Blast Concrete Walls

Diunggah oleh

greynoiseHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Blast Concrete Walls

Diunggah oleh

greynoiseHak Cipta:

Format Tersedia

Structures Congress 2015

151

Summary of Blast Tests on Steel-Plate Reinforced Concrete Walls

Jakob C. Bruhl, M.ASCE1 and Amit H. Varma, M.ASCE2

1

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

Ph.D. Candidate, School of Civil Engineering, Purdue University, West Lafayette,

IN 47907. E-mail: jbruhl@purdue.edu

2

Professor, School of Civil Engineering, Purdue University, West Lafayette, IN

47907. E-mail: ahvarma@purdue.edu

Abstract

Conventional reinforced concrete (RC) structures have historically been the

preferred choice for blast and impact resistant structures. Recent research

demonstrates advantages of steel-plate composite (SC) structures that make them an

excellent candidate for efficient construction of protective structures. Understanding

of the behavior, analysis, and design of SC walls for safety-related nuclear structures

in the US and abroad has advanced in the past decade resulting in the publication of a

new specification for their design. A body of knowledge also exists to design SC

structures to resist the effects of projectile impacts. Research on the behavior of SC

walls subjected to blast does not exist in the public domain a loading which has

been identified as a continuing concern for protective structure design. This paper

summarizes results from blast tests of SC walls.

INTRODUCTION

Steel-plate composite (SC) walls consist of steel faceplates with a poured

concrete core (see Figure 1). Steel headed stud anchors provide composite action

between the concrete infill and steel faceplates. Tie bars provide stability during

construction and in-service shear strength. SC walls have recently been used in

nuclear power plant (NPP) projects and are being considered for the next generation

of small modular reactors (SMR). A specification to design SC structures for NPP

applications, AISC N690s1 Appendix N9 (AISC, 2014), contains guidance to design

each component within an SC wall. For safety-related NPP facilities these walls may

be required to resist the effects of impact or impulsive loads. While there are methods

to design SC walls to resist the local effects of projectile impact (i.e. Bruhl et al.

(2015)) there are no accepted methods to design blast resistant SC walls.

There is limited experimental data on the response of SC walls to blast loads

that can be used to validate a design method. Heng et al. (1995) and Lan et al. (2005)

described the results of blast tests on various configurations of steel-concrete

composite panels. None of these configurations included headed stud anchors or tie

bars, which are both important components of the SC structures discussed in this

paper. They tested fully enclosed steel-concrete-steel (SCS) panels and thin profiled

steel sheeting cast compositely with concrete, similar to that in a composite deck.

ASCE

Structures Congress 2015

Structures Congress 2015

152

Liew & Wang (2011) reported results from a series of blast tests on two different

types of steel-concrete composite panels: cellular stiffened panels and a unique

configuration which used J-hooks in place of headed stud anchors and tie bars. Hulton

& Gough (1999) and Hulton (1995) provided quantitative descriptions of blast tests of

what eventually became the Bi-Steel system. Of the different configurations

previously tested, Bi-Steel is most similar to the general SC system described in this

paper but is proprietary and has some key differences from SC structures designed in

accordance with AISC N690s1 Appendix N9.

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

Pipe Sleeve

(for Penetrations

Through SC Panel)

Steel Headed Stud Anchors

Steel Plate

Tie Bars

Concrete

Embed Plate

for Commodity

Attachments

Steel Plate

Figure 1. Typical SC Wall Section (from Johnson et al. (2014))

The purpose of this paper is to summarize: (1) the blast test program

conducted on a variety of SC walls designed in accordance with AISC N690s1

Appendix N9, (2) results from a representative test specimen, and (3) comparisons of

the blast response of SC walls and RC walls.

EXPERIMENTAL PROGRAM

Twelve one-way SC wall specimens were subjected to blast loads using the

U.S. Army Corps of Engineers Engineering Research and Development Center

(USACE-ERDC) Geotechnical and Structures Laboratory (GSL) Blast Load

Simulator (BLS) located in Vicksburg, MS. This facility can be tuned to create

pressure waves, which replicate those generated by high explosives at various farfield stand-off distances. The components, operation, and limitations of the BLS are

described by Johnson (2013).

