3/ Z7 VZMZM/ZZ : V. Holek 2,216,412

Diunggah oleh

wererDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

3/ Z7 VZMZM/ZZ : V. Holek 2,216,412

Diunggah oleh

wererHak Cipta:

Format Tersedia

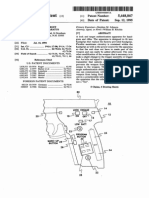

Oct. 1. 1940.

v. HOLEK

2,216,412

FIRING MECHANISM FOR AUTOMATIC FIREARMS

Filed July 14, 193"

FIQJ

43

I2

IO

Fig.3

0

4-5

Fig.5 - F196

so

3/ Z7 VZMzM/ZZ

Patented Oct. 1, 1940

2,216,412

UNITED STATES

earner I orrics

2,216,412

FIRING MECHANISM FOR AUTOMATICl

FIREARMS

Vaclav Holek, Zabovresky, Brunn, Czechoslovakia,

assignor to Ceskoslovenska Zbrojovka, a. s.,

Brno, Brunn, Czechoslovakia, a Czechoslo

vakian company

Application July 14, 1937, Serial No. 153,653

In Czechoslovakia July 20, 1936'

7 Claims.

This invention relates to ?ring mechanism for

automatic ?rearms.

In known ?ring mechanisms the setting

means for permitting the ?ring of single shots or

5 a series of shots and the means for locking the

?ring mechanism are operated by means of sepa~

rate levers, usually disposed laterally of the trig

ger.

The defect of such a ?ring mechanism is

not only its complicated construction, but also

the difficulty of manipulation, which requires

some considerable time for operating the mem

bers which are separated from one another, such

as the trigger and the locking mechanism and the

_ aforesaid setting means.

These defects are eliminated by theconstruc

tion according to the invention, in which there is

provided ?ring mechanism for automatic ?rearms

for ?ring single shots or a series of shots, wherein

the trigger comprises a rod or member mounted

20 in a casing in such a manner as to be displaceable

longitudinally and rotatable, the longitudinal dis

placement of the said rod being utilized to oper

ate a sear to permit ?ring and the rotary move

ment being utilized to set the ?ring mechanism

25 into a position for ?ring single shots or a series of

shots or into a position to lock the said mecha

nism to prevent ?ring.

By the provision of a single trigger member ac

cording to the present invention for operating the

30 sear during ?ring as well as for setting and look

ing the ?ring mechanism, this mechanism is con

siderably simpli?ed, which not only facilitates the

handling of the ?rearm, but also increases safety

in operation.

35

In order that the invention may be clearly un

derstood and readily carried into effect reference

may now be had to the accompanying drawing

illustrating one embodiment thereof by way of

40

example, and in which:

Figure 1 is a longitudinal section showing the

trigger casing with the ?ring mechanism in

locked position,

Figure 2 is a similar section showing the mech

ism in the released position with the trigger de

pressed,

Figure 3 is an elevation of the trigger as seen

in the direction of the arrow 8,

Figure 4 is a fragmentary section on the line

IVIV of Fig. 2, as seen in a direction from right

50 to left, with the trigger removed, '

(CI. 89-27)

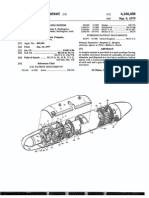

of the ?ring mechanism. The said casing may be

provided with a pistol grip or handles according

to how the arm is to be used, but these are not

shown. The ?ring mechanism proper comprises

the sear, which co-operates with the locking 5

mechanism, and the member which performs

various kinds of movement and operates the sear

during ?ring if set in a certain manner. This

member forms the trigger proper of the mechan

ism and comprises a rod 5 mounted in bearings 2, 10

3 formed in the casing I. At one end, the rod 5 is

provided with an enlarged cylindrical head 6,

which is mounted in a bearing 4 of the casing I.

The enlarged head forms a press button for facil

itating the operation of the trigger. At the other 15

end, the rod 5 is rounded at l, and this rounded

end co-operates with the arm 8 of the sear which

is rockably mounted on a pin 9. The other arm

ID of the sear coacts with a spring I3 which urges

its outer end into the recoil path of the breech

mechanism.v In the example shown, this mech

anism comprises a breech block carrier l2, with

a projection II with which the arm 10 of the sear

co-operates.

