Air Exchanger TD

Diunggah oleh

Rajput PratiksinghHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Air Exchanger TD

Diunggah oleh

Rajput PratiksinghHak Cipta:

Format Tersedia

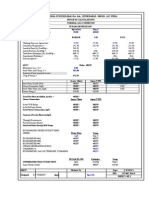

Air-Water Heat Exchanger

Output Summary

Page 1

Released to the following HTRI Member Company:

Xist E Ver. 5.00

17-06-2015 17:35 SN: Vals100+

MKH Units

Rating - Horizontal Countercurrent Flow TEMA BEW Shell With Single-Segmental Baffles

No Data Check Messages.

No Data Check Messages.

Process Conditions

Hot Shellside

Fluid name

Flow rate

(1000-kg/hr)

Inlet/Outlet Y (Wt. frac vap.)

Inlet/Outlet T

(Deg C)

Inlet P/Avg

(kgf/cm2A)

dP/Allow.

(kgf/cm2)

Fouling

(m2-hr-C/kcal)

1.000

160.00

12.556

0.087

Cold Tubeside

Air

3.1409

0.977

40.00

12.512

0.200

0.000200

0.000

32.00

5.112

0.081

Water

27.2797

0.000

37.00

5.072

0.500

0.000300

Exchanger Performance

Shell h

Tube h

Hot regime

Cold regime

EMTD

(kcal/m2-hr-C)

(kcal/m2-hr-C)

(--)

(--)

(Deg C)

739.78

4977.19

Ann-Mist

Sens. Liquid

34.9

Actual U

Required U

Duty

Area

Overdesign

Shell Geometry

TEMA type

Shell ID

Series

Parallel

Orientation

Baffle type

Baffle cut

Baffle orientation

Central spacing

Crosspasses

Tube Geometry

Tube type

Tube OD

Length

Pitch ratio

Layout

Tubecount

Tube Pass

(--)

(mm)

(mm)

(--)

(deg)

(--)

(--)

Thermal Resistance, %

Shell

Tube

Fouling

Metal

62.26

11.38

26.22

0.14

460.60

400.86

0.1361

9.731

14.90

Baffle Geometry

BEW

205.000

1

1

0.00

(--)

(mm)

(--)

(--)

(deg)

(kcal/m2-hr-C)

(kcal/m2-hr-C)

(MM kcal/hr)

(m2)

(%)

(--)

(Pct Dia.)

(--)

(mm)

(--)

Single-Seg.

35.00

Perpend.

200.000

8

Nozzles

Plain

9.525

2000.

1.2598

30

166

1

Shell inlet

Shell outlet

Inlet height

Outlet height

Tube inlet

Tube outlet

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

Velocities, m/s

Shellside

Tubeside

Crossflow

Window

Flow Fractions

4.97

0.97

5.19

9.32

1-9

97.181

97.181

16.738

16.738

73.660

73.660

A

B

C

E

F

0.124

0.479

0.296

0.100

0.000

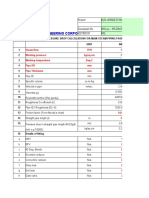

Air-Water Heat Exchanger

Final Results

Page 2

Released to the following HTRI Member Company:

Xist E Ver. 5.00

17-06-2015 17:35 SN: Vals100+

MKH Units

Rating - Horizontal Countercurrent Flow TEMA BEW Shell With Single-Segmental Baffles

Process Data

Hot Shellside

Fluid name

Air

Fluid condition

Total flow rate

(1000-kg/hr)

Weight fraction vapor, In/Out

(--)

1.000

Temperature, In/Out

(Deg C)

160.00

Temperature, Average/Skin

(Deg C)

100.00

Wall temperature, Min/Max

(Deg C)

33.91

Pressure, In/Average

(kgf/cm2A)

12.556

Pressure drop, Total/Allowed

(kgf/cm2)

0.087

Velocity, Mid/Max allow

(m/s)

4.97

Mole fraction inert

((--))

Average film coef.

