HD Valvulas de Control

Diunggah oleh

IsmaelCruzHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

HD Valvulas de Control

Diunggah oleh

IsmaelCruzHak Cipta:

Format Tersedia

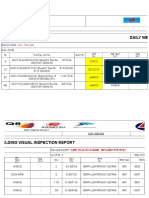

I-HD-01XX

Page:

Of:

CLIENT:

PROJECT:

DATA SHEET

CONTROL VALVES

REV

Preliminary

DATE

290588415.xls

DESCRIPTION

BY

CHK.

APPR.

7103-I-HD-0107

Page:

of

CLIENT:

PROJECT:

CONTENTS

PAGE

P&ID

Cover Sheet

Index Sheet

Notes

FV-0216

FV-0471

FV-0474

FV-0523

FV-0904

FV-0936

LV-0206

LV-0408

LV-0603

PV-0287

PV-0289

PV-0401A

PV-0401B

PV-0402

TV-0205

TV-0401

TV-0411

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

N.A.

N.A.

N.A.

7102-F-PI-014

7102-F-PI-016

7102-F-PI-016

7102-F-PI-021

7102-F-PI-017

7102-F-PI-017

7102-F-PI-080

7102-F-PI-016

7102-F-PI-022

7102-F-PI-024

7102-F-PI-024

7102-F-PI-016

7102-F-PI-016

7102-F-PI-024

7102-F-PI-024

7102-F-PI-080

7102-F-PI-016

A

4/18/2006

REV

DATE

290588415.xls

Preliminary

DESCRIPTION

REMARKS

Supplied by Eclypse

Supplied by Eclypse

RSC

BY

JEB

CHK.

LGA

APPR.

7103-I-HD-0107

Page:

of

CLIENT:

PROJECT:

REFERRED DOCUMENTS

7103-G-IT-0004

Project definition report

7103-P-ET-0010

7103-P-ET-0011

Piping Classes

Manual valves

Supply, design & installation

Instrument list

7103-I-ET-0003

7103-I-LI-0001

APPLICABLE CODES AND STANDARDS

The following codes and standards, (latest revision), shall be applied as part of the requirements of this specification.

ASME B 16.10

ASME B 16.5

Face to face and end to end dimension of the valves

Pipe Flanges & Flanged Fittings

ASME B 16.34

MSS SP 61

Valves flanged, threaded and welding end

Pressure testing of steel valves

API RP 551

API RP 554

Process Measurement Instrumentation

Process Instrument and Control

API RP 500

Recommended Practice for Classification of Locations for Electrical Installations

at Petroleum Facilities Classified as Class I, Division 1 and Division 2.

NOTES

1- The body material shall be according to valve specification 7103-P-ET-0011.

2- Actuator shall be pneumatic simple effect, spring return type. Actuator shall be sized to fully stroke of the valve against the unbalanced

force on the plug for a differential pressure equals to the shut-off pressure. Type and model shall be defined by Vendor.

3- Noise levels shall not exceed 85 dB at one meter downstream and from the pipe.

4- Control Valves shall be provided with smart electro-pneumatic positioner.

5- All tubing and fittings shall be made of stainless steel. The fittings shall be compression with double ferrule type. Tubing and

thread shall be imperial sizing.

6- Where required, solenoid valves will be low power type and with explosion proof enclosure.

7- Electrical equipment will be suitable for Class I Div 2 Group C/D.

8- The selection of the valve models whose tags are PV-0402 and TV-0205, is only for guiding purpose. The sizing and supply

of those valves will be responsibility of Eclypse.

A

4/18/2006

REV

DATE

290588415.xls

Preliminary

DESCRIPTION

RSC

BY

JEB

CHK.

LGA

APPR.

CLIENT:

of

20

PROJECT

SHEET

UNIT

SPEC

7103-I-HD-0107

P.O.

ITEM

TAG

FV-0474

CONTRACT

PID

7103-F-PI-016

MFR SERIAL

PROJECT:

1 Fluid: Bio-Oil

Kg/h

339004

276381

214360

Inlet Pressure

Kpa-g

500

500

500

Outlet Pressure

Kpa-g

480

480

450

Inlet Temperature

Spec Gravity

Viscosity

45

45

45

1.2

1.2

1.2

cP

21

21

21

Kpa-a

5.2

5.2

5.2

Required Cv

801

653

320

Travel

50

44

28

dBA

<85

<85

<85

Vapor Pressure Pv

Allowable / Predicted SPL

In

Out

Pipe Line Size

& Schedule

10"

10"

Sch.

