BS 3958-4 PDF

Diunggah oleh

Anitha MjDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

BS 3958-4 PDF

Diunggah oleh

Anitha MjHak Cipta:

Format Tersedia

BS 3958-4:

1982

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BRITISH STANDARD

CONFIRMED

DECEMBER 2007

Specification for

Thermal insulation

materials

Part 4: Bonded preformed man-made

mineral fibre pipe sections

UDC 662.998:677.522-462

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:1982

Cooperating organizations

The Refrigeration, Heating and Air Conditioning Standards Committee, under

whose direction this British Standard was prepared, consists of

representatives from the following:

Association of Manufacturers of Domestic

Electricity Supply Industry in England and

Electrical Appliances

Wales*

Association of Consulting Engineers

Heating and Ventilating Contractors

Boiler and Radiator Manufacturers

Association

Association Limited

Hevac Association

British Combustion Equipment

Institute of Energy

Manufacturers Association

Institute of Refrigeration*

British Gas Corporation*

Institution of Gas Engineers*

British Refrigeration and Air Conditioning

Lloyds Register of Shipping

Association*

Manufacturers Association of Radiators and

Building Services Research and Information

Association

Convectors Ltd.

Ministry of Defence

Chartered Institution of Building Services*

National Coal Board

Department of Energy Technology

Society of British Gas Industries

Department of Health and Social Security*

Water-tube Boilermakers Association*

Department of the Environment (PSA)

The organizations marked with an asterisk in the above list, together with the

following, were directly represented on the Technical Committee entrusted

with the preparation of this British Standard:

Albury Laboratories Limited

Eps Association

Asbestos Cement Manufacturers Association

Eurisol (UK) Association of Manufacturers of

Limited

Mineral Fibre Insulation

British Ceramic Research Association

Fibre Building Board Development

British Rubber Manufacturers Association

Gypsum Products Development Association

Cranfield Institute of Technology

Institution of Mechanical Engineers

Department of Industry (National Physical

Process Plant Association

Laboratory)

Royal Institute of British Architects

Department of the Environment (Building

Research Establishment)

This British Standard, having

been prepared under the

direction of the Refrigeration,

Heating and Air Conditioning

Standards Committee, was

published under the

authority of the Board

of BSI and comes

into effect on

30 November 1982

Organization Ltd.

Combustion Engineering Association

Structural Insulation Association

Thermal Insulation Manufacturers and

Department of the Environment (Housing

and Construction)

Suppliers Association (TIMSA)

Thermal Insulations Contractors Association

Energy Industries Council

Yarsley Testing Laboratories Ltd.

Engineering Equipment Users Association

Coopted member

BSI 07-1999

Amendments issued since publication

First published March 1968

First revision November 1982

Amd. No.

The following BSI references

relate to the work on this

standard:

Committee reference RHE/9

Draft for comment 80/74589

ISBN 0 580 12852 0

Date of issue

Comments

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:1982

Contents

Cooperating organizations

Foreword

1 Scope

2 References

3 Definitions

4 Sampling and testing

5 Composition

6 Moisture content

7 Physical requirements

8 Fire hazard (assessment of self-heating hazard)

9 Chemical requirements

10 Standard shapes and sizes

11 Dimensional tolerances

12 External finish

13 Marking

Appendix A Information to be supplied when ordering

Appendix B Method of test for alkalinity

Table 1 Thermal conductivity values

Table 2 Finishes and overlaps

Publications referred to

BSI 07-1999

Page

Inside front cover

ii

1

1

1

1

1

1

1

1

2

2

2

2

2

4

4

1

3

Inside back cover

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:1982

Foreword

This revision of this Part of this British Standard is one of a series published

under the direction of the Refrigeration, Heating and Air Conditioning Standards

Committee to specify requirements for a particular range of insulating materials.

It supersedes the 1968 edition which is now withdrawn.