(kcal/m2-hr-C)

Heat transfer safety factor

(--)

Fouling resistance

(m2-hr-C/kcal)

Cold Tubeside

Water

Cond. Vapor

3 1409

3.1409

0.977

40.00

46.90

64.22

12.512

0.200

0.000

32.00

34.50

33.90

5.112

0.081

0.97

Sens. Liquid

27 2797

27.2797

0.000

37.00

37.72

64.09

5.072

0.500

0.9582

739.78

1.000

0.000200

4977.19

1.000

0.000300

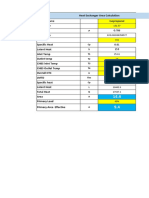

Overall Performance Data

Overall coef., Reqd/Clean/Actual

Heat duty, Calculated/Specified

Effective overall temperature difference

EMTD = ((MTD)) * ((DELTA)) * ((F/G/H))

(kcal/m2-hr-C)

(MM kcal/hr)

(Deg C)

((Deg

g C))

400.86 /

0.1361 /

34.9

36.40 *

624.29 /

0.9585

460.60

* 1.0000

205

mm

Exchanger Fluid Volumes

Approximate shellside (L)

Approximate tubeside (L)

2000

mm

44.2

40.6

Shell Construction Information

TEMA shell type

BEW

Shells Series

1 Parallel

Passes Shell

1 Tube

Shell orientation angle (deg)

0.00

Impingement present

No

Pairs seal strips

2

Shell expansion joint

No

Weight estimation Wet/Dry/Bundle

Shell ID

Total area

Eff. area

1

1

(mm)

(m2)

(m2/shell)

205.000

9.935

9.731

Passlane seal rods (mm) 0.000 No. 0

Rear head support plate

No

454.99 /

370.22 /

84.21 (kg/shell)

Baffle Information

Type

Perpend. Single-Seg.

Crosspasses/shellpass

8

Central spacing

(mm) 200.000

Inlet spacing

(mm) 379.490

Outlet spacing

(mm) 379.490

Baffle thickness

(mm)

5.000

Baffle cut (% dia) 35.00

No. (Pct Area) (mm) to C.L

1

33.75

30.750

2

0.00

0.000

Tube Information

Tube type

Overall length

Effective length

Total tubesheet

Area ratio

Tube metal

(mm)

(mm)

(mm)

((out/in))

Plain

2000.

1959.

41.000

1.2295

Copper

Tubecount per shell

Pct tubes removed (both)

Outside diameter

(mm)

Wall thickness

(mm)

Pitch ((mm))

12.0000 Ratio

Tube pattern (deg)

2-9

166

9.525

0.889

1.2598

30

Air-Water Heat Exchanger

Final Results

Page 3

Released to the following HTRI Member Company:

Xist E Ver. 5.00

17-06-2015 17:35 SN: Vals100+

MKH Units

Rating - Horizontal Countercurrent Flow TEMA BEW Shell With Single-Segmental Baffles

Shellside Performance

Nom vel, X-flow/window

5.19 / 9.32

Flow fractions for vapor phase

A=0.1238 B=0.4793 C=0.2965

E=0.1005

F=0.0000

Shellside Heat Transfer Corrections

Total

0.963

Beta

0.908

Cross

32.26

MOMENTUM

Window

31.97

Gamma

1.061

End

0.909

Fin

1.000

Pressure Drops (Percent of Total)

Ends

7.82

-0.61

Nozzle

Inlet

Outlet

Shell

16.84

11.72

Tube

22.10

14.08

Two-Phase Parameters

Method

RPM

Inlet

Sens Gas

Center

Ann-Mist

H. T. Parameters

Overall wall correction

Midpoint

Prandtl no.

Midpoint

Reynolds no.

Bundle inlet

Reynolds no.

Bundle outlet

Reynolds no.

Fouling layer

(mm)

Outlet

Ann-Mist

Mix F

0.0480

Shell

Tube

14510

20506

8697

1.014

5.07

9982

9827

10570

Thermal Resistance

Shell

Tube

62.26

11.38

Total fouling resistance

Differential resistance

Shell Nozzles

Inlet at channel end-No

Number at each position

Diameter

Velocity

Pressure drop

Height under nozzle

Nozzle R-V-SQ

Shell ent.

Fouling

26.22

Metal

0.14

Over Des

14.90

5.688e-4

3.236e-4

(mm)

(m/s)

(kgf/cm2)

(mm)

(kg/m-s2)

(kg/m-s2)

Inlet

1

97.181

12.05

0.015

16.738

1417.15

1614.91

Outlet

1

97.181

8.44

0.010

16.738

992.27

1130.73

(mm)

(m/s)

(kgf/cm2)

(kg/m-s2)

Inlet

RADIAL

73.660

1.79

0.018

3177.20

Outlet

RADIAL

73.660

1.79

0.011

3182.63

Inlet

Outlet

Tube Nozzle

Diameter

Velocity

Pressure drop

Nozzle R-V-SQ

Annular Distributor

Length

Height

Slot area

Liquid

Outlet

0

Liquid

Outlet

(mm)

(mm)

(mm2)

Diametral Clearances (mm)

