Hydro6 Operation Manual PDF

Diunggah oleh

Castro Dios En Ti ConfioDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hydro6 Operation Manual PDF

Diunggah oleh

Castro Dios En Ti ConfioHak Cipta:

Format Tersedia

Pt. No.

A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

Pt. No. A2034-072-27000

OPERATING MANUAL

Operating Manual

Schlumberger Private

7 in x 2-7/8 in

Hydro-6 Hydraulic Set

Retrievable Packer

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

The following supplemental manuals are required

for complete documentation of this product:

SM-001 Handling & Storage Practices

For copies of these manuals, contact your local

Schlumberger representative.

Operating Manual

Schlumberger Private

REQUIRED

SUPPLEMENTAL MANUALS:

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

Description

The Hydro-6 is a compact, economical, single string hydraulic set retrievable

packer ideal for use in deviated wells, multiple packer completions and applications

where the packer(s) is to be set after the well is flanged up.

Since no mandrel movement occurs during setting, the Hydro-6 may be used in

single packer installations, or as the lower packer in multiple zone dual completions.

It is also ideal for multiple packer single string completions. The Hydro-6 is available

in a wireline controlled selective set version if required.

The Hydro-6 design features a unique system that allows debris to be circulated from

above the packer when releasing.

Features and Benefits

No tubing movement required to set the packer.

Compact design is ideal for highly deviated wells.

Multi-durometer three-piece element system.

Easily adjusted releasing shear system.

Built-in equalizing and circulating system to ensure safe and easy

releasing.

Optional rotational release.

Operating Manual

Schlumberger Private

Normally, the Hydro-6 is released with a straight pick-up shear system that is fully

adjustable. An optional secondary rotational release is also available on most sizes.

The secondary rotational release version can be released by either tension or

rotation.

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

1.0 Engineering Data

Dimensional and Engineering Data

Materials

Connecting Thread - Lower

Connecting Thread Upper

Casing Size

Casing Weight Range

O.D. Max Gauge Ring

O.D. Max - Element

Overall Length

Setting Piston Area

I.D. Min.

I.D. Drift

Body Parts

Center Element

End Elements

O-Ring(s)

Flow Wetted

Back-Ups

2.875 6.5 ppf, EUE Pin

2.875 6.5 ppf, EUE Box

7.000 in.

26 29 ppf

5.968 in.

5.765 in.

60.200 in.

8.84 sq. in.

2.422 in.

2.347 in.

No. of

Shear

Screws

1

2

3

4

5

6

7

8

9

10

11

12

Operating Manual

7 Size

Setting Shear

Pressure

(psi)

225

450

670

900

1,130

1,350

1,575

1,800

2,030

2,255

2,480

2,705

Minimum Differential

Pressure Required for

Packoff (psi)

3,500

3,500

Schlumberger Private

Table A

4140 (P-110)

70 Duro Nitrile

80 Duro Nitrile

Nitrile

4140 (P-110)

Teflon

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

2.0 Assembly Drawing & Reference Dimensions

OD1

ID1

L1

ID2

Length

31

L1

L2

L3

L4

L5

3

31

OD2

7

OD3

4

6

28

Outside Diameter

10

L2

11

32

14

32

14

32

L5

17

9

29

Inside Diameter

ID1

ID2

ID3

15

34

16

34

8

18

23

33

L4

19

3

21

22

24

26

OD4

OD5

30

27

ID3

Operating Manual

3.719 in

5.656 in

5.968 in

5.968 in

3.531 in

2.426 in

2.426 in

2.422 in

Schlumberger Private

OD1

OD2

OD3

OD4

OD5

9

11

L3

15.037 in

8.020 in

35.821 in

4.752 in

60.074 in

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

3.0 Bill of Materials

Operating Manual

Piece Part #

AP527-558-00001

AP514-034-00001

AP890-234-00001

AP514-035-00001

AP514-036-00001

AP100-029-00001

AP514-037-00001

AP513-842-00001

AP513-841-00001

AP510-839-00001

AP890-344-00001

AP100-357-00001

AP890-351-00001

AP514-038-00001

AP514-039-00001

AP100-030-00001

AP100-200-00001

AP511-102-00001

AP519-507-00001

AP514-041-00001

AP100-381-00001

AP100-503-00001

AP516-510-00001

AP510-757-00001

AP514-044-00001

AP822-234-00001

AP822-344-00001

AP823-234-00001

AP823-351-00001

Qty

1

1

2

1

1

24

1

2

1

2

2

1

1

1

1

10

5

5

1

1

10

1

1

1

1

2

4

2

2

Description

2 7/8 EUE BOX X 2 7/8 NUE BOX (P110, 7" LG)

