Use of Steam and Co2 As Activating Agents

Diunggah oleh

vinodJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Use of Steam and Co2 As Activating Agents

Diunggah oleh

vinodHak Cipta:

Format Tersedia

Carbon, Vol. 33, No. 1, pp.

15-23, 1995

Copyright 0 1995 Elsevier Science Ltd

Pergamon

Printed in Great Britain. All rights reserved

0008.6223/95$9.50 + .OO

0008-6223(94)00100-6

THE USE OF STEAM AND CO2 AS ACTIVATING AGENTS

IN THE PREPARATION OF ACTIVATED CARBONS

F. RODRIGUEZ-REINOSO, M. MOLINA-SABIO and M. T. GONZALEZ

Departamento de Quimica InorgAnica, Universidad de Alicante, Apartado 99, E-03080 Alicante, Spain

(Received 22 February 1994; accepted in revised form 11 July 1994)

Abstract-Four

series of activated carbon have been prepared from carbonized olive stones. One of them,

series D, was prepared using carbon dioxide as activating agent, and the other three, series AV, W, and

H, with water vapor under different experimental conditions. Two of the series, D and H, were prepared

in such a way that the gasification rate for both reactants was identical, in an attempt to reduce the effect

of the relative differences in diffusion and accessibility of both gases to the interior of the particles. The

changes in porosity of the original char during activation have been studied by adsorption of N, at 77 K

and CO, at 273 K, as well as by mercury porosimetry. The results obtained show that carbon dioxide produces an opening, followed by widening, of narrow microporosity, whereas water vapor widens the microporosity from the early stages of the process, the resulting activated carbon exhibiting lower micropore

volume. However, dilution of water vapor and high activation temperatures approach the development

of total microporosity by steam to that of carbon dioxide, although there is a more important role of narrow microporosity widening in the former.

Key Words-Activated

carbon, CO, activation, steam activation, porosity development.

1. INTRODUCTION

the micropore volume of fibers activated with carbon

dioxide was larger than when activated with steam;

they claimed that steam produces a larger widening of

the micropores

(which become mesopores) than carbon dioxide.

In principle,

one could expect, following Wigmans[9], that the larger molecular dimensions of the

CO2 molecule would make the diffusion of this molecule through the pore system of the carbon particle

more difficult and slower, with subsequent more limited accessibility to the micropores and slower gasification rate. Although there seems to be no controversy

on the latter (slower gasification rate for CO& the effect on the development of porosity, especially that of

microporosity, does not seem to follow a clear tendency.

The general objective of this work is to study the

development

of porosity in a char subjected to gasification with steam and carbon dioxide. Since the

porosity is also dependent upon the experimental conditions used during activation, several series have been

prepared with steam by modifying the partial pressure

and the activation temperature. Two of the series were

prepared in such a way that the gasification rate with

both activating agents was identical, in an attempt to

reduce the relative differences in diffusion and accessibility of both gases.

The porosity of activated carbons is conditioned,

among other factors, by the carbonaceous

precursor

and the activation method used. In physical activation,

the gasification of a char with gases, the char is reacted

at high temperature (usually above 800C) with steam,

carbon dioxide, or a mixture of these. Both carbon dioxide and steam are mild oxidant at NO-95OC, and

eliminate carbon atoms from the char particle via CO

and/or CO + Hz, in such a way as to favor the selective burning of the interior of the particle, with the

subsequent creation of porosity[ 11.

The experimental

information

described in the literature on the gasification rate of different forms of

carbon, such as graphite[2,3],

coke[4], chars[5-71, or

carbon fibers@], show that, for a given temperature,

the reactivity with steam is larger than with carbon dioxide. However,

when the effect of the activating

agent on the development of porosity is analyzed, the

results do not show a clear tendency. Thus, Tomkov

et a/.[6], when activating brown coal cokes with carbon dioxide and steam to common degrees of burnoff, found that the latter produced activated carbons

with larger adsorptive capacity and wider pore size distribution, with a larger contribution

of mesoporosity.

This tendency is opposite to that described by Wigmans[9], who deduced that carbon dioxide widens the

microporosity

and leads to a larger mesopores/micropores ratio than steam. Kiilh et af.[4], for different

cokes activated in a range of temperatures (900-l lOOC),

showed that the BET surface area of cokes activated

with steam is, in general, larger than when using carbon dioxide in the preparation

of the activated carbons. However,

Ryu et a/.[8], found the opposite

effect when activating pitch-based carbon fibers, since

2. EXPERIMENTAL

All series of activated carbons were prepared from

a common precursor, a char obtained from olive stones

by carbonization

in nitrogen at 850C for 2 hours.

This char was activated in a horizontal furnace under

a constant flow of activating agent, using different

gases (steam and carbon dioxide), activation temper15

16

F.

RODRiGUEZ-REINOSO

ature, and residence time. In this way, four different

series were prepared:

1. Series D: CO* flow (80 ml/min) at 825C for different periods of time, to obtain activated carbons

in the burn-off range 8%80%.

2. Series AV: N,/water

vapor flow (80 ml/min), at

800C for different periods of time to cover the

burn-off range 9-74070.

3. Series W: 100% water vapor flow (100 ml/min,

provided by injection of 0.08 ml/min of liquid

water from a peristaltic pump) at 800C for different periods of time to cover the burn-off

range

lo-71%.

4. Series H: 100% water vapor flow (100 ml/min) at

750C for different periods of time to cover the

burn-off range 8-74%.

A more detailed description of experimental details

for the preparation

of series D, AV, and W can be

found in previous reports[lO-131.

The nomenclature

of all activated carbons includes the burn-off reached

in its preparation.

The comparison

of the changes in porosity of the

char produced by the different experimental

conditions has been based on some parameters

which,

though they do not completely characterize

the carbon, provide very useful information on the evolution

of the different pore size ranges. The parameters chosen are as follows:

1. Micropore volume deduced from the application of

the Dubinin-Raduskhevich

(DR) equation to the

adsorption

isotherms of Nz at 77 K and COZ at

273 K, I/,(N,) and Ve(CO,), respectively. Previous

work[14,15] has shown that the linear part of the

DR plot including experimental

data up to a relative pressure of P/P0 = 0.3, provides the total

volume of micropores,

including

the so-called

supermicropores[l6],

whereas the &(COz) value

(given the very low relative pressure range covered

at the temperature

of adsorption,

273 K) corresponds to the volume of narrow micropores (up to

about 0.7 nm).