Eight different SC wall designs were tested which varied steel plate thickness,

steel plate strength, tie bar spacing, and tie bar diameter (see Table 1). Figure 2

provides design details and Figure 3 depicts a specimen prior to being filled with

ASCE

Structures Congress 2015

Structures Congress 2015

153

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

conncrete. The specimens were one-thhird scale with

w

the folllowing dim

mensions: 4inchhes total thicckness, tsc; 11-inches

1

wiide; and 64--in long. Thhe support frrame within

the BLS was designed

d

to provide sim

mple supporrts with 6-innches of overhang: the

unssupported leength was 522-inches. Various gradees and thickkness of A1011 HSLA

hott-rolled steell sheet were used. Conccrete had dayy-of-test com

mpressive strrengths, fc,

betw

ween 6200-p

psi and 6600-psi. Various diameteers of mild steel

s

threadeed rod were

useed as tie bars, the size of

o which waas determineed using AIS

SC N690 Apppendix N9

andd accounting

g for dynam

mic shear efffects. To accommodat

a

te tie bars, holes were

drillled in each steel sheet and

a hex nutss placed insiide and outsiide of the stteel sheet to

secure tie bars prior to conncrete placem

ment. Compposite actionn for all speccimens was

achhieved using

g 0.25-inch diameter, 1--1/8-inches long, Nelson headed sttud anchors

spaaced at 2-inch

hes on centeer.

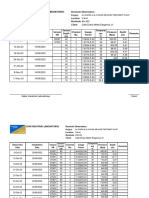

Table 1 provides details

d

abouut the designn of each specimen:

s

plate (sheet)

thicckness, tp; fleexural reinfoorcement rattio, ; ratio of

o stud spaciing, s, to platte thickness

(thee slendernesss ratio); ratiio of stud diiameter, ds, to plate thicckness; grade of A1011

HSLA steel sheet; tie bar diameter, dt, and corressponding sheear reinforceement ratio,

s; and the ratio

o of tie bar sppacing, S, too total specim

men thicknesss, tsc.

s

S

tsc

(b) End

(a) Sidee

ure 2. Blast Test Specim

men Design

n

Figu

A101

11 steel sheet

Headed stud anchors

Hex nuts to secu

ure tie rods to steel sheeet

T

Threaded

tie rods

Figurre 3. Photo of

o SC Specim

men Prior to Infilling with

w Concreete

Table 1. Sp

pecimen Dim

mension and Material Details

Specimen

n

3-2-50-5

3-2b-50-5

3-2-65-5

3-2b-65-5

5-4-50-5

5-2-50-5

5-2b-50-5

5-2-80-5

tp (in)

0.079

0.079

0.069

0.069

0.112

0.112

0.112

0.099

(%)

4.0%

4.0%

3.5%

3.5%

5.6%

5.6%

5.6%

5.0%

s//tp

ds/tp

25.3

25.3

29.0

29.0

35.7

17.9

17.9

20.2

3.16

3.16

3.62

3.62

2.23

2.23

2.23

2.53

Sheet

S

G

Grade

G

Gr50

G

Gr50

G

Gr65

G

Gr65

G

Gr50

G

Gr50

G

Gr50

G

Gr80

ASCE

Structures Congress 2015

dt (inn)

s (%)

S/tsc

0.13880

0.16440

0.13880

0.16440

0.31225

0.16440

0.25000

0.25000

0.37%

0.53%

0.37%

0.53%

0.48%

0.53%

1.23%

1.23%

0.50

0.50

0.50

0.50

1.50

0.50

0.50

0.50

Structures Congress 2015

154

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

Prior to conducting dynamic tests in the BLS, static four-point bending tests

of each specimen were completed. Figure 4 depicts the static test setup. A shear arm

of 18-inches (a/tsc = 4.5) was used for each test. Load was applied by a single

actuator and spreader beam. Displacements were measured at the three quarter-points

of the specimen using linear extensometers. Rotations were measured at the ends and

directly under the load points using inclinometers. Strains on the tension face were

measured at the quarter points and strain on the compression face was measured at

mid-span.

