Isotretinoin

Diunggah oleh

Magda CatalinaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Isotretinoin

Diunggah oleh

Magda CatalinaHak Cipta:

Format Tersedia

Organic Process Research & Development 2005, 9, 302305

Technical Notes

An Efficient Commercial Process for the Preparation of Isotretinoin

Mohammad Salman,* Suresh J. Babu, Vijay K. Kaul, Purna C. Ray, and Naresh Kumar

Chemical Research DiVision, Ranbaxy Research Laboratories, Gurgaon-122 001, India

Abstract:

We describe an efficient process for the preparation of isotretinoin (13-cis isomer of vitamin A acid) in a single step starting

from -ionylidene acetaldehyde (5). The process conditions are

convenient to operate on a commercial scale and afford

isotretinoin of excellent quality; levels of related isomeric

impurities such as tretinoin (all trans retinoic acid) and 9,13di-cis-retinoic acid are extremely low. Thus, condensation of

dienolate of methyl 3,3-dimethylacrylate with -ionylidene

acetaldehyde (5) followed by aqueous acidic workup afforded

isotretinoin in >95% purity. The condensation reaction proceeds via in situ formation of lactone (8); furthermore, the reaction conditions have been optimized to exploit in situ generated

methoxide anion for lactone ring opening to afford the desired

product. Distinct advantages of this process are that it does not

require isolation of intermediate lactone and utilizes in situ

generated methoxide for lactone ring opening, thus obviating

the need for an additional step and base. We also describe an

optimized process for the preparation of -ionylidene acetaldehyde (5), a key intermediate for isotretinoin.

Introduction

Isotretinoin (13-cis-retinoic acid) belongs to a family of

vitamin A (retinol) related compounds. It inhibits sebaceous

gland function and keratinization and is used for the treatment

of dermatological diseases such as acne. It is extremely

effective in very severe and nodulocystic acne and prevents

scarring. Isotretinoin has also been evaluated for its potential

use in certain cancerous conditions.1

Structurally, isotretinoin is a highly conjugated molecule

consisting of a substituted cyclohexene moiety and a polyene

* Author for correspondence. E-mail: mohammad.salman@ranbaxy.com.

Telephone: +1-609-720-8020. Fax: +1-609 720-1155.

Portions of this work have been incorporated in the following patent/patent

applications: U.S. 6,441,226B1 and WO 2003018522 A2.

(1) (a) Wirth, L. J.; Haddad, R. I.; Posner, M. R. Expert ReV. Anticancer Ther.

2003, 3, 339. (b) Toma, S.; et al. Oncol. Rep. 2004, 11, 1297. (c) See, S.

J.; Levin, V. A.; Yung, W. K.; Hess, K. R.; Groves, M. D. Neuro-oncol.

2004, 6, 253. (d) Short, S. C.; Suovuori, A.; Cook, G.; Vivian, G.; Harmer,

C. Clin. Oncol. 2004, 16, 569. (e) Motzer, R. J.; et al. J. Clin. Oncol. 2000,

18, 2972. (f) Robinson, C. P. Drugs Today 1982, 18, 637.

302

Vol. 9, No. 3, 2005 / Organic Process Research & Development

Published on Web 03/03/2005

Scheme 1a

a Reagents: (a) base/protic/aprotic solvent; (b) hV/iodine or hV/Pd-salt or hv/

photosensitizer.

side chain with a terminal carboxy group. All except one of

the double bonds (C-13 double bond) in the side chain are

trans, and it is the stereospecific construction of this polyene

side chain that has challenged synthetic organic chemists for

the past almost three decades. Commercially and readily

available -ionone (4) has been conveniently used for the

construction of the cyclohexene part of isotretinoin.

Reported synthetic approaches2-7 for the construction of

the polyene side chain do not offer a commercially viable

process. In general, the approach has been to develop a

convergent synthesis involving stereospecific coupling of an

appropriate C15 synthon (synthesized from -ionone) and a

C5 synthon. For example, Pattenden and Weedon3 utilized

the reaction of C15-triarylphosphonium salt (Wittig salt) with

a C5-butenolide in diethyl ether. This process however gave

an isomeric mixture (at the C-11 double bond) of 13-cis

retinoic acid in 66.75% yield; the desired 11-trans-13-cis

content was only about 36% and the rest being the corresponding 11,13-di-cis isomer (Scheme 1).

(2) Sollaadie, G.; Girardin, A.; Lang, G. J. Org. Chem. 1989, 54, 2620.

