Crane JSA

Diunggah oleh

Pungky Tri WijayaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Crane JSA

Diunggah oleh

Pungky Tri WijayaHak Cipta:

Format Tersedia

The University of Michigan

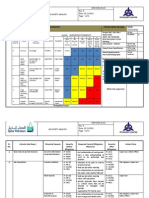

Crane - Job Safety Analysis Form

Task Description _________________________________

_______________________________________________

Job/Work Order No.______________________________

Date: __________________________________________

Personal Protective Equipment

Crane

___ Fall Protection Roof/Hole

Guardrails PFAS (Harness)

___ Traffic Vest

___ Traffic Paddle/Sign

___ Hard Hat

___ Safety Glasses

___ Gloves

___ Protective Footwear

___ Other______________________

___ Other______________________

___ Lift Plan (evaluation below 75%)

___ Annual Certification

___ NCCO (Certified Crane Operator)

Ground/Environmental - Hazards

___

___

___

___

___

___

___

___

___

___

___

___

Utilities Identified

Wind

Electrical Wires - Overhead

1-800-Miss-Dig or UM Utilities

Tunnels Structural review

Rain lightening - ground

Earth Retention System (review)

Restricted Access/Egress

Impact Other buildings

Restricted Lighting

Winter ground movement

Other______________________

___

___

___

___

___

___

Other Hazards

Trenches nearby

Fall Potential

Soft Ground

Type of Out Rigger Pads

Pinch Points

Slip/Trip Potential

Employee Involvement

Rigging Plan

Unit-Specific Training

___ Known Potential Hazards Related

to Job Task

Traffic Control

___ AEC Traffic Coordination Meeting

___

___

___

___

___

___

___

Vehicles

Road Closure Permit from City

Barricades/detour signage

Person assigned to Direct Traffic

Flag Person w/ Vest & Flag

Pedestrian Traffic

Barricade/detour signage Tape

City Sidewalk Closure Permit

Spotters

___ Designated Qualified Rigger

___ Communication Plan

___ Designated Certified Signal

Person

___ Inspection of Rigging

___ Gear w/ known load limits

___ Weight of the load

___ Loads center of gravity

___ Sling angles determined

___ Side loading issues

___ Padded slings

___ Working load limits acquired

___

___

___

___

Hitch load appropriate

Tag lines required

Level load

Any special requirements

Other Items

___ Contact OSEH

___ Pre-Lift Meeting

___ Manufacturers Requirements

___ Staging Area - Trucks/Material

___ Contact Parking for lot closures

Building Occupants

Occupied

___

___

___

___

Evacuated

Weekend or Off Hours Lift No one in the Building

Restrict travel within Building (No one under loads) Post guards - signs

If Occupied Structural review for dropped load

Other - Notify Management for Procedures & Review

Given At Task Location

Task Specific Requirements________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

Names of Personnel

NCCO Qualified Rigger Certified Signal Person -

Contacts

Patti Spence Traffic Coordination Meetings: pasence@bf.umich.edu

Toby E. Hovi OSEH: thovi@umich.edu

Parking Lot Closure Request: closepark@umich.edu, or 647-3615

ATTENTION: Verify that all workers understand their duties and job requirements

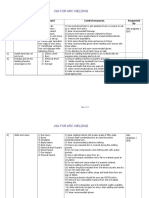

The University of Michigan

Crane - Job Safety Analysis Form

LIFT EVALUATION FORM

1. Activity:

Location of Lift:

Date:

2. Description of Load:

Load Weight:

Block Weight:

Spreader Weight:

Rigging Weight:

Jib Weight:

Jib Ball Weight:

Hoist Line Weight:

Total Load:

3. Crane Manufacturer:

Model Number:

Serial Number:

Maximum Load Radius:

On Outriggers:

Corresponding Boom Angle:

On Tires:

Corresponding Boom Length:

On Crawler-Extended Retracted:

Lift will Be:

____ On Boom ____ On Jib ___ Over Side ____ Over End

Rated Capacity:

Capacity Margin = (Total Load / Rated Capacity) x 100 =

4. Are there Underground Hazards?

___ Yes

___ No

Will Blocking or Crane Mat be Used? ___ Yes

___ No

Soil Conditions:

Are there Fire or Explosive Hazards Within Reach? ___ Yes

Are There Electrical Hazards Within Reach?

Has Permit Been Obtained?

Prepared by:

___ Yes

___ Yes

___ No

___ No

___ No

Date:

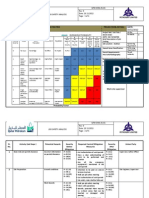

The University of Michigan

Crane - Job Safety Analysis Form

Job Safety Analysis (JSA) is an important accident prevention tool that works by finding

hazards and eliminating or minimizing them before the job is performed and before they have

a chance to become accidents. Use your JSA for job clarification and hazard awareness.