Baffle-to-shell

3.1750

Bundle-to-shell

32.1468

3-9

Tube-to-baffle

0.7938

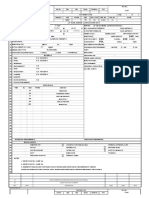

Air-Water Heat Exchanger

Supplementary Results

Page 4

Released to the following HTRI Member Company:

Xist E Ver. 5.00

17-06-2015 17:35 SN: Vals100+

MKH Units

Rating - Horizontal Countercurrent Flow TEMA BEW Shell With Single-Segmental Baffles

Externally Enhanced Tube Geometry

Type

Fin density

Fin height

Fin thickness

Root diameter

Area/length

Plain

Internally Enhanced Tube Geometry

Type

Thickness

Pitch

(fin/meter)

(mm)

(mm)

(mm)

(m2/m)

None

(mm)

(L/D)

Mean Metal Temperatures

Mean shell temperature

73.17 (C)

Mean tube metal temperature in each tubepass, (C)

Tube Pass

1

Inside

43.63

Outside

43.68

Radial

43.66

4-9

Air-Water Heat Exchanger

Page 5

HEAT EXCHANGER RATING DATA SHEET

MKH Units

Service of Unit

Type

BEW

Surf/Unit (Gross/Eff) 9.93 / 9.73 m2

Item No.

Orientation Horizontal

Connected In 1 Parallel 1 Series

Shell/Unit 1

Surf/Shell (Gross/Eff) 9.93 / 9.73 m2

PERFORMANCE OF ONE UNIT

Fluid Allocation

Shell Side

Tube Side

Fluid Name

Air

Water

Fluid Quantity, Total

1000-kg/hr

3.1409

27.2797

Vapor (In/Out)

wt%

100.0

97.7

0.0

0.0

Liquid

wt%

0.0

2.3

100.0

100.0

Temperature (In/Out)

C

160.00

40.00

32.00

37.00

Density

kg/m3

9.7628

13.631 V/L 992.71

995.21

993.51

Viscosity

cP

0.0242

0.0194 V/L 0.6529

0.7644

0.6914

Specific Heat

kcal/kg-C

0.2565

0.2414 V/L 0.9981

0.9987

0.9985

Thermal Conductivity

kcal/hr-m-C

0.0312

0.0239 V/L 0.5412

0.5316

0.5375

Critical Pressure

kgf/cm2A

Inlet Pressure

kgf/cm2A

12.556

5.112

Velocity

m/s

4.97

0.97

Pressure Drop

Drop, Allow/Calc kgf/cm2

0 200

0.200

0 087

0.087

0 500

0.500

0 081

0.081

Average Film Coefficient kcal/m2-hr-C

739.78

4977.19

0.000200

0.000300

Fouling Resistance (min) m2-hr-C/kcal

Heat Exchanged

0.1361 MM kcal/hr MTD (Corrected) 34.9 C

Overdesign 14.90 %

Transfer Rate, Service

400.86 kcal/m2-hr-C Calculated 460.60 kcal/m2-hr-C

Clean 624.29 kcal/m2-hr-C

CONSTRUCTION OF ONE SHELL

Sketch (Bundle/Nozzle Orientation)

Shell Side

Tube Side

Design Pressure

kgf/cm2G

11.523

10.546

Design Temperature

C

No Passes per Shell

1

1

Flow Direction

Connections

In

mm

1 @ 97.181

1 @ 73.660

Size &

Out

mm

1 @ 97.181

1 @ 73.660

Rating

Liq. Out mm

@

@

Tube No.

166 OD 9.525 mm

Thk(Avg) 0.889 mm

Length 2000. mm

Pitch 12.000 mm

Layout 30

Tube Type Plain

Material COPPER

Pairs seal strips

2

Shell ID

205.000 mm

Kettle ID

mm

Passlane Seal Rod No 0

Cross Baffle Type PERPEND. SINGLE-SEG.

%Cut (Diam) 35.00

Impingement Plate

None

mm

Spacing(c/c) 200

200.000

000

mm

Inlet 379

379.490

490

No of Crosspasses

No.

