Manometre Fise Tehnice 2000.i PDF

Diunggah oleh

Gaina IOnutDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Manometre Fise Tehnice 2000.i PDF

Diunggah oleh

Gaina IOnutHak Cipta:

Format Tersedia

004_Layout 2 7/12/13 11:17 AM Page 4

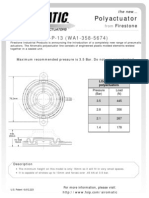

PRESSURE

Series

2000

Magnehelic Differential Pressure Gages

Indicate Positive, Negative or Differential, Accurate within 2%

.025 (.64) SPACE CREATED BY 3

SPACER PADS WHEN SURFACE

MOUNTED. DO NOT OBSTRUCT.

PROVIDES PATH FOR RELIEF OF

OVERPRESSURE.

1-1/4

(31.75)

Differential Pressure Gages

4-1/2

(114.3)

4-3/4

(120.65)

RoHS

(3) 6-32 X 3/16 (4.76) DEEP HOLES

RUBBER PRESSURE RELIEF EQUALLY SPACED ON A 4-1/8

PLUG WILL UNSEAT ITSELF (104.78) BOLT CIRCLE FOR

PANEL MOUNTING

WHEN GAGE IS

1/8 FEMALE NPT

17/32 OVERPRESSURIZED

HIGH PRESSURE

(13.49)

CONNECTION

1/8 FEMALE

NPT HIGH

PRESSURE

CONNECTION

1-3/4

(44.45)

1/8 FEMALE

NPT LOW

PRESSURE

CONNECTION

1/2

(12.70)

15/32

(11.91)

1-11/16

(42.86)

17/32

(13.49)

1/8 FEMALE NPT

LOW PRESSURE

CONNECTION

11/16

(17.46)

7/16

(11.11)

4-3/4 (120.65) PANEL CUTOUT

5

(127)

1-1/4

(31.75)

1/8 FEMALE NPT

HIGH PRESSURE

CONNECTION

1-3/4

(44.45)

4-47/64

(120.27)

4-1/2

(114.3)

1/2

(12.70)

5-1/2

(139.70)

MOUNTING RING

Select the Dwyer Magnehelic gage for high accuracy guaranteed within 2% of

full-scale and for the wide choice of 81 models available to suit your needs precisely. Using

Dwyer's simple, frictionless Magnehelic gage movement, it quickly indicates low air or noncorrosive gas pressures either positive, negative (vacuum) or differential. The design

resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or

cause toxic or leveling problems. It's inexpensive, too.

The Magnehelic gage is the industry standard to measure fan and blower pressures,

filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid

levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also

checks gas-air ratio controls and automatic valves, and monitors blood and respiratory

pressures in medical care equipment.

Mounting

A single case size is used for most models of Magnehelic gages. They can be flush

or surface mounted with standard hardware supplied. Although calibrated for vertical

position, many ranges above 1 may be used at any angle by simply re-zeroing.

However, for maximum accuracy, they must be calibrated in the same position in

which they are used. These characteristics make Magnehelic gages ideal for both

stationary and portable applications. A 4-9/16 hole is required for flush panel

mounting. Complete mounting and connection fittings, plus instructions, are

furnished with each instrument. See page 7 for more information on mounting

accessories.

15/32

(11.91)

2-17/32

(64.29)

3/16

(4.76)

11/16

(17.46)

1/8 FEMALE

NPT LOW

PRESSURE

CONNECTION

SPECIFICATIONS

Service: Air and non-combustible, compatible gases (natural gas option available).

Note: May be used with hydrogen. Order a Buna-N diaphragm. Pressures must be

less than 35 psi.

Wetted Materials: Consult factory.

Housing: Die cast aluminum case and bezel, with acrylic cover. Exterior finish is

coated gray to withstand 168 hour salt spray corrosion test.