I According to the invention, the trigger 5 is pro-

vided with means for setting and locking the

mechanism for ?ring single shots or a series of

shots and for locking the mechanism for prevent

ing ?ring.

'

For setting the ?ring mechanism, there is pro

30

vided an arrangement :0 (Figure 6), which con

sists of a recess on the periphery of the cylin

drical press button 6. The recess is bounded

partly by an end face [5 and partly by longitu

dinal grooves I6, "5, which are formed on the 35

periphery in the direction of the longitudinal axis

of the trigger 5. The width of the longitudinal

grooves l6, 16' corresponds to the width of a pro

jection M. The said projection is provided on

the bearing 4 and extends into the bore thereof.

The press button is furthermore provided with a

thumb piece I! for facilitating the operation of

the trigger 5 during the rotary movement thereof.

This thumb piece also forms an indicator for in

dicating the set position'of the trigger 5, the posi

tions being marked on the outer surface of the

casing I by suitable indicia.

Between the bearings 2 and 3, the rod 5 is of

rectangular cross section and carries a disc 20

having a long boss 23. The disc 20 is provided

Figure 5 shows a detail of the setting means with means co-operating with the stationary

for the trigger, and

parts of the ?ring mechanism and adapted to lo

Figure 6 is a plan view of the trigger press cate the trigger in set position. This means may

comprise a knife-edged radial ridge 26 formed on

button.

55 Referring to the drawing, I indicates the casing the face of the disc 20 adjacent the bearing 2 55

2,216,412

(Figure 5). Radial recesses 21 (Figure 4) are

provided on the adjacent end face of the bearing

2, said recesses being spaced through 45 and

?rearms comprising a casing, a trigger rotatably

against the disc 28 is a spring 39 disposed con

and slidably mounted in said casing, a scar, a

press button on said trigger, a bearing for said

press button having a projection and said press

button having recesses cooperating with said pro

jection to permit slidable movement of said trig

centrically to the rod 5 and bearing at its other

end against a shoulder 28 provided on the rod 5.

thereof and prevent slidable movement of said

corresponding in shape to the ridge 28 engaging

in them in accordance with the setting.

Bearing

ger at only certain-predetermined rotary positions

The spring 38 ?rstly loads the disc 2%, so as'to' :trigger at other rotary positions thereof.

2. A ?ring control mechanism for automatic

the recess 2?, secondly it returns the trigger after _ ?rearms comprising a casing, a trigger rotatably

and. slidably mounted in said casing, a sear, a

?ring into its initial position, wherein the shoul

'press button on said trigger, a bearing for said

der 28 is applied to the bearing 3.

10 cause engagement of the ridge 2% thereof with

In addition to the said positioning means, the

15 disc 20 carries means for co-operating with the

sear l0 and forming locking means for the ?ring

mechanism.

press button having a projection and said press

button having recesses cooperating with said pro

jection to permit slidable movement of said trig

These means may comprise an arm I ger at only certain predetermined rotary positions

2|, which co-operates with a projection 22 formed

thereof and the end face of said press button

being designed to cooperate with said projection

20

For ?ring a shot, the marksman presses withv to prevent slidable movement of said trigger at 20

his ?nger upon the press button of the trigger 5, other rotary positions thereof.

3. A ?ring control mechanism for automatic

the sliding movement being transmitted to the

on the arm i 9 of the sear.

'

sear 8 which releases the breech block member

I 2 and the projection i i whereof operates the ?r

25 ing pin in known manner.

In the position shown in Figure 1, the ?ring

mechanism is locked, so that no shot can be ?red.

In the locked position, the projection Iii of the

bearing 4 is located opposite the end face i 5 (Fig

30 ures 1 and 6) of the press button 6 and prevents

sliding longitudinal movement in the direction of

the arrow 8. In this position not only the trigger

is locked, which is prevented from sliding longi

tudinal movement, but also the sear, since the

arm 2! of the disc 20 is located opposite the pro

jection 22 and thereby prevents the sear from

rocking which might occur unintentionally when

the gun is shaken. Accidental discharge is there

by prevented. By rotation of the press button 6

40 With the aid of the operating thumb piece H to

the right or to the left through an angle of 45

(Figure 3) the ?ring mechanism is set for ?ring.