MAIN MANDREL (P110)

O-RING (90 DURO NITRILE)

TOP CAP (1026)

LOCK MANDREL (P110)

SHEAR SCREW(2000)5/16-24 UNF X 5/16

PACKING ELEMENT MANDREL (P110)

END ELEMENT (BPR-700-EO, 80 DURO NITRILE)

CENTER ELEMENT (BPR-700-CO, 70 DURO, NITRILE)

SPACER RING (FLAT, 5.968 OD., 1018)

O-RING (90 DURO NITRILE)

SNAP RING (TRUARC 5100-387 H)

O-RING (90 DURO NITRILE)

PISTON (P110)

LOCK RING (P110)

RETAINING SCREW 5/8-18 UNF X 1/2 LG.

SLIP SPRING (X-750)

SLIP (8620)

SLIP CAGE (1026, 5.875 OD)

LOWER CONE (P110)

SHEAR SCREW

BOTTOM SUB (2 7/8 NUE BOX X 2 7/8 EUE PIN, P110)

UPPER GAGE RING (5.968 OD., 1018)

GAUGE RING (5.968 OD., 1018)

GUIDE RING (5.968 OD., 1018)

PARBAK RING (TEFLON-FLAT-UNCUT)

PARBAK RING (TEFLON-FLAT-UNCUT)

PARBAK RING (TEFLON-FLAT-CUT)

PARBAK RING (TEFLON-FLAT-CUT)

Schlumberger Private

Item

1

2

3

4

6

7

8

9

10

11

14

15

16

17

18

19

21

22

23

24

26

27

28

29

30

32

32

33

34

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

4.0 Handling, Storage & Make-Up Guidelines

5.0 Running Instructions

shear screws for a maximum tension to release of

50,000 pounds. Install a tubing plugging device as

specified in the well program. This could be a pumpout plug or wireline nipple with a plug or any other

device used to plug the tubing string. The shear

value of a pump-out plug must be greater than the

minimum differential pressure required to achieve

minimum pack-off as shown in Table A.

Prior to running the tool(s) in the hole, determine:

Warning:

4.0 Handling, Storage & Make-Up Guidelines

Detailed handling instructions applicable to all

Schlumberger Completion Systems products are

found in the required supplemental manual Handling,

Storage & Make-Up Guidelines, manual number SM001.

a. Setting Shear Pressure (psi)

b. Tension to Release

Warning:

The packer is designed to set in response to tubing to annulus pressure

differential. When setting in low fluid

level wells, do not fill the tubing while

running in the hole, the differential

hydrostatic pressure may prematurely

set the tool.

The tension to release is the amount of tension in

pounds that must be pulled on the tubing to shear the

shear screws (26) (5,000 pounds each) in-stalled in

the lower cone and release the tool. This amount of

tension is based on well conditions and operating

parameters. Make certain the amount of tension to

release does not exceed the strength of the tubing

string. The packers can be dressed with up to 10

Operating Manual

6.0 To Release Packer

To release the packer, simply pick up until the preset

tension to release value is exceeded. The mandrel is

pressure balanced to annulus pressure above the

tool, (with the same size tubing) so annulus pressure

will not affect release force. After shear screws

release the mandrel, the mandrel moves up exposing

circulation/equalization ports that may be used for

circulation before coming out of the hole. Pull the

first stand slowly to allow the elements and slips to

properly relax. After the packer is fully released, tool

may be tripped out of the hole.

Note: In order to prevent accidental release, the

correct number of shear screws (26) should be

installed even if the rotational release is to be used.