(3) Pattenden, G.; Weedon, B. C. L. J. Chem. Soc. C 1968, 1984.

(4) Garbers, C. F.; Schneider, D. F.; Van Der Merwe, J. P. J. Chem. Soc. C

1968, 1982.

(5) Lucci, R. U.S. Patent 4,556,518, 1985.

(6) John, M.; Paust, J. U.S. Patent 5,424,465, 1995.

(7) Wang, X. C.; Bhatia, A. V.; Hossain, A.; Towne, T. B. PCT Application,

WO 9948866, 1999.

10.1021/op0497815 CCC: $30.25 2005 American Chemical Society

Scheme 2a

a Reagents: (a) (i) trimethylsulfoxonium iodide, NaH/DMSO, (ii) DMSO/THF, -5 C; (b) MgBr ; (c) isomerization; (d) tetraethyl/tetraisopropyl methylene2

disphosphonate, base; (e) alkoxide, DMSO; (f) 5-hydroxy-4-methyl-2(5H)furanone, KO-tert-butoxide, THF/DMSO.

Scheme 3a

Reagents: (i) NaNH2, liq ammonia, ether, -30 C, 72 h, (ii) KOH, (iii) H+/H2O.

Selective isomerization of the 11-cis double bond in the

presence of the 13-cis double bond proved extremely difficult

to accomplish. Some of the methods attempted include photoisomerization using iodine,4 transition metal catalyst,5 or

photosensitizers such as Erythrosin B or Rose Bengal,6 etc.

The above synthetic approach to prepare isotretinoin is

not amenable for commercial scale; limitations include the

need for special equipment for photoisomerization and

suboptimal purity of the desired product.

James Babler8 has described use of phosphonate ester (as

C15 synthon) as the key intermediate for the synthesis of

isotretinoin (Scheme 2); the phosphonate ester in turn was

synthesized in several steps from -ionone. Condensation

of the phosphonate ester with 5-hydroxy-4-methyl-2(5H)furanone (C-5 synthon) afforded isotretinoin. Although this

approach does not involve the cumbersome photoisomerization step, it is uneconomical for commercial manufacturing

because of the number of the steps involved.

A patent report9 has described preparation of isotretinoin

in a single step from -ionylidene acetaldehyde (5) and

methyl 3,3-dimethylacrylate in the presence of sodium amide

and liquid ammonia. However, these reaction conditions

require maintaining low temperatures for more than 22 h

(Scheme 3) making this process suboptimal for commercial

scale synthesis. The patent report also does not indicate the

impurity profile of isotretinoin obtained through this process.

(8) Babler, J. H. U.S. Patent 4,916,250, 1990.

(9) Johnson, J. Y.; Johnson, G. W. GB Patent 835,526, 1958.

Results and Discussion

A more practical approach to isotretinoin synthesis has

been reported by Cainelli et al.10 involving conversion of

lactone (8) to isotretinoin in the presence of KO-tertbutoxide. These authors however described a rather difficult

route to the lactone (8) intermediate. A later report by Dugger

and Heathcock11 described a more efficient synthesis of the

key lactone intermediate (8); condensation of dienolate of

methyl 3,3-dimethyl acrylate (generated from LDA and

methyl 3,3-dimethyl acrylate) with -ionylidene acetaldehyde

(5) at -78 C afforded the desired lactone (8) after

preparative HPLC purification. These two reports in fact form

the basis of our present study. We argued that it should be

possible to optimize the reaction conditions in Dugger and

Heathcocks process to obtain isotretinoin in one single step.

Mechanistically, condensation of dienolate of methyl 3,3dimethyl acrylate with -ionylidene acetaldehyde (5) would

result in the generation of methoxide anion, and we argued

that it should be possible to utilize this in situ generated base

to affect lactone ring opening and obtain isotretinoin. The

novelty of this process would be that it would not require

isolation of lactone intermediate and more importantly would

not require use of additional base (such as KO-tert-butoxide,

as used by Cainelli et al.10).

Indeed, condensation of dienolate of methyl 3,3-dimethyl

acrylate with -ionylidene acetaldehyde (5), first at -78 C

and subsequently at 40 C (to affect ring opening), afforded,

(10) Cainelli, G.; Cardillo, G.; Contento, M.; Grasselli, P.; Umani-Ronchi, A.

Gazz. Chim. Ital. 1973, 103, 117.