Mineral fibre insulation is not normally designed or recommended for the support

of loads, therefore no test for compressive strength is included in this Part.

Other Parts of this standard are:

Part 1: Magnesia preformed insulation;

Part 2: Calcium silicate preformed insulation;

Part 3: Metal mesh faced mineral wool mats and mattresses;

Part 5: Bonded mineral wool slabs (for use at temperatures above 50 C);

Part 6: Finishing materials; hard setting composition, self-setting cement

and gypsum plaster.

A British Standard does not purport to include all the necessary provisions of a

contract. Users of British Standards are responsible for their correct application.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

Summary of pages

This document comprises a front cover, an inside front cover, pages i and ii,

pages 1 to 4, an inside back cover and a back cover.

This standard has been updated (see copyright date) and may have had

amendments incorporated. This will be indicated in the amendment table on

the inside front cover.

ii

BSI 07-1999

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:1982

1 Scope

This Part of this British Standard specifies

composition, moisture content, physical and

chemical requirements for bonded preformed

man-made mineral fibre pipe sections, generally for

use at elevated temperatures. Ceramic fibres are

excluded.

Information to be supplied when ordering is given in

Appendix A.

2 References

The titles of the publications referred to in this

standard are listed on the inside back cover.

3 Definitions

For the purposes of this Part of this British

Standard, the definitions given in BS 874, BS 2972,

BS 3533 and BS 5422 apply.

4 Sampling and testing

Sampling and testing shall be in accordance with

the appropriate clause in BS 2972. For thermal

conductivity determinations and for the assessment

of fire hazard, a flat slab representative of the pipe

section shall be used for the tests.

5 Composition

The material shall be of man-made mineral fibre

made from rock, slag or glass, processed from a

molten state into a fibrous form, and shall be bonded

with a suitable binder.

6 Moisture content

When conditioned at high humidity in accordance

with 40.4 of BS 2972:1975, the moisture content of

the material shall not exceed 5 % by mass.

7 Physical requirements

7.1 Thermal conductivity. When tested in

accordance with the appropriate method of test for

thermal conductivity given in BS 874, the thermal

conductivity shall not exceed the values given

in Table 1.

BSI 07-1999

Table 1 Thermal conductivity values

50

100

150

200

250

300

350

Mean temperature

Thermal conductivity

W/(mK)

0.043

0.052

0.064

0.078

0.093

0.110

0.129

NOTE 1 BS 874 requires the test report to state which method

of test was employed, the bulk density of the material, the hot

face temperature and cold face temperature (generally within the

range 10 C to 50 C), the conditioning procedure and the

moisture content before and after the test.

NOTE 2 In order to comply with the requirements of Table 1,

products of different bulk density may be supplied for use at

different service temperatures. The required service temperature

should be stated by the purchaser.

7.2 Bulk density. For any particular product, the

variation from the manufacturers declared value

for bulk density, calculated at the nominal

thickness, shall not exceed 15 %.

NOTE The bulk density of the material will normally lie within

the range 50 kg/m3 to 200 kg/m3. The manufacturers declared

value for bulk density may vary with the size of section.

7.3 Heat stability. When a sample is heated in

accordance with 21.1 of BS 2972:1975 at the stated

maximum temperature of use, the material shall

maintain its general form and shall not suffer

visible deterioration of the fibrous structure.

7.4 Temperature limitations. Not all products

can give satisfactory service at high hot face

temperatures. The manufacturer shall state the

recommended maximum service temperature and

limiting thickness.

8 Fire hazard (assessment of

self-heating hazard)

The material shall comply with the requirements

of 18.1 to 18.3 of BS 2972:1975 and with the

requirements of 27.1 of BS 5422:1977, as

appropriate.

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:1982

9 Chemical requirements

11 Dimensional tolerances

9.1 Alkalinity. When tested by the method

described in Appendix B, the pH value recorded

shall be between 6.0 and 10.0.