7.0 Disassembly Procedures

1. Place tool in vise gripping on lower portion of the

main mandrel (2) above the bottom coupling (27).

Note: As the tool is disassembled, remove and

discard all o-rings.

2. Remove top coupling (1).

3. Remove set screws (19) from slip cage (23).

4. Remove shear screws (26) from lower cone (24).

Schlumberger Private

The shear setting pressure is the amount of

differential pressure in favor of the tubing at the

setting depth of the tool(s) that is required to shear

the shear screws (7) (2,000 pounds shear value each)

installed in the top gauge cap and piston/upper cone

and begin the setting process. The shear setting

pressure is determined by the downhole conditions

and the operating parameters of the well. It is

recommended that there always be one more shear

screw installed in the top gauge cap than is installed

in the piston/upper cone. This will insure that the

slips are engaged before the packing elements begin

to extrude. The packer mandrel may be pressure

tested up to 70% of the setting shear pressure from

Table A without risk of shearing the shear screws (7),

installed in the piston/upper cone.

Ensure that the pressure required to

shear the screws in the top gauge cap

is not greater than the pressure rating

of the tubing or greater than the

pressure required to shear the pumpout plug.

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

7.0 Disassembly Procedures

5. Disengage lower cone (24) from lock mandrel (6).

Drive lower cone (along with the complete outer

shell of the packer) downward with a soft metal

bar until it releases from the collet.

6. Slide the packer body subassembly (complete

assembly from top gauge cap to collet) off the

top of the main mandrel (2). Set aside.

7. Remove bottom coupling (27) from main mandrel

(2). Take main mandrel (2) out of vise and remove

lower cone (24) from main mandrel (2).

8. Remove slip cage (23) with slips (22) and slip

springs (21) from piston/upper cone (17).

10. Loosen upper gauge ring (28) to expose shear

screws (7). (This step applies to 6-5/8 and larger

sizes only.)

11. Remove brass shear screws (7) from top gauge

cap (4).

12. Remove top gauge cap (4) from lock mandrel (6).

13. Pull spacer ring (11), end packing element (9),

and center packing element (10) off of packing

element mandrel (8).

14. Place backup wrench on ratchet cylinder (12) as

close as possible to the gauge ring. Place

wrench jaws over shear screw groove in the

packing element mandrel (8) and un-thread the

packing element mandrel (8) .

15. Place backup on piston/upper cone (17). Remove

packing element mandrel (8) by unthreading off

of the lock ring (18).

16. Remove snap ring (15).

17. Using spreader pliers, remove lock ring (18). The

lock ring should be inspected for damage such

as pulled threads, scaring, corrosion, etc.

20. Move in vise to make certain vise jaws are

griping on lock mandrel (6) and not on the lock

mandrel (6). Place wrench jaws on lock mandrel

(6), just above slots and remove from lock

mandrel (6).

8.0 Assembly Procedures

1. Install all o-rings in the respective grooves

except the outer o-ring (16) for the piston/upper

cone (17). Use ample grease when assembling

the tool.

Place lock mandrel (6) in vise. Thread on lock

mandrel (6) and tighten.

3. Slide piston/upper cone (17) onto lock mandrel

(6) until the piston/upper cone is past the snap

ring groove on the lock mandrel.

4. Install snap ring (15) onto lock mandrel (6). This

locks the piston/upper cone (17) in place on the

lock mandrel (6).

5. Slide piston/upper cone (17) upward until it

shoulders on snap ring (15). Line up shear screw

holes in piston/upper cone (17) with shear screw

groove in lock mandrel (6) and install brass shear

screws (7).

6. Using spreader pliers install lock ring (18) onto

piston/upper cone (17). Blank end of lock ring

(18) shoulders against the edge of the upper

cone.

7. Install outer o-ring (16) in o-ring groove on

piston/upper cone (17).

8. Coat the fine threads on the piston/upper cone

(17) with ample grease. Slide packing element

mandrel (8) onto piston/upper cone (17) and

thread ratchet cylinder onto the lock ring. Make

18. Remove the brass shear screws (7) from

piston/upper cone (17).

Operating Manual

Schlumberger Private

9. Place the packer body subassembly in the vise,

clamping the vise jaws on the lock mandrel (6) as

close as possible to the piston/upper cone (17).