Sch.

10S

10S

Pipe Line Insulation

Type

Mfr & Model

Spring & Diaphragm

Fisher 1052

Size

40

56

57

On / Off

Max Allowable Pressure

Butterfly

17

18

Size

8"

19

20

Mfr & Model

58

59

Liner Material / ID

60

61

23

24

25

26

27

28

29

Max.Press / Temp.

VALVE BODY / BONNET

21

22

150#

Fisher 8560 E-Disc

316 SST

Body / Bonnet Material

In

Out

End

Connection

Single flged

Forward

Flow Direction

67

68

Type of Bonnet

Lub & Iso Valve

PTFE V-Ring

30

31

Packing Type

69

70

32

33

Type

71

72

34

35

Characteristic

36

37

Max. Rated Cv

Rated Travel

Size

2180

Plug / Ball / Disk Material:

Seat Material

Fl

77

78

79

80

81

Cage / Guide Material

17-4 PH SST

Bushing Material

PEEK/PTFE

43

44

Area Classification:

49

50

51

52

SPECIALS / ACCESSORIES

Stem Material

47

48

Xt

75

76

316 SST/CR PLT

PTFE/316 Spring

40

41

42

45

46

73

74

Linear

Balanced / Unbalanced

TRIM

38

39

Packing Material

NEC Class I Div 2 Group C/D

With low power solenoid suitable for this hazardous location.

82

83

84

85

Continuous

Modulating

open

Min Required Pressure

Available Air Supply Pressure

Nor

8 bar-g

Min

Max

4 bar-g

Bench Range

Actuator Orientation

64

65

66

End Ext / Matl

Eff Area

Spring Action Open / Close

62

63

Flange Face Finish

700

54

55

Type

ANSI Class

Shut-Off

53

ACTUATOR

14

15

16

Minimum

Handwheel Type

Set at

Air Failure Valve

4-20mA

Input Signal

POSITIONER

12

13

Normal

Output

Hart

Smart Electropositioner

DVC6020-AD

Type

Mfr & Model

On Incr Signal Output Incr / Decr

Gauges

Supply & Output

By-Pass

Cam Characteristic

FM or CSA "explosion proof"

Certification

SWITCHES

10

11

Critic Pressure PC:

Maximum

AIR SET

8

9

Bio-Oil to venturi scrubber

Type

Quantity

Mfr & Model

Contacts / Rating

Actuation Points

Fisher 67CFR

Mfr & Model

Set Pressure

Filter

yes

Gauges

Supply and output

Hydro Pressure

TESTS

6

7

SERVICE CONDITIONS

4

5

Flow Rate

LINE

2

3

Service:

Units

86

Rev

A

ANSI / FCI Leakage Class

Class IV

Hydro Pressure

Date

4/18/2006

Revision

Preliminary

By

RSC

Rev

JEB

Approved

LGA

CLIENT:

15

of

20

PROJECT

SHEET

UNIT

SPEC

7103-I-HD-0107

P.O.

ITEM

TAG

PV-0401A

CONTRACT

PID

7103-F-PI-016

MFR SERIAL

PROJECT:

1 Fluid: Nitrogen

6680

Inlet Pressure

Kpa-g

400

400

1100

600

Outlet Pressure

Kpa-g

20

20

150

50

Inlet Temperature

50

50

40

40

Kg/Kmol

28.13

28.13

28.13

28.13

Spec Heats Ratio

cp/cv

1.4

1.4

1.4

1.4

Critic Pressure

Kpa-a

2001

Mol Weight

Required Cg

Allowable / Predicted SPL

& Schedule

Size

3"

19

20

Mfr & Model

62

65

dBA

< 85

< 85

85.5

< 85

3"

3"

Sch.

Sch.

40

40

ANSI Class

150#

Max.Press / Temp.

