Asdf

Diunggah oleh

qpalzm97Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Asdf

Diunggah oleh

qpalzm97Hak Cipta:

Format Tersedia

Platinum Metals Rev.

, 2013, 57, (4), 272280

Organometallics as Catalysts in the Fine

Chemical Industry

Edited by Matthias Beller (Leibniz-Institut fr Organische Katalyse, Universitt Rostock,

Germany) and Hans-Ulrich Blaser (Solvias AG, Basel, Switzerland), Topics in Organometallic

Chemistry, Vol. 42, Springer, Berlin, Heidelberg, Germany, 2012, 154 pages,

ISBN: 978-3-642-32832-9, 171.00, 203.25, US$259.00 (Print version)

http://dx.doi.org/10.1595/147106713X672320

Reviewed by Michel Picquet

Institut de Chimie Molculaire de lUniversit de Bourgogne

(ICMUB), UMR 6302, CNRS, 9 Avenue Alain Savary, 21078

Dijon, France

Email: michel.picquet@u-bourgogne.fr

http://www.platinummetalsreview.com/

Introduction

This new volume of Springers famous series Topics

in Organometallic Chemistry, Volume 42, entitled

Organometallics as Catalysts in the Fine Chemical

Industry, presents the state-of-the-art in the industrial

use of organometallic or coordination complexes

as catalysts for the production of fine chemicals. A

range of reactions is covered through an overview of

chapters and case studies, from catalytic CC bond

formation, hydroformylation and hydrogenation

to olefin metathesis (see below). All of these are

noteworthy for involving platinum group metal

(pgm) complexes as catalysts. Interestingly, technical

challenges encountered in scaling up the reactions

from small quantities to production amounts, as well

as how these issues were tackled, are often described

by the authors, who all belong to the industrial

world. Their contributions make this book a helpful

source of information for specialists in the field of

organometallic catalysis, as well as beginners who

have just entered the field or intend to do so.

Palladium-Catalysed Coupling Reactions

Extensively reviewed by Johannes G. de Vries (DSM

Innovative Synthesis BV, Geleen, The Netherlands)

in the first chapter, palladium-catalysed coupling

reactions appear to be among the most popular

reactions for the production of fine chemicals at

the ton-scale. Provided inhibition and deactivation

of the catalyst is avoided, catalytic CC coupling

may offer several advantages such as total cost

reduction, tolerance to many functional groups (no

waste-producing protection/deprotection steps) and

lower reaction temperatures. Thus, several industrial

processes were developed in fine chemistry using

the well known Heck-Mirozoki, Suzuki-Miyaura,

Sonogashira, Kumada-Corriu and Negishi couplings.

Some of them are given below.

272

2013 Johnson Matthey

Platinum Metals Rev., 2013, 57, (4)

http://dx.doi.org/10.1595/147106713X672320

Using the Heck reaction in one of its synthetic steps,

the herbicide prosulfuron is produced on a large scale

by Syngenta (Figure 1). Tris(dibenzylideneacetone)dipalladium(0) (Pd2(dba)3) is used as a catalyst

precursor without any phosphine ligand and the

precipitated palladium is trapped at the end of the

reaction simply by using charcoal. Naproxen (Figure 1)

is also produced by Albemarle with a scale around

500 tons year1 using the same technology. In this case,

palladium(II) chloride (PdCl2) is used as a metal

source and the neomenthyldiphenylphosphine ligand

is used to reach a substrate-to-catalyst ratio of 20003000.

The ability of the Heck reaction to be performed

without the need of protection/deprotection steps

on the substrate is illustrated by the production of

montelukast, an anti-asthma agent, by Merck and of

the calcium-regulator cinacalcet hydrochloride by

Teva (Figure 1). In the first case, palladium(II) acetate

(Pd(OAc)2) is used as a precatalyst while Tevas

process makes use of the simple Pd/C catalyst. More

sophisticated metal precursors are sometimes used for

maximum efficiency of the reaction. As an example,

for the production of resveratrol (Figure 1), DSM has

reported the use of a chloropalladacycle dimer based

on the acetophenone oxime ligand. Other examples of

the industrial production of fine chemicals involving

a Heck reaction are described, including rilpivirine

(AIDS treatment, Janssen Pharmaceuticals), eletriptan

(anti-migraine, Pfizer), the generic of nebivolol (blood

pressure lowering agent, Zach System), pemetrexed

disodium (anticancer agent, Eli Lilly) and varenicline

(smoking cessation aid, Pfizer).