2. Mesopore

volume deduced from the adsorption

isotherm of N, (77 K), calculated by subtracting

the value of V,(N,) from the amount adsorbed at

P/P0 = 0.95, Qss(N2) - V,(N,). In type I isotherms[l6], the amount adsorbed at pressures near

unity (0.95 in this case) corresponds

to the total

amount adsorbed in both the micropores (filled at

low relative pressures) and the mesopores (filled by

capillary condensation at pressures above 0.2), and

consequently

the subtraction

of V, from the total

amount will provide the volume of mesopores. This

parameter is very useful when comparing the porous texture of activated carbons.

3. Pore volume deduced from mercury porosimetry,

covering the pore size range 7.5-15000 nm, I$,,.

This value is sub-divided into Vmeao(pore size up

ef

d.

to 50 nm) and I,,,,,, (pore size larger than 50 nm),

following the recommendations

of the IUPAC[16].

This permits a more detailed comparison

of pore

structures in the activated carbons.

3. RESULTS

The weight losses (burn-off)

experienced

by the

char as a function of residence time for the four series

of activated carbon prepared are plotted in Fig. 1. It

is clearly shown that the gasification rate is constant

in all series except in series AV, activated with diluted

steam at 8OOC, for which the gasification

rate in

the first stages of the process is about 1% h- but it

increases from 30% burn-off to 1.7% h-. On the

other hand, the reactivity of the char with pure steam

at 800C (series W) is almost double that of series D

(activated with carbon dioxide), even though the activation temperature

for the latter is higher (825C).

In order to obtain activated carbons with steam having comparable gasification rates to those of series D,

the temperature

of gasification had to be lowered to

750C (series H).

The four series of activated carbons prepared will

show if the porosity developed by steam activation is:

1) a function of the gasification rate originated by the

changes in gasification temperature (series W and H);

2) a function of the activation temperature combined

with the dilution of water vapor, keeping to some extent the gasification rate (series AV and H), and 3) dif-

Burn-off

(%)

loo2

20

40

60

80

Time (h)

Fig. 1. Evolution of burn-off versus activation

bons gasified in CO2 and steam.

time for car-

Steam and COz as activating agents

n (mmol/g)

17

VHs@m3/s)

35

1.4

A74 \

meoo macro

\ -\

25

0.6-

0

0.0

0.2

0.4

0.6

0.6

1.0

P/P,

Fig. 2. Adsorption of N, at 77 K for some carbons of series

D, H, W, and AV.

Fig. 3. Cumulative pore volumes (mercury porosimetry) for

some carbons of series D, H, W, and AV (R, in nm).

ferent from the porosity developed by carbon dioxide

activation,

even though the gasification

rate is similar (series AV, H, and D).

Figure 2 includes some examples of N2 (77 K) adsorption isotherms and Fig. 3 some cumulative pore

volume plots deduced from mercury porosimetry,

in

all cases for activated carbons with comparable burnoff, but prepared using the different experimental conditions of the four series. On the other hand, Fig. 4

includes the plots for the evolution of the volume of

different pore size ranges as a function of burn-off,

deduced from the adsorption

of N, at 77 K and mercury porosimetry,

all data being referred to one gram

of activated carbon (see Table 1).

activation is simultaneously to enhance and widen narrow micropores, the latter effect predominating

above

30-40% burn-off, as denoted by the increasing value

of Vo(N,) with respect to Vo(C02). This widening of

microporosity

does not correspond with a remarkable

increase in the volume of mesopores (Fig. 4a), in contrast to the evolution of the volume of macropores,

which reaches values as high as the volume of micropores (compare Figs. 4a and 4~). Although the volumes

of Fig. 4c correspond to pore sizes larger than 7.5 nm,

and consequently

they include part of mesoporosity,

the proportion

of mesoporosity

is relatively small, as

deduced from Fig. 3 and Table 1.

3.1 Series D

In general terms, activation with carbon dioxide

uniformly develops all the pore size ranges of the carbon, in the sense that increasing activation produces

a continuous increase in the volume of micropores and

mesopores (Figs. 4a and 4b) and macropores (Fig. 4c).

Furthermore,

there is a linear relationship between the

different pore volumes and burn-off, with the exception of V,(N,). There is for Vo(N2) a more important

development

of microporosity

for burn-offs

above

40%. On the other hand, V,(N,) and ve(CO,) are coincident only up to about 20% burn-off (see Table I),

the difference in favor of Vo(N,) increasing with activation, especially above 40% burn-off. Consequently,

it is possible to state that the effect of carbon dioxide

3.2 Series AV

Activation with diluted steam at 800C produces,

as in the case of carbon dioxide, a development of all

ranges of porosity in the carbon. However, there are

some clear differences with respect to series D, which

are not important in the first stages of the process, but

become very important

at medium-high

burn-offs.

Thus, the development

of narrow microporosity

is

hindered in the activation with diluted steam, since

Ve(CO,) is almost constant with increasing activation

(Fig. 4b). This means that only widening of existing

narrow micropores occurs during activation, the value

of &(N,) being similar to series D. The difference is

more marked for the values of I&(N2)

- V,(N,),

mesoporosity

(Fig. 4a). In fact, the linear portions

of the adsorption

isotherm at medium-high

relative

F. RODRIGUEZ-REINOSO et al.

18

V (cm3 lg)

0.81

dA

q iW

OAV

AD

OH

qW

OH

b)

0.6

0

Burn-off

IfiD

Fig. 4. Evolution

20

40

60

80

Burn-off

(%)

OAV

o.oc-,

0

(%)

V,,(cm3/9)

T----

20

40

60

80

Burn-off

(%)

of pore volume (per gram of activated carbon) as a functions of burn-off:

micropores

N2, and -----mesopores;

b) micropores

CO,; c) V,,.

pressures (see Fig. 2) for carbons AV74 and D70 are

very different; the former exhibit a larger slope. This

difference means that activation with diluted steam essentially produces a widening of the micropores

to

meso and macropores,

the proportion

of mesopores

a) ~

being more important in series AV than in D, as shown

in Figs. 3 and 4a. Macropore size distribution

is also

different in the two series; the development

of largesize macroporosity

in series D constitutes an important contribution

to the total pore volume and it is

19

Steam and CO, as activating agents

Table 1. Pore volumes (cm3/g) for activated carbons series

CO, (273 K)

N, (77 K)

Carbon

Vo 0%)

vO.95

Vo

v,

(CO,)