VALVE BODY / BONNET

27

28

29

1924

34

Pipe Line Insulation

17

18

25

26

1064

69

Fisher ET

WCC Carbon STL Cast

Body / Bonnet Material

Liner Material / ID

End

Connection

In

Out

RF FLG

RF FLG

Spring & Diaphragm

Fisher 667

Size

40

56

57

On / Off

58

59

Max Allowable Pressure

60

61

Up

Standard

67

68

Lub & Iso Valve

PTFE

69

70

32

33

Type

71

72

34

35

Characteristic

Packing Material

Rated Travel

TRIM

Size

WI / Linear

Balanced

Balanced / Unbalanced

2920

Fl

Max. Rated Cg

Plug / Ball / Disk Material:

Seat Material

73

74

Xt

75

76

416 SST

416 SST

77

78

17-4PH SST

316 SST

40

41

42

Stem Material

Bushing Material

79

80

81

43

44

Area Classification:

82

83

47

48

49

50

51

52

SPECIALS / ACCESSORIES

45

46

Cage / Guide Material

NEC Class I Div 2 Group C/D

With low power solenoid suitable for this hazardous location.

Valve with reduced trim.

This supply includes diffuser 3" 150# RF x 6" SCH 40 BE,

Cg: 4000.

NOTES:

84

85

Eff Area

Continuous

Modulating

close

Spring Action Open / Close

Min Required Pressure

Available Air Supply Pressure

Nor

8 bar-g

Min

Max

4 bar-g

Bench Range

Actuator Orientation

64

65

66

End Ext / Matl

Type of Bonnet

Mfr & Model

62

63

Flange Face Finish

Flow Direction

Type

54

55

Packing Type

38

39

1400

53

30

31

36

37

Shut-Off

In

Out

Pipe Line Size

Globe

23

24

2149

Z factor

Type

21

22

Travel

ACTUATOR

14

15

16

Normal 2

11000

Handwheel Type

Set at

Air Failure Valve

POSITIONER

12

13

Maximun 2

2500

Input Signal

4-20 mA

Type

Smart Electropositioner

DVC6010-AD

Mfr & Model

Output

Hart

On Incr Signal Output Incr / Decr

Gauges

Supply & Output

By-Pass

Cam Characteristic

FM or CSA "explosion proof"

Certification

SWITCHES

10

11

Normal 1

5045

AIR SET

8

9

Maximum 1

Type

Quantity

Mfr & Model

Contacts / Rating

Actuation Points

Fisher 67CFR

Mfr & Model

Set Pressure

Filter

yes

Gauges

Supply and output

Hydro Pressure

TESTS

6

7

SERVICE CONDITIONS

4

5

Blanketing gas to V-402

Kg/h

Flow Rate

LINE

2

3

Service:

Units

86

Rev

A

ANSI / FCI Leakage Class

Class IV

Hydro Pressure

Date

4/18/2006

Revision

Preliminary

By

RSC

Rev

JEB

Approved

LGA

Anda mungkin juga menyukai

- Varco TDS-4S Pocket GuideDokumen21 halamanVarco TDS-4S Pocket GuideAdrian Cantaragiu88% (8)

- Marine Electrical Practice: Marine Engineering SeriesDari EverandMarine Electrical Practice: Marine Engineering SeriesPenilaian: 4 dari 5 bintang4/5 (8)

- Ac Panel Test ReportDokumen14 halamanAc Panel Test ReportUtku Can KılıçBelum ada peringkat

- InstrumentLst&Datasheets Rev0 PDFDokumen34 halamanInstrumentLst&Datasheets Rev0 PDFEnrique FuentesBelum ada peringkat

- DRG Codes Descr: Sales Order: Item No: Qty: Type: DRG No.: DetailsDokumen13 halamanDRG Codes Descr: Sales Order: Item No: Qty: Type: DRG No.: Detailst_syamprasadBelum ada peringkat

- Reference Drawing/ Document:: 1. Jumpering of IO Signals at DCS End Shall Be Done by BHELDokumen5 halamanReference Drawing/ Document:: 1. Jumpering of IO Signals at DCS End Shall Be Done by BHELarunBelum ada peringkat

- Control Valve Specification and Sizing DetailsDokumen34 halamanControl Valve Specification and Sizing DetailsRahulTewari67% (3)

- Oisd STD-141Dokumen31 halamanOisd STD-141Jyotsana Rawat83% (6)

- Unlock-B31.3 Process Piping Course - 07 Layout and SupportDokumen15 halamanUnlock-B31.3 Process Piping Course - 07 Layout and SupportProkopBelum ada peringkat