Twelve industrial processes using another useful

CC bond formation reaction, the Suzuki coupling, are

reported. The largest is operated by Merck to produce

more than 1000 tons year1 of the fungicide boscalid

(Figure 2). In a pivotal step, o-chloronitrobenzene is

coupled to p-chlorophenylboronic acid using catalytic

amounts of Pd(OAc)2 and triphenylphosphine. A

similar catalytic system is used by Clariant to obtain

o-tolylbenzonitrile (OTBN, Figure 2) as a common

intermediate for the production of hundreds of

tons of an entire family of Sartan derivatives as

blood pressure lowering agents. This process is

advantageously run in an aqueous medium using

the water-soluble phosphine 3,3,3-phosphanetriyltris(benzenesulfonic acid) trisodium salt (TPPTS),

thus allowing easy recovery of the catalyst. Crizotinib

(Figure 2), an anticancer drug marketed by Pfizer,

is also obtained through a Suzuki coupling step.

In this case, the optimised catalytic precursor was

found to be (1,1-bis(diphenylphosphino)ferrocene)palladium(II) chloride. Interestingly, after work up,

traces of residual Pd could be removed by simple

treatment with silica-alumina loaded with 15% cysteine.

To replace the unscalable Stille coupling reaction in

the original synthesis of the other anticancer drug

lapatinib (Figure 2), GSK has developed a more

OH

S

O2

CF3

H

N

H

N

O

N

N

Prosulfuron

CO2H

OMe

H

N

MeO

OH

Naproxen

Resveratrol

CO2H

CF3

OH

S

Cl

Cinacalcet

HO

N

Montelukast

Fig. 1. Examples of fine chemicals industrially produced using the palladium-catalysed Heck reaction (creation

of the bold red bond)

273

2013 Johnson Matthey

Platinum Metals Rev., 2013, 57, (4)

http://dx.doi.org/10.1595/147106713X672320

NC

Cl

N

H

N

Cl

Cl

OTBN

Boscalid

Cl

NH

S

O2

H2N

Cl

O

F

N

HN

O

NH

N

Crizotinib

N

N

HN

Lapatinib

N

O

Ruxolitinib

CN

F

O

Cl

O2

N S

H

N

H

Vemurafenib

N

AcO

Abiraterone acetate

Fig. 2. Examples of fine chemicals industrially produced using the palladium-catalysed Suzuki reaction (creation

of the bold red bond)

convenient Suzuki route using Pd/C. In this case, the

residual catalyst is eliminated by simple filtration.

Several synthetic schemes, all containing a Suzuki

reaction step, have also been developed to access

ruxolitinib phosphate, a molecule marketed by

Incyte for the treatment of myelofibrosis. However,

for an industrial process, this Pd-catalysed coupling

should preferably not be the last step in order to

avoid tedious removal of Pd traces down to the

<10 ppm criteria. As counter examples, HoffmannLa Roche and Janssen Pharmaceuticals have

scaled up convergent syntheses of vemurafenib and

abiraterone acetate (Figure 2), respectively. Both

use

dichlorobis(triphenylphosphine)palladium(II)

(PdCl2(PPh3)2) as a catalyst to perform a Suzuki

coupling in the ultimate step for the synthesis of these

anticancer compounds. Some additional examples

of the use of the Suzuki reaction in industrial

processes include the synthesis of the antifungal

agent anidulafungin by Pfizer, of febuxostat (Teijin

Pharma), a molecule used in the treatment of gout

and hyperuricemia, of the quinolone antibiotic

garenoxacin by Toyama Chemical and of nebivolol

by Zach System.

274

Despite the obvious drawback of using a Grignard

reagent intolerant of many functional groups,

several fine chemicals are produced using the

cheapest Kumada-Corriu reaction at the multiton

year1 scale. Most of them are out of the scope of

this review, as they involve the non-pgms nickel,

copper and iron as catalysts. However, for some

peculiar reactions, palladium derivatives are the

preferred catalysts. Thus, Hokko Chemical Industry

is using a catalyst made in situ from PdCl2 and

1,1-bis(diphenylphosphino)ferrocene (dppf) to

couple 1,3-dichlorobenzene and n-propylmagnesium

chloride or p-fluorobromobenzene and p-tertbutoxyphenylmagnesium chloride (Figure 3).

The obtained compounds are precursors for

pharmaceuticals and liquid crystals. In a same

manner, Zambon uses the Kumada-Corriu coupling to

produce diflunisal, a non-steroidal anti-inflammatory

drug (Figure 3). In this case, Pd(OAc)2 is used as

precatalyst and triphenylphosphine is added. It is

noteworthy that chemists at Zambon found that

the homo-coupling of the Grignard reagent could

be reduced to less than 1% when using ultrapure

magnesium. Indeed, any traces of Cu, Fe, Ni and

2013 Johnson Matthey

Platinum Metals Rev., 2013, 57, (4)

http://dx.doi.org/10.1595/147106713X672320

OH

CO2H

Cl

Fine chemical intermediates

Diflunisal

manganese that are typically found in commercial

magnesium could promote this side reaction.

