Hull Form Hydrodynamic Optimization Based On Parametric Modeling

Diunggah oleh

Salma SherbazJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hull Form Hydrodynamic Optimization Based On Parametric Modeling

Diunggah oleh

Salma SherbazHak Cipta:

Format Tersedia

2012 International Conference on Systems and Informatics (ICSAI 2012)

Hull Form Hydrodynamic Optimization Based on Parametric Modeling

Jinfeng Huang

China Ship Development and Design Center

Wuhan China

Abstract-This paper discusses the hydrodynamic optimization of

Following this, an example optimization are presented.

hull form mainly. The study has been carried out using an

The optimization of DTMB 5415 is presented in order to

integrated tool for hydrodynamic optimization, incorporating a

illustrate objectives, methods, and results.

CAD modeler for definition and parametric modification of hull

Measures of merit is wave resistance in calm water,

forms, CFD codes for the evaluation of hydrodynamic

Displacement and Lcb were considered as inequality

performance and software for optimization and decision making.

constraints. The set of free variables contained selected form

A study includes the geometric modeling, hydrodynamic analysis,

parameters of the hull.

design evaluation and shape variation of a DTMB5415. Genetic

Various systems were utilized for this investigation: TU

Algorithm is utilized to explore the design space and to improve

Berlins FRIENDSHIP Modeler for the parametric modeling

the hull shape. The most relevant feature of the tool is its

capability to carry out and automatically evaluate parametric

of ship hull forms, wave resistance codes Shipflow.

modifications of DTMB5415s shape, providing an assessment of

the shape variants and proposing one or several Pareto optimal

shapes. The hydrodynamic design process is implemented: An

advanced parametric modeling kernel is applied for efficient

form generation and variation. The hydrodynamic performance

is analyzed by state-of-the-art Computational Fluid Dynamics

(CFD) codes for calm water resistance. A commercial

optimization system is used to integrate the various CAD and

CFD tools and to carry out the optimization.

Keywords-Hull form Hydrodynamic optimization Parametric

modelingDTMB5415FriendshipShipflow

Achieving hull forms with a very good hydrodynamic

performance has been the ambition of designers ever since the

first ships went out to sea. Hydrodynamic behavior is actually

the big issue of early design and one that requires skill and

experience. The time and effort involved in this design phase

are rather critical as they affect the competition of shipyards

and consultants today more than ever.

In recent years an effort has been made to produce

knowledge and tools to support early design. The key issue is

to be able to easily generate variants of an initial hull and

assess their hydrodynamic performance in order to take the

right decisions.

In this regard, the development of tools for parameter

shape modifications, the use of optimization techniques and

the optimization techniques and the development of CFD tools

are important and are expected to be exploited in early design

activities.

This paper presents a software tool for hull form

optimization based on a parameter approach to hull form

design and modifications. An application is discussed in detail

regarding the optimization of a DTMB5415 ship. This is

carried out based on both potential flow CFD with typical

design objectives and constraints.

Within this paper the synthesis model of hydrodynamic

optimization is first outlined. The novel approach of

parametric modeling of ship hull forms and the tools utilized

for hydrodynamic analysis are then briefly described.

Subsequently, the optimization environment employed to

establish the synthesis model is discussed.

I.

SYNTHESIS MODEL

The synthesis model of hydrodynamic optimization as

presented. comprises four modules, see figure 1:

Geometric modeling of the hull form,

Hydrodynamic analysis of the flow field,

Rational analysis of the associated performance,

Systematic change for improvement.

So as to take full advantage of this synthesis model, a

complete IT (information technology) integration is needed,

i.e., all modules need to be executed without manual

interference. In this way many more design variants can be

investigated than with traditional methods.

Initial

Optimized

Hull form

hull form

Shape

Shape design

variation

Genemetric

Optimization

Modeling

Change

strategy

(geom

parameters

(NLP)

constraints)

Geometric

description

Genemetric

Modeling

(geom

constraints)

Measure

of merit

Flow

field

Perfomance

analysis

Figure 1. Synthesis model of hydrodynamic optimization

II.

