KMT Aqua-Dyne Bare Shaft Series 250 - REV 03-10 - L

Diunggah oleh

Agung SyJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

KMT Aqua-Dyne Bare Shaft Series 250 - REV 03-10 - L

Diunggah oleh

Agung SyHak Cipta:

Format Tersedia

KMT Aqua-Dyne Pumps Are Used Worldwide

For These Water Blasting Applications:

Marine - Ship/Dock Cleaning

Oilfield - Hydrostatic Testing & Pipe Cleaning

Mining - Unclog Machinery

Automotive - Paint Booth Cleaning

Aviation - Clean Fluids on Runways

Power Station - Nuclear Decontamination

...and MUCH MORE!

KMT Aqua-Dyne

Bare Shaft Pumps

Series 250

(Power Ratings: 150-250 HP/112-186

2-186 kw)

For Maximum Water Blasting Productivity

KMT Aqua-Dyne Bare Shaft Pumps

The POWER Inside Every PUMPING UNIT!

The key to KMT Aqua-Dynes long pump life and hundreds of

hours of trouble-free operation are low load packing, special

filtration, a closed loop non-drip cooling and water lubrication

system for alumina ceramic or tungsten carbide plungers.

The individual lightweight suction and discharge manifolds

are easily removed for routine maintenance, and field

changing the packing or plungers takes five minutes with

no special tools required.

Unique VALVE-IN-LINE Fluid End

Unique VALVE-IN-LINE Fluid End Design Provides Higher

Volumetric Efficiency For Increased Productivity & Lower

Operating Costs.

Power End

Power Frame High strength grey iron alloy casting with

sturdily ribbed wall sections.

Crankshaft Aircraft quality alloy steel induction hardened

journals, may extend from either side.

Crankshaft Bearings heavy duty high speed journal

bearings.

Crossheads Cylindrical type high strength alloy castings.

Crosshead wristpins are hardened & ground steel equipped

with double roller bearings. Extension rods are highly polished

stainless steel to eliminate corrosion and weepage.

Lubrication Power end parts are splash lubricated.

Connecting Rods High strength, solid section Ductile

iron.

Oil Wiper Seals Self lubrication polymer.

Superior Design Of The Fluid End Delivers Up To 15%

Increase In Productivity, higher volumetric efficiency, lower

maintenance, quick packing changes and low initial cost over

conventional fluid ends available.

Fluid End

Fluid Cylinders Stainless steel is standard, other materials

available to suit application.

Valve & Seats High strength stainless steel in-line

valve system. All valves may be reconditioned by surface

grinding.

Plungers Non-scoring ceramic.

Packing V-Rings of advanced polymer material are self

adjusting, giving long service when used with non-scoring

ceramic plungers.

Lubrication Plungers and packing are pressure lubricated

by fluid from suction manifolds. Optional oil lubrications are

available.

Manifolds Individual light weight suction and discharge

manifolds are easily removable for simple maintenance.

Different materials are available to suit applications.

Unique VALVE-IN-LINE

Fluid End

*Bare Shaft Pumps are available in Custom & Standard Pumping Unit Packages

THE

SYMBOL

OF QUALITY

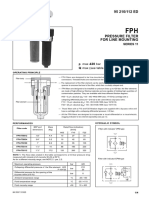

SERIES 250 SPECIFICATIONS

Pressure & Volume are based on 100% Volumetric & Mechanical Efficiency.

