Twinflex20 0106 PDF

Diunggah oleh

binhjukiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Twinflex20 0106 PDF

Diunggah oleh

binhjukiHak Cipta:

Format Tersedia

TWINFLEX 20

FLEXIBLE RUBBER JOINT

FEATURES

High Pressure Application : Twinflex20 is used in pressurized piping systems where noise and vibration

isolation and expansion compensation are necessary. Since the rubber reinforcement with strong chemical

fiber is shaped through newly developed technology, the normal working pressure range is (-0.08Mpa) ~

1.96Mpa (-600mmHg~20kgf/cm2) and bursting pressure is more than 5.39Mpa (55kgf/cm2). Twinflex20

flexible joint is especially suitable for high-pressure application.

Excellent Tightness : Since the rubber face which is fastened to the metal flange is shaped by a new

processs, it has excellent water and air tightness.

Control Unit Integrated Flange : The standard design of Twinflex20 comes with Control-Unit-Integrated

FCD400 flanges. This is a cheaper solution for applications requiring control units than the traditional Back

Plate type. In case of rigidly anchored piping systems where control units may not be needed, ordinary

flanges are also available upon request.

Outstanding Vibration and Noise Absorption : Twin sphere structure significantly reduces vibration and

noise transmission from operating equipment to the piping system because the joints acts as a damperer

which absorbs the greatest percentage of vibration and noise.

Other Advantages :

The packing and gasket are not required.

Applicable both as expansion joint and flexible joint, and also applicable for both purposes concurrently.

Low electrical conductivity.

Mass production makes comparatively low price possible.

APPLICATIONS

Chilled water air conditioning equipment, water pumps, sewerage and sanitary piping systems, etc.

Pressure piping systems for water and warm water used in building equipment and general industrial plants,

etc.

Pump line and turbine lines used for power generation plants, industrial machinery and universal pump

blowers, etc.

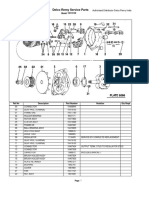

STRUCTURE

No.

1

2

3

4

5

6

7

Parts

Integrated Flanges

Reinforcing Ring

Inside Rubber

Outside Rubber

Reinforcing Fiber

Bolts, Nuts, Washer

Bushing

Materials

Cast Iron (FCD400)

Carbon Steel (SWRH)

Synthetic Rubber

Synthetic Rubber

Synthetic Fiber

Mild Steel (SS400)

Hard Rubber

- Ordinary flange material can be provided to FCD400,

mild steel or SUS304.

- Available flange standards are JIS, ANSI, BS, DIN

and others (drillings).

- Synthetic rubber is EPDM which is the standard

material. (Other kinds of rubber material are

optional.)

- Structure of vacuum ring will be added for alternative

to withstand full vacuum.

TWF20-0106

Dimension and Allowable Movement

Dimension (mm)

Size (mm)

150

200

250

300

Allowable Movement (mm)

Installation Allowance (mm)

A.E.

A.C.

A.M.( o )

10

10

OD2

OD1

T.M.

A.E.

175

212

150

20

20

A.C. A.M.( ) T.M.

30

20

8

200

264

20

20

30

15

200

324

20

20

30

200

372

20

20

30

T.M. = Transverse Movement

200

250

300

A.E. = Axial Elongation

A.C. = Axial Compression

A.M. = Angular Movement

Operating Condition

Max Working Pressure : 20 kgf/cm2 (1.96Mpa)

Negative Pressure :

-600 mmHg. (-0.08Mpa)

Working Temperature : -10oC ~ +80oC

Applicable Fluid :

Water, Sea Water,

Warm Water, Weak Acid,

Weak Alkali, etc.

Control Units

Control units are not required for piping systems with

rigidly anchored supports on both sides of a flexible

joint. The rigidly anchored supports must be capable

of withstanding pressure thrusts generated by the

internal pressure or wide temperature fluctuations.

Control units are always recommended to be used with

Twinflex20 for unanchored piping systems, non-rigidly

anchored system, and piping systems connected to

spring mounted equipment. Furthermore, control units

are always recommended to prevent movements

beyond Twinflex20's limited specification.