8

Rho-V2-Inlet Nozzle 1417.15 kg/m-s2

Shell Entrance

1614.91

Shell Exit

1130.73 kg/m-s2

Bundle Entrance 198.76

Bundle Exit 139.17 kg/m-s2

Weight/Shell

370.22

Filled with Water

454.99

Bundle

84.21 kg

Notes:

Thermal Resistance, % Velocities, m/s

Flow Fractions

Shell

62.26 Shellside

4.97 A

0.124

Tube

11.38 Tubeside

0.97 B

0.479

205

mm

2000

mm

Fouling

Metal

5-9

26.22 Crossflow

5.19 C

0.296

0.14 Window

9.32 E

F

0.100

0.000

Air-Water Heat Exchanger

Input Reprint

Page 6

Released to the following HTRI Member Company:

Xist E Ver. 5.00

17-06-2015 17:35 SN: Vals100+

MKH Units

Rating - Horizontal Countercurrent Flow TEMA BEW Shell With Single-Segmental Baffles

Shell Data

Service type

TEMA type

Run mode

Hot fluid location

Number of shells in series

Number of shells in parallel

Shell inside diameter

Flow in 1st tubepass

Train flow direction

Generic Shell and Tube

BEW

Rating

Shellside

1

1

205.000 mm

Countercurrent

Countercurrent

Reboiler Data

Reboiler type

Inlet pressure location

No piping specified

Inlet nozzle

Tube Data

Tube type

Tube outside diameter

Tube wall thickness

Tube pitch

Tube pitch ratio

Tubepasses per shell

Tube pattern

Tube count method

Tube length

Tube material

Plain

9.525

0.889

12.000

1.260

1

30

Rigorous

2000.

Copper

mm

mm

mm

degrees

mm

Tubepass Arrangement Data

Force symmetric layout

Force cleaning lanes

Tubes to remove for tie rods

No

No

Calculated

Baffle Data

Baffle type

Baffle orientation

Baffle cut percent

Central baffle spacing

Variable baffle spacing

Baffle thickness

Window cut from baffles

Single segmental

Perpendicular

35 % shell ID

200.000 mm

No

5.000 mm

No

Clearance Data

Number of seal strip pairs

Baffle clearance type

Block A stream

Block E stream

Block F stream

Number of passlane seal rods

2

TEMA

No

No

No

Calculated

6-9

Air-Water Heat Exchanger

Input Reprint

Page 7

Released to the following HTRI Member Company:

Xist E Ver. 5.00

17-06-2015 17:35 SN: Vals100+

MKH Units

Rating - Horizontal Countercurrent Flow TEMA BEW Shell With Single-Segmental Baffles

Nozzle Data

Shellside inlet ID

Number of shellside inlet nozzles

Shellside outlet ID

Number of shellside outlet nozzles

Tubeside inlet ID

Number of tubeside inlet nozzles

Tubeside outlet ID

Number of tubeside outlet nozzles

Radial position on shell inlet nozzle

Longitudinal position on shell of inlet nozzle

Radial position on shell outlet nozzle

Tubeside entry type

Tubeside inlet position

Tubeside exit type

Front head location

97.181

1

97.181

1

73.660

1

73.660

1

Side

At rear head

Program decides

Radial

Front head

Same as inlet

Left

mm

mm

mm

mm

Impingement Data

Impingement device present

Impingement type

If required by TEMA

Circular plate

Optional Geometry Data

Small exchanger

Tubesheet type

Shell expansion joint

Floating head support type

Insulated longitudinal baffle

No

Single

No

None

No

Process Conditions Data

Hot Fluid

Cold Fluid

Phase condition

Flow rate

Inlet vapor fraction

Outlet vapor fraction

Inlet temperature

Outlet temperature

Inlet pressure

Allowable pressure drop

Duty multiplier

Two phase

3.1409

--160.00

40.00

12.556

0.200

Sensible liquid

-0

0

32.00

37.00

5.112

0.500

1

Hot Fluid

Cold Fluid

Process Fouling Data

Fouling resistance

2.000e-4

7-9

1000-kg/hr

C

C

kgf/cm2A

kgf/cm2

3.000e-4 m2-hr-C/kcal

Air-Water Heat Exchanger

Input Reprint

Page 8

Released to the following HTRI Member Company:

Xist E Ver. 5.00

17-06-2015 17:35 SN: Vals100+

MKH Units

Rating - Horizontal Countercurrent Flow TEMA BEW Shell With Single-Segmental Baffles

Hot Fluid Property Data

Fluid name

Physical property method

Heat release method

Flash type

Quantity units

Temperature interpolation option

Number of components

Property package

Air

Component by component properties

Program calculated

Integral

Weight

Program

2

HTRI

Hot Fluid Component Data

Component number

Component name

Comp. bank name

Component bank

Component code

Component phase

Component quantity

1

Air

Air

HTRI

3

Vapor

3057.9

2

Water (IAPWS 1997)

Water (IAPWS 1997)