9.2 Corrosive attack. The material shall not

include significant quantities of substances that will

promote corrosive attack on the surfaces with which

it is to be in contact. Where necessary, trace

quantities of water-soluble chlorides shall be

estimated in accordance with section 22 of

BS 2972:1975.

Preformed pipe sections shall be in accordance with

the nominal dimensions stated by the manufacturer

(or supplier, as appropriate), subject to the following

tolerances.

NOTE 1 Water-soluble chlorides are normally present in trace

quantities in most commercial thermal insulating materials. In

the presence of moisture and oxygen and under certain adverse

metallurgical conditions chloride ions are capable of initiating

stress corrosion cracking in susceptible metal alloys such as

austenitic stainless steels.

It is not practicable to indicate a safe upper limit for chloride

content since water can leach out soluble chlorides from

substantial volumes of insulating materials and allow them to be

concentrated at the metal-insulation interface, in addition, water

from outside sources such as the process itself or wind-driven

spray can substantially increase the chloride content of the

insulation.

In conditions potentially conducive to stress corrosion cracking,

appropriate safeguards should be adopted (see BS 5970).

NOTE 2 Some organic matter may be present either in a fibrous

form or as a bonding agent. It is suggested that the composition

of the product be checked with the manufacturer for use in

process conditions where organics may present a hazard,

e.g. processes involving powerful oxidizing agents or thermal

insulation on pipework and plant in a flammable atmosphere.

10 Standard shapes and sizes

10.1 Shape. Standard sections shall be cylindrical

or semi-cylindrical. Very large diameters may be

catered for by multi-segmental sections.

10.2 Sizes. The standard ranges of sizes shall be as

follows.

Length:

0.5 m to 1.2 m

Diameter:

to fit standard pipes of external

diameter up to 610 mm

Length:

3 mm

Thickness:

3 mm

Uniformity:

the local thickness at any

point shall not differ from

the average thickness by

more than 3 mm

Internal diameter:

0, + 1.5 mm (or + 1 %),

whichever is the greater).

12 External finish

Sections shall be finished plain (no applied finish) or

with one of the finishes given in Table 2.

Overlaps shall be as specified in Table 2.

NOTE Other finishes may be supplied by arrangement between

the purchaser and the manufacturer.

13 Marking

Each package containing pipe sections, or the

articles themselves, shall be clearly marked with

the following:

a) the manufacturers name, mark or symbol;

b) the manufacturers type designation, grade

and maximum service temperature limit;

c) the nominal dimensions (length, thickness and

internal diameter of the section);

d) the number of this British Standard,

i.e. BS 3958-41).

Thickness: 19 mm to 120 mm.

NOTE 1 The full range of thicknesses may not be available for

a specific pipe diameter; the thinner sections are generally only

available for small diameter pipes.

NOTE 2 Not all suppliers provide the full range of standard

sizes. Sections of other dimensions may be available by

arrangement with the manufacturer.

1)

Marking BS 3958-4 on or in relation to a product is a claim by the manufacturer that the product has been manufactured in

accordance with the requirements of the standard. The accuracy of such a claim is therefore solely the manufacturers

responsibility. Enquiries as to the availability of third party certification to support such claims should be addressed to the

Director, Quality Assurance Division, British Standards Institution, Maylands Avenue, Hemel Hempstead, Herts HP2 4SQ in

the case of certification marks administered by BSI or to the appropriate authority for other certification marks.

BSI 07-1999

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:1982

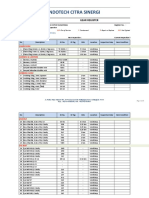

Table 2 Finishes and overlaps

Finish

Typical quality

Overlap

Longitudinal

End

Cotton scrim

Loomstate, weight 0.028 kg/m2 min.,

texture warp 650, weft 400 threads/metre,

min.

38 mm min.

Cotton canvas

Loomstate, weight 0.1 kg/m2 min., texture

warp 1 850, weft 1 500 threads/metre min.