Sequence of Basic Job Steps

Potential Hazard

Access from truck.

1. Falls from truck

Rig equipment for lift

2. Struck by object

Recommended Action or Procedure

1. The riggers will access the

truck bed by using a

portable ladder or fixed

ladder. No jumping.

3. Pinch points

2. All rigging will be inspected

prior to use. The unit will

be picked according to

manufacturers

recommendations.

3. Proper radio communication

and rigging signals will be

used. Pre-meeting with all

parties will establish good

communication and plan.

4. All employees will be clear

of pinch point during initial

lift off of truck. Rigging

will be inspected again to

ensure load is level and

secure.

5. Load will be lifted by tower

crane.

Employees will access the roof

and prepare for lift.

1. Fall hazards at hatch

opening, or edge of roof.

Place unit through hatch

2. Threat of material

dropping on to roof.

3.

Swinging load over crew

and other personnel

1. Employees will be protected

from a fall by using fall

arresting equipment.

Employees will wear full

body harness and retractable

lifeline within 15 feet of

hatch.

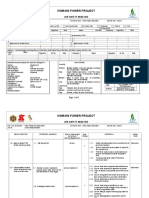

The University of Michigan

Crane - Job Safety Analysis Form

2. The unit will be picked

according to manufacturers

recommendations. The

weight of the unit and

rigging will be

approximately half of the

overall capacity.

3. Good communication will

be maintained with operator

and crew by using two-way

radios.

4. The personnel in the

building will be moved as

necessary.

5. The crew will not work

under suspended load. Tag

lines will be used to

position load

The unit will be set on dollies

and wheeled in place.

1. Pinch points

2. Load shifting - moving

1. Employees will have to use

caution regarding putting

hands, fingers, and etc in

pinch points.

2. Employees will access

rigging by using a

stepladder. The ladder will

be inspected and used

according to regulations and

safe working practices.

Supervisor/Designee Signature: __________________________________________________________________________

The University of Michigan

Crane - Job Safety Analysis Form

I acknowledge receiving these instructions, understand the instructions,

and will fully comply with the assigned job task.

Signature

Badge #

Signature

Badge #

Anda mungkin juga menyukai

- Hazard Analysis Structural SteelDokumen3 halamanHazard Analysis Structural SteelRobbie Grose100% (3)

- Job Safety Analysis Sheet: FacilityDokumen1 halamanJob Safety Analysis Sheet: Facilitywahyu nugrohoBelum ada peringkat

- JSA Erection of Gathering TentDokumen12 halamanJSA Erection of Gathering TentMuhammad Tariq100% (2)

- 2066 2076 2086 Including 2076 (EU) 2086 (EU) Skid-Steer Loaders Operator's ManualDokumen100 halaman2066 2076 2086 Including 2076 (EU) 2086 (EU) Skid-Steer Loaders Operator's ManualjrfackBelum ada peringkat

- JSA - Sand Blasting and PaintngDokumen8 halamanJSA - Sand Blasting and PaintngJohn100% (1)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDokumen9 halamanHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- User's Manual BOOK I PDFDokumen109 halamanUser's Manual BOOK I PDFJulio Rodriguez100% (1)

- QP Painting JSADokumen6 halamanQP Painting JSAMohammed Mujahid100% (2)

- Manual Tig Welding (RRC) - Job ProcedureDokumen3 halamanManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Unsafe Act Unsafe ConditionDokumen1 halamanUnsafe Act Unsafe ConditionrosevelvetBelum ada peringkat

- Jsa Lifting ProcedureDokumen9 halamanJsa Lifting ProcedureMark Irwen GrebialdeBelum ada peringkat

- JSA HandToolsDokumen2 halamanJSA HandToolsCristina Rican100% (3)

- Checklist Hand ToolsDokumen1 halamanChecklist Hand ToolsrexivyBelum ada peringkat

- Jsa For Arc WeldingDokumen3 halamanJsa For Arc Weldingtnssbhaskar100% (5)

- JSADokumen10 halamanJSAmohd firdausBelum ada peringkat

- JSA-020-Safety Watch-Hot WorkDokumen2 halamanJSA-020-Safety Watch-Hot WorkNishad MuhammedBelum ada peringkat

- Crane JSADokumen5 halamanCrane JSAKritsada Tiwutanon100% (1)

- Basic Rigging Print Materials2Dokumen51 halamanBasic Rigging Print Materials2Img Syg100% (2)

- Planned Critical Lift Crane PermitDokumen5 halamanPlanned Critical Lift Crane PermitsurnaikBelum ada peringkat

- Jungheinrich EFG 218 Forklift TruckDokumen454 halamanJungheinrich EFG 218 Forklift TruckLuis Mir100% (1)