19. Remove piston/upper cone (17) from lock

mandrel (6).

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

8.0 Assembly Procedures

certain the lock ring does not move or begin to

ratchet as the ratchet cylinder is threaded.

Friction from the o-ring can cause the lock ring

to ratchet as the ratchet cylinder is threaded.

Gently tap the end of the ratchet cylinder with a

rubber hammer while threading the ratchet

cylinder onto the lock ring. Thread ratchet

cylinder onto lock ring until all threads on the

lock ring are covered by the ratchet cylinder.

15. Tighten guide ring (30) onto lower cone (24).(This

step applies to 6-5/8 and larger sizes only.)

9. Thread lower gauge ring (29) onto packing

element mandrel (8) and tighten. (This step

applies to 6-5/8 and larger sizes only.)

18. Slide the packer body subassembly onto the

main mandrel (2), lock mandrel (6) first. Push the

subassembly onto the main mandrel until it

shoulders. In this position you can see the

bypass holes in the main mandrel above the top

gauge cap.

11. Tighten top gauge cap (4) onto lock mandrel (6)

and install shear screws (7). When top gauge

cap is tight, the shear screw holes in the top

gauge cap will line up with shear screw groove

in the packing element mandrel (8). If the holes

do not line up, the alignment of the lock ring is

wrong and must be redone.

Note: For 6-5/8 and larger sizes, thread upper

gauge ring (28) onto top gauge cap (4). Leave upper

gauge ring (28) loose until shear screws (7) have

been installed in top gauge cap.

12. Remove

this

assembly

(packer

body

subassembly) from the vise and stand upright on

top gauge cap (4).

13. Insert slip (22) with slip spring (21) into window in

slip cage (23). Insert 10-24 UNF screw through

hole in slip cage and thread into the hole in the

center of slip. The 10-24 screw will hold the slip

and slip spring in place in the window of the slip

cage. Repeat until all slips and slip springs are

installed.

14. Slide the slip cage (23) with slips and slip springs

over the lock mandrel (6). Align slots in the slip

cage with the screw holes in the piston/upper

cone (17) and install set screws (19).

Operating Manual

17. Grease entire main mandrel.

19. Snap the lower cone (24) over the lock mandrel

(6) with enough force to engage the fingers of

the collet into the lower cone. Slide the lower

cone and the packer body subassembly upward

until the lower cone shoulders on the main

mandrel. The shear screw holes in the lower

cone will line up with spot-faced holes on the

main mandrel. If collet and lower cone are

properly engaged, the lower cone will spin freely

and the top gauge cap will cover the bypass

holes in the main mandrel.

20. Install retaining screws (19) through slots in slip

cage (23) into holes in lower cone (24). Remove

10-24 UNF screws holding slips in place.

21. Line up shear screw holes in lower cone (24)

with spot faced holes in main mandrel (2) and

install shear screws (26).

Note: For tools with 'secondary rotational release',

align shear screw holes in lower cone (24) with spot

faced holes in shear sleeve (26).

22. Install top coupling #1. Tighten through top

coupling to make up both top coupling and

bottom coupling (27) onto the main mandrel (2).

Schlumberger Private

10. Slide end element (9) onto packing element

mandrel (8), followed by spacer ring (11), center

element (10), spacer ring (11) with the bevel

towards the end element, and end element (11).

16. Slide lower cone (24) onto main mandrel (2). The

lower cone will shoulder. Thread bottom

coupling (27) onto main mandrel (2). Place lower

end of main mandrel (by the bottom coupling) in

vise.

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

9.0 Instructions to Change Setting Shear Value on the Hydro-6 Packer

9.0 Instructions to Change Setting Shear Value on

the Hydro-6 Packer

1. Determine appropriate number of shear screws

from Table A.

2. Secure top or bottom connection in vise.

3. Loosen upper gauge ring (28) from top cap (4).

(This step applies to 6-5/8 and larger sizes only).

4. Remove or add shear screws (7) as required.

Slightly loosen remaining shear screws without

disengaging screws from shear groove.