(11) Dugger, R. W.; Heathcock, C. H. J. Org. Chem. 1980, 45, 1181.

Vol. 9, No. 3, 2005 / Organic Process Research & Development

303

Scheme 4a

a Reagents: (a) triethyl phosphonoacetate, NaNH , toluene, 65 C, 15 h; (b) (i) LAH, THF-hexane, (ii) H+/H O; (c) MnO , hexane, 60 C, 3 h; (d) (i) LDA, methyl

2

2

2

3,3-dimethyl acrylate, -72 C, 1 h, (ii) 40 C, 1 h, (iii) H+/H2O.

after aqueous acid workup, isotretinoin in a single step

(Scheme 4). The process does not require any chromatographic purification step, and simple recrystallisation affords

the desired isotretinoin in good yield and excellent purity.

This process has also been successfully used at the commercial scale for the production of isotretinoin.

We also describe an optimized process for the preparation

of key intermediate, -ionylidene acetaldehyde (5).

Thus, condensation of -ionone (4) with triethyl phosphonoacetate in toluene in the presence of sodium amide afforded

ethyl -ionylidene acetate (6) in 85% isolated yield and

>95% purity. Reduction of ester 6 with lithium aluminum

hydride in a mixture of hexanes and anhydrous THF gave

the corresponding alcohol, -ionylidene ethanol (7); this was

used as such for the oxidation step. Oxidation of 7 with

activated manganese dioxide in hexanes at 60 C afforded

the desired trans--ionylidene acetaldehyde (5, containing

less than 5% of the corresponding 9-cis isomer) in 95% yield

over two steps.

Conclusions

We have successfully developed an efficient commercial

process for the synthesis of isotretinoin (1) and also report

an optimized process for the preparation of key intermediate,

-ionylidene acetaldehyde (5). The reaction conditions are

operationally simple, robust, and amenable to commercial

scale synthesis.

Experimental Section

General. Starting materials were obtained from commercial suppliers and used without further purification. Gas

chromatography was performed with HP 50 (30 mm 0.53

mm column, fused silica coated with dimethylpolysiloxane

as stationary phase, 2.65 m film thickness). HPLC was

performed with a Waters instrument (version 3.05.01) using

a Kromosil C-18 column (5, 250 mm 4.6 mm). 1H NMR

spectra were recorded in CDCl3 using a Bruker 300 MHz.

The chemical shift data are reported as (ppm) downfield

from tetramethylsilane which was used as an internal

standard.

Preparation of Ethyl -Ionylidene Acetate (6). Under

nitrogen and with stirring, a solution of triethyl phosphonoacetate (1.4 kg, 6.25 mol) in toluene (1 L) was added to

a mixture of sodium amide (236 g, 6.05 mol) and toluene

304

Vol. 9, No. 3, 2005 / Organic Process Research & Development

(6.5 L) at about 40 C. The reaction mixture was stirred at

40-45 C for 6 h and cooled to 0-5 C, and a solution of

-ionone (1 kg, 5.2 mol) in toluene (1.5 L) was slowly added

at 0 to 10 C. The reaction mixture was stirred at 65 C,

and progress was monitored by GC. After the completion

of the reaction (-ionone less than 5% by GC, approximately

15 h), the mixture was cooled to 20-25 C, washed with

water (2 4 L), and concentrated under vacuum. Distillation

under reduced pressure (2-3 mm) afforded the desired ethyl

-ionylidene acetate (6) in >95% purity (by GC); yield 1.16

kg (85%); bp 145-150 C at 2.5 mm; 1H NMR 1.01 (s,

6H, 2 CH3), 1.27 (t, 3H, sOCH2CH3, J ) 3.2 Hz), 1.47

(m, 2H, ring-CH2), 1.59 (m, 2H, ring-CH2), 1.68 (s, 3H,

CH3), 2.02 (m, 2H, ring-CH2), 2.33 (s, 3H, CH3), 4.15 (q,

2H, sOCH2, J ) 7.08 Hz), 5.73 (s, 1H, dCH), 6.08 (d, 1H,

dCH, J ) 16 Hz) and 6.54 (d, 1H, dCH, J ) 16 Hz).