S E R IE S 250 P U MP S

F L U ID E N D

S E R IE S

UHP

HP

MP

LP

PLUNGER

D IA M E T E R

IN C H E S (m m )

0 .5 (1 2 .7 0 )

0 .6 2 5 (1 5 .8 7 )

0 .6 2 5 (1 5 .8 7 )

0 .8 7 5 (2 2 .2 2 )

1 (2 5 .4 )

1 .1 2 5 (2 8 .5 7 )

1 .2 5 (3 1 .7 5 )

1 .3 7 5 (3 4 .9 2 )

1 .5 (3 8 .1 )

1 .6 2 5 (4 1 .2 7 )

1 .7 5 (4 4 .4 5 )

1 .8 7 5 (4 7 .6 2 )

2 (5 0 .8 )

2 .1 2 5 (5 3 .9 7 )

2 .2 5 (5 7 .1 5 )

2 .3 7 5 (6 0 .3 2 )

M A X IM U M

PRESSURE

P S I (b a r)

4 0 ,0 0 0 (2 ,7 5 8 )

4 0 ,0 0 0 (2 ,7 5 8 )

3 0 ,0 0 0 (2 ,0 6 8 )

2 0 ,0 0 0 (1 ,3 7 9 )

1 6 ,0 0 0 (1 ,1 0 3 )

1 3 ,0 0 0 (8 9 6 )

1 0 ,0 0 0 (6 8 9 )

9 ,0 0 0 (6 2 0 )

8 ,0 0 0 (5 5 2 )

7 ,0 0 0 (4 8 3 )

6 ,0 0 0 (4 1 4 )

5 ,0 0 0 (3 4 5 )

4 ,5 0 0 (3 1 0 )

4 ,0 0 0 (2 7 6 )

3 ,5 0 0 (2 4 1 )

3 ,0 0 0 (2 0 7 )

Rated Power:

FL OW AT P OWE R

G A L /M I N . ( L I T E R /M I N . )

150 HP

(1 1 2 k w )

5 .7 (2 5 .9 1 )

7 .5 (3 4 .0 9 )

1 1 .3 (5 1 .3 7 )

1 4 .1 (6 4 .1 0 )

1 7 .1 (7 7 .7 4 )

2 2 .5 (1 0 2 .2 9 )

2 5 .2

2 8 .2

3 2 .4

3 7 .8

4 5 .0

5 0 .1

(1 1 4 .5 6 )

(1 2 8 .2 0 )

(1 4 7 .3 0 )

(1 7 1 .8 4 )

(2 0 4 .5 7 )

(2 2 7 .7 6 )

5 6 .4 (2 5 6 .4 0 )

6 4 .8 (2 9 4 .5 9 )

7 5 (3 4 0 .9 5 )

200 HP

(1 4 9 k w )

7 .6

250 HP

(1 8 6 k w )

(3 4 .5 5 )

15

(6 8 .1 9 )

1 8 .8 (8 5 .4 7 )

2 2 .8 (1 0 3 .6 5 )

30

(1 3 6 .3 8 )

3 3 .6 (152.75)

3 7 .6 (170.93)

4 3 .2 (196.39)

5 0 .4 (229.12)

6 0 .0 (272.76)

6 6 .8 (303.68)

7 5 .2 (341.87)

8 6 .4 (392.78)

1 0 0 .0 (454.61)

Up to 250 (186 kw)

Number of Cylinders:

Plunger Stroke:

3.5 (88.9 mm)

Plunger Load:

15,000 Lbs (6804 kg)

Oil Capacity:

2.5 Gallons (11.36 L)

Pump Weight:

1,375 Lbs (624 kg)

(190.93)

(213.66)

(245.49)

(286.40)

(240.95)

(379.60)

9 4 .0 (427.33)

1 0 8 .0 (490.98)

1 2 0 .0 (545.53)

4 2 .0

4 7 .0

5 4 .0

6 3 .0

7 5 .0

8 3 .5

*Dimensions (in inches) may vary base on pump model

KMT GmbH KMT Aqua-Dyne

Auf der Laukert 11 61231 Bad Nauheim (Germany)

Tel: +49-6032-997-0 Fax: +49-6032-997-274

www.aqua-dyne.com sales@aqua-dyne.com

AD Series 250 03/10

KMT Aqua-Dyne Inc.