Static results were used to benchmark numerical models which were then used

to analyze the static behavior of each specimen loaded with increasing uniform

pressure. Two numerical methods were used: (1) a fiber model to calculate momentcurvature relationships and moment-area method to generate load-displacement

relationships, and (2) non-linear explicit finite element analysis using LS-DYNA. The

result of these experiments and analyses was the static resistance function of each

specimen for use in single-degree-of-freedom (SDOF) dynamic analysis to compare

to experimental results.

Figure 4. Static Four-Point Bending Test Setup

Three specimens were tested simultaneously in the BLS by loading them

adjacent to one another with 0.25-inches between each specimen and 0.25-inches

between the end specimens and the BLS frame, as shown in Figure 5. Displacements

at mid-span were measured using linear potentiometers and were also calculated from

accelerometer data as a check. Displacements 8.75-inches from mid-span were

measured using linear extensometers. Strains on the tension (non-blast) face were

measured at the quarter points and strain on the compression (blast) face was

measured at mid-span. Pressure was measured by eight pressure transducers placed

around the perimeter of the frame. Three high-speed video cameras captured the

specimen response from different angles.

ASCE

Structures Congress 2015

Structures Congress 2015

155

1-1/4-in

1-1/4-in

8-in

8-in

~2-in

3-in

Right

Center

Left

Specimen Specimen Specimen

Left

Center

Right

Specimen Specimen Specimen

52-in

3-in

68-in 70-3/4-in

52-in

68-in 70-3/4-in

8-in

8-in

1-1/2-in

1-1/2-in

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

~2-in

(a) Blast Face

(b) Interior (Non-Blast) Face

Figure 5. Test Specimens in BLS Frame and Instrumentation Plan

Four tests were conducted with a total of six BLS shots. The first two tests

consisted of two shots: a lower pressure-impulse intended to stay within the elastic

range of response and a higher pressure-impulse combination intended to exceed the

elastic capacity of the specimens. The second two tests consisted of only the higher

pressure-impulse combination.

REPRESENTATIVE RESULTS

18

90.0

16

80.0

14

70.0

12

60.0

Pressure (psi)

Shear (kips)

The test results of only one specimen are summarized for brevity. This

specimen (5-2b-50-5) represents a typical SC wall design and was a one-third scale

specimen of the minimum practical SC wall (12-in total thickness with 0.25-in steel

plates). It was comprised of A1011 HSLA Grade 50 gage 12 hot-rolled steel sheets

and -inch diameter tie bars at 2-inch spacing. The measured material properties are

provided in Bruhl (2015). The flexural reinforcment ratio using measured steel sheet

thickness was 5.6%. The holes drilled in the steel sheet to accommodate tie bars

resulted in 12.8% reduction in section. Calculated moment capacity of the net section

was 223-kipinches. Static test of the specimen confirmed this moment capacity and

yielded the static resistance functions shown in Figure 6.

10

8

6

5-2b-50-5

0

0.5

1.5

2.5

30.0

3.5

from Moment-Curvature

10.0

FEM

0

40.0

20.0

from Moment-Curvature

50.0

0.0

0.00

FEM

0.50

1.00

1.50

2.00

2.50

Mid-Span Displacement (in)

Mid-Span Displacement (in)

(a) Four-Point Bending

(b) Uniform Pressure

Figure 6. Static Resistance Functions (5-2b-50-5)

ASCE

Structures Congress 2015

3.00

3.50

Structures Congress 2015

156

Pressure (psi)

20

70

1200

250

60

1000

200

15

150

10

100

Pressure

50

Impulse

0

-5

-50

50

100

150

800

40

600

30

400

20

200

Pressure

10

Impulse

50

200

-200

-10

0

50

100

150

200

Time (msec)