Preparation of -Ionylidene Acetaldehyde (5). Under

nitrogen and with stirring, lithium aluminum hydride (110

g, 2.89 mol) was added to a mixture of hexanes (9.5 L) and

anhydrous THF (1 L). A solution of ethyl -ionylidene

acetate (6, 1 kg, 3.82 mol) in THF (2 L) was added slowly

at 30-35 C. The reaction mixture was stirred for 1 h at

30-35 C and cooled to 0-2 C. Aqueous sulfuric acid (0.9

L) was then added very slowly at 0-10 C. The solids were

removed through filtration and washed with hexanes (3.5

L). The combined filtrate containing the desired -ionylidene

ethanol (7) was used as such for the subsequent oxidation

step, as follows.

Under stirring, manganese dioxide (3 kg, 34.5 mol) was

added to the filtrate containing -ionylidene ethanol (7)

obtained in the previous step at room temperature. The

reaction mixture was refluxed at 60 C for 3 h and filtered.

The solids were washed with hexanes (6 L), and the

combined filtrate layer was concentrated under vacuum to

yield the desired -ionylidene acetaldehyde (5); yield 0.80

kg (95.3% over two steps); 9-cis isomer (less than 5% by

HPLC); 1H NMR 1.07 (s, 6H, 2 CH3), 1.48-1.51 (m,

2H, ring-CH2), 1.63-1.66 (m, 2H, ring-CH2), 1.74 (s, 3H,

CH3), 2.06-2.14 (m, 2H, ring-CH2), 2.33 (s, 3H, CH3), 5.95

(d, 1H, dCH, J ) 8.1 Hz), 6.23 (d, 1H, dCH, J ) 16.2

Hz), 6.27 (d, 1H, dCH, J ) 16.2 Hz), and 10.16 (d, 1H,

CHO, J ) 8.1 Hz).

Preparation of Isotretinoin (1). Under nitrogen and with

stirring, a solution of n-BuLi in hexane (15%, 321 mL) was

added to a solution of diisopropylamine (48.6 g, 0.48 mol)

in anhydrous THF (1 L) at -30 C and the mixture was

stirred for 1 h. The reaction mixture was then cooled to -72

C, and methyl 3,3-dimethyl acrylate (54.8 g, 0.48 mol) was

added to it. Stirring was continued at -65 to -75 C for 30

min. A solution of -ionylidene acetaldehyde (5, 100 g, 0.458

mol) in anhydrous THF (350 mL) was added, and the

reaction mixture was stirred at -65 to -75 C for 1 h,

warmed to 40 C, and stirred at this temperature for 1 h.

Solvent was removed under vacuum, and the reaction mixture

was diluted with water (700 mL) and methanol (300 mL).

Activated charcoal (4 g) was then added, and the mixture

was refluxed for 30 min. The heterogeneous mixture was

filtered through Hyflo, and the Hyflo bed was washed with

methanol (300 mL) and water (150 mL). The aqueous

methanolic layer was then washed with hexanes (2 500

mL), acidified with 10% aqueous sulfuric acid to pH 3, and

extracted with dichloromethane (2 500 mL). The combined

dichloromethane layer was washed with water (2 300 mL)

and concentrated in vacuo. Crystallization from methanol

(200 mL) afforded the desired isotretinoin; yield 55 g, (40%).

Recrystallization from methanol (1.375 L) afforded pure

(greater than 99% by HPLC; the tretinoin content was less

than 0.1%) isotretinoin; yield 44.5 g; 1H NMR 1.03 (s,

6H, 2 CH3 at C-1), 1.45-1.49 (m, 2H, ring-CH2 at C-2),

1.60-1.66 (m, 2H, ring-CH2 at C-3), 1.72 (s, 3H, CH3 at

C-5), 2.00-2.05 (m, 5H, CH3 at C-9 and CH2 at C-4), 2.10

(s, 3H, CH3 at C-13), 5.66 (s, 1H, H-14), 6.165 (d, 1H, H-8,

J ) 15 Hz), 6.25-6.32 (m, 2H, H-7 and H-10), 6.98-7.07

(dd, 1H, H-11, J ) 15 Hz,), 7.745 (d, 1H, H-12, J ) 15

Hz), and 11.25 (broad s, 1H, COOH, D2O exchangeable)

Acknowledgment

We are grateful to the Analytical Division of Ranbaxy

Research Laboratories for providing analytical and spectral

data. The authors also wish to thank Professor U. K. Pandit

for many helpful discussions.

Received for review December 3, 2004.