One position may be for ?ring single shots and

the other for ?ring a series of shots, it being un

45 derstood that the ?ring mechanism is provided

with an interrrupter for ?ring single shots, which

may be of any known construction and is not

shown for this reason. During the rotation of

the press button 6, the rectangular portionZE 'of

the rod carries the disc 28 with it, whereby the

50

ridge 26 is disengaged from the recess 21. During

this movement the disc 26 is axially displaced on

the trigger rod 5 to an amount corresponding

to the height of the ridge 26 and thereby com

presses the spring 3!). Upon rotation through an

55 angle of 45, the projection M of the bearing

abuts against the side of the slot 56 or it, so

that further rotation is prevented and the ?ring

mechanism is set for ?ring, since the projection

to

or arm 2! of the disc 29 does not oppose the move

ment of the sear.

When the trigger has been set

into the corresponding position, the ridge 26 en

gages in another radial recess 21 on the bearing

2, since it is pressed by the spring 3t] acting upon

the disc 20, and the mechanism is set for ?ring.

65 The projection M is opposite the slot IE or if

of the press button, so that it does not prevent

sliding longitudinal movement of the trigger,

which is necessary for the operation of the sear 8

70

during ?ring.

What I claim is:

?rearms comprising a casing, a trigger rotatably

and slidably mounted in said casing, a scar, a

disc non-rotatably mounted on said trigger, r. Cl

means on said disc cooperating with said sear for

locking the same and means on said disc for ?x

ing said trigger in certain positions to which it

may be rotated for controlling the ?ring.

4. A ?ring control mechanism for automatic

?rearms comprising a casing, a trigger rotatably

and slidably mounted in said casing, a scar, a disc

non-rotatably mounted on said trigger, means

on said disc cooperating with said sear for locking

the same, a bearing for said trigger having radial

slots therein and a radial ridge on said disc co

operating with said slots for ?xing the trigger in

certain predetermined positions.

5. A ?ring control mechanism for automatic

?rearms comprising a casing, a trigger rotatably

and slidably mounted in said casing, a sear, a disc '

non-rotatably mounted on said trigger, means on

said disc cooperating with said sear for locking

the same, a bearing for said trigger having radial

slots therein and a radial ridge on said disc co

operating with said slots for ?xing the trigger in

certain predetermined positions, and a spring

urging said ridge into said slots, and returning

said trigger to initial position.

6. A ?ring control mechanism for automatic

?rearms comprising a casing, a trigger rotatably '

and slidably mounted in said casing, a scar, a disc

non-rotatably mounted on said trigger, means on

said disc cooperating with said sear for locking

the same, a bearing for said trigger having radial

slots therein and a radial ridge on said disc coop- '

erating with said slots for ?xing the trigger in

certain predetermined positions and a spring

urging said ridge into said slots and returning

said trigger to initial position, and a second bear-~

ing for said trigger limiting the return of said

trigger under the influence of said spring.

7. A ?ring control mechanism for automatic

?rearms comprising a casing, a trigger rotatably

and slidably mounted in said casing, a sear, said

sear being pivotally mounted and having a pro

jection thereon, a disc mounted on said trigger

and said disc having a projection adapted to co

operate with said projection on said sear in order

to prevent pivotal movement of said sear at a H

1. A ?ring control mechanism for automatic

predetermined position of said trigger. v

VACLAV I-IOLEK.