VHg

Vmacro

VmeSO

D-8

D-19

D-34

D-52

D-70

D-80

0.26

0.31

0.39

0.55

0.67

0.78

0.03

0.03

0.04

0.03

0.05

0.05

0.26

0.30

0.36

0.41

0.47

0.51

0.21

0.33

0.47

0.64

0.78

0.93

0.10

0.23

0.40

0.57

0.70

0.81

0.11

0.10

0.07

0.07

0.08

0.12

AV-9

AV-17

AV-37

AV-53

AV-63

AV-74

0.26

0.28

0.41

0.52

0.65

0.77

0.01

0.03

0.11

0.17

0.18

0.31

0.27

0.28

0.31

0.33

0.33

0.34

0.21

0.24

0.47

0.66

0.83

1.33

0.08

0.10

0.32

0.49

0.59

0.93

0.13

0.14

0.15

0.17

0.24

0.40

w-10

W-23

w-41

W-58

w-71

0.24

0.32

0.47

0.62

0.73

0.01

0.03

0.06

0.08

0.12

0.23

0.27

0.30

0.32

0.31

0.22

0.39

0.57

0.66

1.15

0.14

0.30

0.45

0.50

0.90

0.08

0.09

0.12

0.16

0.25

H-8

H-22

H-37

H-52

H-74

0.24

0.33

0.39

0.46

0.55

0.01

0.04

0.04

0.06

0.08

0.21

0.25

0.28

0.30

0.29

0.47

0.53

0.51

0.58

0.94

0.19

0.28

0.41

0.45

0.72

0.28

0.25

0.10

0.13

0.22

uniformly

distributed up to log R = 2.0 (pore width =

200 nm), whereas the largest development in series AV

is localized in the pore size range log R = 2.5-3.0 (pore

width = 600-2000 nm).

size distributions (except in the mesoporosity),

but different from those obtained when activating with CO1

(series D).

3.4

3.3

Mercury porosimetry

Series W

Although series W has also been prepared by activation with steam, it is different from series AV in that

activation takes place in the former with 100% steam,

leading to a larger reactivity (Fig. 1). However, the development of porosity with increasing activation takes

place, in general terms, in a similar fashion to series

AV. In fact, only slight differences are observed in the

values of V,(N,), V,(CO,) and I&, the differences in

&,,(Nz) - Ve(N,) being larger. Such differences may

be observed in more detail in Fig. 2. Thus, the isotherms for AV74 and W71 exhibit a linear portion

of P/P0 = 0.3-0.8, that of the former having a larger

slope, thus indicating a larger development

of mesoporosity with diluted steam activation. Similar conclusions may be reached when comparing the cumulative

plots deduced from mercury porosimetry (Fig. 3). Although the general shape of the plots are similar, the

more marked differences are found in the pore volume

of the smallest pore widths (7.5 nm, log R = 0.57) and

for macropores

of around 1300 nm (log R = 2.8). It

seems then that activation with steam (both pure and

diluted) proceeds in a similar way, namely, widening

of the microporosity,

without appreciable creation of

new micropores.

It is true, however, that the widening is more important when the steam is diluted with

nitrogen. In any case, activation with the two modes

of steam produces activated carbons with similar pore

Series H

Carbons of series H, though prepared with steam

at the same gasification rate (by adjusting the activation temperature)

as series D with carbon dioxide, exhibit a porosity which in general terms is closer to

carbons of the other series prepared by activation with

steam (series AV and W) than to carbons of series D.

This is clearly shown by the similarity in the shape of

the adsorption isotherm of N2 (77 K) in Fig. 2 and the

cumulative pore volume plots deduced from mercury

porosimetry

(Fig. 3). Furthermore,

the evolution of

Ve(CO,) with burn-off for series H is similar to those

of series AV and W. However, the lower activation

temperature

develops to a lower extent all ranges of

porosity. In particular, the micropore and mesopore

volumes are lower than in the other two series, the volume of large size pores being rather similar at low and

medium burn-offs.

Consequently,

it seems as if the

pore size distribution

of the activated carbon is conditioned, in general terms, by the activating agent (carbon dioxide or steam) and not by the experimental

conditions used (temperature,

dilution), which have a

direct influence on the final volume of pores developed, at least in the cases under study here.

3.5

Evolution of porosity during activation

In order to better analyze the creation or destruction of pores during activation, it is much more convenient to use the results expressed per unit mass of

F. RODRIGUEZ-REINOSO et al.

20

the starting char[9,12,17],

as in Figs. 5a, 5b, and 5c.

There is in almost all plots an initial increase in adsorbed volume, followed by a decrease at higher

burn-offs. Therefore, only in the first stages of the ac-

tivation process (low burn-off)

is there creation of

porosity, the widening of which and burning of the exterior of the particle becoming significant at burn-offs

larger than 40 to 50%.

(cm3 /gchar)

AD

OAV

V,(C0,)(cm3

qW

a)

OH

/gchar)

AD

OAV

qW

b)

OH

0.3

0.0

0.0

20

40

60

80

20

40

60

Burn-off (%)

0.41

AD

OAV

Burn-off (96)

OW

cl

OH

0.3

0.2

0.1

0.0

0

20

40

60

80

Burn-off (%)

Fig. 5. Evolution of pore volume (per gram of starting char) as a function of burn-off.

pores N,, and ------

80

mesopores;

b) micropores

CO*; c) vHs.

a) _

micro-

Steam and CO2 as activating agents

It is important to note that the maximum development of micro and macroporosity

in series H (prepared at lower temperature)

takes place at around

20% burn-off, a value lower than for the maxima of

the other series, around 40%-50% burn-off. It is also

observed that for activation with water vapor (series H,

W, and AV) the increase in activation temperature and

the use of diluted steam favor the development

of

mesoporosity measured as V& - Vo(NZ), and of macroporosity (the latter at high burn-offs).

This development of porosity differs from the one observed for

carbon dioxide activation (series D) because, in this

case, activation produces a continuous destruction of

mesoporosity

(Fig. 5a), and there is a marked loss of

macroporosity

from 50% burn off (Fig. SC).

A more in-depth examination

of Fig. 5 permits a

better differentiation

among the series, since it reveals

details of the evolution of porosity in the char particle during activation. This evolution may be summarized for the four series as follows:

1. Series D: there is an opening of microporosity

(V,(CO,) and V,(N2) increase) up to about 20%

burn-off, followed by a widening (V,(NJ increases

and VO(COz) decreases) up to about 40%-50%

burn-off, the microporosity

decreasing thereafter.

A similar evolution is observed for VHgrwhich does

not correspond

to the continuous

decrease in the

mesoporosity

measured by adsorption,

V0,95(N2) b(N2).

2. Series AV: the evolution of microporosity

is similar to series D, the difference being that the widening of narrow micropores beings at lower burn-off

(~20%).

However,

the evolution of meso- and

macroporosity

is completely different, since it increases continually with burn-off.

