Disclosure To Promote The Right To Information

Diunggah oleh

Santosh KumarDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Disclosure To Promote The Right To Information

Diunggah oleh

Santosh KumarHak Cipta:

Format Tersedia

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

1 +, 1 +

01 ' 5

The Right to Information, The Right to Live

Step Out From the Old to the New

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

IS 101-4-3 (1988): Methods of Sampling and Test for Paints,

Varnishes and Related Products, Part 4: Optical Tests,

Section 3: Light Fastness Test [CHD 20: Paints, Varnishes

and Related Products]

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

UDC

66761

: 53568317

First Reprint

FEBRUARY

IS:101

1990)

(Part4/Sec3)-1988

Indian Standard

( Reaffirmed 2004 )

METHODS OF SAMPLING AND TEST FOR

PAINTS, VARNISHES AND RELATED PRODUCTS

PART

Section

OPTICAL

Light

TESTS

Fastness

Test

( Third Revision)

of light fastness of paints for interior

use t

1. Scope - Prescribes a method for the determination

exposure to light from artificial sources under prescribed conditions.

In case of dispute, the xenon arl

shall be used as referee method.

2. Apparatus

2.1 Apparatus

embodying

either a xenon lampor carbon arc may be used.

2.1.1 Test chamberThe test chamber shall consist essentially

of a ventilated enclosure at the

centre of which the source or radiation shall be situated. The test panels shall be held on a suitabli

rack arranged symmetrically around the source so that the irradiance falling on any part of the panel!

does not vary from the mean value by more than f10

percent. The panel rack may be rotates

continuously

around the radiation source to improve the aven distribution

of the light.

The enclosure shall be so constructed

come into contact with the test panels.

The conditions

that any ozone produced

by the radiation

source

does

no1

in the test chamber shall be as follows:

Air temperature

35f5C

Black panel temperature

Relative humidity

50f5C

65A5 percent

2.1.2 Radiation source - The radiation source shall consist of a .suitable xenon lamp or carbon arc,

together with an appropriate filter system which does not significantly

alter the visible output of the arc.

The irradiance on the panels shall be lOOrt25 W/m2 in the range 310 to 400 nm. The irradiance al

wavelengths shorter than 310 nm shall not exceed 05 W/m.

If there is doubt as to whether a particular type of equipment is in accordance with this standard,

Note lshall be established by the user, by the manufacturer of the equipment or by an independent test authority.

Note 2 - In view of the short-term fluctuations of the output of the carbon arc, it is eSSentiSl that

the irradiance shall be taken over a period of not less than 6 h.

2.1.3 The foltowing

for,

items are,alsa required.

2.1.3.1

Cover sheet-

2.1.3.2

Co/our matching cabinet

of aluminium

foil.

2.1.3.3 Calibration standards - For example, wool scqle patterns complying

Method for determination of colour fastness of textile materials to daylight.

2.1.3.4 Cardboard - of thickness

dyed wool calibration standards.

2.1.3.5 Geometric grey scale :olour ( first revision ).

3. Preparation

the average

this

and Coating

approximately

complying

with

05 mm and of rigid

IS : 768-1982

Method

with

quality

IS : 686-1985

for mounting

for evaluating

the

change in

of Test Panel

B.1Unless

otherwise

agreed, use a panel of hard aluminium

and coat it with an etch primer. The

limensions of the panel shall be suitable for the apparatus being used but shall not in any case be

;maller than 60 mm x40 mm.

Adopted

Gr 1

Q September 1988, BIS

30 March 1988

I

BUREAU

MANAK

I

OF

BHAVAN,

INDIAN

STANDARDS

9 BAHADUR SHAH

NEW DELHI 110002

ZAFAR

MARG

IS : 101 ( Part 4/Set

3 ) - 1988

3.2

Coat the panel with theproduct

under test by the specified method and allow it to dry ( or stove )

If normal drying conditions

are specified,

and age in the specified manner and for the specified time.

humidity

of 6525

percent

with

these shall be interpreted

as a temperature

of 2722%

and a relative

free circulation of air and no exposure to direct sunlight.

4. Procedure

4.1 Cover half of the test panel and, where appropriate, the calibration

standard

cover sheet (2.1.3.1 ) and expose it in the apparatus for the specified period.

