EvaporationDokumen2 halamanEvaporationdanena88100% (1)

- Thermodynamics Question Set ADokumen4 halamanThermodynamics Question Set AVivek NegiBelum ada peringkat

- Thermo QuestionsDokumen3 halamanThermo QuestionsHimanshu VasisthaBelum ada peringkat

- ThermoDokumen2 halamanThermoDOZPanda0% (1)

- Steam Power Plant ExamplesDokumen2 halamanSteam Power Plant ExamplesRicky Fredinansyah100% (1)

- Thermo ProblemsDokumen12 halamanThermo ProblemsElaineBelum ada peringkat

- EMCDokumen1 halamanEMCAditya GurunathanBelum ada peringkat

- Basics of ThermodynamicsDokumen36 halamanBasics of ThermodynamicsYeditha Satyanarayana MurthyBelum ada peringkat

- Microsoft Word - Module 4-Steam Power Plant PDFDokumen51 halamanMicrosoft Word - Module 4-Steam Power Plant PDFJames Tnecniv AlborteBelum ada peringkat

- Assignment 1 MEPPEDokumen5 halamanAssignment 1 MEPPEFrancis Paulo CruzBelum ada peringkat

- 01-Sheet 01Dokumen9 halaman01-Sheet 01samir mohamedBelum ada peringkat

- Question Bank Thermal Engineering UPDATEDDokumen6 halamanQuestion Bank Thermal Engineering UPDATEDIrfan ShaikhBelum ada peringkat

- Mock Test For Chemistry For Engineers 2Dokumen2 halamanMock Test For Chemistry For Engineers 2aramikaelatanBelum ada peringkat

- Tutorial 4Dokumen2 halamanTutorial 4Diego Cuarenta JaureguiBelum ada peringkat

- Probset4. EnergybalancesDokumen4 halamanProbset4. EnergybalancesUmmu Qurratul Aini MansorBelum ada peringkat

- Homework SteamDokumen6 halamanHomework SteamCherry May Basinang-RamosBelum ada peringkat

- DocDokumen5 halamanDoccessareBelum ada peringkat

- Problemario MFCDokumen80 halamanProblemario MFCBassaldua AlfreedBelum ada peringkat

- Boiler Efficiency - (10 Questions)Dokumen3 halamanBoiler Efficiency - (10 Questions)THEOPHILUS ATO FLETCHERBelum ada peringkat

- Improved Steam Plant Examples AUG 2020Dokumen52 halamanImproved Steam Plant Examples AUG 2020Thabang0% (2)

- Thermal Engineering - Department of Mechanical EngineeringDokumen8 halamanThermal Engineering - Department of Mechanical EngineeringPrashant KumarBelum ada peringkat

- Le4 LectureDokumen1 halamanLe4 LectureAsh KetchapBelum ada peringkat

- 082 CH 20Dokumen3 halaman082 CH 20Jagdip ShethBelum ada peringkat

- Tutorial Vapor and Combined Power CyclesDokumen3 halamanTutorial Vapor and Combined Power CyclesShariff Mohamad Fairuz0% (1)

- Thermodynamics Important QuestionsDokumen4 halamanThermodynamics Important QuestionsMaha LakshmiBelum ada peringkat

- Thermodynamics Exams PapersDokumen23 halamanThermodynamics Exams PapersAbdul HafizBelum ada peringkat

- Regenerative Rankine CycleDokumen2 halamanRegenerative Rankine CycleRowin Mark SabornidoBelum ada peringkat

- Sheet #7Dokumen4 halamanSheet #7Iam A gnoomBelum ada peringkat

- Thermodynamics Problem Sheet 2Dokumen4 halamanThermodynamics Problem Sheet 2Amna SaeedBelum ada peringkat

- Thermodynamics QuestionsDokumen4 halamanThermodynamics Questionsprateek vyasBelum ada peringkat

- Oneway Anova CRDDokumen36 halamanOneway Anova CRDAakash GoelBelum ada peringkat

- Machine Learning: BITS PilaniDokumen52 halamanMachine Learning: BITS PilaniAakash GoelBelum ada peringkat