3. Series W: the evolution of total microporosity,

Vo(N2), is similar to the two previous series, but

the narrow microporosity,

V,(CO,), is not developed and decreases after 20% burn-off at the same

rate as in series AV. The mesoporosity,

V0,&N2) Vo(N2), increases up to 40% burn-off, remaining

constant thereafter.

VHgfollows a similar pattern

to series AV, but the development

of porosity is

larger for series W at low-medium

burn-offs.

4. Series H: the evolution of narrow microporosity

is

different to the other series, since it is destroyed

from the first stages of activation. However, V,(N,)

increases as in the other series up to 20% burn-off,

the decrease at larger burn-offs taking place at a

higher rate than in any of the other series. Meso

and macroporosity

follow the same sequence as in

series D, but the destruction

of large-size porosity

takes place at lower rate in series H.

4. DISCUSSION

From the results presented above, one can deduce

that there are several factors (activation temperature,

21

steam dilution, and activating agent) conditioning the

porosity of the final activated carbon. In order to facilitate the discussion, it is better to differentiate

the

process for steam activation (influence of temperature

and dilution) and then to compare it with carbon dioxide activation.

4.1

Series H and W

When the activating gas comes in contact with

the char, it will react with both the exterior and the

interior of the particle, the latter requiring previous

diffusion of the activating gas. At the activation temperature used in the preparation

of series H, 75OC,

the diffusion rate of water molecules to the interior of

the particle is sufficiently high to expect a development

of the whole range of porosity, at least in the early

stages of activation. However, the progress of the reaction brings about the production

of CO and H-Z,

which are inhibitors of the reaction (especially H2).

The increase in the concentration

of inhibitors in the

interior of the particle will favor the reaction of steam

at the exterior, with the subsequent destruction of porosity. The results of Fig. 5 for series H show the predominance of external burning upon the reaction in

the interior of the particle at burn-offs higher than

20%. Up to 20% burn-off there is a widening of the

microporosity,

since V,(N,) increases and Vo(C02)

remains almost constant, with a simultaneous

slight

increase in Vo.,,(N2) - V,(N,) and V&. There is destruction of porosity for burn-offs larger than 20%,

especially in the range of microporosity,

since the volume of meso- and macroporosity

decreases slowly (the

widening of porosity produced by steam continues until the end of the process).

The increase in activation temperature

to 800C

(series W) makes the inhibiting effect of hydrogen less

effective[l8,19]

and, consequently,

one could expect

a larger development

of micro-, meso-, and macroporosity than in series H, with the maximum development of porosity displaced to larger burn-offs (around

50%, as shown in Fig. 5). Further increases in activation temperature

do not necessarily imply larger

development

of porosity because the rate for the carbon-Hz0

increases rapidly and the control of the reaction is more influenced by pore and bulk diffusion

effects. Under these conditions, the reaction would take

place predominantly

on the exterior of the particle

[2,20]. For this precursor, the maximum development

of porosity has been found to be in the 800-850C

range[21]. It is noteworthy that for both series W and

H the development

of micro- and macroporosity

is

high in comparison with the increase in mesoporosity

measured by Vo.ss(N2) - Vo(Nz). In fact, the changes

produced in the latter range of pore size are very small

in both series. It seems as though the development

of

macropores produced during activation is due mainly

to direct creation by action of the activating agent on

the exterior of the particles. Thus, the proportion due

to the widening of smaller pores is negligible, except

for carbons obtained at large burn-offs; the widening

F.

22

RODRiCLJEZ-REINOSO

of porosity compensating

the loss of macroporosity,

with a net creation in carbon W-71.

4.2

Series Hand

AV

When water vapor is diluted with nitrogen (series

AV), there is a decrease in gasification rate and, consequently, an increase in activation temperature is convenient. Under these conditions (inhibition by CO and

HZ is less effective due to the increase in temperature),

the reaction of the activating agent in the interior of

the particle is easier, with subsequent development of

micro and mesoporosity

in a wide range of burn-off,

and a simultaneous

retarded development

of macroporosity. Furthermore,

since the reaction in the interior of the particle is more favored than in series H,

there is (see Fig. 5) a creation of microporosity

(initial increase in the volume of narrow micropores) and

further widening of this porosity in a wide range of

burn-off.

The total volume of micropores,

V,(N,),

increases up to about 40% burn-off. This increase in

pore width means a net creation of mesoporosity

and

macroporosity,

which continues up to the end of the

process.

4.3

Series H, AV, and D

The comparison of activation with steam or carbon

dioxide is more complex since, 1) they have different

molecular dimensions, and 2) the reactivity, for a common temperature, is different. For a given porosity the

effective diffusivity of water vapor, with smaller molecular weight and dimensions, is estimated to be around

50% larger than that of carbon dioxide. Such ratio is

maintained approximately

constant with temperature

(in the 750~825C range), since the activation energy

value for the effective diffusivity is very low[20,22].

Consequently,

water vapor would be expected to develop the narrower microporosity

to a larger extent

than carbon dioxide. For series W and D, prepared at

similar temperature

and with a gas flow of 100% for

both activating agents, the results of Figs. 5a and 5b

do not show this expected behavior. This is because

steam produces widening of existing narrow micropores, increase in V,(N,) and decrease in l+,(CO,),

whereas carbon dioxide permits the creation of narrow

micropores, increase in ~&COz), in the first stages of

the process.

It could be argued that the differences found in series W and D are due to the larger experienced reactivity for steam and, consequently,

the results would

not be comparable,

since an increase in reactivity

could mean a larger contribution of mass transport effects over the chemical reaction[2]. A more appropriate comparison

would be to condition the activation

with carbon dioxide and steam in such a way that the

steam reaction produces the same rate of carbon atom

removal from the char as carbon dioxide. This can be

attained by either diluting the steam flow (first stages

of series AV) or by decreasing the reaction temperature (the whole series H), and comparing with series

D. As shown in Fig. 5a, dilution increases the development of microporosity

in the early stages of the ac-

et ai.

tivation process, though pore widening predominates

at burn-off larger than 10%. This widening is so pronounced that, at high burn-offs, the loss of porosity

of large dimensions by external burning is compensated

for, at least in part, by the widening of micropores.

From the results for series H and D (Figs. 4a, 4b,

5a, 5b), it is deduced that the development

of microporosity, as measured by V,(N,) and V,(CO,), by steam

gasification

is much lower than by carbon dioxide.

Furthermore,

as shown in Fig. 5b, there is a continuous destruction of narrow microporosity

in series H,

in contrast with the creation of this porosity taking

place in early stages of series D. On the other hand,

microporosity

widening predominates

to a larger extent for steam.

