ARTS & GEN Cost Analysis 2013

Diunggah oleh

romiifreeHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ARTS & GEN Cost Analysis 2013

Diunggah oleh

romiifreeHak Cipta:

Format Tersedia

Candidates Name:

Olufemi Allen

Candidates #:

100157

Name of School:

Garvey Maceo High School

Centre #:

100157

Territory:

Jamaica

Award:

Single

Proficiency:

General

Year of Exam:

2013

Location:

Vernamfield, Clarendon

Date started:

April 16, 2012

Duration:

6 weeks

DESCRIPTION AND SCHEDULING OF ACTIVITY

1. Preparation of Coop

Removing cake litter

Removing tarpaulin

Cob webbing

Removing feed pans and waterers

Washing tarpaulin

Washing feed pans and waterers 8&9

Sanitizing / washing coop 10

Hanging tarpaulin11

5&6

2. Preparation of Footbath

Sanitizing / washing footbath

12

Maintaining the footbath

13

Adding sponge in footbath and Adding disinfectant with water14

3. Preparation of Brooding Area

Cornering off (setting up barriers) a part of the coop

Setting up heat lamp

Placing saw dust/rice hulls in the coop

Adding white lime to saw dust/rice hulls in the coop

15& 16

17

18

19

Spreading newspapers over saw dust/rice hulls in the coop

Setting up feed pans

21

Setting up waterers

22

4. Receiving Chickens

Turning on heat lamp

23

Placing feed in pans

24

Mixing medication

25

Attaching automatic waterers

26

5. Brooding of Chickens

Observation of the position of chickens 27

Observation of the feeding pattern of chickens 28

6. Daily Feeding

Adding feed to pans 29

Checking water from automatic waterer30

Heisting feeders and waterers31

7. Daily Cleaning of Feeders and Waterers

Washing waterers32

Wiping feeders 33

8. Daily routine

Turning / raking of litter 34

20

Refilling feed pans35

Checking automatic waterers 36

Maintaining foot bath37

Turning heat lamp on 38

Turning heat lamp off39

Rolling up tarpaulin40

Rolling down tarpaulin 41

Collecting feed from store room 42

9. Daily Observation

Position of chickens in brooding area 43

Feeding of chickens 44

Behaviour of the chickens 45

Footbath 46

State of litter 47

10. Medication

Type given and reason for administration 48 &49

Mixing 50

Setting up mixture in automatic waterers 51

11. Mortality

12. Culling

Total number of chickens died over the brooding period and Reason for death 52

Total number of chickens killed over the brooding period,how it was done and the

reason for culling.53

13. Maintaining the footbath

Washing footbath 54

Adding sponge in footbath 55

Adding disinfectant with water 56

14. Extension of Brooding Area

Re-positioning of heat lamp 57

Spreading saw dust / rice hulls 58

Adding white lime 59

Removing barriers 60

Attaching feeders 61

Attaching waterers 62

15. Preparation of chickens for slaughter

Raising of feed pans 63

16. Pre-slaughtering activities

Setting up fire 64

Setting up slaughtering area 65

Sanitizing picking area 66

Sanitizingcutting area andplucking area 67

17. Slaughtering of Chickens

Collecting chickens from coop 68

Killing chickens 69

Picking chickens including feet 70&71

Plucking of Chickens 72

Cutting the anus 73

Removal of offal 74

Packaging of Chickens 75

Washing of chickens 76

Placing chickens in bags 77

18. Marketing of Chickens

Weighing of chickens 78

Selling chickens 79

LIST OF EQUIPMENT AND MATERIALS USED IN BROILER

PRODUCTION

Push broom

Shovel

Hay fork

Feed pan

Waterer

Binding wires

Water

Sponge

Blocks

Board

Lock

Key

Buckets

Bottles

Ice

Soap

Rice hulls

Saw dust

White lime

Knife

Disinfectant

Zinc

Tarpaulin

Wheel barrow

Hose

Heat lamp

Newspaper

Stone

Scathe bright

Clear plastic bags

Decks

Cheese pan

Broom

Auto waterer

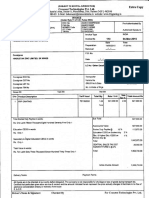

PARTIAL BUDGET FOR GAB BROILER

PROJECT

A. PROJECTED INCOME:

Sale of60 x 4 lbs of Chicken Meat at $145 per lb = $34,800.00

Sale of 22 lbs of Feet at $ 80 per lb = $ 1,760.00

Sale of 27 lbs of Offal (neck, liver, gizzard) at $ 80 per lb = $ 2,160.00

Total Projected Income = $ 38,720.00

PROJECTED EXPENDITURE:

VARIABLE COST:

Cost of 62 Baby Chicks at $65 each = $ 4,030.00

Cost of 10 bags Broiler Ration at $1230 per bag = $ 12,300.00

Cost of 1 pack Hipovit = $ 235.00

Cost of 10 bags Saw Dust at $120 per bag = $ 1,200.00

Cost of Utilities (light & water) = $ 2,500.00

Cost of Transportation (feed, chicks, rice hull etc.) = $ 4,500.00

Cost of Ice = $ 700.00

Cost of 1 pack Plastic bag = $200.00

Total Variable Cost=$ 25,665.00

FIXED COST:

Cost of 1 Tube feeder = $1365.00

Cost of 1 PlassonWaterer = $ 4,900.00

Cost of 1 Heat lamp = $ 930.00

Fixed Cost = $ 7,195.00

Depreciation 10 % of fixed cost = $ 719.05

Total Fixed Cost = $ 7,914.05

Total expenditure =Total Variable Cost + Total Fixed Cost

= $ 7,914.05+$ 25,665.00

= $ 33,579.05

Plus 10% Inflation

= $ 36,936.955

GRAND TOTAL EXPENDITURE = $ 36,936.955

PROJECTED PROFIT:

Net Income = Projected Income Grand Total Expenditure

= $ 38,720.00 - $ 36,936.955

= $ 1,783.045

ACTUAL BUDGET FOR GAB BROILER PROJECT

B. ACTUAL INCOME

Sale of342.5 lbs of Chicken Meat at $155 per lb = $ 53,087.05

Sale of 25 lbs of Feet at $ 90 per lb = $ 2,250.00

Sale of 33.5 lbs of Offal (neck, liver, gizzard) at $90 per lb = $ 3,015

Total Income = $ 58,352.05

ACTUAL EXPENDITURE

VARIABLE COST:

Cost of 65 Baby Chicks at $67 each = $ 4,355.00

Cost of 7 bags Broiler Crumble at $1270 per bag = $ 8,890.00

Cost of 5 bags Broiler Pellet at $1255 per bag = $ 6,275.00

Cost of 1 pack Electrovet = $ 630.00

Cost of 1 pack Booster = $ 495.00

Cost of 1 bottle Hemoplex 250ml = $ 290.00

Cost of 12 bags Rice trash at $100 per bag = $ 1,200.00

Cost of Transportation (feed, chicks, feeders, saw dust etc.) = $ 4,500.00

Cost of 50lbs Ice at $1000 per 100lb = $ 2,000.00

Cost of 1 pack Plastic bag = $ 190.00

Total Variable Cost = $ 28,825.00

FIXED COST:

Cost of 1 Metal tube feeder = $ 500.00

Cost of 1 Heat lamp = $ 505.00

Cost of 1 Plastic tube feeder = $1365.00

Fixed cost = $ 2,370.00

Depreciation 10 % of fixed cost = $ 237.00

Total fixed cost = $ 2,607.00

TOTAL EXPENDITURE = TOTAL VARIABLE COST + TOTAL FIXED COST

= $ 28,825.00+$2,607.00

= $ 31,432

ACTUAL PROFIT:

Net profit = Total income Total expenditure

= $ 58,352.05-$ 31,432

= $ 26,920.05

ANALYSIS

RECOMMENDATIONS

GENERAL COMMENT

CONCLUSION

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Group Iv: Carbon To LeadDokumen7 halamanGroup Iv: Carbon To LeadromiifreeBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Group Vii: The HalogensDokumen9 halamanGroup Vii: The HalogensromiifreeBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- CAPE Carib Studies NotesDokumen271 halamanCAPE Carib Studies NotesTevaughn Campbell72% (32)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Period Three Sodium To ArgonDokumen15 halamanPeriod Three Sodium To ArgonromiifreeBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Qualitative Analysis '10'Dokumen5 halamanQualitative Analysis '10'romiifree100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Physics AssignmentDokumen21 halamanPhysics Assignmentromiifree0% (1)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Heat Sterilisation 1Dokumen27 halamanHeat Sterilisation 1romiifreeBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Biology Internal Assesment: Academic Year: 2014-2015 Unit: 1 Name: Romario Thomas Candidate Number: Tearcher: Mr. HenryDokumen2 halamanBiology Internal Assesment: Academic Year: 2014-2015 Unit: 1 Name: Romario Thomas Candidate Number: Tearcher: Mr. Henryromiifree0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Alkali MetalsDokumen31 halamanAlkali Metalsromiifree100% (1)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Chinese Scholarship Announment 2015Dokumen1 halamanChinese Scholarship Announment 2015romiifreeBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Douglas Forrest Invitational2015 01-18-18!14!47Dokumen43 halamanDouglas Forrest Invitational2015 01-18-18!14!47romiifreeBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Cellular RespirationDokumen29 halamanCellular RespirationromiifreeBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Social and Economic Impacts: HurricanesDokumen18 halamanSocial and Economic Impacts: HurricanesromiifreeBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Epidemiology Review Unit 1Dokumen2 halamanEpidemiology Review Unit 1romiifreeBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Relig Ious Educ Ation Scho OL Base D Asses Smen TDokumen2 halamanRelig Ious Educ Ation Scho OL Base D Asses Smen TromiifreeBelum ada peringkat