Alternatively, biaryl compounds can be produced

by the RZnX-based Negishi reaction. However, the only

two known industrial processes using this reaction

involve nickel catalysts and thus will not be described

in this review. The Sonogashira reaction, which allows

a terminal alkyne to be coupled with an aryl or

alkenyl halide or pseudohalide, makes efficient use of

palladium catalysts. The first industrial large-scale use

of this reaction was the second-generation process

developed by Sandoz for the synthesis of the antifungal

terbinafine with less than 0.05 mol% of PdCl2(PPh3)2

(Figure 4).Two companies, Medichem and Dipharma

Francis, patented synthetic routes to cinacalcet

(Figure 4) using the Sonogashira coupling, the two

approaches almost only differing by the nature of the

palladium source (Pd/C vs. PdCl2). Initially published

by the academic group of Takeshi Fujita (Tohoku

University, Japan), a methodology to obtain fingolimod

hydrochloride (Figure 4) via a Sonogashira reaction

was further developed by Novartis. The worldwide

rights to the process were acquired by this company

and its use in production seems likely. Other examples

of the use of the palladium-catalysed Sonogashira

reaction at the industrial level include the synthesis

of pemetrexed by Eli Lilly, of tazarotene, used for

the treatment of acne, psoriasis and photoageing

and marketed by Allergan, and of vemurafenib by

Hoffmann-La Roche.

In addition to the above-mentioned lead reactions,

other palladium-catalysed coupling reactions can be

used in industrial fine chemical production, although

only two examples are reported. Bristol-Myers Squibb

developed the synthesis of ixabepilone, marketed

for breast cancer treatment, using a Pd2(dba)3/PMe3catalysed allylic substitution step, while an elegant

Pd(OAc)2/PtBu3-mediated CH activation step is

used by Servier to produce ivabradine, an alternative

treatment for angina pectoris.

Applications of Rhodium-Catalysed

Hydroformylation

Chapter 2 is written by Gregory T. Whiteker (Dow

AgroSciences, Indianapolis, USA) and Christopher J.

Cobley (Chirotech Technology Ltd, Cambridge, UK),

and gathers information about the rare commercial

applications of rhodium-catalysed hydroformylation

in the pharmaceutical and fine chemical industries.

So far these have been limited by cost, complexity

or waste treatment issues. However, the authors have

thoroughly reviewed the patent literature to detect the

fine chemicals already obtained on a multikilogram

scale that may thus be on the way to industrial-scale

production.

In the pharmaceutical domain, both BASF and

Roche are operating industrial processes based on

a rhodium-catalysed hydroformylation to produce

vitamin A acetate (Figure 5), starting from different

substrates. The only other recent industrial-scale

application of hydroformylation was reported by

Chirotech for the synthesis of (S)-allysine ethylene

acetal (Figure 5), an important intermediate in the

manufacture of some enzyme inhibitors. In this case,

NH2

H

N

Terbinafine

Fig. 3. Examples of fine

chemicals industrially

produced using the

palladium-catalysed

Kumada-Corriu reaction

(creation of the bold red

bond)

OH

CF3

Cinacalcet

OH

C7H15

Fingolimod

Fig. 4. Examples of fine chemicals industrially produced using the palladium-catalysed Sonogashira reaction

(creation of the bold red bond)

275

2013 Johnson Matthey

Platinum Metals Rev., 2013, 57, (4)

http://dx.doi.org/10.1595/147106713X672320

C

H

OAc

H2N CO2H

C H

O

C

O

O

Vitamin A acetate

ONa

(S)-Allylsine ethylene acetal

Pharmaceutical

building block

Fig. 5. Examples of pharmaceutical derivatives or intermediates industrially produced using a rhodium-catalysed

hydroformylation step

the Rh-biphephos catalyst is used with a 4000:1 molar

substrate to catalyst ratio and the reaction was run

in a 300 l pressure reactor. The aldehyde is isolated

through water extraction, while the catalyst remains in

the organic layer. A multiton amount of (S)-allyl lysine

ethylene acetal was produced this way. A multikilogram

quantity of a pharmaceutical building block (Figure 5)

was produced by Pfizer using a hydroformylation of

norbornene catalysed by 0.15% of Rh(CO)2(acac)

in the presence of dppf. Additionally, examination of

the patent literature also reveals that Pfizer used a

Rh-biphephos-catalysed hydroformylation reaction to

obtain N-Boc-(4-oxobutyl)caprolactam on a 250 g scale

and that Dow performed a 200 g hydroformylation

step to produce a protected amino aldehyde.

Asymmetric hydroformylation is a powerful tool

to introduce chirality in pharmaceuticals. However,

it has remained so far a purely academic domain

with no industrial-scale application. As an example,

(S)-naproxen can be efficiently obtained with

excellent enantioselectivity and regioselectivity

using the chiral hydroformylation approach, but the

currently more economically viable resolution route

dominates at the industrial level.