OP0497815

Vol. 9, No. 3, 2005 / Organic Process Research & Development

305

Anda mungkin juga menyukai

- Basudeb Basu Et Al - A Simple Protocol For Direct Reductive Amination of Aldehydes and Ketones Using Potassium Formate and Catalytic Palladium AcetateDokumen3 halamanBasudeb Basu Et Al - A Simple Protocol For Direct Reductive Amination of Aldehydes and Ketones Using Potassium Formate and Catalytic Palladium AcetateRoundSTICBelum ada peringkat

- Efficient Synthesis of 3-Cyano-6 - (2-Hydroxyphenyl) Pyridines by Multi-Component Condensations On BeadsDokumen3 halamanEfficient Synthesis of 3-Cyano-6 - (2-Hydroxyphenyl) Pyridines by Multi-Component Condensations On BeadsBandita DattaBelum ada peringkat

- CarmegliptinDokumen12 halamanCarmegliptinQuân MinhBelum ada peringkat

- Pramila Sharma, Bharti Vashistha, Ruchi Tyagi, Vidushi Srivastava, Monica Shorey, Bhawani Singh and D. KishoreDokumen11 halamanPramila Sharma, Bharti Vashistha, Ruchi Tyagi, Vidushi Srivastava, Monica Shorey, Bhawani Singh and D. Kishoreram6025Belum ada peringkat

- 04 04 Roberts Target Ans1Dokumen6 halaman04 04 Roberts Target Ans1Albert BohrBelum ada peringkat

- A Practical Synthesis of (-) - Kainic AcidDokumen11 halamanA Practical Synthesis of (-) - Kainic AcidNikhil SarpateBelum ada peringkat

- Two Methods For The Preparation of Sitagliptin PhoDokumen5 halamanTwo Methods For The Preparation of Sitagliptin PhoNadir BashirBelum ada peringkat

- Synthesis of Using The Nanocomposite Catalyst: Biodiesel Mg/Al/Zn Hydrotalcite/SBA-15Dokumen24 halamanSynthesis of Using The Nanocomposite Catalyst: Biodiesel Mg/Al/Zn Hydrotalcite/SBA-15Vikash ChandravanshiBelum ada peringkat

- Angewandte Chemie, Vol. 46 Nb. 7 (2007) P. 1066 - 1070Dokumen5 halamanAngewandte Chemie, Vol. 46 Nb. 7 (2007) P. 1066 - 1070rrgodboleBelum ada peringkat

- Method for preparing important intermediate of cytidineDokumen3 halamanMethod for preparing important intermediate of cytidinergBelum ada peringkat

- An Improved Asymmetric Synthetic Route To D-Biotin Via Hoffmann-Roche Lactone-Thiolactone ApproachDokumen4 halamanAn Improved Asymmetric Synthetic Route To D-Biotin Via Hoffmann-Roche Lactone-Thiolactone ApproachPaulo HenriqueBelum ada peringkat

- Development of A Stereoselective Practical Synthetic Route To Indolmycin, A Candidate Anti-H. Pylori AgentDokumen5 halamanDevelopment of A Stereoselective Practical Synthetic Route To Indolmycin, A Candidate Anti-H. Pylori AgentMaria-LuizaGhidrasanBelum ada peringkat

- Direct Synthesis of Nitriles From Aldehydes in Ionic LiquidsDokumen3 halamanDirect Synthesis of Nitriles From Aldehydes in Ionic LiquidschidambaramrBelum ada peringkat

- A New Process For Deproteinization of ChitinDokumen8 halamanA New Process For Deproteinization of ChitinIrvanno SuinegueBelum ada peringkat

- SC 2005 2317Dokumen8 halamanSC 2005 2317alirezamman20Belum ada peringkat

- CN100999540 Tech, of Producing Cytidine by Chemical Synthesizing ProcessDokumen5 halamanCN100999540 Tech, of Producing Cytidine by Chemical Synthesizing ProcessrgBelum ada peringkat

- Reaksi PA Dan ButanolDokumen5 halamanReaksi PA Dan ButanolUnlucky 2019Belum ada peringkat

- Thiols Formation in Presence of K2co3Dokumen5 halamanThiols Formation in Presence of K2co3Harjinder Singh BhatiaBelum ada peringkat

- Wee 2013Dokumen8 halamanWee 2013David Felipe Munar GarciaBelum ada peringkat

- Polycyclic AlkenesDokumen8 halamanPolycyclic AlkenesDieter ScheibelBelum ada peringkat

- Friedel-Crafts Reaction On Baylis-Hillman Adducts Derived From NitroolefinsDokumen4 halamanFriedel-Crafts Reaction On Baylis-Hillman Adducts Derived From NitroolefinsIAEME PublicationBelum ada peringkat