38 mm min.a

25 mm min.

Aluminium foil

laminate

Foil thickness 0.008 mm min.,

glass fibre reinforced,

paper laminated

38 mm min.a

None

(sealing strip used)

Polyisobutylene

sheet

Thickness 0.8 mm min.

38 mm min.a

25 mm min.

None

May be reduced to 25 mm for sections up to 200 mm in circumference.

BSI 07-1999

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:1982

Appendix A Information to be

supplied when ordering

Appendix B Method of test for

alkalinity

The following information shall be supplied with the

order:

a) the number of this British Standard,

i.e. BS 3958-4;

b) the dimensions of the sections required;

c) the finish required;

d) the maximum service temperature to which

the product will be subjected;

e) a note of any adverse condition in the

environment of the insulation, e.g. acidic fumes;

f) a note of any special requirements concerning

fire safety.

B.1 Preparation of sample. From the bulk

sample, taken in accordance with BS 2972, cut five

pieces, each of approximate mass 5 g, from separate

units where possible. Crush these pieces and mix

thoroughly.

B.2 Determination of pH. Weigh 2 g of the

crushed sample and shake well for 10 min

with 100 mL of distilled or deionized water

(pH 6.5 to 7.5) at room temperature. Leave to settle

for 5 min and measure the pH of the mixture, using

a standard pH meter (see BS 1647 and BS 3145)

and decanting the solution if necessary. Repeat the

test on a further 2 g of the sample and report both

values.

BSI 07-1999

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:1982

Publications referred to

BS 874, Methods for determining thermal insulating properties, with definitions of thermal insulating

terms.

BS 1647, pH scale.

BS 2972, Methods of test for inorganic thermal insulating materials.

BS 3145, Specification for laboratory pH meters.

BS 3533, Glossary of thermal insulation terms.

BS 3958, Specification for thermal insulating materials2).

BS 3958-1, Magnesia preformed insulation.

BS 3958-2, Calcium silicate preformed insulation.

BS 3958-3, Metal mesh faced mineral wool mats and mattresses.

BS 3958-5, Bonded mineral wool slabs (for use at temperatures above 50 C).

BS 3958-6, Finishing materials; hard setting composition, self-setting cement and gypsum plaster.

BS 5422, Specification for the use of thermal insulating materials.

BS 5970, Code of practice for thermal insulation of pipework and equipment (in the temperature range

of 100 C to + 870 C).

2) Referred

to in the foreword only.

BSI 07-1999

Licensed copy: Prasad Kularni, L & T ECC DIVISION, Version correct as of 23/09/2009 12:38, (c) BSI

BS 3958-4:

1982

BSI British Standards Institution

BSI is the independent national body responsible for preparing

British Standards. It presents the UK view on standards in Europe and at the

international level. It is incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of

British Standards should make sure that they possess the latest amendments or

editions.

It is the constant aim of BSI to improve the quality of our products and services.

We would be grateful if anyone finding an inaccuracy or ambiguity while using

this British Standard would inform the Secretary of the technical committee

responsible, the identity of which can be found on the inside front cover.

Tel: 020 8996 9000. Fax: 020 8996 7400.

BSI offers members an individual updating service called PLUS which ensures

that subscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Services. Tel: 020 8996 9001. Fax: 020 8996 7001.

In response to orders for international standards, it is BSI policy to supply the

BSI implementation of those that have been published as British Standards,

unless otherwise requested.

Information on standards

BSI provides a wide range of information on national, European and

international standards through its Library and its Technical Help to Exporters

Service. Various BSI electronic information services are also available which give

details on all its products and services. Contact the Information Centre.

Tel: 020 8996 7111. Fax: 020 8996 7048.

Subscribing members of BSI are kept up to date with standards developments

and receive substantial discounts on the purchase price of standards. For details

of these and other benefits contact Membership Administration.