- MicrofluidicsDokumen5 halamanMicrofluidicsAakash GoelBelum ada peringkat

- 2012 Yearbook PDFDokumen3.698 halaman2012 Yearbook PDFAakash GoelBelum ada peringkat

- 21 ST Century FilmsDokumen15 halaman21 ST Century FilmsAakash GoelBelum ada peringkat

- The Verdict DVDRip (Eng) 1982Dokumen107 halamanThe Verdict DVDRip (Eng) 1982Aakash GoelBelum ada peringkat

- SECOND SEMESTER 2017-2018 Course Handout Date: 07.01.2019: Course No. Course Title Instructor-In-ChargeDokumen5 halamanSECOND SEMESTER 2017-2018 Course Handout Date: 07.01.2019: Course No. Course Title Instructor-In-ChargeAakash GoelBelum ada peringkat

- 4 - IC EnginesDokumen19 halaman4 - IC EnginesAakash GoelBelum ada peringkat

- 7 MF F473 - de G531Dokumen2 halaman7 MF F473 - de G531Aakash GoelBelum ada peringkat

- Automotive Technology: BITS PilaniDokumen21 halamanAutomotive Technology: BITS PilaniAakash Goel100% (1)

- Automotive Technology: Spoiler vs. No SpoilerDokumen9 halamanAutomotive Technology: Spoiler vs. No SpoilerAakash GoelBelum ada peringkat

- Casting WorkshopDokumen5 halamanCasting WorkshopAakash GoelBelum ada peringkat

- MFF311 HandoutDokumen2 halamanMFF311 HandoutAakash GoelBelum ada peringkat

- PS II Chronicle I SEM 2017 2018 PDFDokumen676 halamanPS II Chronicle I SEM 2017 2018 PDFSayan BiswasBelum ada peringkat

- Pre-Requisite Updated On 31st July 2017Dokumen30 halamanPre-Requisite Updated On 31st July 2017Aakash GoelBelum ada peringkat

- Napoleon ScreenplayDokumen155 halamanNapoleon ScreenplayAakash GoelBelum ada peringkat

- CS F372: Operating Systems: BITS PilaniDokumen16 halamanCS F372: Operating Systems: BITS PilaniAakash GoelBelum ada peringkat

- Indirect Sourcing Communications Set For Nokia Internal Use - PPT Video Online DownloadDokumen9 halamanIndirect Sourcing Communications Set For Nokia Internal Use - PPT Video Online DownloadAakash GoelBelum ada peringkat

- MFM Machining Topic 1-6 2 3 ShaperDokumen49 halamanMFM Machining Topic 1-6 2 3 ShaperAakash GoelBelum ada peringkat

- 21 Stcentury FilmsDokumen20 halaman21 Stcentury FilmsAakash GoelBelum ada peringkat

- Rise and Fall of TennisDokumen1 halamanRise and Fall of TennisAakash GoelBelum ada peringkat

- Napoleon ScreenplayDokumen155 halamanNapoleon ScreenplayAakash GoelBelum ada peringkat

- Hockey LegendDokumen1 halamanHockey LegendAakash GoelBelum ada peringkat

- Rise and Fall of TennisDokumen1 halamanRise and Fall of TennisAakash GoelBelum ada peringkat

- IpDokumen5 halamanIpAakash GoelBelum ada peringkat

- SachinDokumen1 halamanSachinAakash GoelBelum ada peringkat

- Making The Perfect TeamDokumen5 halamanMaking The Perfect TeamAakash GoelBelum ada peringkat

- 6165XI Physics GravitationDokumen3 halaman6165XI Physics GravitationAakash GoelBelum ada peringkat

- Lakshay 2013 Physics Assignment Rotational MotionDokumen3 halamanLakshay 2013 Physics Assignment Rotational Motionvaibhavm1230% (2)

- Revision Ror The First TermDokumen29 halamanRevision Ror The First TermNguyễn MinhBelum ada peringkat

- Valve Material SpecificationDokumen397 halamanValve Material Specificationkaruna34680% (5)

- K EtaDokumen14 halamanK EtaJosue Teni BeltetonBelum ada peringkat

- Scope: Procter and GambleDokumen30 halamanScope: Procter and GambleIrshad AhamedBelum ada peringkat