( 2.1.3.3 ) with

the

This procedure advocates the use of the unexposed area adjacent to the exposed area for

comparison, which is useful for checking the progress of the exposure.

Comparisons,

however, shall

be based on contrast with a reference sample or other agreed standard.

4.2 At regular intervals, remove the test panel from the apparatus, remove the cover sheet and observe

the degree of colour change on the test panel and standard.

The comparison shall be carried out in the colour matching

colour change may be determined instrumentally.

cabinet

(2.1.3.2).

If agreed, the

Use may be made of the geometric grey scale ( 2.1.3.5 ), in recording the degree of colour

change. If the test is to be continued, carefully replace the cover sheet in its original position.

4.3 Access the

requirements.

degree

of

light

fastness

of the

test panel

in terms

of the

specified

or agreed

5. Mofiitoring

6.1 The irradiance is specified ( 2.1.2 ) but is liable to fall during operation owing to progressive

ageing of the lamps and filters, inefficient cleaning or incorrect operation.

The user shall, therefore,

carry out regular and frequent checks on the output of the radiation source.

5.2 The checking procedure is not specified

method may be based include the following:

in this

standard.

The

a) Measurement

of the spectral energy distribution

b) Measurement

of irradiance in Gave bands using a photo-electric

c) Chemical actniometry

d) Measurement

polymers.

principles

on which

a suitable

by means of a suitable spectrophotometer;

device with suitable filters;

with suitable filters; and

of actinic effect, for example, by means of blue wool standards or photosensitive

5.3 Should the check. procedure indicate that the irradiance has fallen outside the specified limits,

action shall be taken to restore the radiation to its original level. This may entail renewal of the lamp,

cleaning or renewal of the filters or attention to the operating conditions.

EXPLANATORY

NOTE

This standard is one of a series of standards on paints, varnishes and related products. The

method specified in this standard if carried out under prescribed conditions

have been shown to

correlate acceptably with exposure to daylight through glass. For critical application,

the user should

generally satisfy himself that the degree of correlation is acceptable for this purpose. This standard

supersedes 12 of IS : 101-1964 Methods

of test for ready mixed paints and enamels ( second

revision

).

2

Reprography

Unit,

BE,

New Delhi,

India

Anda mungkin juga menyukai

- New Sensors and Processing ChainDari EverandNew Sensors and Processing ChainJean-Hugh ThomasBelum ada peringkat

- Photonics, Volume 2: Nanophotonic Structures and MaterialsDari EverandPhotonics, Volume 2: Nanophotonic Structures and MaterialsBelum ada peringkat

- Is 7666 1988Dokumen9 halamanIs 7666 1988chepurthiBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen9 halamanDisclosure To Promote The Right To Informationrajpd28Belum ada peringkat

- IEC 60793-1-52 (2001) Change of TemperatureDokumen10 halamanIEC 60793-1-52 (2001) Change of TemperaturejudyyangchBelum ada peringkat

- IEC 60793-1-51 (2001) Dry HeatDokumen10 halamanIEC 60793-1-51 (2001) Dry HeatjudyyangchBelum ada peringkat

- Is 101 6 5 1997 PDFDokumen23 halamanIs 101 6 5 1997 PDFdombipinBelum ada peringkat

- Astm D2565.1970 (Uv)Dokumen2 halamanAstm D2565.1970 (Uv)toys_chileBelum ada peringkat

- Is 101 - 4 - 2Dokumen6 halamanIs 101 - 4 - 2GopalMahantaBelum ada peringkat

- F2393 1479757-1Dokumen3 halamanF2393 1479757-1Thaweekarn ChangthongBelum ada peringkat

- C848 88 (2016)Dokumen7 halamanC848 88 (2016)werrteBelum ada peringkat

- ASTM D 1746-97 TH 2002Dokumen5 halamanASTM D 1746-97 TH 2002Rahartri KelikBelum ada peringkat

- Haze and Luminous Transmittance of Transparent Plastics: Standard Test Method ForDokumen6 halamanHaze and Luminous Transmittance of Transparent Plastics: Standard Test Method ForBrando VenturaBelum ada peringkat

- IEC 60793-1-50 (2001) Damp HeatDokumen10 halamanIEC 60793-1-50 (2001) Damp HeatjudyyangchBelum ada peringkat