PARAMETRIC MODELING

A. GENERAL IDEA

The general idea of parametric modeling is to express

shapes in terms of their desired properties. The specified

1196

978-1-4673-0199-2/12/$31.00 2012 IEEE

properties are treated as input to a CAD system and the

modeling problem then reads: Produce a geometry such that

specified properties are directly met and the shape is

considered good within the design context.

This means that the language the designer uses is based

on high-level and problem-oriented vocabulary instead of the

low-level elements associated with a specific mathematical

representation. Rather than producing a hull form via points

(e.g. offsets, vertices etc.) and subsequently evaluating the

geometry (e.g. form parameters, basic longitudinal curves,

various ship lines, fairness etc.),the naval architect defines the

parameters and lets the system determine the corresponding

geometry. The form parameter approach thus reverses the

conventional modeling technique

B. CAD Tool : FRIENDSHIP MODELER

FRIENDSHIP system have been developed at TU Berlin.

The system follows the classic naval architect's technique of

describing a ship's geometry in terms of longitudinal curves

so-called basic curvesfrom which all design sections are

derived. Basic curves comprise positional, differential and

integral information. The design waterline, the center plane

curve and the deck are straight-forward examples of positional

basic curves. The sectional area curve is the most prominent

integral curve. An example for a differential basic curves is the

curve of sectional slopes at the design waterline. A flexible set

of basic curves is available to accommodate different hull

topologies. The shape of the envisioned hull is exclusively

defined in terms of form parameters from which the basic

curves are laid out. The basic curves then contain all

information necessary to subsequently create an ordered set of

design sections. A surface description of the hull is derived

using the design sections in an interpolation, approximation or

association scheme. The idea of the modeling process is

illustrated in figure 2.

manipulation is required. The advantage of the approach when

compared to traditional modeling techniques is that hull

shapes are generated and modified in a highly-concerted

manner, allowing to evoke both fine-tuned and considerable

changes in geometry by varying just a few selected form

parameters, thus making the FRIENDSHIP system a valuable

choice for formal hydrodynamic optimization.

III.

HYDRODYNAMIC ANALYSIS

A. GENERAL IDEA

At the preliminary design stage the evaluation of

hydrodynamic performance is carried out on the basis of

numerical simulations. For a thorough investigation calmwater resistance need to be taken into account.

B. WAVE RESISTANCE

In deep waters, ship is sailing at the speed of U in still water in

uniform. Assume that the fluid is inviscid, irrotational flow of

incompressible, the velocity potential exists as .Construct

the following definite solution of this problem :

2 = 0

Within the fluid domain V (1)

K

1

1

= (V + ) On the free surface SF (2)

g

2

K

( V ) + g z = 0 On the free surface SF (3)

K K

On the surface of the hull (4)

=V n

n

= ( 0 ,0, 0 )

At infinity

(5)

K

In (4), n is the unit normal vector of the hull

K

surface. V = (U ,0, 0)

The fluid velocity potential

is available when solving

the above problem. Then the fluid disturbance velocity

can be got. According to the Bernoulli equation, fluid pressure

distribution can be got.

1

p = (U x + gz )

2

(6)

The fluid pressure points along the wet surface of the

hull, the fluid forces and moments suffered by the hull can be

got:

K

K

F = ( F1 , F2 , F3 ) = pnds

SB

K

K K

M = ( M 1 , M 2 , M 3 ) = p(r n ) ds

(7)

SB

Figure 2 Parametric modeling process

The FRIENDSHIP system is completely based on Bspline curves and surfaces. Each B-spline is determined from

form parameters by optimizing suitable fairness criteria. Bspline vertices are treated as free variables while form

parameters represent equality constraints. Since fairness is an

intrinsic part of the generation process all shapes are smooth

and display excellent quality. No interactive vertex

Ship wave resistance:

Rw = F1 = pn1ds

SB

Dimensionless wave resistance coefficient:

1197

(8)

Cw =

Rw

(9)

1

V 2 S

2

Heave force and trim moment:

M 2 = p( zn1 xn3 ) ds

SB

F3 = pn3 ds

(10)

SB

NURBS-based high-order panel method has been used to

solve the fluid velocity potential. The fluid velocity potential

K

at the field point p :

( p) =

1

4

K 1

r

1

r

(q )( )dsq

SB + SF

(11)

K

r , r is the distance between field point p and

K

K

K

source point q ,meeting point q respectively. ( q ) is the

In(10):

strength of the distribution source.