Anda mungkin juga menyukai

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsDari EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsBelum ada peringkat

- Rig-E???': Gill!Dokumen6 halamanRig-E???': Gill!luiscremaschiBelum ada peringkat

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Dokumen8 halamanDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamBelum ada peringkat

- 1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieDokumen3 halaman1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieVincent Grangé-PradérasBelum ada peringkat

- Us965386 PDFDokumen6 halamanUs965386 PDFJin SongBelum ada peringkat

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Dokumen12 halamanL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniBelum ada peringkat

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDokumen7 halamanCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitBelum ada peringkat

- Us 4407085Dokumen5 halamanUs 4407085rte678Belum ada peringkat

- No. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed GearingDokumen4 halamanNo. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed Gearingbelchior alvaroBelum ada peringkat

- Anti-Aircraft Fire Control Device (1937)Dokumen10 halamanAnti-Aircraft Fire Control Device (1937)CAP History LibraryBelum ada peringkat

- Us2765819 PDFDokumen8 halamanUs2765819 PDFAzri LunduBelum ada peringkat

- Us4522105 PDFDokumen10 halamanUs4522105 PDFJin SongBelum ada peringkat

- Apron MechanismDokumen7 halamanApron Mechanismgopalpaul0% (2)

- United States Patent 1191: MasuyamaDokumen7 halamanUnited States Patent 1191: MasuyamaAbdullah AljabriBelum ada peringkat

- Benet Mercie BreechDokumen13 halamanBenet Mercie BreechAnonymous htRZ5zTMgBelum ada peringkat

- Us1955360 PDFDokumen8 halamanUs1955360 PDFRodrigoPomaBelum ada peringkat

- Limited States Patent: LngramDokumen7 halamanLimited States Patent: LngramJin SongBelum ada peringkat

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Dokumen16 halamanSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongBelum ada peringkat

- MMM-@U: H. M. SpragueDokumen4 halamanMMM-@U: H. M. SpraguedjsfBelum ada peringkat

- Us 5117735Dokumen14 halamanUs 5117735sdfsdf333Belum ada peringkat

- US2160338 Shuttle Picking Mechanism PDFDokumen5 halamanUS2160338 Shuttle Picking Mechanism PDFParikshit PaulBelum ada peringkat

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Dokumen8 halamanApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiBelum ada peringkat

- Us4854065 PDFDokumen7 halamanUs4854065 PDFJin SongBelum ada peringkat

- United States Patent (191: Von Kale! Et AlDokumen18 halamanUnited States Patent (191: Von Kale! Et AlJoão Paulo Canto RibeiroBelum ada peringkat

- Us955823 PDFDokumen3 halamanUs955823 PDFSashikant SharmaBelum ada peringkat

- US2128620 - Bending MachineDokumen5 halamanUS2128620 - Bending MachinedevheadbotBelum ada peringkat

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Dokumen4 halamanAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1Belum ada peringkat

- Revolver PatentDokumen5 halamanRevolver PatentdududadamikeBelum ada peringkat

- @VLNNR:: Beretta 3,021,763Dokumen8 halaman@VLNNR:: Beretta 3,021,763wererBelum ada peringkat

- Us 1454454Dokumen3 halamanUs 1454454dfdfsdBelum ada peringkat

- United States Patent 1191Dokumen13 halamanUnited States Patent 1191ddeeff715Belum ada peringkat

- Target Kite (1944)Dokumen7 halamanTarget Kite (1944)CAP History LibraryBelum ada peringkat

- Us 8210068us 8210068us 8210068us 8210068Dokumen9 halamanUs 8210068us 8210068us 8210068us 8210068JameszouqunBelum ada peringkat

- United States Patent (191 (11) Patent Number: 4,857,881Dokumen9 halamanUnited States Patent (191 (11) Patent Number: 4,857,881Harish MahadevanBelum ada peringkat

- Us1446763 PDFDokumen7 halamanUs1446763 PDFJin SongBelum ada peringkat

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDokumen6 halamanWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaBelum ada peringkat

- Oct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Dokumen5 halamanOct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Юрий РуденкоBelum ada peringkat

- Us2467764 PDFDokumen10 halamanUs2467764 PDFRodrigoPomaBelum ada peringkat

- Us2291241 PDFDokumen5 halamanUs2291241 PDFbelchior alvaroBelum ada peringkat

- Jan. 4, L 1966 T. W. Spack 3,227,148Dokumen6 halamanJan. 4, L 1966 T. W. Spack 3,227,148MainAvelBelum ada peringkat

- Belt Fed BAR (Belgium) US2136512Dokumen4 halamanBelt Fed BAR (Belgium) US2136512apoorva singhBelum ada peringkat