Schlumberger Private

5. Remove retaining screws (19) from top of slip

cage (23) and slide slip cage down as far as

possible.

6. Rotate packing element mandrel (8) and lock ring

(18) together to access shear screws (7) through

split in lock ring (18).

Note: It is critical to rotate 'cylinder' portion of

element mandrel and locking ring together to prevent

'binding' of lock ring. (Packing element mandrel,

elements and top gauge cap will all rotate together

and upper shear screws must remain in the groove

to maintain orientation of lock ring.

7. Remove or add shear screws (7) as required.

8. Install retaining screws (19) in slip cage (23).

Tighten shear screws (7) in top gauge cap (4).

9. Tighten upper gauge ring (28). (This step applies

to 6-5/8 and larger sizes only).

Operating Manual

10

Pt. No. A2034-072-27000

7 in x 2-7/8 in Hydro 6 Hydraulic Set

Retrievable Packer

Revision Level AA

Revision No. 01

Document 08 AUG 2003

Schlumberger Private

Schlumberger has made every effort to manufacture a safe product of the very highest quality and design. This manual is designed to provide

operating personnel with the information necessary to assemble and disassemble, service and maintain this product. The content of this manual

should not be construed as a fixed rule without regard to sound engineering judgement, nor is it intended to supersede or override any state,

federal or local regulations where applicable.

Schlumberger recommends reading the complete procedure before beginning any operation.

Be sure to note the areas of caution.

Operating Manual

11

Schlumberger Private

LONG-TERM QUALITY AND PERFORMANCE MONITORING

Schlumberger Completion Systems maintains a long-term quality and performance monitoring system for all completion

products. In the event of any service difficulty or malfunction, please contact your local Schlumberger representative for

the appropriate reporting form. Send the form and all pertinent information to the following address:

Q.A. Department, Schlumberger -- P.O. Box 14484 -- Houston, Texas 77221

P. O. Box 14484 Houston, Texas 77221 Telephone: (713) 747-4000 Fax: (713) 747-6751 www.slb.com

Rev. Hydro-6 #01A

Copyright 2002 Schlumberger

* Mark of Schlumberger

Anda mungkin juga menyukai

- Production and Test Packer - RetrievableDokumen30 halamanProduction and Test Packer - RetrievableHendra JurbonBelum ada peringkat

- Hyflo™ III Liner Packer With C-2™ Profile, Hyflo III Liner Packer With HR™ Profile, Hyflo™ III Liner Packer With RH™ ProfileDokumen5 halamanHyflo™ III Liner Packer With C-2™ Profile, Hyflo III Liner Packer With HR™ Profile, Hyflo™ III Liner Packer With RH™ Profilemsm.ele2009Belum ada peringkat

- S2HHydroSetAdapterKit 5667 SU PDFDokumen8 halamanS2HHydroSetAdapterKit 5667 SU PDFDEATH ASSASSIN GAMER100% (1)

- Wire Line SettingDokumen19 halamanWire Line SettingNagarjunSHBelum ada peringkat

- Maximus Product CatalogDokumen78 halamanMaximus Product Catalogapi-155731311Belum ada peringkat

- Plug and Ball CatcherDokumen48 halamanPlug and Ball CatcherDoni KurniawanBelum ada peringkat

- BigBore IIe Subsea Wellhead SystemsDokumen5 halamanBigBore IIe Subsea Wellhead SystemsIrinafanBelum ada peringkat

- Section4a PDFDokumen30 halamanSection4a PDFDoni KurniawanBelum ada peringkat

- PCK para Limpiar PunzadosDokumen19 halamanPCK para Limpiar PunzadosRodolfo RiderBelum ada peringkat

- TV10 Bridge Plug BakerDokumen5 halamanTV10 Bridge Plug BakerAlain AlemanBelum ada peringkat

- Bdmi 213RL00000 RTLTDokumen8 halamanBdmi 213RL00000 RTLTrogerBelum ada peringkat

- Rtts Circulating Valves: SectionDokumen40 halamanRtts Circulating Valves: Sectionwee zooBelum ada peringkat

- 2003 Liner Hangers CatalogDokumen104 halaman2003 Liner Hangers CatalogFABGOILMAN100% (1)