In the fragrance domain, Vertral, a green melonscented component, and Florhydral are produced

by hydroformylation of exo-cyclopentadiene using

Rh 2(2-ethylhexanoate)4 or 1,3-dipropenylbenzene

using a Rh-PPh3 catalyst, respectively (Figure 6). The

citrus-scented limonenal is commercially obtained

by Celanese through the same pathway, while the

woody and spicy Spirambrene is manufactured

by Givaudan and Vigon International according to

a hydroformylationTollens reactionacetalisation

scheme (Figure 6). Many other examples from the

fragrance industry issued from the patent survey are

reported.

Finally, although examples of the use of

hydroformylation as an alternative access to

agrochemicals are reported, none of them seems to

be currently operated for industrial-scale production.

Ruthenium-Catalysed Selective

Hydrogenation

In this chapter, Philippe Dupau (Firmenich SA, La

Plaine, Switzerland) first focuses on the rutheniumcatalysed reduction of conjugated dienes used at

Firmenich. Indeed, although the Ru version of this

reaction has been known for more than a decade,

it suffered until recently from a narrow reaction

scope and a lack of activity which hampered its

implementation at the industrial production level.

In 2008, it was discovered at Firmenich that these

limitations could be overcome by the use of a cationic

[(Cp-type)Ru(diene)][Y] catalyst in the presence

of some weakly acidic additives. This technology

is illustrated by the case study of the industrial

production of (Z)-hex-3-en-1-ol, also called leaf

alcohol, a useful component in flavour and fragrance

chemistry (Figure 7).With their process,this compound

CHO

CHO

CHO

O

O

CH2

H

Vertral

Florhydral

Limonenal

Spirambrene

Fig. 6. Examples of fragrances industrially produced using a rhodium-catalysed hydroformylation step

276

2013 Johnson Matthey

Platinum Metals Rev., 2013, 57, (4)

http://dx.doi.org/10.1595/147106713X672320

OH

H

C

HO

Polysantol

Leaf alcohol

C

H2

DartanolTM

OH

MeO C

H

Pamplewood

is efficiently obtained starting from either sorbic acid

esters (followed by reduction of the ester function) or

sorbic alcohol. In the first case, the reaction is run neat

at 7080C under 15 bar H2 in the presence of 0.005%

of [(Cp*)Ru(COD)][BF4] and 0.10.2% of maleic acid.

When starting from sorbic alcohol, acetone is used as

solvent, all other reaction parameters being the same.

Interesting kinetic and mechanistic investigations

reveal that for sorbic acid ester, the reaction should be

stopped at 95% conversion to maintain high selectivity,

whereas the sorbic alcohol route requires all-trans

starting material to prevent catalyst deactivation.

The chemoselective hydrogenation of carbonylcontaining compounds is another very interesting

reaction in flavour and fragrance chemistry and is

widely operated by Firmenich. To avoid the use of the

patented (diphosphine)(diamine)RuCl2 complexes,

they have developed a series of proprietary amino- or

imino-phosphine Ru complexes, either with bidentate

(PN) or tetradentate (PNNP) ligands. For productionscale use, 2-bis(diphenylphosphino)ethylamine (DPPAE)

was selected and its reaction with (PPh3)3RuCl2 in

tetrahydrofuran (THF) serendipitously led to the

easy-to-handle cationic [(DPPAE)2(PPh3)RuCl][Cl]

complex. With this complex in hand, Polysantol

and nirvanol (Figure 7) are efficiently produced

by hydrogenation of the corresponding ketones under

20 bar H2 using a catalyst loading of 0.00125 mol% at

the multi-ton scale. Several hundreds of tons of another

sandalwood fragrance, DartanolTM (Figure 7), are

also produced yearly using 0.005 mol% of the same

catalyst, although in this case the temperature has

to be lowered from 7080C to 60C due to substrate

thermal instability. Finally, the very interesting

example of the grapefruit and woody smelling

Pamplewood is reported (Figure 7). In this tonscale

production,

[(DPPAE)2(PPh3)RuCl][Cl]

(0.002 mol%) efficiently catalyse the hydrogenation

277

Nirvanol

H

C

HO

Fig. 7. Examples of

fragrances industrially

produced using the

ruthenium-catalysed

Firmenich chemoselective

hydrogenation processes

(hydrogenated bonds in

bold red)

of 7,7-dimethyl-10-methylenebicyclo[4.3.1]decan-3-one

to the corresponding alcohol. However, the latter is

obtained in a 82:18 exo:endo mixture that does not

meet the requirements for optimal olfactive properties.

Nevertheless, this alcohol is further epimerised to

the desired exo:endo ratio using the same catalyst,

simply by increasing the temperature of the batch

while maintaining the hydrogen pressure after the

hydrogenation reaction. A reaction model has been

developed and simulation has enabled the calculation

of the different rate constants in this epimerisation

process.