- BS en 12397-2017Dokumen22 halamanBS en 12397-2017DoicielBelum ada peringkat

- Linde Truck Expert Service and Operational Manuals Wiring Diagrams Etc PDFDokumen627 halamanLinde Truck Expert Service and Operational Manuals Wiring Diagrams Etc PDFASIFBelum ada peringkat

- Ma 13Dokumen93 halamanMa 13Mathias Cremer100% (1)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDokumen9 halamanRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariBelum ada peringkat

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDokumen4 halamanJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDokumen1 halamanJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaBelum ada peringkat

- JHA Blowing PressDokumen5 halamanJHA Blowing PressLuqman OsmanBelum ada peringkat

- Emergency Rescue PlanDokumen5 halamanEmergency Rescue PlanAshutosh100% (1)

- JSA Excavation PDFDokumen6 halamanJSA Excavation PDFmohamedamine.zemouriBelum ada peringkat

- Lifting Operatio in Progress PDFDokumen1 halamanLifting Operatio in Progress PDFsubhanmusadiq100% (1)

- Falling Objects PDFDokumen1 halamanFalling Objects PDFsubhanmusadiqBelum ada peringkat

- Jsa-Jha For Using of Hand ToolsDokumen2 halamanJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Jsa For Piping and Erection RevisedDokumen1 halamanJsa For Piping and Erection RevisedDr AnwarBelum ada peringkat

- 11 - Job Safety Analysis ProcedureDokumen11 halaman11 - Job Safety Analysis ProcedureMohammed MinhajBelum ada peringkat

- Operating The Man LiftDokumen1 halamanOperating The Man LiftEllecer anthony Permejo67% (3)

- Jsa Grinding W Angle GrinderDokumen2 halamanJsa Grinding W Angle GrinderMichael Angelo SanteBelum ada peringkat

- Job Safety Analysis: Required References Jsa ReviewDokumen4 halamanJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (4)

- QP Cutting JSADokumen6 halamanQP Cutting JSAMohammed MujahidBelum ada peringkat

- NSRP Project: Confined Space Entry CertificateDokumen1 halamanNSRP Project: Confined Space Entry CertificateThanh Tung DongBelum ada peringkat

- Jsa Welding Cutting and Grinding at Closing AreaDokumen7 halamanJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- JsaDokumen39 halamanJsajithin shankar100% (3)

- Jsa For WeldingDokumen2 halamanJsa For WeldingMohamed Samir50% (2)

- JSA ExcavationDokumen6 halamanJSA Excavationkermech21607100% (1)

- JSA Welding Confined SpaceDokumen2 halamanJSA Welding Confined Spacegkmlal100% (4)

- 1installation of Steel Structures JHA 1 (06!06!2015)Dokumen33 halaman1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Job Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Dokumen2 halamanJob Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Jayvee Baradas Valdez25% (4)

- Job Safety Analysis - Clinker StorageDokumen4 halamanJob Safety Analysis - Clinker StorageMohammed MinhajBelum ada peringkat

- Ra02 - Container OffloadingDokumen3 halamanRa02 - Container OffloadingSamBelum ada peringkat

- JSA Working in Live AreasDokumen1 halamanJSA Working in Live Areasyc safetyBelum ada peringkat

- JHA # 009 - Hot WorkDokumen7 halamanJHA # 009 - Hot WorkkumarBelum ada peringkat

- Jsa SKDokumen10 halamanJsa SKEngr Tahir UL Haq100% (2)

- Job Safety Analysis: Job Title: Installing Pneumatic Rubber FenderDokumen3 halamanJob Safety Analysis: Job Title: Installing Pneumatic Rubber FenderIhwan AsrulBelum ada peringkat

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokumen2 halamanJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelBelum ada peringkat

- Jsa For The Installation of I EamDokumen5 halamanJsa For The Installation of I EamMohammed MinhajBelum ada peringkat

- JSA NO 2-Piling WorkDokumen3 halamanJSA NO 2-Piling WorkKarthik GanesanBelum ada peringkat

- Job Safety Analysis (Rolling For MS Plates)Dokumen1 halamanJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- JSA ScaffoldingDokumen2 halamanJSA ScaffoldingHrishikesh UnnikrishnanBelum ada peringkat

- Hot Work PermitDokumen1 halamanHot Work PermitvarunstuffBelum ada peringkat

- JSA #19 Grinding, Welding, Gas CuttingDokumen2 halamanJSA #19 Grinding, Welding, Gas CuttingSubham Sohal100% (1)

- JSA For Fab Erec of STRL Steel StackDokumen5 halamanJSA For Fab Erec of STRL Steel StackkrishnakumarBelum ada peringkat