Time (msec)

(a) Lower Pressure Shot (Sensor P5)

(b) Higher Pressure Shot (Sensor P6)

Figure 7. Measured Pressure-Time History and Calculated Impulse

ASCE

Structures Congress 2015

Impulse (psimsec)

25

300

Pressure (psi)

30

Impulse (psimsec)

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

This specimen was tested dynamically twice: first with a lower pressure and

then with a higher pressure. The average measured pressures and impulses were

18.9-psi and 260-psimsec for the first shot and 61.6-psi and 1068-psimsec for the

second shot. Representative pressure-time history and calculated impulse for each

shot are shown in Figure 7.

Transient displacement and strain measurements for both shots are shown in

Figure 8 and Figure 9. When corrected for frame movement, the maximum

displacement of the specimen from the first shot was 0.11-inches with 0.08-inches of

residual displacement. Displacement measured by the potentiometer was close to that

calculated from accelerometer data. The displacement measured by the linear

extensometer was smaller than that from the other two sensors because it was not

located at mid-span as the others were. While yield strain was not reached in the steel

sheets, the strain gages measured small residual strains.

Maximum displacement from the second shot was 0.49-inches with 0.24inches residual displacement (corrected to account for frame movement). The

displacement measured by the potentiometer was larger than that calculated from

accelerometer measurements. The tension steel sheet yielded during the second shot

as evidenced by the change in slope of the strain history at approximately 2000-,

the residual strain of approximately 1500-, and the residual displacement of the

specimen.

After the second shot, the specimens were removed from the frame, cracks

marked and photographs taken. This was not done after the first shot so as not to

disturb the specimen before the second shot. As seen in Figure 10, flexural cracks

were most prevalent near mid-span and there was limited shear cracking. Residual

displacement is evident in this figure.

Structures Congress 2015

157

0.5

1000

750

500

0.25

Microstrain

Displacment (in)

0.375

0.125

-0.125

-25

25

50

75

100

SG4

SG3

SG2

SG1

-250

Cable extensometer

Potentiometer

Accelerometer

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

250

-500

-25

125

25

50

Time (msec)

75

100

125

150

175

200

Time (msec)

(a) Displacements

(b) Strains

Figure 8. Dynamic Response (5-2b-50-5; pr = 18.9-psi; ir = 260-psimsec)

1

4000

3000

0.75

0.5

Microstrain

Displacment (in)

2000

0.25

1000

0

-1000

0

Cable extensometer

Potentiometer

Accelerometer

-0.25

-25

25

50

75

100

125

SG4

SG3

SG2

SG1

-2000

-3000

-25

Time (msec)

25

50

75

100

125

150

175

200

Time (msec)

(a) Displacements

(b) Strains

Figure 9. Dynamic Response (5-2b-50-5; pr = 61.6-psi; ir = 1068-psimsec)

Figure 10. Post-test Crack Map (5-2b-50-5)

COMPARISON OF SC AND RC PERFORMANCE

While flexural reinforcement ratios of the SC specimens included in this study

were larger than typical RC reinforcement ratios, comparison of their performances is

instructive. Thiagarajan, et al., (2014) reported experimental results from a program

which investigated the influence of different reinforcement and concrete strengths.

Their tests of 4-in thick RC slabs were conducted in the BLS and applied pressure

waves nearly identical to those of the high pressure shot shown in Figure 7(b). Each

panel in their study was doubly reinforced with 1.5% total flexural reinforcement.

The panels included shrinkage reinforcement but did not have shear reinforcing steel.

Two varieties of concrete were investigated: normal strength (NSC, 4000-psi) and

high-strength (HSC, 15,500-psi).

Two steel reinforcement strengths were

investigated: conventional (NR, 50-ksi yield) and HSLA-V (VR, 83-ksi yield).