Typical Piping Layout Utilizing Expansion Joints

(when equipment and piping are properly anchored)

Notes

1. Information in the above table is for single displacement only. In case of complex displacement, follow the

below expression.

C.EL(C) = A.EL(C) x {1-(A.T.M.-T.M. x A.A.M.-A.M.)}

A.T.M.

A.A.M.

C.EL(C) = Correct Elongation (Compression)

T.M.

= Transverse Movement

A.EL(C) = Allowable Elongation (Compression)

2.

3.

4.

5.

6.

7.

8.

A.A.M. = Allowable Angular Movement

A.T.M.

= Allowable Transverse Movement

A.M.

= Angular Movement

Install the joint within the range of installing allowance. Do not install joints at full limits of all allowable

movement simultaneously.

In order to avoid elongation of the joint by the reaction force resulted from water pressure, fix pipes before

and behind the joint. If the fixing of the pipes is not sufficient, install the tie rods (control unit) to the joints for

protection.

Fix the bolts and nuts on the counter flange side (external side).

When installing the joint, check for cracks on rubber body surface, especially after a long period of storage.

Keep away from heating source when install. Cover the joint with protection sheet to free from any harm of

spark resulted from welding, pre-arcing and grinding near the spot of joint installation.

If oils, fats, organic solvent (e.g. thinner, toluene), acid or alkali are adhered, wipe them off quickly.

Avoid direct exposure of sunlight in case of outdoor piping to prevent aging and deterioration of rubber.

TOZEN (THAILAND) CO., LTD.

TOZEN CORPORATION.

3388/62 18TH FLOOR, SIRINRAT BLDG.,

RAMA IV RD., BANGKOK 10110 THAILAND

TEL : (66) 0-2367-5721-8

FAX : (66) 0-2367-5729, 0-2367-5066

E-MAIL : sales@tozen.co.th

URL : www.tozen.co.th

8-4, ASAHI YOSHIKAWA

SAITAMA 342-008 JAPAN

TEL : 048-993-1030

FAX : 048-993-1038

TWF20-0106

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- 1327 751 102b - AS-Tronic Truck & Bus Repair Manual (10-, 12 - and 16-Speed Version Without ZF-Intarder Repair Level 3)Dokumen122 halaman1327 751 102b - AS-Tronic Truck & Bus Repair Manual (10-, 12 - and 16-Speed Version Without ZF-Intarder Repair Level 3)Сергей Миненко100% (8)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Test Certificate: CM/L-NO:5530357Dokumen10 halamanTest Certificate: CM/L-NO:5530357TARUNKUMARBelum ada peringkat

- Tension PileDokumen81 halamanTension PileVera CupezBelum ada peringkat

- Design CalculationDokumen13 halamanDesign CalculationSunil KumarBelum ada peringkat

- Student Exploration: Air Track: Name: Akshat Date:12/15/20Dokumen9 halamanStudent Exploration: Air Track: Name: Akshat Date:12/15/20Akshat Pant100% (8)

- A Master's Guide To Ship's Piping 2nd EditionDokumen42 halamanA Master's Guide To Ship's Piping 2nd Editiondassi99100% (1)

- 13UP0911RE Technical ProposalDokumen388 halaman13UP0911RE Technical ProposalAlfonso Perez100% (2)

- Piston, Connecting Rod and Cylinder Liner L28/32H: DescriptionDokumen57 halamanPiston, Connecting Rod and Cylinder Liner L28/32H: DescriptionERepublikPolskaBelum ada peringkat

- Singapore BIM Guide V2Dokumen70 halamanSingapore BIM Guide V2woodyjrBelum ada peringkat

- Steam Distribution CourseDokumen79 halamanSteam Distribution CoursebinhjukiBelum ada peringkat

- BS en 13141-7 2004 Ventilation For Buildings PDFDokumen24 halamanBS en 13141-7 2004 Ventilation For Buildings PDFbinhjukiBelum ada peringkat

