Saic-P-3002 Rev 0

Diunggah oleh

jwochDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Saic-P-3002 Rev 0

Diunggah oleh

jwochHak Cipta:

Format Tersedia

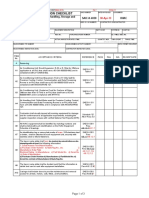

SAUDI ARAMCO ID/PID - 02/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

General - Electrical Equipment, Storage Handling &

Preservation

SAIC NUMBER

SAIC-P-3002

PROJECT TITLE

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

DATE APPROVED

1-Oct-05

QR NUMBER

ELECT-

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

A.

ACCEPTANCE CRITERIA

REFERENCE

Document Review

A1

Review documents for UPS electrical equipment Material Receiving.

Schedule Q

Att. IV, Sec. 3.1

A2

Identification procedure reviewed and implemented for UPS electrical

equipment.

Schedule Q

Att. IV, Sec. 3.2

A3

Material identification shall be implemented for all materials, parts and

components, including partially fabricated assemblies. UPS electrical

equipment shall be identified by using tags, stamps, color coding,

stencils or labels. The location and method of identification shall not

affect the function or quality of the material.

Schedule Q,

Att. lV, Sec. 3.2

A4

The CONTRACTOR shall include procedures for handling, storage, and

preservation of material as specified in all applicable specifications,

manufacturer recommendations and SAUDI Aramco's standards.

Schedule Q,

Att. IV, Sec.5

A5

The procedure shall list all inspection schedules for maintaining the

Schedule Q,

quality of the material or equipment as well as provide for documentation

Att. IV, Sec.5

that the required activities have been performed.

B.

General Requirements

B1

Documentation for traceability reviewed and implemented. UPS electrical

equipment shall be traceable from the manufacturer and supplier through Schedule Q,

Att. IV, Sec. 3.3

delivery, storage, fabrication, erection, installation, repair, modification

and use.

B2

Documented Control System shall be implemented for all Saudi Aramco

supplied material and equipment.

Schedule Q,

Att. lV, Sec. 4

B3

Individuals responsible for special handling, storage and preservation

shall be fully qualified to do so, and supplied with predetermined WORK

and inspection instructions.

Schedule Q,

Att. IV, Sec.5

B4

The CONTRACTOR shall provide documentation that the required

Storage, Handling and Preservation (SHP) activities have been

performed for UPS electrical equipment.

Schedule Q,

Att. IV, Sec.5

C.

Material Inspection

C1

Review Identification and Traceability procedures for UPS electrical

equipment.

Schedule Q

Att. IV, Sec. 3

C2

Review Storage, Handling and Preservation procedure documentation

for UPS electrical equipment.

Schedule Q

Att. IV, Sec. 5

C3

Purchase order and Data Sheet criteria shall be confirmed and

compared with UPS electrical equipment documentation, and checked

for damage, prior to acceptance of shipment.

Schedule Q

Att. IV, Sec. 7.1

Page 1 of 4

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

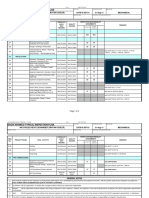

SAUDI ARAMCO ID/PID - 02/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

General - Electrical Equipment, Storage Handling &

Preservation

SAIC-P-3002

WBS / BI / JO NUMBER

PROJECT TITLE

ITEM

No.

SAIC NUMBER

ACCEPTANCE CRITERIA

REFERENCE

D.

Storage

D1

When indoor storage is not possible, the UPS electrical equipment must

be covered with a tarpaulin. This cover should extend to the ground;

however, it should not tightly wrap the UPS electrical equipment. This will

allow the captive air space to breathe, minimizing formation of

condensation.

NFPA 70 (NEC) Sec. 110.3 (B) and Manufacturer's Instruction.

SAES-P-100

Sec. 5.2

D2

Lead acid batteries should be stored in a charge condition, otherwise

sulfating of the plates occurs, which is often an irreversible failure of the

batteries. Suggested storage temperature range is 0 deg C to 25 deg C,

or in accordance with manufacturer's recommendations.

(NEC Sec. 110.3 (B), NEMA PE 1 2.5.12)

SAES-P-100

Sec. 5.2

D3

When lead acid batteries are to be stored for long periods of time, it is

advisable to keep them on a very low rate of trickle charge, in

accordance with the battery manufacturer's recommendations. When

such trickle charging is impractical, the batteries may be charged

periodically. (NEC Sec. 110.3 (B), NEMA PE 1 2.5.12)

SAES-P-100

Sec. 5.2

D4

QC Before Installation- UPS electrical equipment shall conform to all

Schedule Q,

applicable requirements, standards, and specifications prior to release to

Att. IV, Sec.7.1

be used as part of work.