Asymmetric Hydrogenation

After some general remarks on metal complexes

and chiral ligands, Hans-Ulrich Blaser et al. (Solvias

AG, Basel, Switzerland) review the C=C, C=O and

C=N asymmetric hydrogenation reactions that are

currently (or have been) operated for production

of fine chemicals. Pilot-scale processes as well as

some industrially interesting bench-scale reactions

are also considered, all being catalysed by rhodium-,

ruthenium- or iridium-based complexes.

It is noteworthy that rhodium is the principal metal

used in industrial asymmetric hydrogenation processes,

with 11 identified cases. As an early example from the

1970s, Knowles [Rh(dipamp)(COD)][BF4] catalyst has

been applied for years to the production of L-dopa

(Figure 8) by Monsanto. Good turnover frequency

(TOF) (1000 h1), turnover number (TON) (20,000)

and enantioselectivity (95%) were attained at a

ton year1 scale. A similar process was later used by

NSC Technologies for the production of unnatural

amino acids, whereas a slightly different one using

[Rh(eniphos)(nbd)][PF6] was developed by EniChem/

Anic for the large-scale production of phenylalanine

(15 tons year1) as a step towards aspartame. Other

examples of the use of defined cationic rhodium

2013 Johnson Matthey

Platinum Metals Rev., 2013, 57, (4)

http://dx.doi.org/10.1595/147106713X672320

NH2

HO

CO2H

Imagabalin

NH2

HO

CO2H

MeO

F

N

L-Dopa

CO2H

CF3

MeO

Aliskiren intermediate

NH2 O

F

F

Sitagliptin

Fig. 8. Some products of industrial rhodium-catalysed asymmetric hydrogenation processes (hydrogenated

bonds in bold red)

complexes include the asymmetric hydrogenation of

a -enamide in the presence of [Rh(tcfp)(COD)][BF4]

to access 3.8 tons of imagabalin (Figure 8) at Pfizer

or of a duloxetine intermediate, marketed by Eli Lilly,

with [Rh(duanphos)(NBD)][SbF6]. However, in many

cases, the preliminary synthesis of well-defined species

is not compulsary and in situ formed cationic or

neutral Rh-catalysts could be successfully employed.

Indeed, Solvias, then DSM, have reported on the use

of [Rh(NBD)2][BF4]/Walphos or [Rh(COD)2][BF4]/

phosphoramidite/(m-Tol)3P mixtures, respectively,

for the production of an intermediate of aliskiren

(Figure 8), a renin inhibitor. In a similar way, Merck

is currently operating the asymmetric hydrogenation

of an unprotected dehydro -amino amide in the

production of sitagliptin (Figure 8). In this last case,

mechanistic studies have shown that the tautomeric

imine is reduced rather than the initially targeted

C=C bond of the starting enamine. A number of

other interesting examples are given by the authors,

including transfer hydrogenations reactions using

mainly [Rh(Cp*)Cl2]2 as precursor and that were

scaled up to 200 kg.

Triggered by Noyoris discovery of the BinapRu

system,

ruthenium-catalysed

asymmetric

OH

OH

Citronellol

C

C11H23 H

CO2Me

Orlistat intermediate

hydrogenation is now widely used (or at least

under development) in industry. As a flagship of

this chemistry, the production of 300 tons year1 of

citronellol (Figure 9) by Takasago International, with

[Ru(Binap)(CF3CO2)2] as a C=C hydrogenation catalyst

and with excellent enantiomeric excess (ee) (97%),

TON (50,000) and TOF (500 h1), probably remains the

most famous example. Roche has reported a similar

[Ru(MeO-biphep)(CF3CO2)2] catalyst for the

asymmetric C=O reduction of a -keto ester used

as an intermediate in the synthesis of orlistat

(Figure 9), a drug used to treat obesity. In this case,

a TON of 50,000 was reached by adding hydrochloric

acid as a co-catalyst, enabling the process to be scaled

up to 2.2 tons. A process involving a Ru-catalysed C=O

hydrogenation (Ru = [Ru(Tol-Binap)Cl2]2xNEt3) is also

operated by Takasago to produce (R)-1,2-propanediol,

a precursor of the bactericide (S)-oxfloxacin, on a

50 ton year1 scale.

Arene-ruthenium precursors are another class

of efficient pre-catalysts. At Takasago again, an

elegant hydrogenation/dynamic kinetic resolution is

operated to produce a penem antibiotic intermediate

(Figure 9) on a 50120 tons year1 scale. In this process,

[Ru(Tol-Binap)(p-cymene)I][I] is efficiently used

OH

NHCOPh

C

H

CO2Me

Penem intermediate

CO2Me

O cis Methyl

dihydrojasmonate

Fig. 9. Examples products made by industrial ruthenium-catalysed asymmetric hydrogenation processes

(hydrogenated bonds in bold red)

278

2013 Johnson Matthey

http://dx.doi.org/10.1595/147106713X672320

as a pre-catalyst and affords the desired compound

in ee >97% and diastereomeric excess (de) >94%.