- Is 13360 6 9 2001Dokumen12 halamanIs 13360 6 9 2001Surendra singh nathawatBelum ada peringkat

- IEC 60793-1-53 (2001) Water ImmersionDokumen9 halamanIEC 60793-1-53 (2001) Water ImmersionjudyyangchBelum ada peringkat

- Astm d4752 Rub TestDokumen8 halamanAstm d4752 Rub Testhelioxavier2100% (1)

- Is 4260 2004Dokumen10 halamanIs 4260 2004Mehmet SoysalBelum ada peringkat

- Sizing and Counting Particulate Contaminant in and On Clean Room GarmentsDokumen8 halamanSizing and Counting Particulate Contaminant in and On Clean Room GarmentsangeljosechuquiureBelum ada peringkat

- Magnetic Particle Test Inspection Free NDT Sample ProcedureDokumen8 halamanMagnetic Particle Test Inspection Free NDT Sample ProcedureBhavani Prasad0% (1)

- Ultrasonic TestDokumen11 halamanUltrasonic TestHarry DobleBelum ada peringkat

- Eurovent-4 10Dokumen32 halamanEurovent-4 10MichaelBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen11 halamanDisclosure To Promote The Right To Informationraisingh085Belum ada peringkat

- Disclosure To Promote The Right To InformationDokumen11 halamanDisclosure To Promote The Right To InformationnmclaughBelum ada peringkat

- Exposure Procedure For Artificial WeatheringDokumen10 halamanExposure Procedure For Artificial WeatheringDung TienBelum ada peringkat

- IEC 60793-1-54 (2003) Gamma IrradiationDokumen12 halamanIEC 60793-1-54 (2003) Gamma IrradiationjudyyangchBelum ada peringkat

- D 589 - 97 R02 - Rdu4oqDokumen5 halamanD 589 - 97 R02 - Rdu4oqAngel ValladaresBelum ada peringkat

- E 2073 - 00 RtiwnzmtukveDokumen4 halamanE 2073 - 00 RtiwnzmtukvewpmhatBelum ada peringkat

- C1510 01 (2016)Dokumen3 halamanC1510 01 (2016)masoud132Belum ada peringkat

- British Smoke Opacity TestingDokumen6 halamanBritish Smoke Opacity TestingAnneke VermaakBelum ada peringkat

- D1474Dokumen5 halamanD1474hdanyealBelum ada peringkat

- X-Ray Spectrometric Analysis of Lime and Limestone: Standard Test Method ForDokumen5 halamanX-Ray Spectrometric Analysis of Lime and Limestone: Standard Test Method Forbaher74Belum ada peringkat

- Astm d4986 1998Dokumen8 halamanAstm d4986 1998zeqs9Belum ada peringkat

- Norma Holiday Detector ASTM D5162-2001 PDFDokumen4 halamanNorma Holiday Detector ASTM D5162-2001 PDFDuverlyOrlandoMattaVásquez100% (1)

- E2193 02Dokumen3 halamanE2193 02Luz Ma R CBelum ada peringkat

- D589 - 97 Standard Test Method For Opacity of Paper (15°/diffuse Illuminant A, 89 % Reflectance Backing and Paper Backing)Dokumen5 halamanD589 - 97 Standard Test Method For Opacity of Paper (15°/diffuse Illuminant A, 89 % Reflectance Backing and Paper Backing)SubidorDeLibrosBelum ada peringkat

- Astm G 23Dokumen9 halamanAstm G 23Carlos AméricoBelum ada peringkat

- Procedure For UT TestingDokumen13 halamanProcedure For UT TestingKarrar TalibBelum ada peringkat

- Astm D1840Dokumen5 halamanAstm D1840BambangSubagio100% (4)

- TM116Dokumen3 halamanTM116qualityc711Belum ada peringkat

- B 926 - 03 - QjkyngDokumen2 halamanB 926 - 03 - Qjkyngmalika_00Belum ada peringkat

- D 6500 - 00 - Standard Test Method For Diameter of Wool and Other Animal Fibers Using An Optical Fiber Diameter AnalyserDokumen12 halamanD 6500 - 00 - Standard Test Method For Diameter of Wool and Other Animal Fibers Using An Optical Fiber Diameter Analyserlywu2000100% (1)

- D 542 - 95 - Rdu0mi1sruq - PDFDokumen5 halamanD 542 - 95 - Rdu0mi1sruq - PDFAndre CasteloBelum ada peringkat