Tel: 020 8996 7002. Fax: 020 8996 7001.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the

UK, of the publications of the internationalstandardization bodies. Except as

permitted under the Copyright, Designs and Patents Act 1988 no extract may be

reproduced, stored in a retrieval system or transmitted in any form or by any

means electronic, photocopying, recording or otherwise without prior written

permission from BSI.

This does not preclude the free use, in the course of implementing the standard,

of necessary details such as symbols, and size, type or grade designations. If these

details are to be used for any other purpose than implementation then the prior

written permission of BSI must be obtained.

BSI

389 Chiswick High Road

London

W4 4AL

If permission is granted, the terms may include royalty payments or a licensing

agreement. Details and advice can be obtained from the Copyright Manager.

Tel: 020 8996 7070.

Anda mungkin juga menyukai

- BS 3958-1 PDFDokumen10 halamanBS 3958-1 PDFAnitha Mj100% (2)

- BS 3958-2 PDFDokumen10 halamanBS 3958-2 PDFAnitha MjBelum ada peringkat

- BS5422 InsulationDokumen82 halamanBS5422 InsulationStefan CampeanBelum ada peringkat

- BS-5422 Insulating MaterialsDokumen82 halamanBS-5422 Insulating Materialsssebastian8177Belum ada peringkat

- BS 3958 4 PDFDokumen10 halamanBS 3958 4 PDFramy abazaBelum ada peringkat

- BS 476-7-1971 - Fire Tests On Building Materials & Structures - Part 7 - Surface Spread of Flame Tests For MaterialsDokumen18 halamanBS 476-7-1971 - Fire Tests On Building Materials & Structures - Part 7 - Surface Spread of Flame Tests For MaterialsBiplabBelum ada peringkat

- BS 6375-1-2015 - (2015-05-18 - 09-55-44 PM)Dokumen26 halamanBS 6375-1-2015 - (2015-05-18 - 09-55-44 PM)MarcinBelum ada peringkat

- Igem List PDFDokumen9 halamanIgem List PDFSenn OdrapmasdBelum ada peringkat

- Ige TD 12 Ed2 Reprint With Amendments Intro and ScopeDokumen12 halamanIge TD 12 Ed2 Reprint With Amendments Intro and ScopeDaysianneMendes100% (1)

- List of Iso LNG Standards Mapping Oct2018Dokumen5 halamanList of Iso LNG Standards Mapping Oct2018mohammad kassarBelum ada peringkat

- Astm C680 PDFDokumen47 halamanAstm C680 PDFFernando67% (3)

- BS 476 31.1 PDFDokumen14 halamanBS 476 31.1 PDFAlexander AlexanderBelum ada peringkat

- BS 4800Dokumen16 halamanBS 4800Tarek helmyBelum ada peringkat

- BS 3958-2 1982 (E)Dokumen8 halamanBS 3958-2 1982 (E)Danny BiermansBelum ada peringkat

- BS en 1515-4 2009Dokumen22 halamanBS en 1515-4 2009Thiago Ribeiro da Silva100% (1)

- E0909Dokumen6 halamanE0909ahmedbeaetBelum ada peringkat

- Önorm en 10208-2Dokumen6 halamanÖnorm en 10208-2jan_matej56510% (1)

- ASTM C168-97 Standard Terminology Relating To Thermal InsulationDokumen6 halamanASTM C168-97 Standard Terminology Relating To Thermal Insulationdodi ikhsan100% (1)

- Astm C 167Dokumen4 halamanAstm C 167dorbarelBelum ada peringkat

- Hot Dip Galvanized (ISO 9223)Dokumen2 halamanHot Dip Galvanized (ISO 9223)Miguel QueirosBelum ada peringkat

- BS 476-11 1982 - Fire Test On Building Materials and Structures (Part 11-Method For Assessing The Heat Emission From Building Materials) PDFDokumen23 halamanBS 476-11 1982 - Fire Test On Building Materials and Structures (Part 11-Method For Assessing The Heat Emission From Building Materials) PDFMegat AlexanderBelum ada peringkat