Interestingly, in situ formed catalysts can sometimes be

employed as illustrated by the Firmenich production

of the floral-scented cis-methyl dihydrojasmonate

(several tons year1, Figure 9) which makes use

of a [RuH(COD)(COT)][BF4]/chiral diphosphine

system. It is also worth noting that ketones without

- or -coordinating groups can be enantioselectively

reduced to the corresponding alcohols using

Ru(diphosphine)(diamine) systems. Several pilot

plant-scale operations are described but it is not clear

whether they have been implemented as production

processes. The same observation stands for the use of

ruthenium catalysis in transfer hydrogenations.

Finally, the last member of this metal-based tryptich,

iridium-catalysed asymmetric hydrogenation,has been

more rarely used in industry at the production scale.

However, a remarkable example is operated by Syngenta

with the synthesis of more than 10,000 tons year1 of

(S)-metolachlor (Figure 10), a grass herbicide. The

asymmetric step of this process consists of an imine

hydrogenation under 80 bar H2 at 50C and is catalysed

by an in situ generated species obtained by mixing

[Ir(COD)Cl]2 with one of Solvias Josiphos ligands.

Impressive TON (2,000,000) and TOF (>400,000 h1)

are obtained, while asymmetric induction remains

fairly good (ee 80%). Following this example, DSM and

Solvias have developed another example based on

the [Ir(COD)Cl]2/(4-MeO-3,5-(tBu)2C6H2)-MeO-Biphep

couple to produce several tons of biotin from a cyclic

anhydride.

With the three pgms Rh, Ru and Ir, an impressive

number of pilot processes or bench-scale reactions

up to several hundreds of kilograms are also

described, thus making one anticipate that many

more production processes using metal-catalysed

asymmetric hydrogenations will appear in the near

future.

Case Studies

The four other chapters are devoted to case studies

of scaling up syntheses involving transition metalMeO

O

N

Metolachlor

279

Cl

Fig. 10. Metolachlor, a grass

herbicide produced using an

iridium-catalysed asymmetric

hydrogenation

Platinum Metals Rev., 2013, 57, (4)

catalysed steps and the associated challenges that

had to be tackled. Thus, Ioannis N. Houpis (Janssen

Pharmaceuticals Companies of Johnson & Johnson,

Beerse, Belgium) describes the modification of the

synthetic sequence and scale-up optimisation studies

of an all-transition-metal-process to yield a potential

active pharmaceutical ingredient (API). The chosen

route involves some palladium-catalysed Sonogashira

and Suzuki coupling steps (Figure 11). Among the

problems that were solved, it is interesting to note that

the homogeneous Pd(PPh3)4 catalyst could be simply

replaced by Pd/C for the Suzuki coupling step, thus

allowing easy reduction of palladium traces in the

final API (from 250 ppm to 10 ppm).

Another example is given by Adriano F. Indolese

(RohnerChem, Pratteln, Switzerland) for the pilotscale production of 3.7 kg of 5-(4-cyanophenyl)indole

(Figure 11) with a four month deadline. A palladiumcatalysed Suzuki coupling was chosen. From catalyst

screening, a mixture of PdCl2 and P(Tol)3 was selected

and other reaction parameters were optimised by

design of experiment (DOE) at the small-scale level.

With these optimised conditions, no scale-up effect

was observed and two pilot runs of ca. 2 kg each

could be run, affording the targeted compound with

the required purity specifications.

Per Ryberg (AstraZeneca, Sdertlje, Sweden)

depicts scale-up studies of a cyanation reaction that

was performed at AstraZenaca in 2003 and 2004.

This reaction, used as the last step of a multikilogram

synthesis of a drug candidate for the treatment of

glycogen synthase kinase 3 disorder (Figure 11),

was found to be efficiently catalysed by either a

Pd(dba)2/PtBu3 mixture or the preformed

[PdBr(PtBu3)]2 dimer, the latter being preferred for

large-scale application. Technical issues that influence

the large-scale synthesis were addressed: delayed

heating of the reaction mixture was found to be

detrimental, while the cyanide source (Zn(CN)2) had

to be added as the final reagent, both parameters

being linked to poisoning of the Pd catalyst.