The amount of the flow field (such as the hull surface

type value, the fluid velocity potential and the source intensity

distribution, etc.) are expressed by NURBS

m

i, j

p (u , v) =

d i , j N i ,k (u ) N j ,l (v)

i = 0 j =0

m n

i, j

(12)

N i , k (u ) N j ,l (v)

of one or more suitable measures of merit. The measures of

merit depend on a set of significant free variables that are

systematically changed in order to identify one or several

maximums or minimums. Often the search space is restricted

by a set of constraints imposed on the free variables and,

sometimes on the objective function itself. The objective

functions are usually calculated by means of sophisticated

simulation programs, here by means of CFD codes.

In order to set up the synthesis model of hydrodynamic

optimization, see figure 1,an environment is needed which

integrates the various modules of modeling, analysis,

evaluation and variation. This paper uses Friendship to achieve

the integration and optimization of each module.

V.

RESISTANCE PERFORMANCE

David - Taylor pool (DTMB) 5415 ship model has almost

the same shape with the U.S. Navy ship DDG51.DTMB5415

Hull line is a typical high-speed line for military vessels,

which has a huge sonar cover and a square tail. The resistance

performance optimization problem is: Optimize its shape

while meeting certain constraints to improve the resistance

properties. The main dimensions are listed in Table 1.

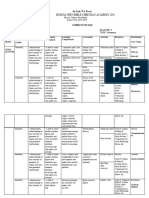

Table 1: DTMB5415 main elements

Waterline

Block

Bwl

Displacement

length

Draft(m)

coefficient

(m)

(t)

Lwl (m)

Cb

i =0 j =0

Where, i , j is the coefficients for NURBS weights

the control vertices,

d i , j is

N i ,k (u ) is k -order B-spline basis.

Calculate discretely in the parameter space

(u , v) .

Discretized (u , v ) into M N grid points. Express the

(11) discretely according to (12) and substituted into (2) - (4)

to get the fluid velocity type. Then yield the hull wave

resistance according to (8) and (9).

IV.

EXAMPLE OF DTMB5415 HULL LINE OPTIMIZATION ON

5.700

0.769

0.372

0.344

0.574

A. DTMB parametric geometry model

In this paper, Friendship software has been used to

achieve DTMB5415 parametric modeling of the whole ship, as

shown in Figure 3 .The global parameters constituting the ship

are listed in Table 2.

OPTIMIZATION

Optimization is the formal process of finding a good

(possibly the best)solution from a set of feasible alternatives. It

follows a rigid format that allows a unified problem

formulation but relies on the possibility to capture the problem

mathematically in respect to the following important terms:

(1)Measure(s)of merit The objective function(s),i.e.,

criterion/criteria, by which a solution is assessed.

(2)Free variables The independent decision variables that

can be modified directly and that uniquely describe the

optimization problem.

(3)Constraints The restrictions imposed on the search

space which reduce the possible combinations of free variables

to those that are considered feasible; one may further

distinguish bounds(i.e., upper and lower limits of each

variable),equality constraints and inequality constraints.

The general idea is that many optimization problems can

be formulated as the search for the minimum or the maximum

Figure 3 DTMB5415 parametric model

Table 2 Llist of the global parameters

1

2

3

4

5

Global

parameters

baseKeel

draft

maxLength

maxbeamAtDeck

midXpos

XAftbase

No.

XAp

8

9

10

Xforbase

XFp

XPeak

Significance

Bottom baseline height

Draft

Maximum length of the hull

half-width value at the deck

X coordinate at the maximum cross-section

The vertical position of baseline end point in the

tail

the X coordinate of end point on waterline at the

tail

X coordinate of first end point on baseline

X coordinate of first end point in waterline

x coordinate of the first front point

Positions of these characteristic parameters

corresponding in the hull geometry are shown in Figure 4.