Accuracy: 2% of FS (3% on - 0, -100 Pa, -125 Pa, 10MM and 4% on - 00, -60

Pa, -6MM ranges), throughout range at 70F (21.1C).

Pressure Limits: -20 in Hg to 15 psig (-0.677 to 1.034 bar); MP option: 35 psig

(2.41 bar); HP option: 80 psig (5.52 bar).

Overpressure: Relief plug opens at approximately 25 psig (1.72 bar), standard

gages only. See Overpressure Protection Note on next page.

Temperature Limits: 20 to 140F* (-6.67 to 60C). -20F (-28C) with low

temperature option.

Size: 4 (101.6 mm) diameter dial face.

Mounting Orientation: Diaphragm in vertical position. Consult factory for other

position orientations.

Process Connections: 1/8 female NPT duplicate high and low pressure taps one pair side and one pair back.

Weight: 1 lb 2 oz (510 g), MP & HP 2 lb 2 oz (963 g).

Standard Accessories: Two 1/8 NPT plugs for duplicate pressure taps, two 1/8

pipe thread to rubber tubing adapter, and three flush mounting adapters with

screws. (Mounting and snap ring retainer substituted for three adapters in MP &

HP gage accessories.)

Agency Approval: RoHS. Note:-SP models not RoHS approved.

For applications with high cycle rate within gage total pressure rating, next higher rating

is recommended. See Medium and High pressure options at lower left.

ACCESSORIES

Flush, Surface or Pipe Mounted

Model A-432 Portable Kit

Combine carrying case with any Magnehelic gage of

standard range, except high pressure connection.

Includes 9 ft (2.7 m) of 3/16 ID rubber tubing,

standhang bracket and terminal tube with holder.

Model A-605 Air Filter Gage Accessory Kit

Adapts any standard Magnehelic gage for use as an

air filter gage. Includes aluminum surface mounting

bracket with screws, two 5 ft (1.5 m) lengths of 1/4

aluminum tubing two static pressure tips and two

molded plastic vent valves, integral compression

fittings on both tips and valves.

Enclosure Mounted

A-605B Air Filter Gage Accessory Kit, Air filter kit with two plastic open/close

valves, two 4 steel static tips, plastic tubing and mounting flange

A-605C Air Filter Gage Accessory Kit, Air filter kit with two plastic open/close

valves, two plastic static tips, plastic tubing and mounting flange

DWYER INSTRUMENTS, INC. | www.dwyer-inst.com

005_Layout 2 7/12/13 11:19 AM Page 5

PRESSURE

Series

2000

Magnehelic Gage Models & Ranges

O-ring seal for cover assures pressure integrity of case.

Clear plastic face is highly resistant to breakage. Provides

undistorted viewing of pointer and scale.

OVERPRESSUREPROTECTION

Blowout plug is comprised of a rubber plug on the rear which

functions as a relief valve by unseating and venting the gage

interior when over pressure reaches approximately 25 psig (1.7

bar).To provide a free path for pressure relief, there are four

spacer pads which maintain 0.023 clearance when gage is

surface mounted. Do not obstruct the gap created by these pads.

The blowout plug is not used on models above 180 of water

pressure, medium or high pressure models, or on gages which

require an elastomer other than silicone for the diaphragm.

The blowout plug should not be used as a system overpressure

control. High supply pressures may still cause the gage to fail due

to over pressurization, resulting in property damage or serious

injury. Good engineering practices should be utilized to prevent

your system from exceeding the ratings or any component.

Precision litho-printed scale is accurate and easy to read.

Red tipped pointer of heat treated aluminum tubing is easy

to see. It is rigidly mounted on the helix shaft.

Pointer stops of molded rubber prevent pointer over-travel

without damage.

Wishbone assembly provides mounting for helix, helix

bearings and pointer shaft.

Jeweled bearings are shock-resistant mounted; provide

virtually friction-free motion for helix. Motion damped with

high viscosity silicone fluid.

Zero adjustment screw is conveniently located in the

plastic cover, and is accessible without removing cover.