- JSA G02 Lift Personnel in Scissor LiftDokumen6 halamanJSA G02 Lift Personnel in Scissor Liftjokerseri100% (3)

- JSA Cable Pulling and Laying Works AutosavedDokumen6 halamanJSA Cable Pulling and Laying Works AutosavedWisnu Wijaya100% (1)

- Civil JSA Form Application of Protective Coating On Sump PitsDokumen1 halamanCivil JSA Form Application of Protective Coating On Sump PitsdrmuhsinBelum ada peringkat

- Tool Box Talk: House KeepingDokumen1 halamanTool Box Talk: House KeepingAli Alqaisy100% (1)

- Method Statement For Construction - Designing Buildings Wiki PDFDokumen5 halamanMethod Statement For Construction - Designing Buildings Wiki PDFKareemAdelBelum ada peringkat

- Job Safety AnalysisDokumen4 halamanJob Safety AnalysisDedi Apriadi71% (7)

- Maintenance Sim17-200 GB PDFDokumen279 halamanMaintenance Sim17-200 GB PDFIvan Dario100% (1)

- Solon PremiumDokumen30 halamanSolon PremiumWildan HeroBelum ada peringkat

- Ex ProjDokumen4 halamanEx Projcatchankit007Belum ada peringkat

- Electric Powered Forklifts: B15T / B18T / B20T - 5Dokumen4 halamanElectric Powered Forklifts: B15T / B18T / B20T - 5DoDuyBacBelum ada peringkat

- Bucket Elevator Installation Manual 473793 Revised 2016Dokumen77 halamanBucket Elevator Installation Manual 473793 Revised 2016YhaneBelum ada peringkat

- Convention Centre-E-8.11.2019 - R0Dokumen11 halamanConvention Centre-E-8.11.2019 - R0ManojBelum ada peringkat

- StratosDokumen4 halamanStratosCelith Rossy Inga PeñaBelum ada peringkat

- Crown ESR4000 Service ManualDokumen310 halamanCrown ESR4000 Service ManualBPBelum ada peringkat

- Ge700-2020-Gc14 Plot 21 RoofDokumen6 halamanGe700-2020-Gc14 Plot 21 RoofDaniel CryerBelum ada peringkat

- Rexnord-Falk Reductores Quadrive Serie 5000Dokumen52 halamanRexnord-Falk Reductores Quadrive Serie 5000maueicio2Belum ada peringkat

- Manual of Traction Machine 曳引机安装使用及维护手册V9.1英文适用于YTTD、YTDDokumen28 halamanManual of Traction Machine 曳引机安装使用及维护手册V9.1英文适用于YTTD、YTDShihab AlakhallyBelum ada peringkat

- Godrej Reach Truck CatalogueDokumen8 halamanGodrej Reach Truck Catalogueasif.ayyub7624Belum ada peringkat

- Method Statement For Installation of Thread Rod Support and Cable Tray Using Boomscissor LiftDokumen6 halamanMethod Statement For Installation of Thread Rod Support and Cable Tray Using Boomscissor LiftNaveenBelum ada peringkat

- 02 Lift Hoisting & Safety Equipment PDFDokumen2 halaman02 Lift Hoisting & Safety Equipment PDFleekeanyewBelum ada peringkat

- C90 Driver InstructionDokumen13 halamanC90 Driver Instructionmunawar100% (1)

- Structure StatusDokumen32 halamanStructure Statusrohit_me083Belum ada peringkat

- Microcontroller Based Elevator SystemDokumen3 halamanMicrocontroller Based Elevator SystemEditor IJLTEMASBelum ada peringkat

- Geared Machines March 2018Dokumen31 halamanGeared Machines March 2018mahmoud abasBelum ada peringkat

- Old 3120720 AP 600S, 600SJ, 660SJ JLG Parts EnglishDokumen144 halamanOld 3120720 AP 600S, 600SJ, 660SJ JLG Parts EnglishMuhammad AwaisBelum ada peringkat

- Material Approval StatusDokumen47 halamanMaterial Approval StatusAlemayehu AyalewBelum ada peringkat

- Operator Manual sp4000 Na en PDFDokumen21 halamanOperator Manual sp4000 Na en PDFEmmanuel Chavez VargasBelum ada peringkat

- Bentec Brosch - Mechanische - Edit PDFDokumen11 halamanBentec Brosch - Mechanische - Edit PDFBabi LakhdariBelum ada peringkat

- HaGun Gantry Crane + Method of Works Install Stator Generator+Strand Jack + 03JuLy14 PDFDokumen23 halamanHaGun Gantry Crane + Method of Works Install Stator Generator+Strand Jack + 03JuLy14 PDFHaGun Gantry100% (1)

- MS 1183 5 1990Dokumen40 halamanMS 1183 5 1990Yeo WeizheBelum ada peringkat