Anda mungkin juga menyukai

- Machine Design Elements and AssembliesDari EverandMachine Design Elements and AssembliesPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- TWS 600SDokumen44 halamanTWS 600Sfrank vBelum ada peringkat

- Lantec LW Series Winches Catalog PDFDokumen16 halamanLantec LW Series Winches Catalog PDFFareedMohmed100% (1)

- 50PVB ProductDokumen29 halaman50PVB Producthakimmunas100% (1)

- Fuel System With Unit Injector PDE and EDC MS6: Issue 2Dokumen60 halamanFuel System With Unit Injector PDE and EDC MS6: Issue 2Musharraf KhanBelum ada peringkat

- KMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFDokumen2 halamanKMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFMark1025Belum ada peringkat

- KMT Aqua Dyne Bare Shaft Series 500 - REV 03 10 - L2Dokumen2 halamanKMT Aqua Dyne Bare Shaft Series 500 - REV 03 10 - L2Jeff RyersonBelum ada peringkat

- Mud Pumps BrochureDokumen16 halamanMud Pumps BrochureIsabel Farias-López100% (2)

- Bombas JumboDokumen8 halamanBombas JumboSilviopkBelum ada peringkat

- Vickers Vane v10 v20 PDFDokumen24 halamanVickers Vane v10 v20 PDFTom TraviBelum ada peringkat

- Valves, Valve Springs, Valve Rotocoils, and LocksDokumen55 halamanValves, Valve Springs, Valve Rotocoils, and Locksbetoven8437Belum ada peringkat

- Downhole MotorsDokumen31 halamanDownhole MotorsRFVBelum ada peringkat

- KDTDokumen1 halamanKDTapandey070273Belum ada peringkat

- Kollmorgen Powermax II CatalogDokumen4 halamanKollmorgen Powermax II CatalogElectromateBelum ada peringkat

- Dynex SelectionDokumen19 halamanDynex SelectionFathi Musa50% (2)

- Sp4800 Sp8800 FlipbookDokumen6 halamanSp4800 Sp8800 FlipbookTimothy Mcmillan100% (1)

- 3887bhf Ws - BHF Series (b3887bhf)Dokumen4 halaman3887bhf Ws - BHF Series (b3887bhf)Oscar GonzalesBelum ada peringkat

- B3887BHF1Dokumen4 halamanB3887BHF1xianmingBelum ada peringkat

- Polaris Hydraulic Gear Pump CatalogDokumen88 halamanPolaris Hydraulic Gear Pump Catalogbtone911100% (1)

- Manual Split ToshibaDokumen86 halamanManual Split ToshibaTiago Melo0% (1)

- PSC CatalogDokumen24 halamanPSC CatalogRbn Crls GlBelum ada peringkat

- CI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsDokumen12 halamanCI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsAndre Gazali MalikBelum ada peringkat

- 9600 4kw-200kwDokumen64 halaman9600 4kw-200kwHendrewel Ferreira NunesBelum ada peringkat

- 4520VQ Double Vane Pump Vickers (Catalog)Dokumen6 halaman4520VQ Double Vane Pump Vickers (Catalog)Handoko ArimurtiBelum ada peringkat

- Dimension EsDokumen12 halamanDimension EsMarcelo Elicer Hernandez DazaBelum ada peringkat

- Centrifugal PumpDokumen32 halamanCentrifugal PumpAhmadMoaazBelum ada peringkat

- Stolle Ragsdale BodymakersDokumen2 halamanStolle Ragsdale BodymakersPackiaraj Krishnasamy0% (1)

- Especificaciones Lowara C CE CK CEKDokumen11 halamanEspecificaciones Lowara C CE CK CEKAlejandro MozoBelum ada peringkat

- Ks Ac Synchronous MotorsDokumen6 halamanKs Ac Synchronous MotorsAlberto Hernandez0% (1)

- 8" Submersible Motors Standard: ApplicationsDokumen7 halaman8" Submersible Motors Standard: Applicationswpt_meBelum ada peringkat

- Nema P2 Stepper System TBDokumen4 halamanNema P2 Stepper System TBRomulo Cardoso100% (1)

- Brochure BEGEMANN BS Pumps-Low ResolutionDokumen6 halamanBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorBelum ada peringkat