- Astm C 1290 - Fibrous Glass Balnket For DuctsDokumen4 halamanAstm C 1290 - Fibrous Glass Balnket For DuctsleandroschroederBelum ada peringkat

- UL 1709 Ed 2017Dokumen43 halamanUL 1709 Ed 2017frgonzalezc100% (1)

- BS en 13160-1 - 2003Dokumen38 halamanBS en 13160-1 - 2003bakhtyar210% (1)

- BS en 12495 - 2000 - Cathodic Protection For Fixed Steel Offshore StructuresDokumen39 halamanBS en 12495 - 2000 - Cathodic Protection For Fixed Steel Offshore StructuresagaefaijaeiBelum ada peringkat

- Air and Water Permeability of Sandwich Panel JointsDokumen43 halamanAir and Water Permeability of Sandwich Panel JointsThiên BìnhBelum ada peringkat

- FPAS FSA Awareness Session PDFDokumen172 halamanFPAS FSA Awareness Session PDFStephan AntounBelum ada peringkat

- BS en 12201 4 2012Dokumen24 halamanBS en 12201 4 2012Janardhana Reddi0% (1)

- BYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709Dokumen2 halamanBYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709FPA InspectorBelum ada peringkat

- C552Dokumen25 halamanC552nasir100% (2)

- BS 2989 HDG-Steel PDFDokumen16 halamanBS 2989 HDG-Steel PDFAdelio MercadejasBelum ada peringkat

- Iso 7345:1997Dokumen10 halamanIso 7345:1997Blaise Roithridh100% (1)

- BS 476-23-1987Dokumen24 halamanBS 476-23-1987Hadi Iz'aanBelum ada peringkat

- Bs-Iso 12241Dokumen61 halamanBs-Iso 12241juninho7050% (2)

- BS en 12502-3Dokumen18 halamanBS en 12502-3laboratorium logamBelum ada peringkat

- BS 4346 - 3Dokumen13 halamanBS 4346 - 3Ronnie1478Belum ada peringkat

- Rapid Rise Fire Tests of Protection Materials For Structural SteelDokumen43 halamanRapid Rise Fire Tests of Protection Materials For Structural Steelmuleacidic100% (1)

- As 1324.2-2003 Air Filters For Use in General Ventilation and Air Conditioning Methods of TestDokumen8 halamanAs 1324.2-2003 Air Filters For Use in General Ventilation and Air Conditioning Methods of TestSAI Global - APACBelum ada peringkat

- AMCA Publication 501-09 - Application Manual For Air Louvers - PreviewDokumen8 halamanAMCA Publication 501-09 - Application Manual For Air Louvers - PreviewSurajit Paul0% (1)

- MTO - Cathodic Protection - Temporary Systems and Below Ground Items - GreeceDokumen5 halamanMTO - Cathodic Protection - Temporary Systems and Below Ground Items - GreeceyamegBelum ada peringkat

- (BS 8554) - Code of Practice For The Sampling and Monitoring of Hot and Cold Water Services in BuildingsDokumen59 halaman(BS 8554) - Code of Practice For The Sampling and Monitoring of Hot and Cold Water Services in BuildingsCristian DraghiciBelum ada peringkat

- BS 476 Fire Tests On Building Materials and Structures: Presented byDokumen33 halamanBS 476 Fire Tests On Building Materials and Structures: Presented byaryasusu100% (1)

- Underground PE Wrapped Pipe 21 Years Paling LamaDokumen14 halamanUnderground PE Wrapped Pipe 21 Years Paling Lamahengkiirawan2008Belum ada peringkat

- BS 5422-2009Dokumen82 halamanBS 5422-2009zshehadeh100% (1)