- Joctamiflu PDFDokumen8 halamanJoctamiflu PDFFikriansyah Bin IrmanBelum ada peringkat

- Organic Letters (2008), 10 (17), 3907-3909Dokumen3 halamanOrganic Letters (2008), 10 (17), 3907-3909James TianBelum ada peringkat

- Iodide-Catalyzed Reductions: Development of A Synthesis of Phenylacetic AcidsDokumen6 halamanIodide-Catalyzed Reductions: Development of A Synthesis of Phenylacetic AcidsMike Roller100% (1)

- Transition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesDari EverandTransition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesBelum ada peringkat

- J Biortech 2021 125399Dokumen10 halamanJ Biortech 2021 125399Đỗ Thế KiênBelum ada peringkat

- (Elearnica - Ir) - Towards The Total Synthesis of Tashironin Related Allo-Cedrane Natural ProdDokumen4 halaman(Elearnica - Ir) - Towards The Total Synthesis of Tashironin Related Allo-Cedrane Natural ProdMohamadMostafaviBelum ada peringkat

- Meglumine Sulphate NB Reddy AIP ProceedingsDokumen5 halamanMeglumine Sulphate NB Reddy AIP ProceedingsRatnakaram Venkata NadhBelum ada peringkat

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeDari EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeBelum ada peringkat

- CV3P0502Dokumen5 halamanCV3P0502narendraBelum ada peringkat

- Umihara Et Al-2017-Chemistry - A European JournalDokumen3 halamanUmihara Et Al-2017-Chemistry - A European JournalNathalia MojicaBelum ada peringkat

- PDF To WordDokumen102 halamanPDF To Wordfuthanul weweBelum ada peringkat

- Itaconic Acid As CatalystDokumen5 halamanItaconic Acid As CatalystmalikBelum ada peringkat

- Designer substrate yields valuable heterocyclesDokumen6 halamanDesigner substrate yields valuable heterocyclesRaul TejedaBelum ada peringkat

- A Simple, Green and One-Pot Four-Component Synthesis of 1,4-Dihydropyridines and Their AromatizationDokumen6 halamanA Simple, Green and One-Pot Four-Component Synthesis of 1,4-Dihydropyridines and Their AromatizationEdgar HernándezBelum ada peringkat

- Tetrahedron Letters: Payal Malik, Debashis ChakrabortyDokumen3 halamanTetrahedron Letters: Payal Malik, Debashis ChakrabortyBagusChandraMahardhikaBelum ada peringkat

- THE STRUCTURE OF METOPON - J. Am. Chem. Soc., 1953, 75 (17), PP 4373-4374Dokumen2 halamanTHE STRUCTURE OF METOPON - J. Am. Chem. Soc., 1953, 75 (17), PP 4373-4374muopioidreceptorBelum ada peringkat

- Efficient synthesis of dihydrojunenol via cyclase phaseDokumen7 halamanEfficient synthesis of dihydrojunenol via cyclase phaseVictor CiocalteaBelum ada peringkat

- Organic Process Research & Development, 19 (3), 444-448 - 2015Dokumen5 halamanOrganic Process Research & Development, 19 (3), 444-448 - 2015rrgodboleBelum ada peringkat

- Op4 PDFDokumen6 halamanOp4 PDFPaula Andrea GutiérrezBelum ada peringkat

- Synthesis of Simple (E) - 2 - (2-Nitrobut-2-Enyloxy) Benzaldehyde Derivatives From (E) - (3-Chloro-2 - Nitroprop-1-Enyl) BenzeneDokumen6 halamanSynthesis of Simple (E) - 2 - (2-Nitrobut-2-Enyloxy) Benzaldehyde Derivatives From (E) - (3-Chloro-2 - Nitroprop-1-Enyl) BenzeneIAEME PublicationBelum ada peringkat

- Oleh: Kelompok 3 Budiman Yasir N012171029 Risna N012171012 Rismayanti Fauziah N012171022Dokumen41 halamanOleh: Kelompok 3 Budiman Yasir N012171029 Risna N012171012 Rismayanti Fauziah N012171022yunitaBelum ada peringkat

- Org. Lett. 2008, 10, 2075. A Facile Preparation of Imidazolinium ChloridesDokumen3 halamanOrg. Lett. 2008, 10, 2075. A Facile Preparation of Imidazolinium ChloridesDeiby ZambranoBelum ada peringkat