HTRI

1

Mixed

82.97

Cold Fluid Property Data

Fluid name

Physical property method

Heat release method

Flash type

Quantity units

Temperature interpolation option

Number of components

Property package

Water

Component by component properties

Program calculated

Integral

Weight

Program

1

HTRI

Cold Fluid Component Data

Component number

Component name

Comp. bank name

Component bank

Component code

Component phase

1

Water (IAPWS 1997)

Water (IAPWS 1997)

HTRI

1

Liquid

Control Methods Data

Shellside friction factor method

Tubeside friction factor method

Pure longitudinal flow

Pure component condensation

Condensing correlation

Mole fraction inerts

Momentum exclusion

Pure component boiling

Check film boiling

Nucleate boiling method

Component boiling method

Commercial

Commercial

No

No

HTRI Proration

0

0%

No

Yes

Physical property/theoretical boiling range

Nucleate and convective

8-9

Air-Water Heat Exchanger

Input Reprint

Page 9

Released to the following HTRI Member Company:

Xist E Ver. 5.00

17-06-2015 17:35 SN: Vals100+

MKH Units

Rating - Horizontal Countercurrent Flow TEMA BEW Shell With Single-Segmental Baffles

Control User-Defined Methods Data

Add non-nucleate boiling

Yes

Control Vibration Data

Damping factor method

Include inlet vibration support

Include outlet vibration support

HTRI Method

No

No

9-9

Anda mungkin juga menyukai

- Steam CondenserDokumen2 halamanSteam CondenserAlphaEcc EngineeringTeamBelum ada peringkat

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDokumen2 halamanHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamBelum ada peringkat

- Vessel Weight CheckDokumen8 halamanVessel Weight ChecknileshBelum ada peringkat

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDokumen37 halamanDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTOROBelum ada peringkat

- Double FdexchangerDokumen8 halamanDouble FdexchangerBoško IvanovićBelum ada peringkat

- Heat Exchanger Calculation Version 2Dokumen2 halamanHeat Exchanger Calculation Version 2huangjlBelum ada peringkat

- Filter Separator Revised Feb 19 2004Dokumen1 halamanFilter Separator Revised Feb 19 2004motalebyBelum ada peringkat

- Design of a Double Pipe Heat Exchanger CalculationsDokumen2 halamanDesign of a Double Pipe Heat Exchanger CalculationsSaqib RaoufBelum ada peringkat

- US Units Heat Exchanger Specification SheetDokumen1 halamanUS Units Heat Exchanger Specification SheetDwi PutraBelum ada peringkat

- Half Pipe Coil AgitatedDokumen1 halamanHalf Pipe Coil AgitatedNITINBelum ada peringkat

- Final Ventury Working For Wet Alkaline ScrubberDokumen11 halamanFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapBelum ada peringkat

- Maz - Design - Separator Capacity EvaluationDokumen5 halamanMaz - Design - Separator Capacity EvaluationNaeem HussainBelum ada peringkat

- Dowtherm Vent CondenserDokumen1 halamanDowtherm Vent Condensersushant_jhawerBelum ada peringkat

- EIND 3184 15 Liquid Flash Vessel SizingDokumen20 halamanEIND 3184 15 Liquid Flash Vessel SizingzamijakaBelum ada peringkat

- Vertical Separator SizingDokumen4 halamanVertical Separator SizingnemprrBelum ada peringkat

- Burner specification document summaryDokumen6 halamanBurner specification document summaryHafiz Muhammad AbubakarBelum ada peringkat

- Demister SizingDokumen3 halamanDemister SizingD K SBelum ada peringkat

- h-101 TwiceDokumen20 halamanh-101 TwiceAdela ShofiaBelum ada peringkat

- Steam Drum LevelsDokumen11 halamanSteam Drum LevelsAnith kumar Reddy100% (1)

- Heat Exchanger Specification Sheet SI UnitsDokumen2 halamanHeat Exchanger Specification Sheet SI UnitssalamrefighBelum ada peringkat

- Aes DesignDokumen97 halamanAes DesigndineshsirasatBelum ada peringkat

- Transfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersDokumen1 halamanTransfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersMarco Ordoñez0% (1)

- Heat Exchanger Specification SheetDokumen1 halamanHeat Exchanger Specification SheetGreisly MarrugoBelum ada peringkat

- Asme Tubesheet (Heater 10m2)Dokumen23 halamanAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Dish End Weight CalculationDokumen5 halamanDish End Weight CalculationAniket royBelum ada peringkat

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDokumen2 halamanDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658Belum ada peringkat

- Optimization of Distillation Column for Methanol and Water SeparationDokumen131 halamanOptimization of Distillation Column for Methanol and Water SeparationFauzulBelum ada peringkat