- BS En253Dokumen50 halamanBS En253VaradarajBelum ada peringkat

- BS EN 12007-1-2000 Novi StandardDokumen22 halamanBS EN 12007-1-2000 Novi StandardJockoJoleBelum ada peringkat

- En 12068Dokumen48 halamanEn 12068pametnjakovicmladji100% (12)

- Igem ListDokumen9 halamanIgem ListMilad YadollahiBelum ada peringkat

- BS 2782-7-Method 732F-1991Dokumen12 halamanBS 2782-7-Method 732F-1991Anıl ZiylanBelum ada peringkat

- ASPE05 - An Industry Guide To Design For Installation of Fire & Smoke Resisting Dampers (Grey Book)Dokumen27 halamanASPE05 - An Industry Guide To Design For Installation of Fire & Smoke Resisting Dampers (Grey Book)Basil OguakaBelum ada peringkat

- BS en 13160-2 2016Dokumen70 halamanBS en 13160-2 2016CK CkkouBelum ada peringkat

- BS 4800Dokumen6 halamanBS 4800frederickplc100% (4)

- PD 7974-5 2014Dokumen62 halamanPD 7974-5 2014Steve Job100% (1)

- Is 13411Dokumen44 halamanIs 13411Aditya PratapBelum ada peringkat

- BS1747-1 :1969Dokumen14 halamanBS1747-1 :1969Jessica FarrugiaBelum ada peringkat

- GBE-CW6 Part-1-1993Dokumen44 halamanGBE-CW6 Part-1-1993pcmfilho100% (2)

- Marine Concrete Specs-HkDokumen5 halamanMarine Concrete Specs-HkMohammed Faisal TBelum ada peringkat

- Bs 3262 3Dokumen11 halamanBs 3262 3Hamid Naveed100% (1)

- Wis 4 34 04Dokumen16 halamanWis 4 34 04Tai WeiBelum ada peringkat

- Bs 2842Dokumen16 halamanBs 2842APIBelum ada peringkat

- 1040-3040 M SchemeDokumen47 halaman1040-3040 M SchemeAnitha MjBelum ada peringkat

- BS 5422 PDFDokumen82 halamanBS 5422 PDFAnitha Mj75% (4)

- BS 3533 PDFDokumen22 halamanBS 3533 PDFKarunakaran Nallasingam100% (2)

- BS 874-3.2 PDFDokumen18 halamanBS 874-3.2 PDFAnitha Mj100% (1)

- Considerations in The Design of Smoke Management Systems For AtriumsDokumen6 halamanConsiderations in The Design of Smoke Management Systems For AtriumsAnitha MjBelum ada peringkat

- Pressure - Temperature Ratings of Plain End Seamless Chromium - Molybdenum Alloy Steel Pipe To ASTM A335 Grade P11 (1 % Chromium - % Molybdenum)Dokumen2 halamanPressure - Temperature Ratings of Plain End Seamless Chromium - Molybdenum Alloy Steel Pipe To ASTM A335 Grade P11 (1 % Chromium - % Molybdenum)Anitha MjBelum ada peringkat

- The Explosives Rules, 1983 PDFDokumen130 halamanThe Explosives Rules, 1983 PDFAnitha MjBelum ada peringkat

- TECHNICAL SPECIFICATION Tankage PDFDokumen75 halamanTECHNICAL SPECIFICATION Tankage PDFAnitha MjBelum ada peringkat

- Petroleum Acts PDFDokumen81 halamanPetroleum Acts PDFAnitha MjBelum ada peringkat

- Dabacon Error Codes in PDMSDokumen7 halamanDabacon Error Codes in PDMSAnitha MjBelum ada peringkat

- Equivalent Papers K To L SchemeDokumen1 halamanEquivalent Papers K To L SchemeAnitha Mj0% (1)

- 17 Safety InventoryDokumen47 halaman17 Safety Inventorymishrakanchan 2396Belum ada peringkat

- Waste Heat BoilerDokumen7 halamanWaste Heat Boilerabdul karimBelum ada peringkat