- PLC Upgrade Project DocumentationDokumen16 halamanPLC Upgrade Project Documentationbhaskar112rkumarBelum ada peringkat

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDokumen14 halamanA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- AWWA M11ed4Dokumen16 halamanAWWA M11ed4авдей александр33% (3)

- Cng-000-El-011 Voltage Drop Calculation (MS) r1Dokumen6 halamanCng-000-El-011 Voltage Drop Calculation (MS) r1Aris KancilBelum ada peringkat

- Command Line Entries for PDMS and DraftDokumen13 halamanCommand Line Entries for PDMS and DraftSasha KatichBelum ada peringkat

- Zau 74 102017 CS 8180 00034 PDFDokumen200 halamanZau 74 102017 CS 8180 00034 PDFvasudhaBelum ada peringkat

- Post Weld Head Treament Piping-ProcedureDokumen12 halamanPost Weld Head Treament Piping-ProcedureAnh Võ100% (1)

- Datasheet For Restriction OrificeDokumen42 halamanDatasheet For Restriction OrificeSujith Sekar50% (2)

- Firewater Pumps Bid EvaluationDokumen43 halamanFirewater Pumps Bid EvaluationTeguh Setiono100% (1)

- Electrical Data SheetDokumen5 halamanElectrical Data Sheetrajpre1213100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Heat-Shrink Sleeve Installation StandardDokumen32 halamanHeat-Shrink Sleeve Installation Standardolalekan100% (1)

- Welding Book PipingDokumen184 halamanWelding Book PipingMahaveer Singh100% (2)

- EORP Power and Motor Control Centre Data SheetDokumen22 halamanEORP Power and Motor Control Centre Data Sheetvaithy2011100% (1)

- Indcon Projects Electrode Qualification Procedure IOCL Gas PipelineDokumen11 halamanIndcon Projects Electrode Qualification Procedure IOCL Gas PipelineAkhilesh Kumar67% (3)

- Deepwater Subsea Vertical Tree Systems (Amendments-Supplements To ISO 13628-4)Dokumen46 halamanDeepwater Subsea Vertical Tree Systems (Amendments-Supplements To ISO 13628-4)Jacob PhilipBelum ada peringkat

- Ea 682808 001 R05Dokumen7 halamanEa 682808 001 R05anbarasusivaprakasam100% (1)

- Gate Valve DSDokumen5 halamanGate Valve DSkhaireddin100% (1)

- Astec Valves Inspection Certificate SummaryDokumen4 halamanAstec Valves Inspection Certificate SummaryShankar RajBelum ada peringkat

- Firetrace ManualDokumen72 halamanFiretrace ManualIsrael Silva Hgo.Belum ada peringkat

- Ict 2Dokumen91 halamanIct 2sherubdBelum ada peringkat

- Micom p139 Over Current RelayDokumen4 halamanMicom p139 Over Current Relayanoop_jan139885100% (1)

- QC TolaranceDokumen35 halamanQC TolaranceRajkumar A100% (1)

- Data Sheet For Power TransformerDokumen3 halamanData Sheet For Power TransformerNakkolopBelum ada peringkat

- Ideal Steam DrumDokumen6 halamanIdeal Steam DrumFahad RockingBelum ada peringkat

- FLSmidth Pneumatic Transport CompressorDokumen1.191 halamanFLSmidth Pneumatic Transport CompressorDavid HidalgoBelum ada peringkat

- Evaporator Data Sheet - SKO0501049 Rev0Dokumen10 halamanEvaporator Data Sheet - SKO0501049 Rev0chublackBelum ada peringkat

- MIB 303 Separation System, Module - Installation Instructions - 1997Dokumen24 halamanMIB 303 Separation System, Module - Installation Instructions - 1997Centrifugal SeparatorBelum ada peringkat

- E 7403-9002g Motor List CustomerDokumen5 halamanE 7403-9002g Motor List Customerraobabar21Belum ada peringkat

- J20 e Dat VD 525651 PDFDokumen4 halamanJ20 e Dat VD 525651 PDFAariz Khan100% (1)

- Control ValveDokumen254 halamanControl ValveAJAY1381Belum ada peringkat

- 750-347 CBH, - L, - La, - L1, - L2Dokumen40 halaman750-347 CBH, - L, - La, - L1, - L2diogenes torresBelum ada peringkat