- HRD Hot Water Pump P001Dokumen6 halamanHRD Hot Water Pump P001nguyenquoc1988Belum ada peringkat

- CS SS - Pipe Weight CalculationDokumen1 halamanCS SS - Pipe Weight CalculationTashrif Yusuf0% (1)

- STEAMcalc 12.8 RupiahDokumen1.009 halamanSTEAMcalc 12.8 RupiahlightsonsBelum ada peringkat

- Section 7Dokumen64 halamanSection 7WlopezaBelum ada peringkat

- Cooling Tower ComparisonDokumen4 halamanCooling Tower ComparisonKiran DasBelum ada peringkat

- Calculation For Steam Blow Rev03Dokumen6 halamanCalculation For Steam Blow Rev03tauqeerBelum ada peringkat

- Shell & Tube Condenser Design MethodDokumen4 halamanShell & Tube Condenser Design MethodwestewrBelum ada peringkat

- Sizing For Vaporiser/Flash Vessel: InputsDokumen3 halamanSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranBelum ada peringkat

- Circulating Fluidized Bed Boiler Design and OperationDokumen9 halamanCirculating Fluidized Bed Boiler Design and OperationSanket BhaleraoBelum ada peringkat

- LP Gas Amine Contactor Process DataDokumen6 halamanLP Gas Amine Contactor Process DataEddy RainBelum ada peringkat

- Surface Condenser Thermal Analysis (100914)Dokumen11 halamanSurface Condenser Thermal Analysis (100914)amlanfacebookBelum ada peringkat

- Combustion CalculationsDokumen6 halamanCombustion CalculationsDaniel AriefinBelum ada peringkat

- 1 Darcy Friction CalculatorDokumen2 halaman1 Darcy Friction CalculatorTheodoros AtheridisBelum ada peringkat

- Art - 'S TEMA DesignationsDokumen4 halamanArt - 'S TEMA Designationsmuhammad_asim_10Belum ada peringkat

- Experienced Based Rules of Chemical EngineeringDokumen33 halamanExperienced Based Rules of Chemical Engineeringintania66Belum ada peringkat

- Method of Heat Exchanger Sizing Kern MethodDokumen10 halamanMethod of Heat Exchanger Sizing Kern Methodvazzoleralex6884Belum ada peringkat

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Dokumen4 halamanSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRIBelum ada peringkat

- Desuperheater Boiler Feed Water RequirementDokumen2 halamanDesuperheater Boiler Feed Water Requirementmehul10941Belum ada peringkat

- Knock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet NozzleDokumen11 halamanKnock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet Nozzlejazeel alaviBelum ada peringkat

- Ejemplo Tubesheet Asme UHXDokumen14 halamanEjemplo Tubesheet Asme UHXPedro Montes MarinBelum ada peringkat

- Propane Storage TankDokumen1 halamanPropane Storage TankMarakanaMaheshBelum ada peringkat

- Centrif Pumps1 SpreadsheetDokumen2 halamanCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Heat Exchanger Area & Boilup Rate CalculationDokumen19 halamanHeat Exchanger Area & Boilup Rate CalculationNitin KurupBelum ada peringkat

- Shell & Tube Heat Exchanger Rating ProjectDokumen20 halamanShell & Tube Heat Exchanger Rating ProjectFareeha HasanBelum ada peringkat

- Sizing Column Distillation C-Factor MethodDokumen20 halamanSizing Column Distillation C-Factor MethodCHANADASBelum ada peringkat

- Htri Trial PDFDokumen39 halamanHtri Trial PDFcroprobosBelum ada peringkat

- Htri FileDokumen24 halamanHtri FileEalumalai MuthuBelum ada peringkat

- Heat HXerDokumen2 halamanHeat HXerGade JyBelum ada peringkat

- Heat Exchanger Rating Data SheetDokumen1 halamanHeat Exchanger Rating Data SheetagusnnnBelum ada peringkat

- Natural Gas Steam Heater SummaryDokumen14 halamanNatural Gas Steam Heater SummarySivi NallamothuBelum ada peringkat

- Output Summary from HTRI Xhpe Ver. 6.00Dokumen40 halamanOutput Summary from HTRI Xhpe Ver. 6.00amruta21Belum ada peringkat

- Condenser & EvaporatorDokumen21 halamanCondenser & EvaporatorfitratulqadriBelum ada peringkat

- Output Summary: See Runtime Message Report For Warning MessagesDokumen3 halamanOutput Summary: See Runtime Message Report For Warning MessagesSimranjeet SinghBelum ada peringkat

- Branch Data March17Dokumen109 halamanBranch Data March17Rajput PratiksinghBelum ada peringkat