All results given above show that microporosity

widening is observed in all series prepared with steam,

and it seems relatively clear that the activating agent

is the parameter controlling to a larger extent the development of porosity. Carbon dioxide produces an

increase in narrow microporosity

in the early stages

of activation, whereas steam is more effective in micropore widening. The explanation

of the different

porous structure of activated carbons prepared by activation with steam and carbon dioxide is not simple,

but two hypotheses could be advanced. Considering

that activation is taking place in a char with a narrow

microporosity,

of pore width similar to the size of the

nitrogen molecule, as shown[23] by the fact that adsorption is a rate process with a positive temperature

coefficient (the adsorption of 90 K is much larger than

that of N2 at 77 K):

1) for a common overal reactivity, the water molecules within the porous structure react less selectively than carbon dioxide, producing micropore

widening. A previous work[24] has shown the different attack of carbon dioxide and steam on graphite, and it is ascribed to the fact that the carbon

dioxide is linear, with oxygen atoms in the two ends,

whereas the water molecule is angular, with oxygen in the middle.

2) activation with carbon dioxide leaves in the carbon

structure a larger number of oxygen surface groups

than steam[25]; these surface groups, in the activated carbons obtained in the early stages of activation (when porosity is still relatively narrow),

may act as constrictions

of the micropore, reducing the effective pore width. This effect will disappear at larger burn-offs,

when the pore size is

larger. Further work is in progress to determine

if this hypothesis can be proved to be the more

realistic.

5. CONCLUSIONS

The results described in this work are based on an

experimental program designed to elucidate the different effect of the activating agent (carbon dioxide or

steam) in the development

of porosity of a char obtained from olive stones. The four series of activated

Steam and CO, as activating

carbons prepared cover a wide range of experimental

conditions

and burn-off,

and include samples prepared with both activating

agents using the same

activation rate. The results clarify the apparent discrepancies in previous published work[4,6,8,9],

in the

sense that:

1) Carbon dioxide produces an opening, followed later

by widening, of narrow microporosity,

whereas

steam widens the microporosity

from the early

stages of the activation process, even in the case in

which the removal rate of carbon atoms from the

char is the same for the two activating agents.

2) For a common gasification

rate, activation with

pure steam leads to activated carbons with lower

micropore volume than carbon dioxide. However,

dilution of water vapor and high activation temperatures approach the development

of total microporosity by steam to that of carbon dioxide, although there is a more important role of narrow

microporosity

widening in the former.

3) Steam activation produces a larger development of

meso- and macroporosity

than carbon dioxide activation, the resulting activated carbon exhibiting

a wider pore size distribution.

Acknowledgements-This

work was supported

by the

DGICYT

(project

No. PB91-0747).

M.T.G.

thanks the

DGICYT for a fellowship to carry out this work.

REFERENCES

1. R. C. Bansal, J. B. Donnet, and H. F. Stoekcli, Active

Curbon. Marcel Dekker, New York (1988), p. 14.

2. P. L. Walker, Jr., F. Rusinko, Jr., and L. G. Austin, In

Advances in Catalysis (Edited by D. D. Eley, P. W. Selwood, and P. B. Weisz), Vol. XI, p. 133. Academic

Press, New York (1959).

3. G. R. Henning,

In Chemistry and Physics of Carbon

(Edited by P. L. Walker, Jr.), Vol. 2, p. 33. Marcel Dekker, New York (1966).

4. H. Kiihl, M. M. Kashani-Motlagh,

H. J. Miihlen, and

K. H. van Heek, Fuel 71, 879 (1992).

5. G. Q. Lu and D. D. Do, Carbon 30, 21 (1992).

agents

23

6. K. Tomkov, T. Siemieniewska,

F. Czechowski,

and A.

Jankowska,

Fuel 56, 121 (1977).

7. W. F. DeGroot and G. N. Richards,

Carbon 27, 247

(1989).

8. S. K. Ryu, H. Jin, D. Gondy, N. Pusset, and P. Ehrburger, Carbon 31, 841 (1993).

9. T. Wigmans, Carbon 27, 13 (1989).

A. Linares-Solano,

J. M. Martin10. J. Garrido-Segovia.

Martinez, M. Molina-Sabio,

F. Rodriguez-Reinoso,

and

R. Torregrosa, J. Chem. Sot., Faraday Trans. I 83, 1081

(1987).

A. Linares-Solano,

M. Molina11. F. Rodriguez-Reinoso,

Sabio, and I. Perez-Lled6,

Extended Abstracts 17th Biennial Conference on Carbon, Lexington,

KY (1985),

p. 239.

In Fundamental Issues in Con12. F. Rodriguez-Reinoso,

trol of Carbon Gasification Reactivity (Edited by J.

Lahaye and P. Ehrburger),

NATO ASI Series E-192,

p. 533. Kluwer Academic Publishers,

Dordrecht,

Netherlands (1991).

and F. Rodriguez13. M. T. GonzBlez, M. Molina-Sabio,

Reinoso, Proceedings Carbon 92, Essen, Germany, Paper P-C5, Deutsche Keramische

Gesellschaft

(1992),

p. 310.

J. M. Martin-Martinez,

14. J. Garrido, A. Linares-Solano,

M. Molina-Sabio,

F. Rodriguez-Reinoso,

and R. Torregrosa, Langmuir 3, 76 (1987).

J. Garrido, J. M. Martin-Martinez,

15. F. Rodriguez-Reinoso,

M. Molina-Sabio,

and R. Torregrosa,

Carbon 27, 23

(1989).

16. S. J. Gregg and K. S. W. Sing, Adsorption, Surface and

Porosity. Academic Press, London (1982).

17. H. Marsh and B. Rand, Carbon 9, 47 (1971).

and M. A. Elliott, In Chemis18. C. G. von Fredersdorff

try of Coal Utilization (Edited by H. H. Lowry), Supplementary

Volume, p. 754. Wiley, New York (1963).

C. Y. Chen, and D. S. Scott, Znd.

19. J. F. Johnstone,

Engng. Chem. 44, 1564 (1952).

Prog. Energy Combust. Sci. 4, 221

20. N. M. Laurendau,

(1978).

M. Molina-Sabio,

and F. Rodriguez21. M. T. Gonzilez,

Reinoso, Carbon 32, 1407 (1994).

22. G. F. Froment and K. B. Bischoff, Chemical Reactor

Anafysis and Design. John Wiley, New York (1979),

p. 163.

J. D. L6pez-Gonzrilez,

and C.

23. F. Rodriguez-Reinoso,

Berenguer,

Carbon 20, 513 (1982).