D5

Incoming UPS electrical equipment shall be visually inspected for Schedule Q,

damage / defects occurred during transportation.

Att. IV, Sec.7.1

D6

UPS electrical equipment shall be carefully inspected when the unit is

received, inspect the carton for any sign of damage or tampering.

NFPA 70 (NEC) Sec. 110.3 (B), Manufacturer's Instruction.

SAES-P-100

Sec. 5.2

D7

Where possible, UPS electrical equipment should be stored indoor in a

clean dry area.

NFPA 70 (NEC) Sec. 110.3 (B) and Manufacturer's Instruction.

SAES-P-100

Sec. 5.2

E.

Handling

E1

Special safety handling of UPS electrical equipment should be used and

stored in an upright position unless they have been designed for allaltitude use. (NEC Sec. 110.3 (B), NEMA PE 1 2.5.12)

SAES-P-100

Sec 5.2

E2

General Handling - UPS and Battery equipment shall be checked for

damage by store yard personnel prior to acceptance of shipment,

unloading, or handling. No visible shipping or handling damage.

(NFPA 70, NEC Art. 110.3(B), manufacturer's instructions)

SAES-P-100

Sec 5.2

E3

General Handling - UPS electrical equipment shall be firmly lagged (no

loose or missing pieces) and undamaged from shipping and handling.

(NFPA 70, NEC Art. 110.3(B), manufacturer's instructions)

SAES-P-100

Sec 5.2

E4

General Handling - Shipper and receiving store yard personnel shall be

fully aware of manufacturer's special handling instructions (if provided on

the UPS electrical equipment boxes or in the purchase documents) prior

to unloading or handling.

(NFPA 70, NEC Art. 110.3(B), manufacturer's instructions)

SAES-P-100

Sec 5.2

E5

General Handling - Manufacturer's special handling instructions (if

provided on the UPS electrical equipment wooden boxes or in the

purchase documents) shall be followed.

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

E6

General Handling - UPS electrical equipment Wooden boxes, crates and

UPS panels shall not be dropped.

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

Page 2 of 4

DATE APPROVED

1-Oct-05

QR NUMBER

ELECT-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

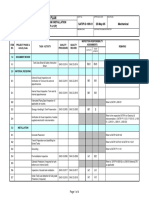

SAUDI ARAMCO ID/PID - 02/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

General - Electrical Equipment, Storage Handling &

Preservation

SAIC-P-3002

WBS / BI / JO NUMBER

PROJECT TITLE

ITEM

No.

SAIC NUMBER

ACCEPTANCE CRITERIA

REFERENCE

E7

Avoid severe jarring and / or dropping of UPS electrical equipment.

NFPA 70 (NEC) Sec. 110.3 (B) and Manufacturer's Instruction.

SAES-P-100

Sec. 5.2

E8

Handle UPS electrical equipment with care to prevent damage to

components or special finishes.

NFPA 70 (NEC) Sec. 110.3 (B) and Manufacturer's Instruction.

SAES-P-100

Sec. 5.2

F.

Storage and Preservation

F1

General - Firm dry support shall be provided for storage of UPS electrical

equipment wooden boxes, crates and panels.

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

F2

General - UPS electrical equipment Wooden boxes, crates and panels

shall be stored to provide easy access for lifting and moving.

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

F3

General - UPS electrical equipment Wooden boxes, crates and panels

shall be stored away from chemicals and petroleum products (including

potential spilled liquids and spray mist).

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

F4

General - UPS electrical equipment Wooden boxes, crates and panels

shall be stored away from chemicals and petroleum products (including

potential spilled liquids and spray mist).

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

F5

General - UPS electrical equipment Wooden boxes, crates and panels

shall be stored indoors.

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

F6

General - UPS electrical equipment Wooden boxes, crates and panels

shall be stored away from construction equipment, road traffic, falling or

flying objects, and areas where there is a significant risk of physical

damage.

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

F7

Outdoors - UPS electrical equipment Wooden boxes, crates and panels

shall be supported off the ground and provided with a weatherproof (i.e.,

rain and dust-tight) cover.