- F AdaptersDokumen122 halamanF Adaptersxuanphuong2710Belum ada peringkat

- Swirlax BurnerDokumen3 halamanSwirlax BurnerSafeer AbbasBelum ada peringkat

- Service Parts List: Transmission 6422-84 4265557Dokumen47 halamanService Parts List: Transmission 6422-84 4265557Bryan RibeiroBelum ada peringkat

- Demag Vinç BilgileriDokumen28 halamanDemag Vinç BilgileriZahid ArıcıBelum ada peringkat

- Pipe Spacing CalculatorDokumen9 halamanPipe Spacing CalculatorJuan Pablo ApazaBelum ada peringkat

- Att WY CatalogDokumen8 halamanAtt WY CatalogbinhjukiBelum ada peringkat

- Specification FFU (Model 2x4 AH) PDFDokumen3 halamanSpecification FFU (Model 2x4 AH) PDFbinhjukiBelum ada peringkat

- A.O.Smith Catlog Hotwater PDFDokumen10 halamanA.O.Smith Catlog Hotwater PDFbinhjukiBelum ada peringkat

- Valve0114 PDFDokumen14 halamanValve0114 PDFbinhjukiBelum ada peringkat

- Valve0114 PDFDokumen14 halamanValve0114 PDFbinhjukiBelum ada peringkat

- Booster Basics PresentationDokumen49 halamanBooster Basics PresentationbinhjukiBelum ada peringkat

- Design Calculation-Inia-Pergola 1Dokumen10 halamanDesign Calculation-Inia-Pergola 1Glastal EngineersBelum ada peringkat

- PHY Acceleration ProblemsDokumen4 halamanPHY Acceleration Problemsminna1208Belum ada peringkat

- AGA3 1990 AlgorithmDokumen3 halamanAGA3 1990 Algorithmyan2huaBelum ada peringkat

- Ultra - Temp Installation and Maintenance Manual IOM 101.2Dokumen16 halamanUltra - Temp Installation and Maintenance Manual IOM 101.2Abdiel Kadir Martinez MendozaBelum ada peringkat

- Format - CISDokumen8 halamanFormat - CISgopichandallakaBelum ada peringkat

- Liebherr Hs DimensionsDokumen12 halamanLiebherr Hs DimensionsLiebherrBelum ada peringkat

- Liquefied Petroleum Gas Cylinder Level Indicator and Transporting DeviceDokumen105 halamanLiquefied Petroleum Gas Cylinder Level Indicator and Transporting DeviceAyorinde Oladele Tiwalade100% (1)

- Delco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaDokumen2 halamanDelco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaWilson AcostaBelum ada peringkat

- FE700 Installation Manual Echo SounderDokumen58 halamanFE700 Installation Manual Echo SounderNidhin.c.prakashBelum ada peringkat

- Simulink Model For Teaching The 'Stick-Slip' Friction Phenomenon in 'Machine Vibration and Noise' CourseDokumen10 halamanSimulink Model For Teaching The 'Stick-Slip' Friction Phenomenon in 'Machine Vibration and Noise' Courseeko123Belum ada peringkat

- XE145F Presentation AUMDokumen21 halamanXE145F Presentation AUMrudyBelum ada peringkat

- BOOM Camion (165 297)Dokumen133 halamanBOOM Camion (165 297)David BriceñoBelum ada peringkat

- 100 PSV 001 AZ Safety Pressure Valve (Design)Dokumen2 halaman100 PSV 001 AZ Safety Pressure Valve (Design)magdy salehBelum ada peringkat

- Metalworking 24479 Metaalbewerking UKDokumen21 halamanMetalworking 24479 Metaalbewerking UKOmkec DelalićBelum ada peringkat

- Bom - UPLDokumen20 halamanBom - UPLalokbdasBelum ada peringkat

- Ansys Asas 12.1Dokumen4 halamanAnsys Asas 12.1Faizan HabibBelum ada peringkat

- Texturing Methods PDFDokumen4 halamanTexturing Methods PDFAnoop KizhakathBelum ada peringkat

- Air-Floating Oven DryingDokumen8 halamanAir-Floating Oven DryingEdgar KosgeyBelum ada peringkat