ASCE

Structures Congress 2015

Structures Congress 2015

158

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

Maximum mid-span deflections were largest for NSC-NR panels (8.7-inches) and

smallest for HSC-VR panels (4.8-inches) indicating that the use of higher strength

materials improved the blast resistance of RC structures. Comparing the response of

the NSC-NR panels to specimen 5-2b-50-5 suggests that typical SC walls deflect

much less than typical RC walls subjected to the same blast pressure.

Coyle & Cormie (2009) suggested that the same level of protection could be

provided by a Bi-Steel wall which was less than half the thickness of an RC wall.

Their comparison was between a Bi-Steel wall with 8% and a RC wall with 1% total

flexural reinforcement. A numerical investigation of SC and RC wall sections with

the same reinforcement ratio was reported by Bruhl & Varma (2014). Their study

included nine SC models and nine RC models consisting of 12-inch thick wall

sections comprised of conventional construction materials (5000-psi concrete and

Grade 50 steel). The flexural reinforcement ratio was approximately 5% for both the

SC and RC section. Various lengths and pressure-impulse combinations were

included in the study. Results indicated smaller deflections for SC structures

compared to RC structures. The authors concluded that this was due, in part, to the

fact that the steel reinforcement in an SC wall is at the extreme fiber while it cannot

be for an RC wall due to clear cover requirements. Thus, for the same section depth,

the moment capacity and flexural rigidity is inherently larger for an SC wall than an

RC wall of the same thickness. It is important to note that RC walls have significant

rebar congestion and concrete placement issues at reinforcement ratios greater than

1.5%. The advantages of SC walls become evident for high reinforcement ratios.

CONCLUSIONS

This paper provided an overview of a test program investigating the

performance of one-way SC structures subjected to blast pressures and presented

results from one specimen. Results from this study confirmed the influence of

reinforcement ratio and steel strength on blast resistance. Results corroborated

conclusions by others that SC structures provide improved blast resistance when

compared to RC structures. Continued investigation of the blast response of SC

structures to other than far-field explosions is necessary. Improved understanding of

connection details and the influence of shear reinforcement are important.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the assistance of Dr. Carol Johnson,

USACE ERDC, for her efforts during planning and execution of this experimental

program. The authors also thank the USACE ERDC technical staff that assisted in

the execution of the test program. This research was funded by the U.S. Department

of Energy (SL-14ID020104).

REFERENCES

American Institute of Steel Construction. (2014). Specification for Safety-Related

Steel Structures for Nuclear Facilities Supplement No. 1 (AISC N690s1)

PUBLIC REVIEW DRAFT DATED 5-1-14. Chicago, IL: American Institute of

ASCE

Structures Congress 2015

Structures Congress 2015

159

Downloaded from ascelibrary.org by Fernando S-F on 07/22/15. Copyright ASCE. For personal use only; all rights reserved.

Steel Construction. Retrieved from

http://www.aisc.org/WorkArea/showcontent.aspx?id=37900

Bruhl, J. C. (2015). Response of Steel-Plate Reinforced Concrete Walls Subjected to

Impulsive Loads (Doctoral Dissertation). Purdue University.

Bruhl, J. C., & Varma, A. H. (2014). Preliminary Study of Blast Response of Steel

Plate-Reinforced Concrete Walls. In Structures Congress 2014 (pp. 105116).

Reston, VA: American Society of Civil Engineers.

doi:10.1061/9780784413357.011

Bruhl, J. C., Varma, A. H., & Johnson, W. H. (2015). Design of composite SC walls

to prevent perforation from missile impact. International Journal of Impact

Engineering, 75, 7587. doi:10.1016/j.ijimpeng.2014.07.015

Coyle, N., & Cormie, D. (2009). Design of elements in steel-concrete-steel composite

materials. In D. Cormie, G. Mays, & P. Smith (Eds.), Blast effects on buildings

(2nd ed., pp. 154176). London, UK: Thomas Telford.

Heng, L., Kennedy, L. J., & Mays, G. C. (1995). Blast Resistance of Fully Enclosed

Steel-Concrete-Steel Standwich Panels. In 7th International Symposium on

Interaction of the Effects of Munitions with Structures (pp. 189197).

Mannheim, Germany.