(NFPA 70, NEC Art. 110.3 (B), manufacturer's instructions)

SAES-P-100

Sec 5.2

F8

Care must also be taken to protect the UPS electrical equipment from

flooding or from harmful chemical vapors.

NFPA 70 (NEC) Sec. 110.3 (B) and Manufacturer's Instruction.

SAES-P-100

Sec. 5.2

F9

One copy of the manufacturer's standard installation instruction

(including weather and winterizing) shall be packed and shipped with the

equipment. (NEC Sec. 110.3 (B), NEMA PB 1 2.11.1)

G.

Shipping & Transportation

G1

Shipping crates shall be marked with handling and storage instructions.

Labels on the shipping crate shall state the storage conditions, date of

shipment, and the date beyond which the product must not be stored.

Page 3 of 4

NEMA PB 1

Sec. 2.11.1

17-SAMSS-511

Sec. 17.5

DATE APPROVED

1-Oct-05

QR NUMBER

ELECT-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 02/19/05 - REV 0 (Standards Cutoff - August 2004)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Electrical Equipment, Storage Handling &

Preservation

SAIC-P-3002

WBS / BI / JO NUMBER

PROJECT TITLE

ITEM

No.

DATE APPROVED

ACCEPTANCE CRITERIA

REFERENCE

1-Oct-05

QR NUMBER

ELECT-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule Q Quality Requirements (Pro Forma Contract), November 2003

2. Schedule G Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), July 1993

3. NFPA 70 National Electrical Code (NEC), 2002 Edition

4. SAES-P-100 Basic Power System Design Criteria, 30 September 2003

5. 17-SAMSS-511 Stationary Storage Batteries 28 April, 2004

6. NEMA PE 1 Uninterruptible Power Systems (UPS) - Specification and Performance Verification 2003 Edition

7. NEMA PB 1 Panelboards 2000 Edition

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the manufacturer

indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

PID Representative

QC Inspector

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 4 of 4

N = NO F = FAILED

Anda mungkin juga menyukai

- Saic P 3002Dokumen1 halamanSaic P 3002aneeshjokay0% (1)

- Satip-P-103-01 Rev 1Dokumen6 halamanSatip-P-103-01 Rev 1AdamuBelum ada peringkat

- Satip-X-600-02 Rev 1 For CP SystemDokumen4 halamanSatip-X-600-02 Rev 1 For CP SystemSaleem MohammedBelum ada peringkat

- SACIC-T-5603 Comms Facilities - Cable Rack - Material ReceivingDokumen4 halamanSACIC-T-5603 Comms Facilities - Cable Rack - Material ReceivingArshad ImamBelum ada peringkat

- SAIC & SATR - InstrumentationDokumen7 halamanSAIC & SATR - InstrumentationAdel KlkBelum ada peringkat

- SAIC-K-4038 Rev 7Dokumen3 halamanSAIC-K-4038 Rev 7shahzadaBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen5 halamanSaudi Aramco Inspection ChecklistAdel KlkBelum ada peringkat

- Saic K 4006Dokumen2 halamanSaic K 4006mohamadBelum ada peringkat

- SAIC-P-3017 Rev 7 FinalDokumen14 halamanSAIC-P-3017 Rev 7 FinalEnginerShahzadGhaffarBelum ada peringkat

- SAIC & SATR - InstrumentationDokumen8 halamanSAIC & SATR - InstrumentationAdel KlkBelum ada peringkat

- SAIC-P-3008 Rev 7 FinalDokumen10 halamanSAIC-P-3008 Rev 7 FinalEnginerShahzadGhaffarBelum ada peringkat

- SAIC-P-3005 Rev 7 FinalDokumen2 halamanSAIC-P-3005 Rev 7 FinalEnginerShahzadGhaffarBelum ada peringkat

- SATIP-X-400-01 Rev 5Dokumen3 halamanSATIP-X-400-01 Rev 5aamirapiBelum ada peringkat

- SAIC-J-6401 - Rev 0Dokumen4 halamanSAIC-J-6401 - Rev 0Adel KlkBelum ada peringkat

- Saic P 3423Dokumen7 halamanSaic P 3423spravin231Belum ada peringkat

- SATR-J-6911Rev 0 PDFDokumen6 halamanSATR-J-6911Rev 0 PDFAdel KlkBelum ada peringkat

- SATR-J-6602 Rev 0 PDFDokumen9 halamanSATR-J-6602 Rev 0 PDFAdel KlkBelum ada peringkat

