Check Maf Kia Carnival Diesel

Diunggah oleh

julio797Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Check Maf Kia Carnival Diesel

Diunggah oleh

julio797Hak Cipta:

Format Tersedia

2009 > D 2.

9 WGT > Mass Air Flow Sensor (MAFS) > P0103

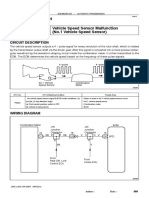

COMPONENT LOCATION

GENERAL DESCRIPTION

Intake Air Temperature Sensor(IATS) is hot film sensor and senses mass air flow. ECM performs EGR

system feed back control with the information of measured mass air flow. (The role of MAFS in diesel

engine is different from gasoline engine. Fuel injection quantity is decided by MAFS signal in gasoline

engine.)When EGR gas(contains no oxygen) flowing into combustion chamber increases, the air

passing through MAFS(contains oxygen) decreases. Thus, with the output signal change of MAFS

accompanied by EGR actuator actuation, ECM determines the amount of recirculated EGR gas

quantity.

NOx is produced from the reaction of nitrogen and oxygen.

If least intake air required for complete combustion flows into combustion chamber by controlling

EGR gas(contains no oxygen) which is recirculated to combustion chamber, NOx decreases

because there is no supplementary oxygen to react with nitrogen.

DTC DESCRIPTION

P0103 is set when MAFS singal line voltage is above 5.0V(above 1000mg/stroke). This code is due to 1)

short in ground circuit or 2)short to battery in singal or power circuit 3)MAFS component failure.

DTC DETECTING CONDITION

Item

Threshold Value

Detecting Condition

MAFS

output value above 1000mg/stroke

(OC/SC+)

EGR control

Fail Safe

Possible Cause

inhibited

ECM calcultaes mass air flow using

engine speed data

Check

lamp

MAFS

MAFS

circuit

component

NO

OC (Open Circuit) : Open, SC- (Short Circuit - ) : Short to ground , SC+ (Short Circuit +) : Short to

battery

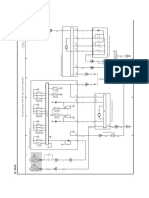

SIGNAL WAVEFORM AND DATA

1/7

2009 > D 2.9 WGT > Mass Air Flow Sensor (MAFS) > P0103

MAFS waveform looks like saw teeth at idle. This waveform is displayed because intake pulse is

sensed at MAFS .(because there is no throttle valve at diesel engine.) Therefore, this waveform is

correct.

SPECIFICATION

Air flow

10 Kg/h

15 Kg/h

30 Kg/h

60 Kg/h

120 Kg/h

Voltage

1.23V

1.37V

1.70V

2.18V

2.75V

Air flow

250 Kg/h

370 Kg/h

480 Kg/h

640 Kg/h

Voltage

3.47V

3.97V

4.23V

4.61V

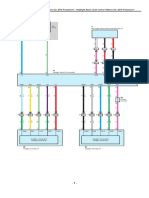

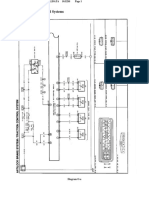

SCHEMATIC DIAGRAM

2/7

2009 > D 2.9 WGT > Mass Air Flow Sensor (MAFS) > P0103

MONITOR SCANTOOL DATA

1. Connect Scantool to Data Link Connector (DLC).

2. Warm engine up to normal operating temperature.

3. Turn "OFF" electrical devices and A/C.

4. Monitor "AIR FLOW VOLTAGE" and "EGR VALVE CONTROL PWM" displayed on Scantool.

Specification : When EGR actuator do not operate(EGR actuator duty 5%) : 2.0~2.5V

average

When EGR actuator operates(EGR actuator duty 95%) : 1.5~2.2V average

3/7

2009 > D 2.9 WGT > Mass Air Flow Sensor (MAFS) > P0103

TERMINAL AND CONNECTOR INSPECTION

1. Electrical systems consist of a lot of harness and connectors, poor connection of terminals can cause

various problems and damage of component.

2. Perform checking procedure as follows.

(1) Check damage of harness and terminals : Check terminals for contact resistance, corrosion and

deformation.

(2) Check connecting condition of ECM and component connector : Check terminal seperation,

damage of locking device and connecting condition between terminal and wiring.

Disconnect the pin which requires checking at mail connector and insert it to the terminal at

female connector for checking connecting condition. ( after checking, reconnect the pin at

correct position )

3. Is the problem found?

Repair the trouble causing part and go to "Verification of Vehicle Repair".

Go to "Power Circuit Inspection".