Hulton, F. G. (1995). The Behaviour of Steel-backed Reinforced Concrete Panels

under Explosive Attack. In 7th International Symposium on Interaction of the

Effects of Munitions with Structures (pp. 111116). Mannheim, Germany.

Hulton, F. G., & Gough, M. S. (1999). The development of steel-plate/reinforced

concrete composite panels to resist explosive attack. In 9th International

Symposium on Interaction of the Effects of Munitions with Structures (pp. 63

69). Berlin-Straussberg, Germany.

Johnson, C. F. (2013). Concrete Masonry Wall Retrofit Systems for Blast Protection

(Doctoral Dissertation). Texas A&M University.

Johnson, W., Bruhl, J., Reigles, D., Li, J., & Varma, A. (2014). Missile Impact on SC

Walls: Global Response. In Structures Congress 2014 (pp. 14031414). Reston,

VA: American Society of Civil Engineers. doi:10.1061/9780784413357.124

Lan, S., Lok, T.-S., & Heng, L. (2005). Composite structural panels subjected to

explosive loading. Construction and Building Materials, 19(5), 387395.

doi:10.1016/j.conbuildmat.2004.07.021

Liew, J. Y. R., & Wang, T. Y. (2011). Novel Steel-Concrete-Steel Sandwich

Composite Plates Subject to Impact and Blast Load. Advances in Structural

Engineering, 14(4), 673688. doi:10.1260/1369-4332.14.4.673

Thiagarajan, G., Kadambi, A. V., Robert, S., & Johnson, C. F. (2014). Experimental

and finite element analysis of doubly reinforced concrete slabs subjected to blast

loads. International Journal of Impact Engineering, 75, 162173.

doi:10.1016/j.ijimpeng.2014.07.018

ASCE

Structures Congress 2015

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Cumulative Deformation Capacity of Steel Braces Under Various Cyclic Loading HistoriesDokumen11 halamanCumulative Deformation Capacity of Steel Braces Under Various Cyclic Loading HistoriesgreynoiseBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Numerical Investigation On Accuracy of Mass Spring Models FoDokumen13 halamanNumerical Investigation On Accuracy of Mass Spring Models FogreynoiseBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Foundations of LEED PDFDokumen28 halamanFoundations of LEED PDFChris AnthonyBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Cultural Cold War The CIA and The World of Arts and LettersDokumen1 halamanThe Cultural Cold War The CIA and The World of Arts and LettersgreynoiseBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- CORRELATIONS BETWEEN THE DISPLACEMENT RESPONSE SPECTRA AND The Parameters Characterising The Magnitude of The Ground MotionDokumen8 halamanCORRELATIONS BETWEEN THE DISPLACEMENT RESPONSE SPECTRA AND The Parameters Characterising The Magnitude of The Ground MotiongreynoiseBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Effects of Cut-and-Cover Tunnel Construction On Adjacent Piles of An Overpass in Bangkok Soft ClayDokumen8 halamanEffects of Cut-and-Cover Tunnel Construction On Adjacent Piles of An Overpass in Bangkok Soft ClayAA_BB_HHBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Performance-Based Design of Seismically Isolated BridgesDokumen953 halamanPerformance-Based Design of Seismically Isolated BridgesgreynoiseBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Performance of T-Stub To CFT Joints Using Blind Bolts With Headed AnchorsDokumen11 halamanPerformance of T-Stub To CFT Joints Using Blind Bolts With Headed AnchorsgreynoiseBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- 33-ODOT Prestressed Design FINALDokumen444 halaman33-ODOT Prestressed Design FINALMustafa UzyardoğanBelum ada peringkat

- Simplified Seismic Analysis Procedures For Elevated TanksDokumen19 halamanSimplified Seismic Analysis Procedures For Elevated TanksCesar Yoshio Sanchez HuchiyamaBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Shock and Vibration BulletinDokumen286 halamanThe Shock and Vibration BulletingreynoiseBelum ada peringkat