Finally, Cheng-yi Chen (Merck Research Laboratories,

Rahway, USA) fully describes a scalable and costeffective synthesis of vaniprevir (Figure 11), a

20-membered ring protease inhibitor that possesses

activity against the hepatitis C virus. The key step

of this synthesis was identified as a 20-membered

macrolactamisation through ring-closing metathesis

(RCM) which had to be optimised in terms of volume

productivity. This could be achieved using the GrubbsHoveyda second generation catalyst and simultaneous

2013 Johnson Matthey

Platinum Metals Rev., 2013, 57, (4)

http://dx.doi.org/10.1595/147106713X672320

Suzuki

Sonogashira

N

CO2H

Suzuki

N

H

5-(4-cyanophenyl)indole

from RohnerChem

API from

Janssen Pharmaceuticals

Cyanation

H

N

OH

NC

N

Fig. 11. Products

illustrating

case studies of

some scaled up

pgm-catalysed

reactions

Suzuki

NC

O

O

H

N

RCM

H

N

O

N

N

O

O

N

H

O

Drug candidate

from AstraZeneca

introduction of solutions of the starting diene and the

Ru catalyst. Additionally, by raising the temperature,

but adding 2,6-dichloroquinone, the catalyst amount

could be lowered to 0.2 mol%. Interestingly, other

routes involving Heck, Sonogashira or Suzuki

couplings were examined but were found less

effective.

Conclusions

Despite the massive use of metal-based catalysis in

the manufacture of bulk chemicals for many years,

the development of organometallic-based processes

for pharmaceuticals, fragrances or agrochemicals

production is surprisingly still in its adolescence.

However, the industrial processes described in this

book clearly illustrate the great potential of pgms as

valuable tools in this field. Moreover, the numerous

examples of production processes, pilot plant or

bench-scale reactions depicted will surely inspire

chemists who are facing synthetic problems. Finally,

this book may also serve as a valuable source of

information not only for research purposes, but also

for students and colleagues teaching organometallic

catalysis.

280

Vaniprevir from Merck

The Reviewer

Dr Michel Picquet obtained his PhD

in Chemistry from the Universit de

Rennes I, France, under the supervison of

Professor P. H. Dixneuf and Dr C. Bruneau

in 1998. After a years post-doctoral

position in the group of Professor R.

A. Sheldon (Delft Technical University,

The Netherlands), he was hired by the

Universit de Bourgogne in 1999 as an

Assistant Professor. His research interests

include organometallic catalysis and the

use of ionic liquids. Since 2009, he is

also interested by organometallics for

biological applications. He also teaches

Organometallic Synthesis and Catalysis at

Masters level.

Organometallics as

Catalysts in the Fine

Chemical Industry

2013 Johnson Matthey

Anda mungkin juga menyukai

- News 5Dokumen2 halamanNews 5qpalzm97Belum ada peringkat

- News 7Dokumen2 halamanNews 7qpalzm97Belum ada peringkat

- News 5Dokumen2 halamanNews 5qpalzm97Belum ada peringkat

- News 5Dokumen2 halamanNews 5qpalzm97Belum ada peringkat

- News 5Dokumen2 halamanNews 5qpalzm97Belum ada peringkat

- News 5Dokumen2 halamanNews 5qpalzm97Belum ada peringkat

- Thechallengesofpreventive Diplomacy:Theunitednations' Post-ColdwarexperiencesinafricaDokumen22 halamanThechallengesofpreventive Diplomacy:Theunitednations' Post-Coldwarexperiencesinafricaqpalzm97Belum ada peringkat

- Heisig Complete v3Dokumen93 halamanHeisig Complete v3popo63301Belum ada peringkat

- News 5Dokumen2 halamanNews 5qpalzm97Belum ada peringkat

- AgalactosidasepnpDokumen3 halamanAgalactosidasepnpqpalzm97Belum ada peringkat

- AgalactosidasepnpDokumen3 halamanAgalactosidasepnpqpalzm97Belum ada peringkat

- RTK1 Supplement (Newly Approved General-Use Kanji)Dokumen27 halamanRTK1 Supplement (Newly Approved General-Use Kanji)nfwuBelum ada peringkat

- UAV SubsystemsDokumen8 halamanUAV SubsystemsAmaryllis MiraeBelum ada peringkat

- Thechallengesofpreventive Diplomacy:Theunitednations' Post-ColdwarexperiencesinafricaDokumen22 halamanThechallengesofpreventive Diplomacy:Theunitednations' Post-Coldwarexperiencesinafricaqpalzm97Belum ada peringkat

- Beamer User GuideDokumen245 halamanBeamer User GuideColossus RhodesBelum ada peringkat

- UAV SubsystemsDokumen8 halamanUAV SubsystemsAmaryllis MiraeBelum ada peringkat

- Design Considerations For Long Endurance Unmanned Aerial VehiclesDokumen55 halamanDesign Considerations For Long Endurance Unmanned Aerial Vehiclesnivas_mechBelum ada peringkat

- 17Dokumen46 halaman17physicsdocs90% (10)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Izod Impact (ASTM D 256)Dokumen1 halamanIzod Impact (ASTM D 256)Farhan AdhliBelum ada peringkat

- Topical Application of (L.) : Formulation and Evaluation of Hydrophilic Cream With Antioxidant ActivityDokumen10 halamanTopical Application of (L.) : Formulation and Evaluation of Hydrophilic Cream With Antioxidant ActivityFika Rasita SariBelum ada peringkat