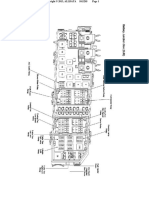

POWER CIRCUIT INSPECTION

1. IG KEY "OFF", ENGINE "OFF"

2. Disconnect MAFS connector.

3. IG KEY "ON"

4. Check the voltage or MAFS connector terminal 2 and 4.

Specification : terminal 2 : 4.8V~5.1V

terminal 4 : 11.5V~13.0V

5. Is the measured voltage within the specification?

Go to "Signal Circuit Inspection".

When output voltage is not detected at terminal 2 :

Repair open between MAFS connector terminal 2 and ECM connector(C06-2) terminal 45 and go

to "Verification of Vehicle Repair".

When output voltage is not detected at terminal

4/74 :

2009 > D 2.9 WGT > Mass Air Flow Sensor (MAFS) > P0103

When output voltage is not detected at terminal 4 :

Repair open in FAM 15A INJ FUSE and related circuit, and go to "Verification of Vehicle Repair".

SIGNAL CIRCUIT INSPECTION

1. Check open in signal circuit

(1) IG KEY "OFF", ENGINE "OFF"

(2) Disconnect MAFS connector and ECM connector.

(3) Check continuity between MAFS connector terminal1 and ECM connector terminal 46.

Specification : Continuity( below 1.0 )

(4) Is the measured continuity within the specification?

Go to "2. Check short to battery in signal circuit" as follows.

Repair open in signal circuit and go to "Verification of Vehicle Repair".

2. Check short to battery in signal circuit

(1) IG KEY "OFF", ENIGINE "OFF"

(2) Disconnect MAFS connector and ECM connector.

(3) IG KEY "ON"

(4) Measure the voltage of MAFS connector terminal 1.

Specification : 0.0V~0.1V

(5) Is the measured voltage within the specification?

Go to "Ground Circuit Inspection".

5/7

2009 > D 2.9 WGT > Mass Air Flow Sensor (MAFS) > P0103

Go to "Ground Circuit Inspection".

Repair short to battery in signal circuit and go to "Verification of vehicle Repair".

GROUND CIRCUIT INSPECTION

1. IG KEY "OFF", ENGINE "OFF"

2. Disconnect MAFS connector.

3. IG KEY "ON"

4. Measure the voltage of MAFS connector terminal 2. [ TEST "A" ]

5. Check the voltage between MAFS connector terminal 2 and 3. [ TEST "B" ]

( terminal 2 : Check + prove , terminal 3 : Check - prove )

Specification : [TEST "A"] Voltage - [TEST "B"] Voltage = below 200mV

6. Is the measured voltage within the specification? (Is ground circuit grounded correctly?)

Go to"Component Inspection".

When "B" voltage is not detected : Repair open in ground circuit and go to "Verification of Vehicle

Repair".

When the voltage difference between "A" and "B" is above 200mV : Eliminate the causes of

excessive resistance and go to "Verification of Vehicle Repair".

COMPONENT INSPECTION

1. IG KEY "OFF", ENGINE "OFF"

2. Check that AFS is installed in correctly according to the direction of arrow on AFS assy'.

3. Check contamination of air cleaner filter.

4. IG KEY "ON", ENGINE "ON"

5. Let IDLE RPM last after warming engine up.

6. Check the leakage of intake system(the leakage or damage of intercooler).

7. Check that EEGR actuator does not operate.

( EEGR actuator turns "OFF" 68 sec. after rapid acceleration. Disconnect EEGR actuator connector

if needed. )

8. Monitor signal voltage of MAFS when engine speed lasts at approx. 800RPM.

Specification : signal voltage fluctuatess between 2.0 and 2.5V.

9. Is the measured voltage within the specification?

6/7

2009 > D 2.9 WGT > Mass Air Flow Sensor (MAFS) > P0103

Go to "Verification of Vehicle Repair".

Replace MAFS assy' and go to "Verification of Vehicle Repair".

VERIFICATION OF VEHICLE REPAIR

After a repair, it is essential to verify that the fault is corrected.

1. After connecting Scantool select "DIAGNOSTIC TROUBLE CODES(DTCs)" mode.

2. Clear recorded DTC using Scantool.

3. Drive the vehicle within DTC "Enable conditions" in "General information".

4. After selecting "DIAGNOSTIC TROUBLE CODES(DTCs)" mode and check if DTC is recorded again.

5. Are any DTCs recorded ?

Go to the DTC guide of recorded NO. in Scantool.

System operates within specification.