- Data Sheet for Power TransformerDokumen3 halamanData Sheet for Power TransformerMuhammad Ibad AlamBelum ada peringkat

- PP10CC 00 6PGB Yr Abc 001 PDFDokumen20 halamanPP10CC 00 6PGB Yr Abc 001 PDFanbesivam87Belum ada peringkat

- Sov - 1Dokumen1 halamanSov - 1biswasdipankar05Belum ada peringkat

- PP10CC 0009 6mal Yr Abc 001Dokumen30 halamanPP10CC 0009 6mal Yr Abc 001anbesivam87Belum ada peringkat

- Line List: Bandar Abbas Gas Condensate Refinery ProjectDokumen31 halamanLine List: Bandar Abbas Gas Condensate Refinery Projectmb_sirousBelum ada peringkat

- Maintain pipeline temperature with skin effect trace heatingDokumen7 halamanMaintain pipeline temperature with skin effect trace heatingSivagurunathan SpBelum ada peringkat

- Piping Installation Welding InspectionDokumen3 halamanPiping Installation Welding Inspectiontranvando1986Belum ada peringkat

- Hydrotech Pump Proposal SummaryDokumen50 halamanHydrotech Pump Proposal SummaryHisham ElsayedBelum ada peringkat

- Technical OfferDokumen50 halamanTechnical OfferHisham ElsayedBelum ada peringkat

- 1Dokumen2 halaman1sachinrmishraBelum ada peringkat

- C2 G 20 Max 3080000 Btu Output 10 To 1 TurndownDokumen8 halamanC2 G 20 Max 3080000 Btu Output 10 To 1 TurndownBülent KabadayiBelum ada peringkat

- Post Weld Heat Treatment Report: °C °c/hrDokumen6 halamanPost Weld Heat Treatment Report: °C °c/hrtranvando1986Belum ada peringkat

- Cat Konik 9Dokumen11 halamanCat Konik 9Soma GhoshBelum ada peringkat

- C.T Test ReportDokumen1 halamanC.T Test ReportyazensalehBelum ada peringkat

- Ivar Aasen Field Development Project - PDQDokumen21 halamanIvar Aasen Field Development Project - PDQayemyothantBelum ada peringkat

- Andrew Bannerman - 002 - 001. Previous Comments "LIS Instead of LIT" Has Been AddressedDokumen10 halamanAndrew Bannerman - 002 - 001. Previous Comments "LIS Instead of LIT" Has Been Addressedj.serranozavaletaBelum ada peringkat

- Masoneilan 35-35112 Valve Spec SheetDokumen12 halamanMasoneilan 35-35112 Valve Spec Sheetmggz_15Belum ada peringkat

- 0186 MOM DSP 025 062 0030 Valvulas de Control 2Dokumen266 halaman0186 MOM DSP 025 062 0030 Valvulas de Control 2Lukas Ramírez SchiaffinoBelum ada peringkat

- GE PAC8000 Controller ListDokumen24 halamanGE PAC8000 Controller Listwqs_19Belum ada peringkat

- Electrical Load List: Project: South Yaran Oil Field Development ProjectDokumen8 halamanElectrical Load List: Project: South Yaran Oil Field Development ProjectmBelum ada peringkat

- VSD ManualDokumen127 halamanVSD Manualvisakhgs0% (1)

- Ivar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3228-00 01EDokumen3 halamanIvar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3228-00 01EayemyothantBelum ada peringkat

- Documents for Final Anti-Heeling SystemDokumen122 halamanDocuments for Final Anti-Heeling SystemAlexey PlekhanovBelum ada peringkat

- SC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LDokumen1 halamanSC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LHumayun NawazBelum ada peringkat

- SC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LDokumen1 halamanSC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LHumayun NawazBelum ada peringkat

- Phu Giang Electric Co - LTDDokumen54 halamanPhu Giang Electric Co - LTDBùi Thanh SơnBelum ada peringkat

- Ivar Aasen Field Development Project - PDQDokumen3 halamanIvar Aasen Field Development Project - PDQayemyothantBelum ada peringkat

- SC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LDokumen1 halamanSC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LHumayun NawazBelum ada peringkat