- Barras de Levas Crower ToyotaDokumen4 halamanBarras de Levas Crower ToyotaRedin RacingBelum ada peringkat

- Slurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Dokumen5 halamanSlurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Guilherme CamposBelum ada peringkat

- Boring Bar ManualDokumen41 halamanBoring Bar ManualPranjal Chakraborty100% (1)

- Honda / AcuraDokumen7 halamanHonda / Acuracrower_scribdBelum ada peringkat

- SKD Split Case Centrifugal Pump BrochureDokumen4 halamanSKD Split Case Centrifugal Pump BrochureGiovanny Salazar FloresBelum ada peringkat

- Rock Valve: Stationary Concrete PumpsDokumen8 halamanRock Valve: Stationary Concrete PumpsRafael R ABelum ada peringkat

- 700CFM To 1000CFM QXD - ENDokumen2 halaman700CFM To 1000CFM QXD - ENJamal HabbasBelum ada peringkat

- Din Reactors CEDokumen3 halamanDin Reactors CEvallamreddyBelum ada peringkat

- Standard Motors AustriaDokumen24 halamanStandard Motors AustriaFlorinD2014Belum ada peringkat

- BAGFLODokumen68 halamanBAGFLOAlicia ViridianaBelum ada peringkat

- Ebara - 8bhelDokumen6 halamanEbara - 8bheldovanvonbBelum ada peringkat

- Section08 A4 PDFDokumen808 halamanSection08 A4 PDFjakkyjeryBelum ada peringkat

- Yanmar Engine Type 6CXM-GTE2Dokumen2 halamanYanmar Engine Type 6CXM-GTE2Yoga_DMBelum ada peringkat

- Part 12-Jikov CarburetorDokumen23 halamanPart 12-Jikov Carburetorkorolito100% (1)

- Dgcen5 1101a ADokumen1 halamanDgcen5 1101a Akevinkok38Belum ada peringkat

- Eta CurvesDokumen38 halamanEta Curvesfebime60% (5)

- E-Self Priming PumpsDokumen27 halamanE-Self Priming PumpsTeguh SetionoBelum ada peringkat

- LV Renewal Parts CatalogDokumen25 halamanLV Renewal Parts CatalogvdaBelum ada peringkat

- Agitator SizingDokumen4 halamanAgitator SizingArbee AquinoBelum ada peringkat

- TTS Cargo Cranes: Product SpecificationDokumen4 halamanTTS Cargo Cranes: Product SpecificationRangga Wijaya DimyatieBelum ada peringkat

- PLL 2144Dokumen80 halamanPLL 2144Amit TandelBelum ada peringkat

- Mab Diverter Valves: For Pneumatic Conveying ApplicationsDokumen6 halamanMab Diverter Valves: For Pneumatic Conveying Applicationsaatsh38Belum ada peringkat

- s60 Marine Training 2005Dokumen184 halamans60 Marine Training 2005Antony MorenoBelum ada peringkat

- Valve Automation Brochure USDokumen8 halamanValve Automation Brochure USprufino2Belum ada peringkat

- Gate Valves Closing TorqueDokumen6 halamanGate Valves Closing TorqueWaltico SaljareBelum ada peringkat

- Southern Marine Engineering Desk Reference: Second Edition Volume IiDari EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiBelum ada peringkat

- High-Performance GM LS-Series Cylinder Head GuideDari EverandHigh-Performance GM LS-Series Cylinder Head GuidePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDari EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesBelum ada peringkat

- Duplomatic Inline Filter CatalogueDokumen4 halamanDuplomatic Inline Filter Cataloguejulia bordenBelum ada peringkat

- TURBINE Logics and InterlocksDokumen62 halamanTURBINE Logics and Interlockskalyanm20351586% (7)

- Dinamika - 4 Kinetika Benda Tegar - Gaya Percepatan IIDokumen19 halamanDinamika - 4 Kinetika Benda Tegar - Gaya Percepatan IIAnonymous UwdDHhYUBelum ada peringkat