24. R. T. Yang and C. Wong, J. Catalysis 82, 245 (1983).

and F. Rodriguez25. M. T. Gonzrilez, M. Molina-Sabio,

Reinoso, Extended Abstracts 21st Biennial Conference

on Carbon, Buffalo, NY (1993), p. 416.

Anda mungkin juga menyukai

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasDari EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasBelum ada peringkat

- Development of The "Micro Combustor"Dokumen6 halamanDevelopment of The "Micro Combustor"Haris AbdullaBelum ada peringkat

- Production of Synthesis GasDokumen18 halamanProduction of Synthesis GasGonzalo TitoBelum ada peringkat

- MW 323Dokumen8 halamanMW 323dio prabowoBelum ada peringkat

- 49 1 Anaheim 03-04 0837Dokumen2 halaman49 1 Anaheim 03-04 0837castelo_grandeBelum ada peringkat

- 09 Combustion (Burners, Combustion Systems)Dokumen1 halaman09 Combustion (Burners, Combustion Systems)ahmed1581973Belum ada peringkat

- AC Catalst PTDokumen5 halamanAC Catalst PTJarretBelum ada peringkat

- Cooling Effect by Adsorption DesorptionDokumen5 halamanCooling Effect by Adsorption DesorptionParimal BhambareBelum ada peringkat

- Superficial VelocityDokumen8 halamanSuperficial VelocitybatazivoBelum ada peringkat

- Belghit 2009Dokumen6 halamanBelghit 2009mohammedelamenBelum ada peringkat

- Yeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Dokumen8 halamanYeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Mohammed AsherBelum ada peringkat

- Lewis Number Effects On Turbulent Burning VelocityDokumen8 halamanLewis Number Effects On Turbulent Burning VelocitycoccoBelum ada peringkat

- Production of Synthesis Gas: Caalysis Today, 18 (1993) 305-324Dokumen20 halamanProduction of Synthesis Gas: Caalysis Today, 18 (1993) 305-324ainmnrhBelum ada peringkat

- Gasification of Selected Woody PlantsDokumen8 halamanGasification of Selected Woody PlantsCitra Adelina SitorusBelum ada peringkat

- Effects of Wet CO Oxidation On The Operation of Engines and Power GeneratorsDokumen6 halamanEffects of Wet CO Oxidation On The Operation of Engines and Power GeneratorsEduardoBelum ada peringkat

- Unique Gasifier For Hydrogen Prod 2Dokumen15 halamanUnique Gasifier For Hydrogen Prod 2Arumugam RamalingamBelum ada peringkat

- Development of A Zero-Emissions Sulfur-Recovery Process. 1.Dokumen12 halamanDevelopment of A Zero-Emissions Sulfur-Recovery Process. 1.Soroosh ZareBelum ada peringkat

- Comparative Study Between Fluidized Bed and Fixed Bed ReactorsDokumen14 halamanComparative Study Between Fluidized Bed and Fixed Bed Reactorsanon_982022273Belum ada peringkat

- Applied Thermal Engineering: W.S. Loh, I.I. El-Sharkawy, K.C. NG, B.B. SahaDokumen6 halamanApplied Thermal Engineering: W.S. Loh, I.I. El-Sharkawy, K.C. NG, B.B. SahaMarijke HeggerBelum ada peringkat

- Feasibility of In-Situ Combustion of Tar From A Tarmat ReservoirDokumen16 halamanFeasibility of In-Situ Combustion of Tar From A Tarmat ReservoirReservorio UagrmBelum ada peringkat

- Optimisation of SRUDokumen12 halamanOptimisation of SRUHuzefaFDBelum ada peringkat

- Lopes2009 (Adsorber) PDFDokumen30 halamanLopes2009 (Adsorber) PDFmauraBelum ada peringkat

- P01 19 PDFDokumen0 halamanP01 19 PDFgarridolopezBelum ada peringkat

- Ni Catalysts With Mo Promoter For Methane Steam ReformingDokumen7 halamanNi Catalysts With Mo Promoter For Methane Steam ReformingGeorge CojocaruBelum ada peringkat

- Alvarez Galvan 2011 Applied Catalysis B EnvironmentalDokumen11 halamanAlvarez Galvan 2011 Applied Catalysis B EnvironmentalBabak RouhiBelum ada peringkat

- International Journal of Heat and Mass Transfer: Kuniyasu Ogawa, Yosuke Inagaki, Akio OhnoDokumen17 halamanInternational Journal of Heat and Mass Transfer: Kuniyasu Ogawa, Yosuke Inagaki, Akio OhnodzakyBelum ada peringkat

- Sadooghi PaperDokumen5 halamanSadooghi PaperKarlaqd CaramónBelum ada peringkat

- Hydrogen From SMR 1Dokumen2 halamanHydrogen From SMR 1Pramanshu RajputBelum ada peringkat

- MW 12Dokumen8 halamanMW 12dio prabowoBelum ada peringkat

- Research Article: Parametric Study of High-Efficiency and Low-Emission Gas BurnersDokumen8 halamanResearch Article: Parametric Study of High-Efficiency and Low-Emission Gas BurnersRolando PradaBelum ada peringkat

- Decrease in Carbonyl Sulfide in The Feed To Claus Converters Shift CatalystsDokumen3 halamanDecrease in Carbonyl Sulfide in The Feed To Claus Converters Shift CatalystsJoel OngBelum ada peringkat

- Preparation of Sorbents. The PotassiumDokumen5 halamanPreparation of Sorbents. The PotassiumFarah TalibBelum ada peringkat

- Get FileDokumen9 halamanGet FileAzza M. ElnenaeyBelum ada peringkat

- Co-Gasification of Colombian CoalDokumen7 halamanCo-Gasification of Colombian Coalwcamilo015Belum ada peringkat

- An Investigation of Reaction Furnace Temperatures and Sulfur RecoveryDokumen10 halamanAn Investigation of Reaction Furnace Temperatures and Sulfur RecoveryIffatBelum ada peringkat

- CO2 AdsorberDokumen5 halamanCO2 Adsorbersmastic8884985Belum ada peringkat

- Activation of Waste Tire Char Upon Cyclic Oxygen Chemisorption#DesorptionDokumen8 halamanActivation of Waste Tire Char Upon Cyclic Oxygen Chemisorption#DesorptionFrancisco HerasBelum ada peringkat

- Spontaneous Combustion Coal Parameters For The Crossing-Point Temperature (CPT) Method in A Temperature-Programmed System (TPS)Dokumen15 halamanSpontaneous Combustion Coal Parameters For The Crossing-Point Temperature (CPT) Method in A Temperature-Programmed System (TPS)lopohi2934Belum ada peringkat