- Aziridine Indole PDFDokumen3 halamanAziridine Indole PDFkisps100% (1)

- Resoluçao Butirato 2007Dokumen7 halamanResoluçao Butirato 2007yarajaqueBelum ada peringkat

- Chitosan Catalyst for Chalcones SynthesisDokumen8 halamanChitosan Catalyst for Chalcones SynthesisRicardo Fajardo DíazBelum ada peringkat

- Imidazolium-Catalyzed Synthesis of An Imidazolium CatalystDokumen13 halamanImidazolium-Catalyzed Synthesis of An Imidazolium CatalystCarmen AguilarBelum ada peringkat

- [Organic Process Research & Development 2012-Nov 30 Vol. 16 Iss. 12] Weiberth, Franz J._ Yu, Yong_ Subotkowski, Witold_ Pemberton, Cl - Demonstration on Pilot-Plant Scale of the Utility of 1,5,7-Triazabicyclo[4.4.0]Dokumen3 halaman[Organic Process Research & Development 2012-Nov 30 Vol. 16 Iss. 12] Weiberth, Franz J._ Yu, Yong_ Subotkowski, Witold_ Pemberton, Cl - Demonstration on Pilot-Plant Scale of the Utility of 1,5,7-Triazabicyclo[4.4.0]Эмилия МинисBelum ada peringkat

- Influence of Salts on Selective Coagulation of Whey Proteins and their Application in the Isolation of β-LactoglobulinDokumen5 halamanInfluence of Salts on Selective Coagulation of Whey Proteins and their Application in the Isolation of β-LactoglobulinirfanBelum ada peringkat

- 471 5178 1 PBsDokumen12 halaman471 5178 1 PBsJohnBelum ada peringkat

- Pear 2015Dokumen6 halamanPear 2015JuanPabloOvalleQuinteroBelum ada peringkat

- Advances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsDari EverandAdvances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsLalit Kumar SinghBelum ada peringkat

- Tbaf (-) 80 Patent WO2008089093A2 - Efficient Processes For Preparing Steroids and Vitamin D Derivatives With ... - Google PatentsDokumen50 halamanTbaf (-) 80 Patent WO2008089093A2 - Efficient Processes For Preparing Steroids and Vitamin D Derivatives With ... - Google PatentsRajpal Singh KochharBelum ada peringkat

- An Efficient, Surfactant Mediated Biginelli Condensation For The One Pot Synthesis of Dihydropyrimidine DerivativesDokumen7 halamanAn Efficient, Surfactant Mediated Biginelli Condensation For The One Pot Synthesis of Dihydropyrimidine DerivativesRizka AmaliaBelum ada peringkat

- Galli Et Al-2002-Helvetica Chimica ActaDokumen14 halamanGalli Et Al-2002-Helvetica Chimica ActaRodrigo Alejandro Romo MuñozBelum ada peringkat

- Joc - 7099Dokumen8 halamanJoc - 7099Diogo DiasBelum ada peringkat

- Catalysis Communications: Leonardo N. Silva, Valter L.C. Gonçalves, Claudio J.A. MotaDokumen4 halamanCatalysis Communications: Leonardo N. Silva, Valter L.C. Gonçalves, Claudio J.A. MotaAdib PriatamaBelum ada peringkat

- Preparation of Ester Derivatives of Fatty Acids For GC AnalysisDokumen27 halamanPreparation of Ester Derivatives of Fatty Acids For GC Analysism_m_hamedi3866Belum ada peringkat

- Bio-Based SolventsDari EverandBio-Based SolventsFrançois JérômeBelum ada peringkat

- Understanding Catalytic Biomass Conversion Through Data MiningDokumen7 halamanUnderstanding Catalytic Biomass Conversion Through Data MiningerikjanrasBelum ada peringkat

- Pharmaton CapsulesDokumen1 halamanPharmaton CapsulesAvian ÁlvarezBelum ada peringkat

- Vitamins: Types, Functions and SourcesDokumen3 halamanVitamins: Types, Functions and SourcesFajli100% (1)

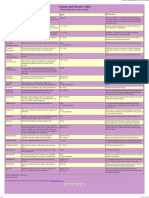

- Vitamin and Mineral TABLEDokumen1 halamanVitamin and Mineral TABLEHibozoBelum ada peringkat