- Full-Opening Multiple-Stage Cementing Equipment: Halliburton Part No. 100004670.NX (813.01759.NX)Dokumen48 halamanFull-Opening Multiple-Stage Cementing Equipment: Halliburton Part No. 100004670.NX (813.01759.NX)Doni KurniawanBelum ada peringkat

- Seal Bore Packer System - RetrievableDokumen8 halamanSeal Bore Packer System - RetrievableFabio ParceroBelum ada peringkat

- Completion Schematic #1: Stimulate and Test ZonesDokumen1 halamanCompletion Schematic #1: Stimulate and Test Zonesasset_kulmagambetovBelum ada peringkat

- 7.000 X 2.875 DLH Packer With J-Release (17-26) 938-7000-028 Rev ADokumen5 halaman7.000 X 2.875 DLH Packer With J-Release (17-26) 938-7000-028 Rev ANorbey Ashley Gasca AlzateBelum ada peringkat

- 06 Openhole IsolationDokumen24 halaman06 Openhole IsolationMuhammad ShahrukhBelum ada peringkat

- TechWest Liner EquipmentDokumen71 halamanTechWest Liner EquipmentDon BraithwaiteBelum ada peringkat

- TRDP - SSSVDokumen23 halamanTRDP - SSSVsambhajiBelum ada peringkat

- Packer Cross Reference GuideDokumen3 halamanPacker Cross Reference GuideMaxime BerthoméBelum ada peringkat

- Drilling & Intervention Services Completion Systems Artificial Lift SystemsDokumen72 halamanDrilling & Intervention Services Completion Systems Artificial Lift Systemshijoetigre100% (1)

- As Retrievable Bridge Plug: A) DescriptionDokumen7 halamanAs Retrievable Bridge Plug: A) DescriptionAlain AlemanBelum ada peringkat

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDokumen15 halamanPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Belum ada peringkat

- Completion Components: Oil and Gas Well CompletionsDokumen28 halamanCompletion Components: Oil and Gas Well CompletionsJuan SueBelum ada peringkat

- ADS 11H Completion Program REV-0Dokumen32 halamanADS 11H Completion Program REV-0Emmanuel IfedioraBelum ada peringkat

- Design Overview: Basic Design and Maintenance InstructionsDokumen5 halamanDesign Overview: Basic Design and Maintenance Instructionsazze bouzBelum ada peringkat

- 4200Dokumen44 halaman4200Hamdi Said100% (1)

- Seal Assemblies (Locator, Anchor, Latch)Dokumen2 halamanSeal Assemblies (Locator, Anchor, Latch)Yougchu LuanBelum ada peringkat

- Coiled Tubing BHADokumen88 halamanCoiled Tubing BHAOmer SaeedBelum ada peringkat

- 07 StraddlesDokumen12 halaman07 StraddlesyariyantoBelum ada peringkat

- Packer 7in Crest-II Sapex SpecDokumen3 halamanPacker 7in Crest-II Sapex SpecbayuBelum ada peringkat

- Welltec Profile BrochureDokumen82 halamanWelltec Profile Brochuretongsabai100% (1)

- Bn67 Completion Schematic - Final 4 Apr 16Dokumen1 halamanBn67 Completion Schematic - Final 4 Apr 16sharil 9228Belum ada peringkat

- Camisa Deslizable Modelo L para H2SDokumen5 halamanCamisa Deslizable Modelo L para H2SCO BDBelum ada peringkat

- Wellhead - Ope - ManualDokumen73 halamanWellhead - Ope - ManualsambhajiBelum ada peringkat

- MAN-10004933/C Lift Bail/Test Plug Assy: User Manual (Operation and Service)Dokumen45 halamanMAN-10004933/C Lift Bail/Test Plug Assy: User Manual (Operation and Service)Huy DoBelum ada peringkat

- R Selective Test Tool PDFDokumen5 halamanR Selective Test Tool PDFazze bouzBelum ada peringkat

- 5 Mandrels & Landing NipplesDokumen34 halaman5 Mandrels & Landing NipplesWaled FekryBelum ada peringkat