O-ring seal provides pressure tightness.

Die cast aluminum case is precision made and iridite-dipped to

withstand 168 hour salt spray corrosion test. Exterior finished in

baked dark gray hammerloid. One case size is used for all

standard pressure options, and for both surface and flush

mounting.

Helix is precision made from an alloy of high magnetic

permeability. Mounted in jeweled bearings, it turns freely,

following the magnetic field to move the pointer across

the scale.

Silicone rubber diaphragm with integrally molded O-ring is

supported by front and rear plates. It is locked and sealed in

position with a sealing plate and retaining ring. Diaphragm motion

is restricted to prevent damage due to overpressures.

Calibrated range spring is flat spring steel. Small amplitude

of motion assures consistency and long life. It reacts to

pressure on diaphragm. Live length adjustable for calibration.

Samarium Cobalt magnet mounted at one end of range spring

rotates helix without mechanical linkages.

Range Inches

of Water

Model

.05-0-.2

2000-00N

0-.25

2000-00

0-.50

2000-0

0-1.0

2001

0-2.0

2002

0-3.0

2003

0-4.0

2004

0-5.0

2005

0-6.0

2006

0-8.0

2008

0-10

2010

0-12

2012

0-15

2015

0-20

2020

0-25

2025

0-30

2030

0-40

2040

0-50

2050

0-60

2060

0-80

2080

0-100

2100

0-120

2120

0-150

2150

0-160

2160

0-180

2180*

0-250

2250*

Zero Center Ranges

0.125-0-0.125

2300-00

.25-0-.25

2300-0

.5-0-.5

2301

1-0-1

2302

2-0-2

2304

5-0-5

2310

10-0-10

2320

15-0-15

2330

Model

2201

2202

2203

2204

2205

2210*

2215*

2220*

2230**

Range

PSI

0-1

0-2

0-3

0-4

0-5

0-10

0-15

0-20

0-30

Range,

CM of

Water

Model

0-15

2000-15CM

0-20

2000-20CM

0-25

2000-25CM

0-50

2000-50CM

0-80

2000-80CM

0-100

2000-100CM

0-150

2000-150CM

0-200

2000-200CM

0-250

2000-250CM

0-300

2000-300CM

Zero Center Ranges

2-0-2

2300-4CM

5-0-5

2300-10CM

15-0-15

2300-30CM

These ranges calibrated

for vertical scale position.

Accuracy +/-3%

Accuracy +/-4%

*MP option standard

**HP option standard

Range MM

of Water

Model

0-6

2000-6MM

0-10

2000-10MM

0-15

2000-15MM

0-25

2000-25MM

0-30

2000-30MM

0-50

2000-50MM

0-80

2000-80MM

0-100

2000-100MM

0-125

2000-125MM

0-150

2000-150MM

0-200

2000-200MM

0-250

2000-250MM

0-300

2000-300MM

Zero Center Ranges

3-0-3

2300-6MM

5-0-5

2300-10MM

10-0-10

2300-20MM

Range, Pa

Model

10-0-50

2000-60NPA

0-60

2000-60PA

0-100

2000-100PA

0-125

2000-125PA

0-250

2000-250PA

0-300

2000-300PA

0-500

2000-500PA

0-750

2000-750PA

0-1000

2000-1000PA

Zero Center Ranges

Range, Pa

Model

30-0-30

2300-60PA

50-0-50

2300-100PA

60-0-60

2300-120PA

100-0-100

2300-200PA

125-0-125

2300-250PA

150-0-150

2300-300PA

250-0-250

2300-500PA

500-0-500

2300-1000PA

Dual Scale Air Velocity Units

Range,

For use with pitot tube

Model

kPa

2000-0.5KPA

0-0.5

2000-1KPA

0-1

Range in W.C./

2000-1.5KPA

0-1.5

Model

Velocity F.P.M.