- Keur 00822-108 200601Dokumen3 halamanKeur 00822-108 200601erik0007Belum ada peringkat

- PV 1303Dokumen10 halamanPV 1303tufantasma100% (2)

- Total Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceDokumen5 halamanTotal Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceJesus Gonzalez GracidaBelum ada peringkat

- D 5757 - 95 - Rdu3ntctukveDokumen4 halamanD 5757 - 95 - Rdu3ntctukveDH BBelum ada peringkat

- Thickness of Lightly Doped Silicon Epitaxial Layers On Heavily Doped Silicon Substrates Using An Infrared Dispersive SpectrophotometerDokumen8 halamanThickness of Lightly Doped Silicon Epitaxial Layers On Heavily Doped Silicon Substrates Using An Infrared Dispersive Spectrophotometervuqar0979Belum ada peringkat

- Ultrasonic ProcedureDokumen31 halamanUltrasonic ProcedureChristopher Jones100% (1)

- Method 13a - DeterminationDokumen30 halamanMethod 13a - DeterminationShakti MohapatraBelum ada peringkat

- D 4752 - 98 - Rdq3ntitotgDokumen8 halamanD 4752 - 98 - Rdq3ntitotgmorchedtounsiBelum ada peringkat

- G76 30608-1Dokumen6 halamanG76 30608-1Alejandro Valdés RojasBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen8 halamanDisclosure To Promote The Right To InformationSantosh KumarBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen10 halamanDisclosure To Promote The Right To InformationSaptarshi SenguptaBelum ada peringkat

- UT Equipment Calibration ProcedureDokumen14 halamanUT Equipment Calibration ProcedureSantanu Saha100% (4)

- Physical Pharmaceutics-II Lab Manual as per the PCI SyllabusDari EverandPhysical Pharmaceutics-II Lab Manual as per the PCI SyllabusBelum ada peringkat

- Reliability Investigation of LED Devices for Public Light ApplicationsDari EverandReliability Investigation of LED Devices for Public Light ApplicationsBelum ada peringkat

- Humidity MIL-STD-810E 507.3 PDFDokumen17 halamanHumidity MIL-STD-810E 507.3 PDFSantosh KumarBelum ada peringkat

- Packaged Water Everywhere: Not All Brands Fit To DrinkDokumen10 halamanPackaged Water Everywhere: Not All Brands Fit To DrinkSantosh KumarBelum ada peringkat

- Uncertainty Estimation For SDAR-OES Internal Standard MethodDokumen7 halamanUncertainty Estimation For SDAR-OES Internal Standard MethodSantosh KumarBelum ada peringkat

- Iso-648 Laboratory Glassware - Single-Volume PipettesDokumen18 halamanIso-648 Laboratory Glassware - Single-Volume PipettesDawn HaneyBelum ada peringkat

- IA-05Vector Product of Two Vectors (28-30)Dokumen1 halamanIA-05Vector Product of Two Vectors (28-30)Santosh KumarBelum ada peringkat

- 10Dokumen94 halaman10Santosh KumarBelum ada peringkat

- Amh43 209-152Dokumen4 halamanAmh43 209-152Santosh KumarBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen6 halamanDisclosure To Promote The Right To InformationSantosh KumarBelum ada peringkat

- Is 2266 2002Dokumen24 halamanIs 2266 2002Santosh KumarBelum ada peringkat

- Is 10810 5 1984Dokumen6 halamanIs 10810 5 1984Santosh Kumar0% (1)

- Is 10810 4 1984Dokumen7 halamanIs 10810 4 1984Santosh KumarBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen8 halamanDisclosure To Promote The Right To InformationSantosh KumarBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen7 halamanDisclosure To Promote The Right To InformationSantosh KumarBelum ada peringkat

- A New Generation of General Purpose Bandsaw Blades From Bahco MilfordDokumen4 halamanA New Generation of General Purpose Bandsaw Blades From Bahco MilfordSantosh KumarBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen8 halamanDisclosure To Promote The Right To InformationSantosh KumarBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen9 halamanDisclosure To Promote The Right To InformationSantosh KumarBelum ada peringkat