- GocDokumen20 halamanGocSuyog SardaBelum ada peringkat

- Ui CuroxDokumen5 halamanUi CuroxHuber AlvaradoBelum ada peringkat

- Solvent Free, Low Viscosity, Epoxy Primer: Mixing DescriptionDokumen2 halamanSolvent Free, Low Viscosity, Epoxy Primer: Mixing DescriptionSameehu TVBelum ada peringkat

- 5269science SPECIAL SAMPLE PAPER 4Dokumen7 halaman5269science SPECIAL SAMPLE PAPER 4AnuragBelum ada peringkat

- Lab 3: Degradable and Non-Degradable Polymers Ryan BetzDokumen11 halamanLab 3: Degradable and Non-Degradable Polymers Ryan Betzapi-417373570Belum ada peringkat

- Elemental AnalysisDokumen1 halamanElemental AnalysisppiccoliniBelum ada peringkat

- SWTS - PFS - KlarAid PC1190 PDFDokumen2 halamanSWTS - PFS - KlarAid PC1190 PDFindahpsBelum ada peringkat

- Servo Prime & LP: Description ApplicationDokumen1 halamanServo Prime & LP: Description ApplicationRAHULGUNDHER25Belum ada peringkat

- 2023-Nickelplatinghandbooka5 Printablepdf PDFDokumen104 halaman2023-Nickelplatinghandbooka5 Printablepdf PDFKodagnanaso kodagBelum ada peringkat

- t2 Chem Revision Ex 6 - Answer SchemeDokumen9 halamant2 Chem Revision Ex 6 - Answer SchemeNicholas OwBelum ada peringkat

- Instant Download American Immigration A Very Short Introduction Very Short Introductions 1st Edition Ebook PDF PDF FREEDokumen33 halamanInstant Download American Immigration A Very Short Introduction Very Short Introductions 1st Edition Ebook PDF PDF FREEsam.hirt196100% (40)

- Herbal ShampooDokumen8 halamanHerbal ShampooSatpal kumarBelum ada peringkat

- Dyeing With Vat Dyes PDFDokumen30 halamanDyeing With Vat Dyes PDFAjith SatyapalaBelum ada peringkat

- A Supramolecular Chemistry Basis For Molecular Logic and ComputationDokumen10 halamanA Supramolecular Chemistry Basis For Molecular Logic and ComputationPathrodo MediaBelum ada peringkat

- Fabcom Batteries - BrochureDokumen7 halamanFabcom Batteries - BrochureFabcom BatteriesBelum ada peringkat

- Technologies For Uranium Recovery From PhosphoricDokumen16 halamanTechnologies For Uranium Recovery From PhosphoricvzgscribdBelum ada peringkat

- Calcium and Magnesium EDTA ISO-6059-1984Dokumen8 halamanCalcium and Magnesium EDTA ISO-6059-1984maría joséBelum ada peringkat

- Absorption in Sieve PlateDokumen13 halamanAbsorption in Sieve PlateDEEPAK KUMARBelum ada peringkat

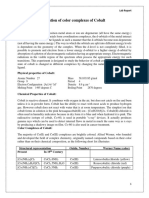

- Formation of Color Complexes of CobaltDokumen4 halamanFormation of Color Complexes of Cobaltsidra tariqBelum ada peringkat

- Stainless Steel Flux Cored Tig: Alloy Description and ApplicationDokumen1 halamanStainless Steel Flux Cored Tig: Alloy Description and ApplicationNGUYEN VINHBelum ada peringkat

- Boiler Chemicals Untuk Pabrik CPO PDFDokumen7 halamanBoiler Chemicals Untuk Pabrik CPO PDFMuhammad Abdurrokhim ABelum ada peringkat

- Antidote LectureDokumen78 halamanAntidote LectureAliyan KhosoBelum ada peringkat

- Jamb Chemistry 2021 Key PointsDokumen15 halamanJamb Chemistry 2021 Key PointsAbiodun BamideleBelum ada peringkat

- B3 ItemDokumen10 halamanB3 ItemksatriahujanBelum ada peringkat

- High Performance Liquid Chromatography (HPLC)Dokumen11 halamanHigh Performance Liquid Chromatography (HPLC)Benjamin DanielBelum ada peringkat

- Y-Site Injection Drug Compatibility Chart For GENERAL Wards: Key To SymbolsDokumen1 halamanY-Site Injection Drug Compatibility Chart For GENERAL Wards: Key To Symbolsdiah100% (1)

- Diagram Worksheet: Water Molecules: Examiner's NoteDokumen2 halamanDiagram Worksheet: Water Molecules: Examiner's NotenicoleBelum ada peringkat

- 1-3 DiketoneDokumen4 halaman1-3 Diketoneshenn0Belum ada peringkat