- SAIC-P-3301 Rev 4Dokumen2 halamanSAIC-P-3301 Rev 4sikandar1234Belum ada peringkat

- SATR-J-6406 Rev 0 PDFDokumen10 halamanSATR-J-6406 Rev 0 PDFAdel KlkBelum ada peringkat

- Mil-D-81873 An - Aqs-13bDokumen44 halamanMil-D-81873 An - Aqs-13bLittle Lumut1Belum ada peringkat

- Saic P 3426Dokumen8 halamanSaic P 3426spravin231Belum ada peringkat

- SAIC-L-2136 Rev 0Dokumen3 halamanSAIC-L-2136 Rev 0philipyapBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen10 halamanSaudi Aramco Inspection Checklistnisha_khanBelum ada peringkat

- Satip F 001 04Dokumen4 halamanSatip F 001 04Anonymous 4e7GNjzGWBelum ada peringkat

- QMIS LBE Rev Mech Final OldDokumen683 halamanQMIS LBE Rev Mech Final Oldh_aldhwyain100% (9)

- SAIC-K-4001 Rev 7Dokumen3 halamanSAIC-K-4001 Rev 7Rohit BassBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen3 halamanSaudi Aramco Inspection Checklistnisha_khanBelum ada peringkat

- Satip e 007 01Dokumen2 halamanSatip e 007 01Anonymous 4e7GNjzGWBelum ada peringkat

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDokumen4 halaman1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnBelum ada peringkat

- SAIC-X-3001 Rev 2Dokumen2 halamanSAIC-X-3001 Rev 2josephjohn2Belum ada peringkat

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDokumen8 halamanSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamBelum ada peringkat

- Tools 2Dokumen1 halamanTools 2sijoy josephBelum ada peringkat

- SAIC-P-3005 Rev 3 General - Channel, Strut, and Support Materials - Material ReceivingDokumen3 halamanSAIC-P-3005 Rev 3 General - Channel, Strut, and Support Materials - Material ReceivingShaikh Mohd QaisarBelum ada peringkat

- Amadeus Gas Pipeline - Project Justifications - Item 8 - 18756-5-HAD-001 HAZ Dossier - Katherine Off-Take SS Rev 0 - August 2015Dokumen91 halamanAmadeus Gas Pipeline - Project Justifications - Item 8 - 18756-5-HAD-001 HAZ Dossier - Katherine Off-Take SS Rev 0 - August 2015VivianBelum ada peringkat

- SAIC-P-3627 Rev 3Dokumen13 halamanSAIC-P-3627 Rev 3Leonil Ibañez BiñanBelum ada peringkat

- 038-Pro Welding Consumable Control Procedure PDFDokumen20 halaman038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Dokumen4 halaman1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnBelum ada peringkat

- Alert Operators Transmission - Aot: All AircraftDokumen6 halamanAlert Operators Transmission - Aot: All AircraftEdwar ZulmiBelum ada peringkat

- Saudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 ElectDokumen3 halamanSaudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 Electkarthi51289Belum ada peringkat

- SAIC-P-3705 Rev 3Dokumen9 halamanSAIC-P-3705 Rev 3Leonil Ibañez BiñanBelum ada peringkat

- SAIC-P-3003 Rev 7 FinalDokumen7 halamanSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarBelum ada peringkat

- ILF-SPC-SRT-EL-810-0 Cathodic Protection - Specification PDFDokumen13 halamanILF-SPC-SRT-EL-810-0 Cathodic Protection - Specification PDFMaheshNayeniBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen3 halamanSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- FQPDokumen9 halamanFQPtushar647Belum ada peringkat

- 60 CON NSH MS C 0040 - Rev.HDokumen10 halaman60 CON NSH MS C 0040 - Rev.HShahbaz ImamBelum ada peringkat

- Projet Topping de Condensat - Skikda SC Instrument Specification For Tank Gauging SystemDokumen19 halamanProjet Topping de Condensat - Skikda SC Instrument Specification For Tank Gauging SystemKARIMBelum ada peringkat

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Dokumen3 halaman1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- Inspection Procedure: 00-SAIP-51 31 August, 2004 Electrical Inspection Document Responsibility: Inspection DepartmentDokumen5 halamanInspection Procedure: 00-SAIP-51 31 August, 2004 Electrical Inspection Document Responsibility: Inspection Departmentaamirtec301Belum ada peringkat