- Inspection and Test Plan Rotating Equipment:: LPG PumpDokumen4 halamanInspection and Test Plan Rotating Equipment:: LPG PumpErico Haryanto LumbanrajaBelum ada peringkat

- EQUIMECH1Dokumen8 halamanEQUIMECH1Gavin Raymond BrionesBelum ada peringkat

- CLG842 (Dcec Ii) Om 201501006-EnDokumen192 halamanCLG842 (Dcec Ii) Om 201501006-EnCarlos Astudillo VargasBelum ada peringkat

- Do's and Don'Ts For Eq Resistant Design of BuildingsDokumen44 halamanDo's and Don'Ts For Eq Resistant Design of BuildingsPraveen Gavad100% (1)

- Project: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Dokumen14 halamanProject: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Mohamed Wasim ShaikhBelum ada peringkat

- Weiss ITC Manual 13 Web Engl 201307Dokumen123 halamanWeiss ITC Manual 13 Web Engl 201307Ciprian BalcanBelum ada peringkat

- Electromagnetic Induction 1. ACJC - 08H2P1 - Q31Dokumen22 halamanElectromagnetic Induction 1. ACJC - 08H2P1 - Q31Jorge Vega RodríguezBelum ada peringkat

- PSV Thermal SizingDokumen16 halamanPSV Thermal Sizingahmad santoso0% (1)

- Gas Condensate ReservoirsDokumen11 halamanGas Condensate ReservoirsMaisam AbbasBelum ada peringkat

- A-30 Magnetic Base Drilling Machine OEM ManualDokumen1 halamanA-30 Magnetic Base Drilling Machine OEM ManualD Ian RobinsonBelum ada peringkat

- Penthouse Spring 1984Dokumen2 halamanPenthouse Spring 1984John M. CavoteBelum ada peringkat

- Parts Manual: Model: DVX 5 Ton FC With Tsj436 Simpson EngineDokumen147 halamanParts Manual: Model: DVX 5 Ton FC With Tsj436 Simpson EngineJohnson James80% (5)

- Assignment 1 2Dokumen2 halamanAssignment 1 2Jeevan GBelum ada peringkat

- Reactor Internals Design PDFDokumen81 halamanReactor Internals Design PDFBest HopeBelum ada peringkat

- Cad Cam SyllabusDokumen4 halamanCad Cam SyllabuskrishrathoreBelum ada peringkat

- Air Chain Hoist MLK SerieDokumen20 halamanAir Chain Hoist MLK SerieSergei KurpishBelum ada peringkat

- Petroleum Applications: Application and Installation GuideDokumen28 halamanPetroleum Applications: Application and Installation GuideVictor NunezBelum ada peringkat

- Parkercatalog MotorsMasterDokumen39 halamanParkercatalog MotorsMasterAgus YulfizarBelum ada peringkat

- Crc-p-600 Welding Machine Spec. Brochure 2Dokumen4 halamanCrc-p-600 Welding Machine Spec. Brochure 2gdgfd100% (1)

- Megamin Activ, Buy Now This Super Potent AntioxidantDokumen3 halamanMegamin Activ, Buy Now This Super Potent AntioxidantMartin LewisBelum ada peringkat

- Latestrage CatalogDokumen120 halamanLatestrage CatalogRWBalmeloBelum ada peringkat

- 1.1 Roller With Brush:: Fig3.1: Design of BrushDokumen7 halaman1.1 Roller With Brush:: Fig3.1: Design of Brush19-317 rohit PalleBelum ada peringkat

- Brake SystemDokumen26 halamanBrake SystemFamela Mae RicaBelum ada peringkat

- Fire Pump Proposal Summary: WeightDokumen3 halamanFire Pump Proposal Summary: WeightDerkung BenowatBelum ada peringkat

- Honda E-StormDokumen104 halamanHonda E-StormJaimeDiazDiazBelum ada peringkat

- VRM For ASECDokumen77 halamanVRM For ASECHazem Hasan100% (5)