- Recruitment and SelectionDokumen50 halamanRecruitment and SelectionAmrita BhatBelum ada peringkat

- Loading and Hauling Dump Truck: DumperDokumen2 halamanLoading and Hauling Dump Truck: DumperRJBelum ada peringkat

- Brittan Bradford ResumeDokumen2 halamanBrittan Bradford Resumeapi-574584381Belum ada peringkat

- Lock Maiolo Savonarola MachiavelliDokumen22 halamanLock Maiolo Savonarola MachiavelliHeliogabolusBelum ada peringkat

- Comsigua HBIDokumen0 halamanComsigua HBIproxywarBelum ada peringkat

- Simulation of Inventory System PDFDokumen18 halamanSimulation of Inventory System PDFhmsohagBelum ada peringkat

- Seventh Pay Commission ArrearsDokumen11 halamanSeventh Pay Commission Arrearssantosh bharathyBelum ada peringkat

- Catalog ITEM - Pdf4a3667894b315Dokumen552 halamanCatalog ITEM - Pdf4a3667894b315Domokos LeventeBelum ada peringkat

- 0192-En 13948-2008Dokumen9 halaman0192-En 13948-2008Borga ErdoganBelum ada peringkat

- Unit 3 Approaches To The Study of Medieval Urbanisation : StructureDokumen20 halamanUnit 3 Approaches To The Study of Medieval Urbanisation : StructureSunil SunilBelum ada peringkat

- Theoretical Grammar of EnglishDokumen132 halamanTheoretical Grammar of EnglishMisarabbit NguyenBelum ada peringkat

- Summative Lab Rubric-Intro To ChemistryDokumen1 halamanSummative Lab Rubric-Intro To ChemistryGary JohnstonBelum ada peringkat

- 2022 05 141RBSF351652506386Dokumen6 halaman2022 05 141RBSF351652506386tathagat jhaBelum ada peringkat

- SIP Project ProposalDokumen2 halamanSIP Project ProposalDeep SutariaBelum ada peringkat

- Pre Post and Infix NotationsDokumen12 halamanPre Post and Infix NotationsGolla GirijaBelum ada peringkat

- If You Restyou RustDokumen4 halamanIf You Restyou Rusttssuru9182Belum ada peringkat

- Serie 20 Sauer DanfossDokumen18 halamanSerie 20 Sauer DanfossCristian100% (1)

- Maximus MHX DatasheetDokumen5 halamanMaximus MHX Datasheetjulya julyaBelum ada peringkat

- ExerciseDokumen10 halamanExerciseNguyen Mai QuynhBelum ada peringkat

- Vernacular in Andhra PradeshDokumen1 halamanVernacular in Andhra PradeshNandyala Rajarajeswari DeviBelum ada peringkat

- Inspection List For Electrical PortableDokumen25 halamanInspection List For Electrical PortableArif FuadiantoBelum ada peringkat

- Literature 101 Assignment: Step 1: Graphic OrganizerDokumen2 halamanLiterature 101 Assignment: Step 1: Graphic OrganizercatarinaBelum ada peringkat

- Awb 4914934813Dokumen1 halamanAwb 4914934813Juandondr100% (1)

- Addis Ababa University Lecture NoteDokumen65 halamanAddis Ababa University Lecture NoteTADY TUBE OWNER100% (9)

- Kelley DavisDokumen3 halamanKelley Davisapi-626701108Belum ada peringkat

- Civil & Structural Designer'S Data Pack: Section 7: MasonryDokumen5 halamanCivil & Structural Designer'S Data Pack: Section 7: MasonryMirea Florentin0% (1)

- Metal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatDokumen13 halamanMetal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatbluexpectroBelum ada peringkat

- Human Resource Development Multiple Choice Question (GuruKpo)Dokumen4 halamanHuman Resource Development Multiple Choice Question (GuruKpo)GuruKPO90% (20)