- 1A Wound Care AdviceDokumen2 halaman1A Wound Care AdviceGrace ValenciaBelum ada peringkat

- Neopuff PDFDokumen4 halamanNeopuff PDFoechimBelum ada peringkat

- Assignment - Lab Accidents and PrecautionsDokumen6 halamanAssignment - Lab Accidents and PrecautionsAnchu AvinashBelum ada peringkat

- Pengaruh Kualitas Anc Dan Riwayat Morbiditas Maternal Terhadap Morbiditas Maternal Di Kabupaten SidoarjoDokumen9 halamanPengaruh Kualitas Anc Dan Riwayat Morbiditas Maternal Terhadap Morbiditas Maternal Di Kabupaten Sidoarjohikmah899Belum ada peringkat

- Epicor Software India Private Limited: Brief Details of Your Form-16 Are As UnderDokumen9 halamanEpicor Software India Private Limited: Brief Details of Your Form-16 Are As UndersudhadkBelum ada peringkat

- Royal British College IncDokumen5 halamanRoyal British College IncLester MojadoBelum ada peringkat

- Thanks For Visiting Our Page!: Hi Doc!Dokumen15 halamanThanks For Visiting Our Page!: Hi Doc!bey luBelum ada peringkat

- What Is A VolcanoDokumen2 halamanWhat Is A VolcanonatachaBelum ada peringkat

- METHOD STATEMENT FOR INSTALLATION OF Light FixturesDokumen5 halamanMETHOD STATEMENT FOR INSTALLATION OF Light FixturesNaveenBelum ada peringkat

- Interviewing Skill Workshop (KAU)Dokumen54 halamanInterviewing Skill Workshop (KAU)DrKomal KhalidBelum ada peringkat

- Mixed Topic Revision 4Dokumen18 halamanMixed Topic Revision 4YaakkwBelum ada peringkat

- Hope Hospital Self Assessment ToolkitDokumen120 halamanHope Hospital Self Assessment Toolkitcxz4321Belum ada peringkat

- Guinea Pig: Domestication: Basic Species InformationDokumen4 halamanGuinea Pig: Domestication: Basic Species InformationBondBelum ada peringkat

- Laboratory Cold ChainDokumen22 halamanLaboratory Cold ChainEmiBelum ada peringkat

- Fast FashionDokumen9 halamanFast FashionTeresa GonzalezBelum ada peringkat

- Transfer and Business Taxation SyllabusDokumen5 halamanTransfer and Business Taxation SyllabusamqqndeahdgeBelum ada peringkat

- GEC - ReviewerDokumen23 halamanGEC - ReviewerGlycel BagabagonBelum ada peringkat

- Home Composting SystemsDokumen8 halamanHome Composting Systemssumanenthiran123Belum ada peringkat

- RRC Group D Notification 70812Dokumen11 halamanRRC Group D Notification 70812admin2772Belum ada peringkat

- Soal UAS Bahasa Inggris 2015/2016: Read The Text Carefully! Cold Comfort TeaDokumen5 halamanSoal UAS Bahasa Inggris 2015/2016: Read The Text Carefully! Cold Comfort TeaAstrid AlifkalailaBelum ada peringkat

- Chia (Salvia Hispanica L.) Oil Stability Study of The Effect of NaturDokumen7 halamanChia (Salvia Hispanica L.) Oil Stability Study of The Effect of NaturInta Nur IlmiBelum ada peringkat

- 5SDD 71B0210Dokumen4 halaman5SDD 71B0210Merter TolunBelum ada peringkat

- EV Hammer Impact Crusher - ENDokumen8 halamanEV Hammer Impact Crusher - ENKeshav NandaBelum ada peringkat

- Gender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaDokumen53 halamanGender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaADBGADBelum ada peringkat

- Food and Beverage Control Systems Can Help You Introduce The Same Financial Rigour To Your Dining Establishment or Catering Company That YouDokumen11 halamanFood and Beverage Control Systems Can Help You Introduce The Same Financial Rigour To Your Dining Establishment or Catering Company That Younarinder singh saini100% (4)

- Parche CRP 65 - Ficha Técnica - en InglesDokumen2 halamanParche CRP 65 - Ficha Técnica - en IngleserwinvillarBelum ada peringkat