1198

in

(1) Displacement constraints:

Disp

Disp

Disp

1%

(2) Vertical position of buoyancy center constraints:

Lcb o Lcb

Lcb o

Figure 4 The main geometric parameters reflected in the ship

hull

B. set design variables

This study is to optimize the sonar shield shape and select

the parameters which control the change of sonar shape as

design variables. The corresponding changing ranges are

shown in Table 3.

Of which: Disp o Disp were the initial displacement

and the optimized displacement, Lcb o Lcb were the initial

vertical position of buoyancy center and the optimized vertical

position of buoyancy center. In optimization, the change of

displacement and vertical position of buoyancy center are

within a certain range. According to the constraint of plus or

minus 1% ,the four binding parameters are defined in Table 4

below.

Table 3 Definition for design variables

No.

Variable name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

X_domeTip

dome_TipElevation

xtemlow

xminlow

domelowaftmidZ

XmaxH

domeupMaxH

domeupaftH

domemaxHprofile

domeupforfulns

domeaftmidH

fulnsatstemlow

domelowfulnsmid

domeupfulnsBeg

domeupfulnsEnd

domeupC1fullness

domelowForfullness

fulnsdomepffore

domeElevationMid

domeupForeTan

domeBeamtipfulns

Xmaxbeam

domeMaxbeam

domeaftbeam

domebeamc2TanEnd

Variable value

Variable

Variable

upper limit

lower limit

0.38

0.406

0.04

0.09

0.407

0.415

0.49

0.54

0.02

0.04

0.485

0.53

0.145

0.155

0.117

0.133

0.160

0.170

0.60

0.76

0.135

0.15

0.75

0.79

0.81

0.84

0.716

0.75

0.655

0.695

0.1

0.25

0.3

0.4

0.76

0.8

0.062

0.082

8

16

0.7

0.85

0.513

0.553

0.115

0.135

0.065

0.09

-18

-14

Table 4 Definition of constraint parameters

The initial

value

0.39485

0.0723

0.409818

0.515

0.03100467

0.50788434

0.149959

0.1251

0.165

0.68

0.143

0.77

0.828

0.73725

0.675

0.15

0.36

0.7835

0.072

15.2

0.8

0.533

0.1257

0.07503

-16

C. Definition of target parameters

As the ship belongs to high-speed boats, wave resistance

accounts for the main ingredients in the total resistance.

Therefore, wave resistance coefficient C w has been the chosen

as the target for optimization.

D.

1%

Set constraint

Choose the change of displacement and vertical position

of buoyancy center as constraint value to ensure the optimized

ship's displacement and vertical position of buoyancy center

does not change a lot, which are defined as follows:

Order

Number

Constraint

name

maxDisp

minDisp

maxLcb

minLcb

Meaning

Maximum

displacement

Minimum

displacement

maximum of

vertical

position of

buoyancy

center

minimum of

vertical

position of

buoyancy

center

Constraints

Constraint

parameter

<=0.558253

displacement

>=0.547198

displacement

<=3.55729

lcb

>=3.48685

lcb

E. Optimization algorithm

In this paper, the gradient algorithm (T-Search) has been

chosen as the optimization algorithm. This optimization

algorithm is a optimal solution within a small range of search.

When searching, a suitable direction is found for each time.

The chosen direction should make the search fastest, while

ensuring the search range is in the feasible region. In order to

achieve this goal, search along the direction of the constraint

tangent and ensure there is no constraint violations. In the

optimization process, the maximum number of calculation

times is 100.

F.

Results of resistance optimization

After 20h of computing, optimization results are in Table

5, Table 6 below. Comparison of the free surface wave

contour map and the side longitudinal waveform before and

after optimization are shown in Figure 5,comparison of the

surface before and after optimization is shown in Figure 6.

Table 5 Optimization result

No.