- The Oxidation of Soot A Review of Experiments, Mechanisms and Modesl - Stanmore-Etal - 2001Dokumen22 halamanThe Oxidation of Soot A Review of Experiments, Mechanisms and Modesl - Stanmore-Etal - 2001Hemanth KappannaBelum ada peringkat

- Energy Efficiency in Building Using Co2 Heat Pump Water HeatingDokumen7 halamanEnergy Efficiency in Building Using Co2 Heat Pump Water HeatingMarclauryn AdewaleBelum ada peringkat

- Hydrogen As Future Energy SourceDokumen8 halamanHydrogen As Future Energy SourceWilliam ChangBelum ada peringkat

- Design, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed CombustionDokumen9 halamanDesign, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed Combustionapi-3799861Belum ada peringkat

- My Awma Paper VersionsDokumen97 halamanMy Awma Paper VersionsOμάδα 5Belum ada peringkat

- Hydrogen Production From Natural Gas Thermal Cracking: Design and Test of A Pilot-Scale Solar Chemical ReactorDokumen7 halamanHydrogen Production From Natural Gas Thermal Cracking: Design and Test of A Pilot-Scale Solar Chemical ReactorChandarshekar SwaminathanBelum ada peringkat

- Evaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresDokumen5 halamanEvaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresjulianapohlmannufrgsBelum ada peringkat

- 1 s2.0 001793108490262X MainDokumen18 halaman1 s2.0 001793108490262X MainReza KH100% (1)

- Chemical-Looping Combustion of Solid Fuels in A 10 KW Pilot - Batch Tests With Five FuelsDokumen8 halamanChemical-Looping Combustion of Solid Fuels in A 10 KW Pilot - Batch Tests With Five FuelsAzharuddin Ehtesham FarooquiBelum ada peringkat

- Ethylene Production Via Partial Oxidation and Pyrolysis of Ethane - M. Dente, A. Berettal, T. Faravelli, E. Ranzi, A. Abbr, M. Notarbartolo PDFDokumen6 halamanEthylene Production Via Partial Oxidation and Pyrolysis of Ethane - M. Dente, A. Berettal, T. Faravelli, E. Ranzi, A. Abbr, M. Notarbartolo PDFAlejandro HernandezBelum ada peringkat

- 1 s2.0 S1540748922002073 MainDokumen10 halaman1 s2.0 S1540748922002073 Main别康民Belum ada peringkat

- An Experimental Investigation of A Flue GasDokumen9 halamanAn Experimental Investigation of A Flue GasmichaelBelum ada peringkat

- Journal of The Energy Institute: Luning Tian, Wei Yang, Zhenhui Chen, Xianhua Wang, Haiping Yang, Hanping ChenDokumen7 halamanJournal of The Energy Institute: Luning Tian, Wei Yang, Zhenhui Chen, Xianhua Wang, Haiping Yang, Hanping ChenBill ChenBelum ada peringkat

- Ignition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionDokumen8 halamanIgnition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionthinhklBelum ada peringkat

- Report On Sulphur RecoveryDokumen9 halamanReport On Sulphur Recoveryvidit SinghBelum ada peringkat

- Minchao Han, Yuhua Ai, Zheng Chen, Wenjun Kong: A B A C ADokumen7 halamanMinchao Han, Yuhua Ai, Zheng Chen, Wenjun Kong: A B A C AEduardoBelum ada peringkat

- Process Optimization-Carrasquero (OQ8)Dokumen7 halamanProcess Optimization-Carrasquero (OQ8)raktim66Belum ada peringkat

- Activities and Selectivities Temperatures Relevant Chemical Interconversions Copper Metal-Oxide Catalysts at Heat-Pumps Based Isopropanol/ AcetoneDokumen4 halamanActivities and Selectivities Temperatures Relevant Chemical Interconversions Copper Metal-Oxide Catalysts at Heat-Pumps Based Isopropanol/ AcetoneOlga ĆalasanBelum ada peringkat

- Assignment 04,204107027Dokumen14 halamanAssignment 04,204107027Shanku Pratim BorahBelum ada peringkat

- Hong AnalysisDokumen38 halamanHong AnalysisleovenuBelum ada peringkat

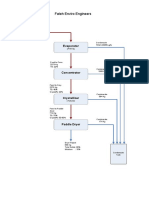

- Fateh Enviro Engineers SchemeDokumen1 halamanFateh Enviro Engineers SchemevinodBelum ada peringkat

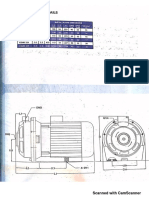

- Gokul - 8.7.16Dokumen8 halamanGokul - 8.7.16vinodBelum ada peringkat

- Final Theses Sunny M.Ed.Dokumen101 halamanFinal Theses Sunny M.Ed.vinodBelum ada peringkat

- Jay Ambe Axial Pump AF - 10 CurveDokumen1 halamanJay Ambe Axial Pump AF - 10 CurvevinodBelum ada peringkat

- Artificial IntelligenceDokumen14 halamanArtificial IntelligencevinodBelum ada peringkat

- Jay Ambe AF - 16 CurveDokumen1 halamanJay Ambe AF - 16 CurvevinodBelum ada peringkat

- Kriloskar KSMB Pump SeriesDokumen1 halamanKriloskar KSMB Pump SeriesvinodBelum ada peringkat

- 0.5 MLD PlantDokumen1 halaman0.5 MLD PlantvinodBelum ada peringkat

- Personality AssessmentDokumen69 halamanPersonality AssessmentvinodBelum ada peringkat

- IO Grundfos HEPDokumen100 halamanIO Grundfos HEPDeepikaBelum ada peringkat

- Operation Characteristic of A Mechanical Vapor Recompression Heat Pump Driven by A Centrifugal FanDokumen8 halamanOperation Characteristic of A Mechanical Vapor Recompression Heat Pump Driven by A Centrifugal FanvinodBelum ada peringkat

- Modeling of Ammonia Removal From Wastewater Using Air Stripping/ Modified Clinoptilolite: Reusability, Optimization, Isotherm, Kinetic, and Equilibrium StudiesDokumen22 halamanModeling of Ammonia Removal From Wastewater Using Air Stripping/ Modified Clinoptilolite: Reusability, Optimization, Isotherm, Kinetic, and Equilibrium StudiesvinodBelum ada peringkat

- Water Spray Reactor For Ammonia Removal Via Air Stripping: An Evaluation On Mass Transfer and Process EfficiencyDokumen8 halamanWater Spray Reactor For Ammonia Removal Via Air Stripping: An Evaluation On Mass Transfer and Process EfficiencyvinodBelum ada peringkat