- Test Package: Cooling Water 5.0 42.0 3.5 Water 7.5Dokumen4 halamanTest Package: Cooling Water 5.0 42.0 3.5 Water 7.5AnhNtCaoBelum ada peringkat

- Post Weld Heat Treatment Report: °C °c/hrDokumen6 halamanPost Weld Heat Treatment Report: °C °c/hrtranvando1986Belum ada peringkat

- 7.14 CP14571 Blower PackageDokumen29 halaman7.14 CP14571 Blower PackageIsaias de la CruzBelum ada peringkat

- PASS Hybrid Module and SF6 Surge Arrester DatasheetDokumen18 halamanPASS Hybrid Module and SF6 Surge Arrester DatasheetelensaladaBelum ada peringkat

- RFI-3410 - Daily Fit Up Inspection Report-OKDokumen92 halamanRFI-3410 - Daily Fit Up Inspection Report-OKnguyennamxmBelum ada peringkat

- Rambler Competent Persons Technical Report Sept2004Dokumen53 halamanRambler Competent Persons Technical Report Sept2004IsmaelCruzBelum ada peringkat

- Hardy Cross Method Solves Pipe Network Flow ProblemsDokumen8 halamanHardy Cross Method Solves Pipe Network Flow ProblemsEcosullc E IrlBelum ada peringkat

- Rotary valves and airlocks guideDokumen6 halamanRotary valves and airlocks guidegallowdrBelum ada peringkat

- Fondos Buitre: Rechazan Embargar Activos Del Banco CentralDokumen43 halamanFondos Buitre: Rechazan Embargar Activos Del Banco CentralMinutoUno.comBelum ada peringkat

- Rotary valves and airlocks guideDokumen6 halamanRotary valves and airlocks guidegallowdrBelum ada peringkat

- Emitterline Lime en LeachingDokumen2 halamanEmitterline Lime en LeachingvictorBelum ada peringkat

- VME MinogaDokumen199 halamanVME MinogaFakhri DzulfiqarBelum ada peringkat

- HWDP 6 5-8 - 8 1-2 OD X 4 1-2 ID PDFDokumen2 halamanHWDP 6 5-8 - 8 1-2 OD X 4 1-2 ID PDFEdson Aguilar HerreraBelum ada peringkat

- 007-Stand Post Type Fire HydrantDokumen6 halaman007-Stand Post Type Fire HydrantshabahatBelum ada peringkat

- BOQ Assela Final (Non-Priced) August 2021Dokumen87 halamanBOQ Assela Final (Non-Priced) August 2021HailuGelanHubenaBelum ada peringkat

- Application Guide: Refrigerant Piping Manual For Small Split Cooling and Heat Pump SystemsDokumen28 halamanApplication Guide: Refrigerant Piping Manual For Small Split Cooling and Heat Pump SystemsKevin Bryan Santos MendozaBelum ada peringkat

- Manufacturing Range Thread GaugesDokumen2 halamanManufacturing Range Thread GaugesKarthik RajanBelum ada peringkat

- C 3031 Ih 8-F TSP002 Att00Dokumen21 halamanC 3031 Ih 8-F TSP002 Att00Joseph Samir Eshak100% (1)

- Lit C UsaDokumen20 halamanLit C UsaLuis Eduardo Albarracin RugelesBelum ada peringkat

- Item # Ae102-8, Aeroquip Fire Sleeve - Ae102-8: List PriceDokumen3 halamanItem # Ae102-8, Aeroquip Fire Sleeve - Ae102-8: List PriceWalid HannaBelum ada peringkat

- Method Statement-DI-MWSPDokumen19 halamanMethod Statement-DI-MWSPKumar Abhishek100% (1)

- AdvantEDGE Manual Rev 4Dokumen104 halamanAdvantEDGE Manual Rev 4Flor F. MendivilBelum ada peringkat

- AutoCAD PLANT 3D 2015 System Tools Variables CadgroupDokumen24 halamanAutoCAD PLANT 3D 2015 System Tools Variables CadgroupperoooBelum ada peringkat

- Non-Metallic Expansion Joints: Standard Specification ForDokumen3 halamanNon-Metallic Expansion Joints: Standard Specification ForIlkuBelum ada peringkat

- Solid State Burner Management Controls SERIES D40-41: DescriptionDokumen16 halamanSolid State Burner Management Controls SERIES D40-41: Description_keoBelum ada peringkat