1

2

3

4

1199

Variable Description

Control

Variable name

parts

X_domeTip

Sonar

position

Variable value

The initial

Optimized

value

value

0.39485

0.38636

dome_TipElevation

0.0723

xtemlow

0.409818

0.05889

0.4148

xminlow

0.515

0.5067

domelowaftmidZ

0.03100467

0.02506

XmaxH

0.50788434

0.52099

domeupMaxH

8

9

0.149959

0.14613

domeupaftH

0.1251

0.13173

domemaxHprofile

0.165

0.16408

10

domeupforfulns

11

domeaftmidH

0.68

0.6086

0.143

0.13709

0.77

0.7697

12

fulnsatstemlow

13

domelowfulnsmid

0.828

0.8164

14

domeupfulnsBeg

0.73725

0.72873

15

domeupfulnsEnd

0.675

0.69410

16

domeupC1fullness

0.15

0.24096

17

domelowForfullness

0.36

0.33804

18

fulnsdomepffore

0.7835

0.793

19

domeElevationMid

0.072

0.07982

20

domeupForeTan

15.2

15.9

21

domeBeamtipfulns

0.8

0.73386

22

Xmaxbeam

0.533

0.5494

23

domeMaxbeam

0.1257

0.12567

24

domeaftbeam

0.07503

0.08338

25

domebeamc2TanEnd

-16

-17.92

Table 6 Comparison between constraint and objective

name

Initial

value

Optimized

value

lcb

3.28005

3.2912

0.552726

0.549639

0.89321677

0.67616622

Constraint

Disp

Objective

Cw10

Changing value

Backward

0.339%

Increase

0.5585%

-3

Decline 24.30%

Optimization

Original

Figure 6 Comparison of the surface before and after

optimization

From the comparison results we can see that the

optimized ship's wave resistance decreased 24.3%, vertical

position of buoyancy center move forward slightly and the

number of waveforms reduces near the optimized hull. Figure

10 illustrate the amplitude of wave slices in the vicinity of the

optimized bow becomes smaller.

VI.

CONCLUSION

In this paper, Friendship system software platform has

been used to complete the DTMB 5415 hull form

optimization. Following conclusions:

(1) Friendship based full hull line parametric modeling is

feasible and the hull line can be transformed automatically

through modifying the characteristic parameters.

(2) The optimization search of the ship space has been

completed by using gradient-based algorithm. Even though it

can get good result, further study is needed to judge whether it

is a global optimal solution.

(3) optimization of the ship takes long, further research is

needed to improve the optimization efficiency.

(4) The optimization goal of this paper is wave resistance

coefficient and further study is required for multi-objective

optimization methods.

ACKNOWLEDGEMENTS

The author is gratefully thankful to the research team

members and the Support of The 111 Project (B08031),

National Natural Science Foundation of China (No:51039006).

REFERENCES

[1]

[2]

[3]

Figure 5 comparison of the free surface wave contour map and

the side longitudinal waveform before and after optimization

[4]

1200

Neu,W.L.,W.H.Mason(2000). "A prototype tool for multidisciplinary

design optimization of ships" ,Ninth congress of the International

Maritime Association of the Mediterranean,Naples,Italy,pp 1-10.

Yang, Young-Soon, Chang-kue park(2006). "A Study on the Integration

of Interdisciplinary Ship Design Including Hull Form at thePreliminary

Design Stage," The Fourth China-Japan-Korea Joint Symposiumon

Optimization of Structural and Mechanical Systems, Kunming, China.pp

315-320.

Parsons Randall, L.Scott(2004). " Formulation of Multicriterion Design

Optimization problems for Solution with Scalar Numerical optimization

Methods, " JSR.

Feng, baiwei, Liu zuyuan(2009). Research and application on interface

technique for ship CAD/CFD integration optimization,SHIP

ENGINEERING,Vol31,PP116-120.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Document FileDokumen18 halamanDocument FileSalma SherbazBelum ada peringkat

- RingDokumen4 halamanRingSalma SherbazBelum ada peringkat

- 3-D Modeling of Axial Fans CFDDokumen20 halaman3-D Modeling of Axial Fans CFDmatteo_1234Belum ada peringkat

- Ship-to-Ship Interaction During Overtaki PDFDokumen16 halamanShip-to-Ship Interaction During Overtaki PDFSalma SherbazBelum ada peringkat