- Elder Tools International: DescriptionDokumen7 halamanElder Tools International: Descriptionnurwinanto01Belum ada peringkat

- Anc Storm ValveDokumen9 halamanAnc Storm ValveCarlos Holguin100% (1)

- Dibujos de Completacion de PozoDokumen34 halamanDibujos de Completacion de PozomalconBelum ada peringkat

- WOT - Tech Data Sheets PDFDokumen43 halamanWOT - Tech Data Sheets PDFAmbroise RICHARDBelum ada peringkat

- Botil Model BTCN Mechanical Set PackerDokumen2 halamanBotil Model BTCN Mechanical Set PackerReivaj JavierBelum ada peringkat

- Tubing Punch ADokumen22 halamanTubing Punch AOrtiz Rivera SergioBelum ada peringkat

- 8023Dokumen10 halaman8023Tamer Hesham AhmedBelum ada peringkat

- Cleaning and Dressing PBR PDFDokumen5 halamanCleaning and Dressing PBR PDFMohamed AbozeimaBelum ada peringkat

- BakerDokumen4 halamanBakerWilliam EvansBelum ada peringkat

- Ttt2b Drillable TlsDokumen26 halamanTtt2b Drillable TlsMahmoud Ahmed Ali AbdelrazikBelum ada peringkat

- H81106 C-1 Running Tool and A PDFDokumen9 halamanH81106 C-1 Running Tool and A PDFSantosh MishraBelum ada peringkat

- Technical Specification 3.5 CompletionDokumen43 halamanTechnical Specification 3.5 Completionbasil ameenBelum ada peringkat

- Catalog Flow Control EquipmentDokumen14 halamanCatalog Flow Control Equipmenthosam aliBelum ada peringkat

- Drilling With Casing 04Dokumen15 halamanDrilling With Casing 04Dian Sikumbang100% (2)

- Weatherford Lamb Libya Limited - Casing Exit & Selective ReDokumen75 halamanWeatherford Lamb Libya Limited - Casing Exit & Selective ReRicardo Hurtado HernándezBelum ada peringkat

- Reliant 10K Hornet Mechanical Tension Set Packer: Packer Systems Technical Unit ™ Product Family No. H64682Dokumen49 halamanReliant 10K Hornet Mechanical Tension Set Packer: Packer Systems Technical Unit ™ Product Family No. H64682Razvan RaduBelum ada peringkat

- 20brochure PDFDokumen27 halaman20brochure PDFparet999Belum ada peringkat

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDari EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsBelum ada peringkat

- 2, 5 Inch Side Door Stripper PDFDokumen16 halaman2, 5 Inch Side Door Stripper PDFOvRrj AhmedBelum ada peringkat

- Tech 1183 Man StripperDokumen19 halamanTech 1183 Man StripperDonna Gray100% (1)

- Ariadne, Omphale or HerculesDokumen11 halamanAriadne, Omphale or HerculesVesna MatićBelum ada peringkat

- Execises 1st Year Bachillerato (3rd Term)Dokumen11 halamanExecises 1st Year Bachillerato (3rd Term)centralvarBelum ada peringkat

- Merchant Marine Academy 2nd Semester - P. Papaleonidas - 2011-89-99Dokumen11 halamanMerchant Marine Academy 2nd Semester - P. Papaleonidas - 2011-89-99Наталья ЛандикBelum ada peringkat

- Co Que C C C C C C C C: Flip Book - Robust Communication System - Low Technology-SchematicDokumen32 halamanCo Que C C C C C C C C: Flip Book - Robust Communication System - Low Technology-SchematicAdhitya TaslimBelum ada peringkat

- Full Test Bank For College Algebra 12Th Edition by Gustafson PDF Docx Full Chapter ChapterDokumen36 halamanFull Test Bank For College Algebra 12Th Edition by Gustafson PDF Docx Full Chapter Chapterzedlenimenthy6kr100% (12)

- Phrasal Verbs in English: Examples Examples Examples ExamplesDokumen14 halamanPhrasal Verbs in English: Examples Examples Examples ExamplesAbhimanyu SinghBelum ada peringkat