- Housner GW 1954Dokumen42 halamanHousner GW 1954Carlos RoblesBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- SATREPS Report E FinalDokumen170 halamanSATREPS Report E FinalgreynoiseBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Numerical Wave Tanks Based On Finite Element and BoundaryDokumen22 halamanNumerical Wave Tanks Based On Finite Element and BoundarygreynoiseBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Numerical Investigation On Accuracy of Mass Spring Models FoDokumen13 halamanNumerical Investigation On Accuracy of Mass Spring Models FogreynoiseBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Sponsors For ConferenceDokumen1 halamanSponsors For ConferencegreynoiseBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Finite Element Analysis of A Seismically Excited Cylindrical Storage Tank, Ground Supported, and Partially Filled With LiquidDokumen114 halamanFinite Element Analysis of A Seismically Excited Cylindrical Storage Tank, Ground Supported, and Partially Filled With LiquidgreynoiseBelum ada peringkat

- Committee Reviewers StaffDokumen3 halamanCommittee Reviewers StaffgreynoiseBelum ada peringkat

- Exhibitors For ConferenceDokumen1 halamanExhibitors For ConferencegreynoiseBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 13 394Dokumen14 halaman13 394deepakmitrBelum ada peringkat

- Characteristics of Local Site Effects on Seismic MotionDokumen7 halamanCharacteristics of Local Site Effects on Seismic MotiongreynoiseBelum ada peringkat

- ART 2011 1 AOGR 3d Reservoir Modeling PDFDokumen4 halamanART 2011 1 AOGR 3d Reservoir Modeling PDFgreynoiseBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Welcome Conference SpeechDokumen1 halamanWelcome Conference SpeechgreynoiseBelum ada peringkat

- Appendix CDokumen1 halamanAppendix CgreynoiseBelum ada peringkat

- Key Note Lectures ConferenceDokumen9 halamanKey Note Lectures ConferencegreynoiseBelum ada peringkat

- LRFD Design of SuperstructureDokumen1.288 halamanLRFD Design of SuperstructureJeong Woon KangBelum ada peringkat

- Omron Presion Manual Hem-637 - 2006 Im Eng1Dokumen17 halamanOmron Presion Manual Hem-637 - 2006 Im Eng1greynoiseBelum ada peringkat

- Design Characteristics of High Damping Rubber Bearing: Dimension and Performance Properties of H-RBDokumen3 halamanDesign Characteristics of High Damping Rubber Bearing: Dimension and Performance Properties of H-RBgreynoiseBelum ada peringkat

- EulaDokumen3 halamanEulaBrandon YorkBelum ada peringkat

- Liquid SolutionsDokumen9 halamanLiquid SolutionsrockBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- RMTUTORIALSDokumen10 halamanRMTUTORIALSAnyasi UcheBelum ada peringkat

- Water Table Observation - 12 MarchDokumen5 halamanWater Table Observation - 12 Marchrupeshkumar642mdsBelum ada peringkat

- Pascal's Principle and Hydraulics ExplainedDokumen4 halamanPascal's Principle and Hydraulics ExplainedMochamad Yoga Windu DharmawanBelum ada peringkat

- Soluforce Catalogue PDFDokumen32 halamanSoluforce Catalogue PDFsureshisisis100% (1)

- SIHIDokumen3 halamanSIHIjesica31Belum ada peringkat

- Dynamics: Engr. Kristian C. MagsalinDokumen47 halamanDynamics: Engr. Kristian C. MagsalinCed SisonBelum ada peringkat

- Pressure testing methods for gas supply systemsDokumen27 halamanPressure testing methods for gas supply systemsMatej ZirdumBelum ada peringkat

- Wanted Gravity DamDokumen167 halamanWanted Gravity Damhabtamu0% (1)

- Astm-F1759 - Hdpe Mahole DesignDokumen12 halamanAstm-F1759 - Hdpe Mahole DesignSusanta PanigrahyBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Fluid Mechanics: Lecture Notes ofDokumen30 halamanFluid Mechanics: Lecture Notes ofAlsharksi AviationBelum ada peringkat