- Probabilistic Mechanics of Explosive FragmentationDokumen6 halamanProbabilistic Mechanics of Explosive FragmentationSalma Sherbaz100% (1)

- Mathematical Model of Different Differential EquationsDokumen13 halamanMathematical Model of Different Differential EquationsSalma SherbazBelum ada peringkat

- Analytical Prediction of Trajectories For High-Velocity Direct Fire Munitions PDFDokumen72 halamanAnalytical Prediction of Trajectories For High-Velocity Direct Fire Munitions PDFSalma SherbazBelum ada peringkat

- Explosive volcanic eruptions computedDokumen12 halamanExplosive volcanic eruptions computedSalma SherbazBelum ada peringkat

- Golden-Section Search For Optimization in 1-DDokumen7 halamanGolden-Section Search For Optimization in 1-DSalma SherbazBelum ada peringkat

- 127 132 PDFDokumen6 halaman127 132 PDFMuhammad IrfanBelum ada peringkat

- Ship Behavior in Shallow WaterDokumen20 halamanShip Behavior in Shallow WaterTomas GrigoliusBelum ada peringkat

- Airflow AnalysisDokumen7 halamanAirflow AnalysisSalma SherbazBelum ada peringkat

- CFD Fluent en El Casco DTMB 5415Dokumen34 halamanCFD Fluent en El Casco DTMB 5415klzsailingBelum ada peringkat

- A Practical System For Hydrodynamic Optimization of Ship Hull FormsDokumen7 halamanA Practical System For Hydrodynamic Optimization of Ship Hull FormsSalma SherbazBelum ada peringkat

- A Study of Spin Effects On Tennis Ball AerodynamicsDokumen8 halamanA Study of Spin Effects On Tennis Ball AerodynamicsFabrizzio ValerBelum ada peringkat

- Linear Programming With MatlabDokumen279 halamanLinear Programming With MatlabBinod Dhakal100% (2)

- Applications Diffrntl EqnsDokumen20 halamanApplications Diffrntl EqnsMujeeb AbdullahBelum ada peringkat

- CFD Fluent en El Casco DTMB 5415Dokumen34 halamanCFD Fluent en El Casco DTMB 5415klzsailingBelum ada peringkat

- 1029Dokumen15 halaman1029Richard Leonel Vasquez MezaBelum ada peringkat

- A Study On The Design Optimization of An AUV by Using Computational Fluid Dynamic AnalysisDokumen7 halamanA Study On The Design Optimization of An AUV by Using Computational Fluid Dynamic AnalysisSalma SherbazBelum ada peringkat

- Init Val ProblemsDokumen19 halamanInit Val ProblemsMujeeb AbdullahBelum ada peringkat

- 19.2 First Order Differential EquationsDokumen19 halaman19.2 First Order Differential EquationsSalma SherbazBelum ada peringkat

- Wave Restance For High-Speed CatamaransDokumen30 halamanWave Restance For High-Speed CatamaransKay OosterwegelBelum ada peringkat

- Eulers-Method Best Example of Using Euler Method in Chemical ReactionDokumen48 halamanEulers-Method Best Example of Using Euler Method in Chemical ReactionSalma SherbazBelum ada peringkat

- Mathematical Modeling and ODEDokumen44 halamanMathematical Modeling and ODESalma SherbazBelum ada peringkat

- Analysis of The Flow Around A Cruise Ferry Hull by The Means of CFDDokumen95 halamanAnalysis of The Flow Around A Cruise Ferry Hull by The Means of CFDSalma SherbazBelum ada peringkat

- Ordinary Differential Equation PDFDokumen12 halamanOrdinary Differential Equation PDFedisonmalahitoBelum ada peringkat

- Modeling Falling RaindropsDokumen8 halamanModeling Falling Raindropsohsnap1017Belum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Amsterdam Orphanage Design by Aldo Van EyckDokumen16 halamanAmsterdam Orphanage Design by Aldo Van EyckAr Shubham KumarBelum ada peringkat

- Elementry Shapes-1Dokumen3 halamanElementry Shapes-1SHEIKH SHABIRBelum ada peringkat