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDokumen4 halamanSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுBelum ada peringkat

- SAIC-W-2XXX-11 Control of Welding ConsumablesDokumen5 halamanSAIC-W-2XXX-11 Control of Welding ConsumablesAnsuman KalidasBelum ada peringkat

- 00 Saip 51Dokumen5 halaman00 Saip 51Rodolius LibaoBelum ada peringkat

- Amadeus Gas Pipeline - Project Justifications - Item 8 - 18756-5-HAD-009 HAZ Dossier - Channel Island MS - August 2015Dokumen445 halamanAmadeus Gas Pipeline - Project Justifications - Item 8 - 18756-5-HAD-009 HAZ Dossier - Channel Island MS - August 2015kherrimanBelum ada peringkat

- Pioneer VSX 2014i S VSX 1014s K Rrv3008 SMDokumen171 halamanPioneer VSX 2014i S VSX 1014s K Rrv3008 SMhifi-electronicBelum ada peringkat

- PCPL 0532 4 407 03Dokumen4 halamanPCPL 0532 4 407 03tceterexBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen5 halamanSaudi Aramco Inspection Checklistnisha_khanBelum ada peringkat

- Industrial Piping and Equipment Estimating ManualDari EverandIndustrial Piping and Equipment Estimating ManualPenilaian: 5 dari 5 bintang5/5 (7)

- Offshore Electrical Engineering ManualDari EverandOffshore Electrical Engineering ManualPenilaian: 4 dari 5 bintang4/5 (9)

- FAR/AIM 2021: Federal Aviation Regulations/Aeronautical Information ManualDari EverandFAR/AIM 2021: Federal Aviation Regulations/Aeronautical Information ManualBelum ada peringkat

- The Handbook of Lithium-Ion Battery Pack Design: Chemistry, Components, Types and TerminologyDari EverandThe Handbook of Lithium-Ion Battery Pack Design: Chemistry, Components, Types and TerminologyPenilaian: 3 dari 5 bintang3/5 (7)

- Pi-Ec19412 - 190619Dokumen1 halamanPi-Ec19412 - 190619jwochBelum ada peringkat

- PolyFlow BrochureDokumen6 halamanPolyFlow BrochurejwochBelum ada peringkat

- Printable Spencerian Practice Sheets PDFDokumen5 halamanPrintable Spencerian Practice Sheets PDFjwochBelum ada peringkat

- Lucy Edmonds - Modern Calligraphy - A Step-by-Step Guide To Mastering The Art of Creativity (2018, Orion) PDFDokumen98 halamanLucy Edmonds - Modern Calligraphy - A Step-by-Step Guide To Mastering The Art of Creativity (2018, Orion) PDFjwoch100% (13)

- Supersealer Sb10: Rotary Continuous Band SealerDokumen2 halamanSupersealer Sb10: Rotary Continuous Band SealerjwochBelum ada peringkat

- Mil F 24385FDokumen24 halamanMil F 24385FjwochBelum ada peringkat

- Pipelines and Buried PipesDokumen22 halamanPipelines and Buried PipesjwochBelum ada peringkat

- Boundary Layers PDFDokumen1 halamanBoundary Layers PDFjwochBelum ada peringkat

- 9 Taylor DispersionDokumen1 halaman9 Taylor DispersionjwochBelum ada peringkat

- Buoyant Plumes, Thermals, Etc.: Turbulent Flow and TransportDokumen1 halamanBuoyant Plumes, Thermals, Etc.: Turbulent Flow and TransportjwochBelum ada peringkat

- Variable Design Point Method.Dokumen56 halamanVariable Design Point Method.jwochBelum ada peringkat

- Floating Roofs Single DeckDokumen41 halamanFloating Roofs Single DeckjwochBelum ada peringkat

- Engineered Pipe Supports: Constant Supports SizingDokumen9 halamanEngineered Pipe Supports: Constant Supports SizingjwochBelum ada peringkat

- Methyl Isocyanate (MIC) Rundown & Storage System: The Bhopal Gas Tragedy Technical Series Part 1 of 4Dokumen3 halamanMethyl Isocyanate (MIC) Rundown & Storage System: The Bhopal Gas Tragedy Technical Series Part 1 of 4Jesse Haney IIIBelum ada peringkat

- Xtreet 250X 2017 Parts Catalogue 2016 08 16 1Dokumen32 halamanXtreet 250X 2017 Parts Catalogue 2016 08 16 1JeovannyAlexanderMatamorosSanchezBelum ada peringkat