2000-2KPA

0-2

2000-00AV 0-.25/300-2000

2000-2.5KPA

0-2.5

2000-3KPA

0-3

2000-0AV 0-.50/500-2800

2000-4KPA

0-4

2000-5KPA

0-5

2001AV

0-1.0/500-4000

2000-8KPA

0-8

2000-10KPA

0-10

2002AV

0-2.0/1000-5600

2000-15KPA

0-15

2000-20KPA

0-20

2005AV

0-5.0/2000-8800

2000-25KPA

0-25

2000-30KPA

0-30

2010AV

0-10/2000-12500

Zero Center Ranges

.5-0-.5

2300-1KPA

1-0-1

2300-2KPA

1.25-0-1.25

2300-2.5KPA

1.5-0-1.5

2300-3KPA

Dual Scale English/Metric Models

Range,

Range,

in w.c.

Pa or kPa

Model

0-.25

0-62 Pa

2000-00D

0-0.5

0-125 Pa

2000-0D

0-1.0

0-250 Pa

2001D

0-2.0

0-500 Pa

2002D

0-3.0

0-750 Pa

2003D

0-4.0

0-1.0 kPa

2004D

0-5.0

0-1.25 kPa

2005D

0-6.0

0-1.5 kPa

2006D

0-8.0

0-2.0 kPa

2008D

0-10

0-2.5 kPa

2010D

0-15

0-3.7 kPa

2015D

0-20

0-5 kPa

2020D

0-25

0-6.2 kPa

2025D

0-50

0-12.4 kPa

2050D

0-60

0-15 kPa

2060D

VELOCITY AND VOLUMETRIC FLOW UNITS

Scales are available on the Magnehelic that read in velocity units (FPM, m/s) or volumetric flow units (SCFM, m3/s, m3/h). Stocked velocity units with dual range scales in inches

w.c. and feet per minute are shown above. For other ranges contact the factory.

When ordering volumetric flow scales please specify the maximum flow rate and its corresponding pressure. Example:0.5 in w.c. = 16,000 CFM.

ACCESSORIES

A-321, Safety Relief Valve

A-448, 3-piece magnet kit for mounting Magnehelic gage directly to

magnetic surface

A-135, Rubber gasket for panel mounting

A-401, Plastic Carry Case

A-310A 3-Way Vent Valves

In applications where pressure is continuous and the

Magnehelic gage is connected by metal or plastic

tubing which cannot be easily removed, we suggest

using Dwyer A-310A vent valves to connect gage.

Pressure can then be removed to check or re-zero the

gage.

CONTACT US | U.S. 219/879-8000 | U.K. (+44) (0)1494-461707 | A.U. (+61) (0) 2 4272 2055 | China +852-23181007

Differential Pressure Gages

Bezel provides flange for flush mounting in panel.

Anda mungkin juga menyukai

- Catalogo de Presion ReotempDokumen48 halamanCatalogo de Presion Reotempdiuska13Belum ada peringkat

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDari EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryBelum ada peringkat

- Shaffer ShpericalDokumen11 halamanShaffer Shpericaljeinerdt100% (1)

- Redflex BrochureDokumen24 halamanRedflex BrochuremecarrascogBelum ada peringkat

- Elastomeric Ring Seals: Static and DynamicDokumen13 halamanElastomeric Ring Seals: Static and DynamicArnaldo BenitezBelum ada peringkat

- Sapag JHP Valves Jun04 enDokumen18 halamanSapag JHP Valves Jun04 enanwar01Belum ada peringkat

- MeasureMaster Dual Chamber Orifice FittingDokumen6 halamanMeasureMaster Dual Chamber Orifice FittingirfanBelum ada peringkat

- DQ CatalogDokumen16 halamanDQ Catalogm_ramas2001Belum ada peringkat

- Cokebuster: A Proven SolutionDokumen11 halamanCokebuster: A Proven Solutionengg_mech77Belum ada peringkat