- STATE MCQ CCMP 2018 BY DR RAMESH BORADEDokumen28 halamanSTATE MCQ CCMP 2018 BY DR RAMESH BORADEGirish WaruBelum ada peringkat

- Vitamin ADokumen4 halamanVitamin AThunyapornBelum ada peringkat

- Determination of Vitamin A in FoodsDokumen3 halamanDetermination of Vitamin A in FoodsHafizur RahmanBelum ada peringkat

- Manual of Forever Living ProductsDokumen105 halamanManual of Forever Living Productsspiritualbeing100% (20)

- Summative TestDokumen21 halamanSummative TestRubie Ann Capila Panes100% (1)

- POSTPARTUM CAREDokumen58 halamanPOSTPARTUM CAREGino Al Ballano BorinagaBelum ada peringkat

- Buenafe JC FoodChem Week 11 To 13Dokumen1 halamanBuenafe JC FoodChem Week 11 To 13john buenafeBelum ada peringkat

- Multiple Choice Questions: Q.1. Plant Virus ContainsDokumen25 halamanMultiple Choice Questions: Q.1. Plant Virus ContainsS. Ramgopal RaoBelum ada peringkat

- Case Study F. BaylosisDokumen27 halamanCase Study F. BaylosisJenina Rosa P. Llanes100% (1)

- Methods for MicronutrientsDokumen64 halamanMethods for MicronutrientsLeguizamon Carate NelsonBelum ada peringkat

- MOCK BOARD EXAM ON NUTRITIONAL BIOCHEMISTRYDokumen25 halamanMOCK BOARD EXAM ON NUTRITIONAL BIOCHEMISTRYJermeLou Bao100% (14)

- Classification Feed and FodderDokumen4 halamanClassification Feed and FoddermathiBelum ada peringkat

- Nutrition For Preschool-Age ChildrenDokumen57 halamanNutrition For Preschool-Age Childrenzeverino castillo50% (2)

- NCERT Exemplar Problems From Class 6 Science Components of FoodDokumen8 halamanNCERT Exemplar Problems From Class 6 Science Components of Foodsmruti sangitaBelum ada peringkat

- Adolescent and Youth Health Program (AYHP)Dokumen11 halamanAdolescent and Youth Health Program (AYHP)Shereen AlobinayBelum ada peringkat

- Health EducationDokumen23 halamanHealth EducationdinirajBelum ada peringkat

- The Great Fast Paleo StyleDokumen11 halamanThe Great Fast Paleo StylePatricia Balzer100% (1)

- Mel Tappans Personal Survival Letter Issue 25 (Tappan)Dokumen27 halamanMel Tappans Personal Survival Letter Issue 25 (Tappan)buckonbeachBelum ada peringkat

- A Response To Dr. Joe Mercola On Cod Liver Oil - The Weston A. Price FoundationDokumen19 halamanA Response To Dr. Joe Mercola On Cod Liver Oil - The Weston A. Price FoundationRicardo BritoBelum ada peringkat

- Chlorella The Emerald FoodDokumen121 halamanChlorella The Emerald Foodalbertleehh100% (3)

- Quiz Bee Nutrition MonthDokumen8 halamanQuiz Bee Nutrition MonthJohndred ArroyoBelum ada peringkat

- The Truth About Vitamins in Nutritional SupplementsDokumen26 halamanThe Truth About Vitamins in Nutritional SupplementsZelnidBelum ada peringkat

- Basic Need For GeriatricsDokumen38 halamanBasic Need For GeriatricsMuhammad Yatsrib SemmeBelum ada peringkat

- Nanahs ReportDokumen36 halamanNanahs ReportThiago leonardBelum ada peringkat

- LESSON EXEMPLAR-Percentage CompositionDokumen5 halamanLESSON EXEMPLAR-Percentage CompositionIvy Rose Abadilla-Sierra67% (3)

- Nutri QuizDokumen4 halamanNutri Quizmarife gupaalBelum ada peringkat

- Carrots As NutritionDokumen3 halamanCarrots As NutritionJohn ApostleBelum ada peringkat

![[Organic Process Research & Development 2012-Nov 30 Vol. 16 Iss. 12] Weiberth, Franz J._ Yu, Yong_ Subotkowski, Witold_ Pemberton, Cl - Demonstration on Pilot-Plant Scale of the Utility of 1,5,7-Triazabicyclo[4.4.0]](https://imgv2-1-f.scribdassets.com/img/document/639410752/149x198/b3a17583da/1681910419?v=1)