- DisabilityDokumen2 halamanDisabilityRajput PratiksinghBelum ada peringkat

- Survey Report On Methane & Non-Methane Hydrocarbon in Ambient Air FORDokumen31 halamanSurvey Report On Methane & Non-Methane Hydrocarbon in Ambient Air FORRajput PratiksinghBelum ada peringkat

- Aai SyllabusDokumen27 halamanAai Syllabussuresh_496Belum ada peringkat

- AdvtNo 11 2020 EnglDokumen21 halamanAdvtNo 11 2020 EnglMonu SharmaBelum ada peringkat

- Railways ALP 2018 Official Recruitment NotificationDokumen57 halamanRailways ALP 2018 Official Recruitment NotificationKshitija83% (6)

- AEPL Player ListDokumen5 halamanAEPL Player ListRajput PratiksinghBelum ada peringkat

- Indian Coast Guard Recruitment - Assistant Commandant 2017Dokumen9 halamanIndian Coast Guard Recruitment - Assistant Commandant 2017Hiten BansalBelum ada peringkat

- Official Notification For UPSC Recruitment 2018Dokumen40 halamanOfficial Notification For UPSC Recruitment 2018Shrishanti KaleBelum ada peringkat

- Guidelines for Ex-servicemen BenefitsDokumen1 halamanGuidelines for Ex-servicemen BenefitsRajput PratiksinghBelum ada peringkat

- Territorial Army Notification 2019 SSBCrackDokumen3 halamanTerritorial Army Notification 2019 SSBCrackHarsh JasrotiaBelum ada peringkat

- Office of The Collector and District Magistrate: B9 Matrubhoomi Society NR D Mart NikolDokumen1 halamanOffice of The Collector and District Magistrate: B9 Matrubhoomi Society NR D Mart NikolRajput PratiksinghBelum ada peringkat

- Design and Manufacturing of Automatic Multipoint Spanner For Maruti 800Dokumen61 halamanDesign and Manufacturing of Automatic Multipoint Spanner For Maruti 800Rajput PratiksinghBelum ada peringkat

- Sept16 PDFDokumen1 halamanSept16 PDFRajput PratiksinghBelum ada peringkat

- Indian Air Force: Call Up Letter: Meteorological BranchDokumen3 halamanIndian Air Force: Call Up Letter: Meteorological BranchRajput PratiksinghBelum ada peringkat

- 314Dokumen620 halaman314Dia Fatima MaguikayBelum ada peringkat

- 1 Innings Of:: CRICKET ON ICE: Twenty20 Score SheetDokumen2 halaman1 Innings Of:: CRICKET ON ICE: Twenty20 Score SheetArk TripathiBelum ada peringkat

- Attendance Mustor ReportDokumen4 halamanAttendance Mustor ReportRajput PratiksinghBelum ada peringkat

- ESICDokumen16 halamanESICTopRankersBelum ada peringkat

- How To Prepare For ExamDokumen21 halamanHow To Prepare For ExamRajat SukhijaBelum ada peringkat

- Rainfall Figures in Gujarat Upto 8 Am On July 18th 2017Dokumen4 halamanRainfall Figures in Gujarat Upto 8 Am On July 18th 2017DeshGujaratBelum ada peringkat

- AEPL Cricket Team Match PreviewDokumen1 halamanAEPL Cricket Team Match PreviewRajput PratiksinghBelum ada peringkat

- ResignationDokumen1 halamanResignationAlan KhorBelum ada peringkat

- 24 Jun 2016 1304322739hcqxsdeannexure3commonpfrDokumen166 halaman24 Jun 2016 1304322739hcqxsdeannexure3commonpfrSrikanthBelum ada peringkat

- Survey Report On Methane & Non-Methane Hydrocarbon in Ambient Air FORDokumen31 halamanSurvey Report On Methane & Non-Methane Hydrocarbon in Ambient Air FORRajput PratiksinghBelum ada peringkat

- Planning-23-5-20 - 31-5-20Dokumen1 halamanPlanning-23-5-20 - 31-5-20Rajput PratiksinghBelum ada peringkat

- File HandlerDokumen44 halamanFile HandlerImranBelum ada peringkat

- File HandlerDokumen44 halamanFile HandlerImranBelum ada peringkat

- ResignationDokumen1 halamanResignationAlan KhorBelum ada peringkat

- TDS - Jotaprime Mastic - English (Uk) - Issued.26.11.2010Dokumen4 halamanTDS - Jotaprime Mastic - English (Uk) - Issued.26.11.2010Rajput PratiksinghBelum ada peringkat