- Pressure Gauge TeklandDokumen11 halamanPressure Gauge Teklandพสธร สอนทองBelum ada peringkat

- PRH04-300 FLG PDFDokumen5 halamanPRH04-300 FLG PDFengp3077Belum ada peringkat

- Clarkson KGFDokumen8 halamanClarkson KGFJorge Castro CucurellaBelum ada peringkat

- Tel TruDokumen28 halamanTel TruVeronica MendosaBelum ada peringkat

- Regulador 1253 B - American M.Dokumen8 halamanRegulador 1253 B - American M.Jheysson FloresBelum ada peringkat

- Hydraulic Seals Data From ParkerDokumen7 halamanHydraulic Seals Data From Parkerjuan_set8822Belum ada peringkat

- Damper Guide BookDokumen21 halamanDamper Guide Booksbmmla100% (1)

- Mechanical Seals in AgitatorsDokumen6 halamanMechanical Seals in AgitatorsLy Ca TieuBelum ada peringkat

- Velan Forged Steel Gate, Globe & ChecksDokumen25 halamanVelan Forged Steel Gate, Globe & Checksmhorst1Belum ada peringkat

- Perrin High Pressure Valves For Hydrogen ServiceDokumen12 halamanPerrin High Pressure Valves For Hydrogen ServiceKunming Wang100% (1)

- Superior Gas Chlorinators BrochureDokumen16 halamanSuperior Gas Chlorinators BrochureAqua Technology GroupBelum ada peringkat

- Broady 3500 BrochureDokumen12 halamanBroady 3500 Brochureahmedm2020Belum ada peringkat

- HPT3Dokumen12 halamanHPT3Mehdi Soltani100% (1)

- TRDP - SSSVDokumen23 halamanTRDP - SSSVsambhajiBelum ada peringkat

- Angle Seat Valve: High Cycle-Life On/Off Control ValveDokumen6 halamanAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyBelum ada peringkat

- FIS113eng Hi Temp BellowsDokumen8 halamanFIS113eng Hi Temp Bellowsmahesh_eilBelum ada peringkat

- Product Range: Gate Valve / Sluice ValveDokumen6 halamanProduct Range: Gate Valve / Sluice ValveTanmoy DuttaBelum ada peringkat

- Accessories: Value Series GaugesDokumen8 halamanAccessories: Value Series GaugesarmandotrifulcaBelum ada peringkat

- Convertidor Mechanical S108KDokumen8 halamanConvertidor Mechanical S108KALBERTOBelum ada peringkat

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDokumen12 halamanAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyBelum ada peringkat

- Magnehelic Gauge CalibrationDokumen7 halamanMagnehelic Gauge CalibrationgrajukankayyaBelum ada peringkat

- Grove G9 Wafer Gate ValveDokumen9 halamanGrove G9 Wafer Gate Valvetxlucky80Belum ada peringkat

- 2, 5 Inch Side Door Stripper PDFDokumen16 halaman2, 5 Inch Side Door Stripper PDFOvRrj AhmedBelum ada peringkat

- Hose Technic DataDokumen28 halamanHose Technic Dataerol_ay98Belum ada peringkat

- 2011 07 Mar00080 en Katalog Typs WebDokumen28 halaman2011 07 Mar00080 en Katalog Typs WebzayerirezaBelum ada peringkat

- Seepex N RangeDokumen6 halamanSeepex N RangeKetpat ChBelum ada peringkat

- TYPE 5611/5611Q: Elastomer Bellows SealsDokumen8 halamanTYPE 5611/5611Q: Elastomer Bellows SealsLuvys Garcia MartinezBelum ada peringkat

- Ue 24013Dokumen8 halamanUe 24013Johnny CormanBelum ada peringkat

- What Is A Flushing RingDokumen6 halamanWhat Is A Flushing RingFarooqBelum ada peringkat

- PTFE Piston RingsDokumen21 halamanPTFE Piston RingsRajaSekarsajjaBelum ada peringkat