- Clinical InterviewDokumen29 halamanClinical InterviewVasundhara RanaBelum ada peringkat

- Melag Meladem 65 - Watertreatment - User ManualDokumen4 halamanMelag Meladem 65 - Watertreatment - User Manualamanuel waleluBelum ada peringkat

- Chapter6-Sedimentary RocksDokumen6 halamanChapter6-Sedimentary Rockssanaiikhan2020Belum ada peringkat

- TED Lecture: "10 Ways To Have A Better Conversation" by Celeste Headlee. Vocabulary Words TranslationDokumen2 halamanTED Lecture: "10 Ways To Have A Better Conversation" by Celeste Headlee. Vocabulary Words TranslationEnni BuraBelum ada peringkat

- BRD8025 DDokumen24 halamanBRD8025 Dsluz2000Belum ada peringkat

- Breast UltrasoundDokumen57 halamanBreast UltrasoundYoungFanjiensBelum ada peringkat

- DS BR ACRYLIC PU CoatingDokumen3 halamanDS BR ACRYLIC PU CoatingSomak DuariBelum ada peringkat

- Portagauge - Technical Specifications - March 13Dokumen3 halamanPortagauge - Technical Specifications - March 13dimasjosesmithBelum ada peringkat

- Using Transistor As A Switch - ErmicroblogDokumen24 halamanUsing Transistor As A Switch - ErmicroblogRKMBelum ada peringkat

- Marketing of Wacom Bamboo Graphic Tablet CTHDokumen5 halamanMarketing of Wacom Bamboo Graphic Tablet CTHAnggiet Dwi KestriBelum ada peringkat

- Us District Court of Massachusetts Promotes Human and Constitutional Rights Violator Magistrate Judge Leo T. Sorokin To Chief Magistrate JudgeDokumen98 halamanUs District Court of Massachusetts Promotes Human and Constitutional Rights Violator Magistrate Judge Leo T. Sorokin To Chief Magistrate Judgetired_of_corruptionBelum ada peringkat

- Literary Text Vs Informational TextDokumen4 halamanLiterary Text Vs Informational TextKathlyn Mercado AlcedoBelum ada peringkat

- Chemical Spillage Training 2024Dokumen30 halamanChemical Spillage Training 2024Sreedharan KannanBelum ada peringkat

- Chapter 1Dokumen43 halamanChapter 1arun neupaneBelum ada peringkat

- Film Script Writing GuideDokumen2 halamanFilm Script Writing GuideMrAlexSexton100% (3)

- AirAsia Branding RateCard 2015Dokumen7 halamanAirAsia Branding RateCard 2015Michael SBelum ada peringkat

- Sag 011 5267 DSN PW em 24.380 24.520 Ol SG2 100 01Dokumen1 halamanSag 011 5267 DSN PW em 24.380 24.520 Ol SG2 100 01Sanjay SwamiBelum ada peringkat

- Industrial Control Transformers (Machine Tool) - 9070T100D55Dokumen2 halamanIndustrial Control Transformers (Machine Tool) - 9070T100D55chardBelum ada peringkat

- CS310 Dec 2021 - KCCDokumen18 halamanCS310 Dec 2021 - KCCLAWRENCE ADU K. DANSOBelum ada peringkat

- Paul Stockman - PsyclockDokumen7 halamanPaul Stockman - Psyclockseridj islemBelum ada peringkat

- Cim 210 NotesDokumen127 halamanCim 210 NotesJay up100% (3)

- Fiat 500L Owner's Manual (Page 370 of 428) - ManualsLib1Dokumen2 halamanFiat 500L Owner's Manual (Page 370 of 428) - ManualsLib1FabrizioBelum ada peringkat

- OSU TemplateDokumen193 halamanOSU TemplateDani SardinhaBelum ada peringkat

- Muhammad Ramdhan Suwandi-N8d-360179141Dokumen6 halamanMuhammad Ramdhan Suwandi-N8d-360179141Rija SunaBelum ada peringkat

- T&D FinalDokumen69 halamanT&D Finalthella deva prasadBelum ada peringkat

- FRS MethodologyDokumen2 halamanFRS MethodologyHenry FlorendoBelum ada peringkat

- Economics NotesDokumen21 halamanEconomics NotesBARSHABelum ada peringkat

- M&D OutlineDokumen6 halamanM&D Outlineyared100% (1)