- Us 3706152Dokumen7 halamanUs 3706152rte678Belum ada peringkat

- %WWMD%WM: J. H. Vanderslig-E. Flanging MachineDokumen4 halaman%WWMD%WM: J. H. Vanderslig-E. Flanging MachineOO G-sus OoBelum ada peringkat

- Pistol Nickl Us1427966Dokumen11 halamanPistol Nickl Us1427966cll1968Belum ada peringkat

- Ulllted States Patent (19) (11) Patent Number: 5,937,809Dokumen15 halamanUlllted States Patent (19) (11) Patent Number: 5,937,809LazarBelum ada peringkat

- Berthier Us1366863Dokumen9 halamanBerthier Us1366863cll1968Belum ada peringkat

- Braiding MachineDokumen7 halamanBraiding Machinejojaberi100% (1)

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDokumen4 halamanMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniBelum ada peringkat

- Thrust Reverser Hook Latch System PatentDokumen13 halamanThrust Reverser Hook Latch System PatentkevnwongBelum ada peringkat

- MD r19 - Part - B PPT NewDokumen42 halamanMD r19 - Part - B PPT Newashok junapudiBelum ada peringkat

- July 5, 1966: Filed Oct. 24, 1961Dokumen9 halamanJuly 5, 1966: Filed Oct. 24, 1961MURALIPRAKASH.S 18BIT131100% (1)

- Us4358986 PDFDokumen9 halamanUs4358986 PDFJin SongBelum ada peringkat

- Us 4023499Dokumen4 halamanUs 4023499ererBelum ada peringkat

- US2525422Dokumen6 halamanUS2525422Rambabu ChBelum ada peringkat

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Dokumen13 halaman(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuBelum ada peringkat

- Us1866891 PDFDokumen8 halamanUs1866891 PDFbelchior alvaroBelum ada peringkat

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Dokumen3 halamanM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonBelum ada peringkat

- Us1434007 PDFDokumen5 halamanUs1434007 PDFsebastian escobarBelum ada peringkat

- Feb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3Dokumen7 halamanFeb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3ValBMSBelum ada peringkat

- Water Rocket GliderDokumen6 halamanWater Rocket GliderwererBelum ada peringkat

- United States Patent: (10) Patent N0.: (45) Date of PatentDokumen8 halamanUnited States Patent: (10) Patent N0.: (45) Date of PatentwererBelum ada peringkat

- United States Patent: GeringDokumen4 halamanUnited States Patent: Geringwerer100% (1)

- Us 6429769Dokumen12 halamanUs 6429769wererBelum ada peringkat

- Us 7886471Dokumen7 halamanUs 7886471wererBelum ada peringkat

- Us 6055759Dokumen6 halamanUs 6055759wererBelum ada peringkat

- Us 6131519Dokumen4 halamanUs 6131519dgfhjsdg hfsdhyjBelum ada peringkat

- Us 5705763Dokumen11 halamanUs 5705763wererBelum ada peringkat

- Us 5355768Dokumen7 halamanUs 5355768wererBelum ada peringkat

- Unlted States Patent (19) (11) Patent Number: 5,335,579Dokumen8 halamanUnlted States Patent (19) (11) Patent Number: 5,335,579fghdfjerBelum ada peringkat

- Us 5448847Dokumen9 halamanUs 5448847wererBelum ada peringkat

- Us 4676137Dokumen6 halamanUs 4676137fghdfjerBelum ada peringkat

- Us 5168114Dokumen5 halamanUs 5168114wererBelum ada peringkat

- Us 4207797Dokumen7 halamanUs 4207797fghdfjerBelum ada peringkat

- Us 2718818Dokumen6 halamanUs 2718818wererBelum ada peringkat

- Nun M.: BC BM 0000Dokumen12 halamanNun M.: BC BM 0000shdhsjkBelum ada peringkat

- @VLNNR:: Beretta 3,021,763Dokumen8 halaman@VLNNR:: Beretta 3,021,763wererBelum ada peringkat

- First Quarter Summative Test in Math 7Dokumen2 halamanFirst Quarter Summative Test in Math 7Lemanuel097 FloresBelum ada peringkat

- Ready To Use Therapeutic Food in RwandaDokumen25 halamanReady To Use Therapeutic Food in RwandaKABERA RENEBelum ada peringkat