- Transfer Using Gait Belt PDFDokumen2 halamanTransfer Using Gait Belt PDFKim WashingtonBelum ada peringkat

- Asumin Asm Macro 6638 MsdsDokumen5 halamanAsumin Asm Macro 6638 MsdsMuhammad Aasim HassanBelum ada peringkat

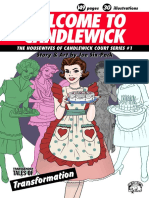

- Housewives of Candlewick Court 01 - Welcome To Candlewick PDFDokumen156 halamanHousewives of Candlewick Court 01 - Welcome To Candlewick PDFBear Bear100% (2)

- Pogremushka OvechkaDokumen9 halamanPogremushka OvechkaCarlos Alexis Arteaga Gómez100% (1)

- Korean Wave (한류)Dokumen10 halamanKorean Wave (한류)NikolyBelum ada peringkat

- Blue ValentineDokumen101 halamanBlue ValentineBen ZichBelum ada peringkat

- Boutique Women Designer Wear Rs. 6.22 Million Jun-2018 PDFDokumen21 halamanBoutique Women Designer Wear Rs. 6.22 Million Jun-2018 PDFfaddi2238Belum ada peringkat

- 15.what's Your Worst Habit (Schlechteste Angewohnheit) ?Dokumen3 halaman15.what's Your Worst Habit (Schlechteste Angewohnheit) ?uworissimoBelum ada peringkat

- Code 144 BookDokumen38 halamanCode 144 BookVictor Vander0% (1)

- Ambitious Vocabulary: So First Next Lonely Afraid Because Interesting ExcitingDokumen4 halamanAmbitious Vocabulary: So First Next Lonely Afraid Because Interesting ExcitingBilbo BagginsBelum ada peringkat

- 36VictorianDressPatterns PDFDokumen133 halaman36VictorianDressPatterns PDFPAULABelum ada peringkat

- PDS Pro Struct 618LV October 2017 Replaces January 2014Dokumen2 halamanPDS Pro Struct 618LV October 2017 Replaces January 2014Amar Babu ChBelum ada peringkat

- Breathable FabricDokumen1 halamanBreathable Fabricmohitjuneja83Belum ada peringkat

- The Hudsucker Proxy: For Educational Purposes OnlyDokumen147 halamanThe Hudsucker Proxy: For Educational Purposes Onlymaxi314Belum ada peringkat

- Leadville 100 Miles Athlete Guide 2019 Edition. Classic Ultra Trail USA in ColoradoDokumen35 halamanLeadville 100 Miles Athlete Guide 2019 Edition. Classic Ultra Trail USA in ColoradoMayayo: Carrerasdemontana.comBelum ada peringkat

- House of Sky and Breath - Sarah J. Maas (Bonus Chapters)Dokumen33 halamanHouse of Sky and Breath - Sarah J. Maas (Bonus Chapters)Saadia NomanBelum ada peringkat

- Second-Quarterly-Test-in-TLE-6-with-TOS and Answer KeyDokumen5 halamanSecond-Quarterly-Test-in-TLE-6-with-TOS and Answer KeyArlene HernandezBelum ada peringkat

- Lektion-Se 11046 Reading ComprehensionDokumen55 halamanLektion-Se 11046 Reading ComprehensionsoulsellBelum ada peringkat

- Rebel Without A CauseDokumen7 halamanRebel Without A Causeamorrow1Belum ada peringkat

- Super Model International NR 2Dokumen80 halamanSuper Model International NR 2Konrad100% (6)

- PQCP-06.03.09 Concrete Crack RepairDokumen3 halamanPQCP-06.03.09 Concrete Crack RepairmiaicarbaBelum ada peringkat

- Castles & Crusades - Castle Keeper's ScreenDokumen4 halamanCastles & Crusades - Castle Keeper's ScreenSalvador Marques Jr.Belum ada peringkat

- Fashion History During:-1990s-Technology Era 2000s-Internet EraDokumen29 halamanFashion History During:-1990s-Technology Era 2000s-Internet EradenisBelum ada peringkat

- Montabert HC109Dokumen14 halamanMontabert HC109Yiğit Erpak100% (2)