- Anthony Graham's ProjectDokumen7 halamanAnthony Graham's ProjectromiifreeBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Candidate Name Sex Date of Birth Age No of Electors Total Votes Received Constituenc y Name Percent Votes ReceivedDokumen4 halamanCandidate Name Sex Date of Birth Age No of Electors Total Votes Received Constituenc y Name Percent Votes ReceivedromiifreeBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Agri Sba (Crop)Dokumen18 halamanAgri Sba (Crop)romiifreeBelum ada peringkat

- Trinbarjam Elections Commission General Election 2014 Test ConstituencyDokumen2 halamanTrinbarjam Elections Commission General Election 2014 Test ConstituencyromiifreeBelum ada peringkat

- Cost Analysis For Science Crops and Livestock EnterpriseDokumen18 halamanCost Analysis For Science Crops and Livestock EnterpriseromiifreeBelum ada peringkat

- Cost Analysis of NestleDokumen8 halamanCost Analysis of NestleKiran Virk75% (4)

- Cash Budget Model Cash Budget Model - Case Study: InflowsDokumen1 halamanCash Budget Model Cash Budget Model - Case Study: Inflowsayu nailil kiromahBelum ada peringkat

- Case Study 2 ContinentalDokumen2 halamanCase Study 2 ContinentalSandeep Konda100% (2)

- 18e Key Question Answers CH 4Dokumen2 halaman18e Key Question Answers CH 4AbdullahMughal100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Indian Income Tax Return Acknowledgement: Name of Premises/Building/VillageDokumen1 halamanIndian Income Tax Return Acknowledgement: Name of Premises/Building/VillagecachandhiranBelum ada peringkat

- Cows and ChickensDokumen9 halamanCows and Chickensapi-298565250Belum ada peringkat

- Endogenous Growth TheoryDokumen16 halamanEndogenous Growth TheoryMaimoona GhaniBelum ada peringkat

- Groen BPP-40E Tilt SkilletDokumen2 halamanGroen BPP-40E Tilt Skilletwsfc-ebayBelum ada peringkat

- Product Life CycleDokumen19 halamanProduct Life CycleTamana Gupta100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Sign ExtrusionDokumen33 halamanSign Extrusionfirebird1972Belum ada peringkat

- HZL 4100070676 Inv Pay Slip PDFDokumen12 halamanHZL 4100070676 Inv Pay Slip PDFRakshit KeswaniBelum ada peringkat

- Evolution of International BusinessDokumen6 halamanEvolution of International Businessabhijeetpatil150% (1)

- Joint Product PricingDokumen2 halamanJoint Product PricingAmit Manhas100% (1)

- 2016 04 1420161336unit3Dokumen8 halaman2016 04 1420161336unit3Matías E. PhilippBelum ada peringkat

- TRH 14 ManualDokumen22 halamanTRH 14 ManualNelson KachaliBelum ada peringkat

- 8C PDFDokumen16 halaman8C PDFReinaBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Chp14 StudentDokumen72 halamanChp14 StudentChan ChanBelum ada peringkat

- Project Budget WBSDokumen4 halamanProject Budget WBSpooliglotaBelum ada peringkat

- Problem Set3Dokumen4 halamanProblem Set3Jack JacintoBelum ada peringkat

- LEVI's SWOT and TOWS AnalysisDokumen13 halamanLEVI's SWOT and TOWS AnalysisRakeysh Coomar67% (3)

- Hazardous Consignment Note BlankDokumen3 halamanHazardous Consignment Note BlankChristopher HenryBelum ada peringkat

- ReshapeDokumen4 halamanReshapearnab1988ghoshBelum ada peringkat

- Fashion and StatusDokumen11 halamanFashion and StatusDiana ScoriciBelum ada peringkat

- FRBM Act: The Fiscal Responsibility and Budget Management ActDokumen12 halamanFRBM Act: The Fiscal Responsibility and Budget Management ActNaveen DsouzaBelum ada peringkat

- EconomicsDokumen14 halamanEconomicscliffordsamuelBelum ada peringkat

- Ficci Ey M and e Report 2019 Era of Consumer Art PDFDokumen309 halamanFicci Ey M and e Report 2019 Era of Consumer Art PDFAbhishek VyasBelum ada peringkat

- CH 12Dokumen27 halamanCH 12DewiRatihYunusBelum ada peringkat

- TFG Manuel Feito Dominguez 2015Dokumen117 halamanTFG Manuel Feito Dominguez 2015Yenisel AguilarBelum ada peringkat

- Betma Cluster RevisedDokumen5 halamanBetma Cluster RevisedSanjay KaithwasBelum ada peringkat

- Purchase Order-Orders Monitoring & Analysis ToolDokumen5 halamanPurchase Order-Orders Monitoring & Analysis ToolSukriti BabbarBelum ada peringkat

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDari EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Real Life: Construction Management Guide from A-ZDari EverandReal Life: Construction Management Guide from A-ZPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- A Place of My Own: The Architecture of DaydreamsDari EverandA Place of My Own: The Architecture of DaydreamsPenilaian: 4 dari 5 bintang4/5 (242)