- W01 358 7561Dokumen29 halamanW01 358 7561MROstop.comBelum ada peringkat

- PRS09 TC V PDFDokumen4 halamanPRS09 TC V PDFengp3077Belum ada peringkat

- PRH09 PDFDokumen4 halamanPRH09 PDFengp3077Belum ada peringkat

- Brochure F CM Ceram ValveDokumen6 halamanBrochure F CM Ceram ValvetunradotBelum ada peringkat

- Flow Safe - F84L - CatalogueDokumen12 halamanFlow Safe - F84L - CataloguecookienutBelum ada peringkat

- Reg RedQ Specialy Regulators PDFDokumen20 halamanReg RedQ Specialy Regulators PDFDavid SaldarriagaBelum ada peringkat

- Fischer Type 99Dokumen8 halamanFischer Type 99piattaformaBelum ada peringkat

- Crane Engineering Data 1Dokumen56 halamanCrane Engineering Data 1jerry666aBelum ada peringkat

- Autoclave Technical InfoDokumen16 halamanAutoclave Technical Info136339Belum ada peringkat

- Autoclave Subsea Ball ValvesDokumen20 halamanAutoclave Subsea Ball Valvesvp989Belum ada peringkat

- Bettis HD-Series ActuatorsDokumen6 halamanBettis HD-Series Actuatorstxlucky80Belum ada peringkat

- CO2 AnsulDokumen17 halamanCO2 AnsulJorge RVBelum ada peringkat

- PRH 04 Ex PDFDokumen5 halamanPRH 04 Ex PDFengp3077Belum ada peringkat

- Three Way ValvesDokumen8 halamanThree Way ValvesWalter JosephBelum ada peringkat

- Wa1 358 5674Dokumen30 halamanWa1 358 5674MROstop.comBelum ada peringkat

- Floating Flange Rubber Expansion Joints: Series 980Dokumen8 halamanFloating Flange Rubber Expansion Joints: Series 980Roland Bon IntudBelum ada peringkat

- Fitting CatalogueDokumen38 halamanFitting CataloguearavindBelum ada peringkat

- SBF LongdDokumen10 halamanSBF LongdcatalineulaBelum ada peringkat

- Piping Handbook - Hydrocarbon Processing - 1968Dokumen140 halamanPiping Handbook - Hydrocarbon Processing - 1968VS271294% (16)

- 100ah - 12V - 6FM100 VISIONDokumen2 halaman100ah - 12V - 6FM100 VISIONBashar SalahBelum ada peringkat

- A Sample of Wet Soil Has A Volume of 0Dokumen8 halamanA Sample of Wet Soil Has A Volume of 0eph0% (1)

- An 80-Mg Railroad Engine A Coasting at 6.5 KM - H Strikes A 20Dokumen4 halamanAn 80-Mg Railroad Engine A Coasting at 6.5 KM - H Strikes A 20Aura Milena Martinez ChavarroBelum ada peringkat

- Comparative Tracking Index of Electrical Insulating MaterialsDokumen6 halamanComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinBelum ada peringkat

- Ball Mill SizingDokumen10 halamanBall Mill Sizingvvananth100% (1)

- 20 Site SummaryDokumen2 halaman20 Site SummaryMuzammil WepukuluBelum ada peringkat

- Compact 40/25Dokumen58 halamanCompact 40/25znim04Belum ada peringkat

- Braun KF40 - CDokumen17 halamanBraun KF40 - CAgung UtoyoBelum ada peringkat

- TechSpec MistralDokumen4 halamanTechSpec MistralScarab SweepersBelum ada peringkat

- Prospects For Alkaline Zero Gap Water Electrolysers For Hydrogen ProductionDokumen16 halamanProspects For Alkaline Zero Gap Water Electrolysers For Hydrogen Productionkhan47pkBelum ada peringkat

- Cif Purge Plug Systems en 3Dokumen3 halamanCif Purge Plug Systems en 3abdeljalil elbadrBelum ada peringkat