- Banarasi Sari#Dokumen7 halamanBanarasi Sari#SHIKHA SINGHBelum ada peringkat

- TleDokumen15 halamanTleChristine Joy Dela CruzBelum ada peringkat

- R. M. Ballantyne: The Coral IslandDokumen4 halamanR. M. Ballantyne: The Coral IslandValentina VinogradovaBelum ada peringkat

- Daily RoutineDokumen2 halamanDaily RoutineKiss Kinga100% (1)

- Act 5, Scene 1Dokumen3 halamanAct 5, Scene 1Arihant KumarBelum ada peringkat

- Paul PoiretDokumen19 halamanPaul Poiretbagbooks54Belum ada peringkat

- Blank Dungeon Starters PDFDokumen2 halamanBlank Dungeon Starters PDFIan McKeownBelum ada peringkat

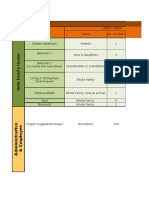

- Space Programming: Area/Space User'S Area Users No. of UsersDokumen6 halamanSpace Programming: Area/Space User'S Area Users No. of UsersMary Rose CabidesBelum ada peringkat

- Grandpas EulogyDokumen6 halamanGrandpas EulogyLailah Rose AngkiBelum ada peringkat

- Wattle and Daub: Craft, Conservation and Wiltshire Case StudyDokumen112 halamanWattle and Daub: Craft, Conservation and Wiltshire Case StudyPriyanka SuteBelum ada peringkat

- Jeopardy Cards - Passive: InventionsDokumen3 halamanJeopardy Cards - Passive: InventionsNanaBelum ada peringkat

- Life Will ChangeDokumen4 halamanLife Will ChangeHachiman HikigayaBelum ada peringkat

- Kodaly Journal PDFDokumen68 halamanKodaly Journal PDFNatalia BuenoBelum ada peringkat

- Online Shopping 8 December 2011: BBC Learning English 6 Minute EnglishDokumen6 halamanOnline Shopping 8 December 2011: BBC Learning English 6 Minute Englishjorgmarta2952Belum ada peringkat

- May 2014-1Dokumen412 halamanMay 2014-1Andi DumayBelum ada peringkat

- Mrs Dalloway AnalysisDokumen8 halamanMrs Dalloway AnalysisStéphanieBelum ada peringkat

- "Approach Strong Deliveress! From George Crumb's Apparition - A Case Study in Analysis and Performance of Post-Tonal MusicDokumen21 halaman"Approach Strong Deliveress! From George Crumb's Apparition - A Case Study in Analysis and Performance of Post-Tonal MusicAlexBelum ada peringkat

- The Battle of WaterlooDokumen14 halamanThe Battle of Waterlooana zetinaBelum ada peringkat

- Filipino AuthorsDokumen6 halamanFilipino Authorsyoshimitsu yoshidaBelum ada peringkat

- Asinaria PDFDokumen176 halamanAsinaria PDFCésar Arroyo LBelum ada peringkat

- The World of Apu - RayDokumen21 halamanThe World of Apu - Rayjim kistenBelum ada peringkat

- The Studio CroonersDokumen4 halamanThe Studio Croonersjslmb33Belum ada peringkat

- Iso-Iec 10646-2014 PDFDokumen118 halamanIso-Iec 10646-2014 PDFFernando MartínBelum ada peringkat

- The Philosophy of Immanuel Kant: Alfred WeberDokumen18 halamanThe Philosophy of Immanuel Kant: Alfred WeberGerald Jem BernandinoBelum ada peringkat

- E SiddalDokumen9 halamanE SiddalWilliams D CHBelum ada peringkat

- JessesIceCreamStand3 5Dokumen5 halamanJessesIceCreamStand3 5yoBelum ada peringkat

- Genre and Elements of LiteratureDokumen55 halamanGenre and Elements of LiteratureAngilly Librea100% (1)

- Innocence and Experience (Reading Execise 1)Dokumen3 halamanInnocence and Experience (Reading Execise 1)Izan SallehBelum ada peringkat

- Tekomas Printing CultureDokumen62 halamanTekomas Printing CultureNisrina AzzahraBelum ada peringkat

- Al-Masjid Al-Haram, Makkah, Saudi Arabia - editEDDokumen5 halamanAl-Masjid Al-Haram, Makkah, Saudi Arabia - editEDHaziqueZulkifliBelum ada peringkat