- Water RochetDokumen33 halamanWater RochetDerara UmetaBelum ada peringkat

- NPSH Calculating It PDFDokumen6 halamanNPSH Calculating It PDFSanthosh ThekkethottiyilBelum ada peringkat

- Specifying Shell and Tube Heat ExchangersDokumen10 halamanSpecifying Shell and Tube Heat ExchangersMicheal BrooksBelum ada peringkat

- Filtrec F100 SeriesDokumen8 halamanFiltrec F100 Serieshkhan10Belum ada peringkat

- 15Dokumen10 halaman15Tuan Nguyen ManhBelum ada peringkat

- Thermal Energy Calculations and ConceptsDokumen8 halamanThermal Energy Calculations and ConceptsPraphul MalolBelum ada peringkat

- Tutorial Fluent (Dados NETO)Dokumen216 halamanTutorial Fluent (Dados NETO)Suellen Freire Rigatto100% (1)

- ST BFV Torque Table (Rev5.0)Dokumen2 halamanST BFV Torque Table (Rev5.0)Anand KumarBelum ada peringkat

- NFPA 20 Fire Pump Start Stop SettingsDokumen1 halamanNFPA 20 Fire Pump Start Stop Settingsnewaz20100% (1)

- ASNT Level III Questions - HDDDokumen28 halamanASNT Level III Questions - HDDMohammedBujair57% (7)

- Cavanagh (1980) Ground Reaction Forces in Distance RunningDokumen10 halamanCavanagh (1980) Ground Reaction Forces in Distance RunningLaboratory in the WildBelum ada peringkat

- Gas Cylinder RulesDokumen50 halamanGas Cylinder RulesSwaminathan GS100% (9)

- d6066 (PotencialLicuefaccion)Dokumen16 halamand6066 (PotencialLicuefaccion)Victor HernandezBelum ada peringkat

- Pre ASTM D 1149-2018Dokumen5 halamanPre ASTM D 1149-2018Ranga67% (3)

- PVT Express: Delivering Early Fluid Analysis DataDokumen5 halamanPVT Express: Delivering Early Fluid Analysis DataAnderson MatosBelum ada peringkat

- Fluid Flow in Circular TubeDokumen38 halamanFluid Flow in Circular Tubeahmed50% (2)

- gh10 IomDokumen4 halamangh10 IomUsman ArshadBelum ada peringkat

- Hamilton Water Supply Design GuideDokumen7 halamanHamilton Water Supply Design GuideHoàngViệtAnhBelum ada peringkat

- Astm F 442-99Dokumen7 halamanAstm F 442-99JORGE ARTURO TORIBIO HUERTA100% (2)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDari EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaBelum ada peringkat

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDari EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniversePenilaian: 4.5 dari 5 bintang4.5/5 (50)

- The Fabric of Civilization: How Textiles Made the WorldDari EverandThe Fabric of Civilization: How Textiles Made the WorldPenilaian: 4.5 dari 5 bintang4.5/5 (57)

- Sully: The Untold Story Behind the Miracle on the HudsonDari EverandSully: The Untold Story Behind the Miracle on the HudsonPenilaian: 4 dari 5 bintang4/5 (103)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDari EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationPenilaian: 4.5 dari 5 bintang4.5/5 (46)

- A Place of My Own: The Architecture of DaydreamsDari EverandA Place of My Own: The Architecture of DaydreamsPenilaian: 4 dari 5 bintang4/5 (241)

- Pale Blue Dot: A Vision of the Human Future in SpaceDari EverandPale Blue Dot: A Vision of the Human Future in SpacePenilaian: 4.5 dari 5 bintang4.5/5 (586)

- Highest Duty: My Search for What Really MattersDari EverandHighest Duty: My Search for What Really MattersBelum ada peringkat

- The Weather Machine: A Journey Inside the ForecastDari EverandThe Weather Machine: A Journey Inside the ForecastPenilaian: 3.5 dari 5 bintang3.5/5 (31)