- EM230 BR BM3 Fitting InstructionsDokumen2 halamanEM230 BR BM3 Fitting InstructionsRoman BabaevBelum ada peringkat

- Understanding Low Voltage Power Distribution SystemsDokumen64 halamanUnderstanding Low Voltage Power Distribution SystemsJorge Luis Mallqui Barbaran100% (1)

- G270han01 V0Dokumen26 halamanG270han01 V0NemkoBelum ada peringkat

- Antikythera MechanismDokumen25 halamanAntikythera MechanismchetansergiurazvanBelum ada peringkat

- Whirlpool Duet HTDokumen96 halamanWhirlpool Duet HTdanny85901100% (2)

- VB Script ReferenceDokumen27 halamanVB Script ReferenceRajkumarBelum ada peringkat

- DSP45 12aDokumen5 halamanDSP45 12aDaniel BarbuBelum ada peringkat

- SQ Presentation 2021-r2Dokumen43 halamanSQ Presentation 2021-r2nadeem4ahmed-805026Belum ada peringkat

- Honeywell P7640B1032 Differential Pressure Sensors PDFDokumen2 halamanHoneywell P7640B1032 Differential Pressure Sensors PDFMarcello PorrinoBelum ada peringkat

- SemDokumen31 halamanSemkaushik4208Belum ada peringkat

- Idlers - Medium To Heavy Duty PDFDokumen28 halamanIdlers - Medium To Heavy Duty PDFEd Ace100% (1)

- Chapter 2 - 2 Plane Curvilinear MotionDokumen37 halamanChapter 2 - 2 Plane Curvilinear MotionAlfredo Ruiz ValenciaBelum ada peringkat

- Jacky Smith Resume Project ManagerDokumen1 halamanJacky Smith Resume Project ManagerGrey GrayBelum ada peringkat

- State ManagementDokumen16 halamanState Managementnegikamal703Belum ada peringkat

- Valve Body PDFDokumen9 halamanValve Body PDFTimur TOT100% (2)

- Gordon NovelDokumen50 halamanGordon NovelNic Hotep100% (2)

- 25252525Dokumen38 halaman25252525Ivan GonzalezBelum ada peringkat

- Laws of UX: Using Psychology to Design Better Products & ServicesDari EverandLaws of UX: Using Psychology to Design Better Products & ServicesPenilaian: 5 dari 5 bintang5/5 (9)

- Transformed: Moving to the Product Operating ModelDari EverandTransformed: Moving to the Product Operating ModelPenilaian: 4 dari 5 bintang4/5 (1)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneDari EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DonePenilaian: 4.5 dari 5 bintang4.5/5 (5)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemDari EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemBelum ada peringkat

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesDari EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesBelum ada peringkat

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- 507 Mechanical Movements: Mechanisms and DevicesDari Everand507 Mechanical Movements: Mechanisms and DevicesPenilaian: 4 dari 5 bintang4/5 (28)

- A Complete Guide to Safety Officer Interview Questions and AnswersDari EverandA Complete Guide to Safety Officer Interview Questions and AnswersPenilaian: 4 dari 5 bintang4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsDari EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsPenilaian: 4 dari 5 bintang4/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsDari EverandDesign for How People Think: Using Brain Science to Build Better ProductsPenilaian: 4 dari 5 bintang4/5 (8)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDari EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsBelum ada peringkat

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDari EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsBelum ada peringkat

- Analog Design and Simulation Using OrCAD Capture and PSpiceDari EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceBelum ada peringkat

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDari EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperiencePenilaian: 4 dari 5 bintang4/5 (19)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDari EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisPenilaian: 5 dari 5 bintang5/5 (1)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsDari EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsPenilaian: 5 dari 5 bintang5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDari EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchPenilaian: 4 dari 5 bintang4/5 (10)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionDari EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionBelum ada peringkat