- Chapter 1-Part 1: Half-Wave RectifiersDokumen50 halamanChapter 1-Part 1: Half-Wave RectifiersWeehao SiowBelum ada peringkat

- VES-5097 Inspection and Testing of ValvesDokumen14 halamanVES-5097 Inspection and Testing of ValvesBayumi Tirta JayaBelum ada peringkat

- Maths - 2B Imp QuestionsDokumen93 halamanMaths - 2B Imp QuestionsBandaru Chiranjeevi100% (1)

- s10763 017 9799 1 PDFDokumen19 halamans10763 017 9799 1 PDFJoy PascoBelum ada peringkat

- Catalogo Tarifa Hisense 2016Dokumen37 halamanCatalogo Tarifa Hisense 2016David GarciaBelum ada peringkat

- X L W C: Motor Shaft CapacitiveDokumen14 halamanX L W C: Motor Shaft CapacitiveMuhammad Fauzan Ansari Bin AzizBelum ada peringkat

- Achidram, Ashwamedham & KatakamDokumen228 halamanAchidram, Ashwamedham & KatakamSubhash Sharma100% (9)

- Gauss Contest: Grade 7Dokumen4 halamanGauss Contest: Grade 7irwan syahBelum ada peringkat

- Group 2 Main Control Valve: 1. StructureDokumen23 halamanGroup 2 Main Control Valve: 1. StructureАлексейBelum ada peringkat

- Modeling COVID-19 Epidemics in An Excel SpreadsheeDokumen15 halamanModeling COVID-19 Epidemics in An Excel SpreadsheeMagesha kumarBelum ada peringkat

- Complex Numbers SpreadsheetDokumen2 halamanComplex Numbers SpreadsheetrodwellheadBelum ada peringkat

- AC Commutator Motors Repulsion Series Motor UniversalDokumen3 halamanAC Commutator Motors Repulsion Series Motor UniversalwhrferBelum ada peringkat

- HVAC Control in The New MillenniumDokumen389 halamanHVAC Control in The New Millenniumnicky1213aBelum ada peringkat

- 1 s2.0 S0960077922005665 MainDokumen8 halaman1 s2.0 S0960077922005665 MainSajjad AliBelum ada peringkat

- The Structure of The AtomDokumen26 halamanThe Structure of The AtomUnknownKidBelum ada peringkat

- Preliminary Wing Design Parameter Selection Rev 3 PDFDokumen8 halamanPreliminary Wing Design Parameter Selection Rev 3 PDFvirgilioBelum ada peringkat

- ABM11 BussMath Q1 Wk3 ProportionsDokumen12 halamanABM11 BussMath Q1 Wk3 ProportionsArchimedes Arvie Garcia100% (1)

- Actaury Ref BooksDokumen8 halamanActaury Ref BooksvamshidsBelum ada peringkat

- DD210-V 9604sb PDFDokumen4 halamanDD210-V 9604sb PDFBrandon MoralesBelum ada peringkat

- Barnes en Bloor - NieuwDokumen14 halamanBarnes en Bloor - NieuwpietpaaltjenBelum ada peringkat

- Segment RoutingDokumen375 halamanSegment RoutinglillibithBelum ada peringkat

- Java LabDokumen67 halamanJava Labشیخ صاحبBelum ada peringkat

- Face Mask DetectionDokumen34 halamanFace Mask DetectionAmarjeet AmratBelum ada peringkat

- Busiess Analytics Data Mining Lecture 7Dokumen37 halamanBusiess Analytics Data Mining Lecture 7utkarsh bhargavaBelum ada peringkat

- Folded PlatesDokumen23 halamanFolded Platesbhushruti100% (1)

- Lecture 2 - Inverse Laplace TransformsDokumen3 halamanLecture 2 - Inverse Laplace TransformsAmirah MapandiBelum ada peringkat

- Cool Fire Manual 45M620N2UK-01Dokumen198 halamanCool Fire Manual 45M620N2UK-01prejby91% (11)

- Resultat 50 Infos - KrnageDokumen1 halamanResultat 50 Infos - Krnagesarbalice39Belum ada peringkat