- Grade 10 - Lesson Plan - SimilarityDokumen4 halamanGrade 10 - Lesson Plan - SimilarityshipradangBelum ada peringkat

- MM MergedDokumen541 halamanMM MergedAkash KumarBelum ada peringkat

- A Glimpse of The Development of The Nab PDFDokumen44 halamanA Glimpse of The Development of The Nab PDFBetter Me PsychBelum ada peringkat

- Guidelines for solving projection of planes problemsDokumen2 halamanGuidelines for solving projection of planes problemsreddy rajaBelum ada peringkat

- Nid Mdes 2018Dokumen24 halamanNid Mdes 2018shivam agarwalBelum ada peringkat

- Section and Development of Solid ProblemsDokumen14 halamanSection and Development of Solid ProblemsNikhil AlunaBelum ada peringkat

- RotationDokumen7 halamanRotationShereen FizaBelum ada peringkat

- Fireworks Tutorial: Creating a Basic Logo in Under 40 StepsDokumen6 halamanFireworks Tutorial: Creating a Basic Logo in Under 40 Stepsamadeus_x64Belum ada peringkat

- Journal of Xi'an University Shape Functions Cubic TriangleDokumen11 halamanJournal of Xi'an University Shape Functions Cubic TrianglesunnywhizBelum ada peringkat

- DCO20001 - NGUYEN Thi Linh Chi - 103367449 - Chococup6Dokumen44 halamanDCO20001 - NGUYEN Thi Linh Chi - 103367449 - Chococup6Linh Chi NguyenBelum ada peringkat

- Appendix C - LEVEL OF DEVELOPMENTDokumen3 halamanAppendix C - LEVEL OF DEVELOPMENTHi HiBelum ada peringkat

- Math Curriculum Map-Grade-7-Quarter 3Dokumen4 halamanMath Curriculum Map-Grade-7-Quarter 3april joy makilanBelum ada peringkat

- Mapeh BowDokumen46 halamanMapeh Bowmyline estebanBelum ada peringkat

- AutoCAD Commands OverviewDokumen264 halamanAutoCAD Commands Overviewemperor_vamsiBelum ada peringkat

- Airfoil Optimization Paper ParsecDokumen7 halamanAirfoil Optimization Paper ParsecKavya M SBelum ada peringkat

- DK Workbooks Language Arts, Math and Science, Grade 2 by DKDokumen82 halamanDK Workbooks Language Arts, Math and Science, Grade 2 by DKJoyce Wang100% (5)

- Department of Education: Topic: Time Frame: Date: I. OutcomesDokumen3 halamanDepartment of Education: Topic: Time Frame: Date: I. Outcomesglenn paul catotoBelum ada peringkat

- Textile Repeats and PatternsDokumen17 halamanTextile Repeats and PatternsSuzenne Jyn Mendoza71% (7)

- 0580 w18 QP 33 PDFDokumen16 halaman0580 w18 QP 33 PDFHilmar AlfianBelum ada peringkat

- An Approach To Drawing FlowersDokumen3 halamanAn Approach To Drawing FlowersjzainounBelum ada peringkat

- Learning SketchupDokumen16 halamanLearning Sketchupgerardtt2772Belum ada peringkat

- Seminar Math 2016 Students ST Mary PDFDokumen40 halamanSeminar Math 2016 Students ST Mary PDFHadi Faizal Mohd RoselyBelum ada peringkat

- Handout 20299 AR20299-Aubin-AU2016Dokumen40 halamanHandout 20299 AR20299-Aubin-AU2016KelvinatorBelum ada peringkat

- 1Dokumen16 halaman1Tavish AppadooBelum ada peringkat

- Bansho Geometry 2d Student ExamplesDokumen21 halamanBansho Geometry 2d Student ExamplesMoHd ShukRiBelum ada peringkat

- Bond NVRDokumen28 halamanBond NVRTadmore Tutors TuitonBelum ada peringkat

- Area of A TrapezoidDokumen9 halamanArea of A TrapezoidGabriela IonitaBelum ada peringkat

- ICSEClass 2 Maths SyllabusDokumen8 halamanICSEClass 2 Maths Syllabussailasree potayBelum ada peringkat