- PT Mass BalanceDokumen3 halamanPT Mass BalancevinodBelum ada peringkat

- Img 0006-1Dokumen1 halamanImg 0006-1vinodBelum ada peringkat

- Chemical For NeutralizationDokumen2 halamanChemical For NeutralizationvinodBelum ada peringkat

- Stripper ColumnDokumen1 halamanStripper ColumnvinodBelum ada peringkat

- Effluent DataDokumen1 halamanEffluent DatavinodBelum ada peringkat

- Manish KumarDokumen4 halamanManish KumarvinodBelum ada peringkat

- Process Biochemistry: Beatriz Veleirinho, J.A. Lopes-da-SilvaDokumen4 halamanProcess Biochemistry: Beatriz Veleirinho, J.A. Lopes-da-SilvavinodBelum ada peringkat

- Solving PH Problems On A SpreadsheetDokumen6 halamanSolving PH Problems On A SpreadsheetvinodBelum ada peringkat

- FSSAIDokumen1 halamanFSSAIvinodBelum ada peringkat

- Evap DDokumen27 halamanEvap DvinodBelum ada peringkat

- Activated Carbons From LignocellulosicDokumen8 halamanActivated Carbons From LignocellulosicvinodBelum ada peringkat

- Operating Cost Analysis and Treatment of Domestic Wastewater by Electrocoagulation Using Aluminum ElectrodesDokumen7 halamanOperating Cost Analysis and Treatment of Domestic Wastewater by Electrocoagulation Using Aluminum ElectrodesvinodBelum ada peringkat

- Removal of Color in Cane Juice ClarificationDokumen8 halamanRemoval of Color in Cane Juice ClarificationFederico LeonBelum ada peringkat

- Sugarcane Material 2520balanceDokumen7 halamanSugarcane Material 2520balanceSagir AdamuBelum ada peringkat

- Crest Cellulose - Heat and Mass AblanceDokumen1 halamanCrest Cellulose - Heat and Mass AblancevinodBelum ada peringkat

- Units 6-10 Review TestDokumen20 halamanUnits 6-10 Review TestCristian Patricio Torres Rojas86% (14)

- Navamsa Karma and GodDokumen9 halamanNavamsa Karma and GodVisti Larsen50% (2)

- A Scenario of Cross-Cultural CommunicationDokumen6 halamanA Scenario of Cross-Cultural CommunicationN Karina HakmanBelum ada peringkat

- Csm6 Ext1y11 BookDokumen955 halamanCsm6 Ext1y11 BookJesse Davis100% (12)

- Diagnosis: Acute GastroenteritisDokumen1 halamanDiagnosis: Acute GastroenteritisSakshi RanabhatBelum ada peringkat

- 1929 Davos DisputationDokumen20 halaman1929 Davos DisputationEstevao Cruz100% (1)

- 9.2 Volumetric Analysis PDFDokumen24 halaman9.2 Volumetric Analysis PDFJoaquinBelum ada peringkat

- TOEIC® Practice OnlineDokumen8 halamanTOEIC® Practice OnlineCarlos Luis GonzalezBelum ada peringkat

- Middle Grades ReportDokumen138 halamanMiddle Grades ReportcraignewmanBelum ada peringkat

- Amtek Auto Analysis AnuragDokumen4 halamanAmtek Auto Analysis AnuraganuragBelum ada peringkat

- Donna Claire B. Cañeza: Central Bicol State University of AgricultureDokumen8 halamanDonna Claire B. Cañeza: Central Bicol State University of AgricultureDanavie AbergosBelum ada peringkat

- (Durt, - Christoph - Fuchs, - Thomas - Tewes, - Christian) Embodiment, Enaction, and Culture PDFDokumen451 halaman(Durt, - Christoph - Fuchs, - Thomas - Tewes, - Christian) Embodiment, Enaction, and Culture PDFnlf2205100% (3)

- Polynomials Level 3Dokumen17 halamanPolynomials Level 3greycouncilBelum ada peringkat

- Unsaturated Polyester Resins: Influence of The Styrene Concentration On The Miscibility and Mechanical PropertiesDokumen5 halamanUnsaturated Polyester Resins: Influence of The Styrene Concentration On The Miscibility and Mechanical PropertiesMamoon ShahidBelum ada peringkat

- Oration For Jon Kyle ValdehuezaDokumen2 halamanOration For Jon Kyle ValdehuezaJakes ValBelum ada peringkat

- Vrushalirhatwal (14 0)Dokumen5 halamanVrushalirhatwal (14 0)GuruRakshithBelum ada peringkat

- Vocabulary Task Harry PotterDokumen3 halamanVocabulary Task Harry PotterBest FriendsBelum ada peringkat

- Angel Number 1208 Meaning Increased FaithDokumen1 halamanAngel Number 1208 Meaning Increased FaithKhally KatieBelum ada peringkat

- Soal Midtest + Kunci JawabanDokumen28 halamanSoal Midtest + Kunci JawabanYuyun RasulongBelum ada peringkat

- 115 FinargDokumen294 halaman115 FinargMelvin GrijalbaBelum ada peringkat

- RPT Form 2 2023Dokumen7 halamanRPT Form 2 2023NOREEN BINTI DOASA KPM-GuruBelum ada peringkat

- Context: Lesson Author Date of DemonstrationDokumen4 halamanContext: Lesson Author Date of DemonstrationAR ManBelum ada peringkat

- Bird Beak ActivityDokumen4 halamanBird Beak Activityapi-314222661Belum ada peringkat

- Baltimore Catechism No. 2 (Of 4)Dokumen64 halamanBaltimore Catechism No. 2 (Of 4)gogelBelum ada peringkat

- Radiopharmaceutical Production: History of Cyclotrons The Early Years at BerkeleyDokumen31 halamanRadiopharmaceutical Production: History of Cyclotrons The Early Years at BerkeleyNguyễnKhươngDuyBelum ada peringkat

- WWW - Ib.academy: Study GuideDokumen122 halamanWWW - Ib.academy: Study GuideHendrikEspinozaLoyola100% (2)

- 38 Page 2046 2159 PDFDokumen114 halaman38 Page 2046 2159 PDFAkansha SharmaBelum ada peringkat

- In Christ Alone My Hope Is FoundDokumen9 halamanIn Christ Alone My Hope Is FoundJessie JessBelum ada peringkat

- Assignment Submission Form: Pgid Name of The MemberDokumen9 halamanAssignment Submission Form: Pgid Name of The MemberNamit GaurBelum ada peringkat

- Broshure JepanDokumen6 halamanBroshure JepanIrwan Mohd YusofBelum ada peringkat