- Assignment 2Dokumen6 halamanAssignment 2Umar ZahidBelum ada peringkat

- 2023 Key Stage 2 Mathematics Braille Transcript Paper 1 ArithmeticDokumen8 halaman2023 Key Stage 2 Mathematics Braille Transcript Paper 1 ArithmeticMini WorldBelum ada peringkat

- Lecture Notes in Computational Science and EngineeringDokumen434 halamanLecture Notes in Computational Science and Engineeringmuhammad nurulBelum ada peringkat

- Lecture Antenna MiniaturizationDokumen34 halamanLecture Antenna MiniaturizationJuhi GargBelum ada peringkat

- Automobile Engg-UNIT-1Dokumen28 halamanAutomobile Engg-UNIT-1Muthuvel MBelum ada peringkat

- Kalman Filter Tutorial - PresentationDokumen65 halamanKalman Filter Tutorial - Presentationcarlazar100% (2)

- COP ImprovementDokumen3 halamanCOP ImprovementMainak PaulBelum ada peringkat

- Hypothesis TestingDokumen2 halamanHypothesis TestingNerish PlazaBelum ada peringkat

- General Types of Intermolecular Forces 11-LDokumen33 halamanGeneral Types of Intermolecular Forces 11-LClarenz N. Turan100% (1)

- GAS-RELEASE CALCULATORDokumen3 halamanGAS-RELEASE CALCULATOREduardo Paulini VillanuevaBelum ada peringkat

- Microelectronics: Circuit Analysis and Design, 4 Edition by D. A. Neamen Problem SolutionsDokumen6 halamanMicroelectronics: Circuit Analysis and Design, 4 Edition by D. A. Neamen Problem SolutionsJano Jesus AlexBelum ada peringkat

- Fractional Brownian Motions in Financial Models, Simulation and PricingDokumen111 halamanFractional Brownian Motions in Financial Models, Simulation and Pricingnahv_08Belum ada peringkat

- Certificate: Shear MachineDokumen3 halamanCertificate: Shear MachinegilbertoBelum ada peringkat

- Novel Proteinaceous Infectious Particles Cause ScrapieDokumen10 halamanNovel Proteinaceous Infectious Particles Cause ScrapieMikey HaveyBelum ada peringkat

- Common MisconceptionsDokumen7 halamanCommon MisconceptionsBoazz750Belum ada peringkat

- Ground Plane AntennaDokumen7 halamanGround Plane AntennaarijeetdguyBelum ada peringkat

- 10th Geometrical ConstructionDokumen2 halaman10th Geometrical Constructionapi-242227794100% (1)

- State-Of-The-Art CFB Technology For Utility-Scale Biomass Power PlantsDokumen10 halamanState-Of-The-Art CFB Technology For Utility-Scale Biomass Power PlantsIrfan OmercausevicBelum ada peringkat

- Artikel Materi Skripsi - Qurrotu Aini-2Dokumen13 halamanArtikel Materi Skripsi - Qurrotu Aini-2Qurrotu AiniBelum ada peringkat

- VPRS-4300D Catalogue PDFDokumen4 halamanVPRS-4300D Catalogue PDFHoàngTrầnBelum ada peringkat

- Human Skin Structure & FunctionsDokumen3 halamanHuman Skin Structure & FunctionsIshansi AgrawalBelum ada peringkat

- Peabody y Movent ABCDokumen11 halamanPeabody y Movent ABCIngrid BarkoBelum ada peringkat

- Quasi VarianceDokumen2 halamanQuasi Varianceharrison9Belum ada peringkat

- TIPS ON MEASUREMENT UNCERTAINTIESDokumen2 halamanTIPS ON MEASUREMENT UNCERTAINTIESrahmaBelum ada peringkat

- Flex-Shaft Attachment Instructions Model 225: WarningDokumen1 halamanFlex-Shaft Attachment Instructions Model 225: WarningFernando Lopez Lago100% (1)

- C - Brim - 1909 80 - QDokumen40 halamanC - Brim - 1909 80 - Qmanohar rathodBelum ada peringkat

- 25 Most Frequently Asked DSA Questions in MAANGDokumen17 halaman25 Most Frequently Asked DSA Questions in MAANGPranjalBelum ada peringkat

- List of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Dokumen9 halamanList of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Sateesh NayaniBelum ada peringkat

- Automate Distribution of Quantity in MIGODokumen8 halamanAutomate Distribution of Quantity in MIGOyougesh100% (2)

- Manriding Tirfor O-MDokumen16 halamanManriding Tirfor O-MPhillip FrencilloBelum ada peringkat