7/7

Anda mungkin juga menyukai

- Hyundai Accent 98 MFI Control SystemDokumen98 halamanHyundai Accent 98 MFI Control Systemwessamalex100% (1)

- Captiva Series II Product OverviewDokumen10 halamanCaptiva Series II Product OverviewYudhie W Arthana RBelum ada peringkat

- DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance ProblemDokumen2 halamanDTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problempeter_nicks5441Belum ada peringkat

- 2008-07-31 074935 04 CelicaDokumen10 halaman2008-07-31 074935 04 CelicaCesar Alarcón Solis100% (1)

- DTC P0418 Secondary Air Injection System Relay "A" CircuitDokumen4 halamanDTC P0418 Secondary Air Injection System Relay "A" CircuitOrkhon GanchimegBelum ada peringkat

- Landcruiser 200 CodesDokumen9 halamanLandcruiser 200 Codesmarran almarranyBelum ada peringkat

- Vitara J20A ECU AnalysisDokumen2 halamanVitara J20A ECU AnalysisRenan AlvimBelum ada peringkat

- Diagnosis With Blink Code - Edc7 - 2002 - 01Dokumen10 halamanDiagnosis With Blink Code - Edc7 - 2002 - 01Jason KozminskaBelum ada peringkat

- P1656 PDFDokumen3 halamanP1656 PDFTalleban TalBelum ada peringkat

- Codigos ObdDokumen36 halamanCodigos ObdJorge Alfonso RodriguezBelum ada peringkat

- LACETTI Engine (71-100) - 1.8DDokumen30 halamanLACETTI Engine (71-100) - 1.8DDangLuyenBelum ada peringkat

- Afs BDokumen15 halamanAfs BMaiChiVuBelum ada peringkat

- Navara qr25deBCSDokumen20 halamanNavara qr25deBCSAhmedBelum ada peringkat

- Camshaft Sensor 2.4 MitsubishiDokumen14 halamanCamshaft Sensor 2.4 MitsubishiJoselorenzo Torres ABelum ada peringkat

- Distributor Installation: Crankshaft Position Sensor RemovalDokumen2 halamanDistributor Installation: Crankshaft Position Sensor RemovalKeyboardMan1960Belum ada peringkat

- C100 Service Training Manual: Engine Mechanical (2.4L DOHC) : Participant's HandoutDokumen32 halamanC100 Service Training Manual: Engine Mechanical (2.4L DOHC) : Participant's Handoutsertex_joBelum ada peringkat

- Srs Airbag Control System: SectionDokumen92 halamanSrs Airbag Control System: Sectionjair HernandezBelum ada peringkat

- Enviando Denso Mitsubishi l200 Common RailDokumen55 halamanEnviando Denso Mitsubishi l200 Common Railisrael machicado calle100% (3)

- Coduri Eroare Diverse P C B UDokumen46 halamanCoduri Eroare Diverse P C B Uanon_863197658100% (1)

- Engine Control LS600HLDokumen66 halamanEngine Control LS600HLnang32Belum ada peringkat

- Description: Eps System Description - Eps ControlDokumen34 halamanDescription: Eps System Description - Eps ControlpaniyaBelum ada peringkat

- Система управления двигателемDokumen3 halamanСистема управления двигателемEdik Bonifacio MamaniBelum ada peringkat

- Eclipse 2GTurbo ECU PinoutsDokumen5 halamanEclipse 2GTurbo ECU PinoutsNik Mohd HasaniBelum ada peringkat

- DTC C1511/11 Torque Sensor 1 Malfunction DTC C1512/11 Torque Sensor 2 Malfunction DTC C1513/11 Torque Sensor Deviation Excessive Torque Sensor Power Supply Voltage Malfunc-TionDokumen3 halamanDTC C1511/11 Torque Sensor 1 Malfunction DTC C1512/11 Torque Sensor 2 Malfunction DTC C1513/11 Torque Sensor Deviation Excessive Torque Sensor Power Supply Voltage Malfunc-TionSajjad KhaliqBelum ada peringkat

- Code DescriptionDokumen37 halamanCode DescriptionاحمدميدوBelum ada peringkat

- Evo 4 5 6 Conversion To Evo7 8 ECU Pinout DiagramsDokumen10 halamanEvo 4 5 6 Conversion To Evo7 8 ECU Pinout DiagramsRemus TuningBelum ada peringkat

- T TC014 06Dokumen2 halamanT TC014 06mario100% (1)

- Gr00004300a 13aDokumen202 halamanGr00004300a 13aEduardo Enrique Rojas ValenzuelaBelum ada peringkat

- VGRS Actuator MalfunctionDokumen3 halamanVGRS Actuator MalfunctionHenry YogaswaraBelum ada peringkat

- Biante SKYACTIV: Dimension & Weight Seating & TrimDokumen4 halamanBiante SKYACTIV: Dimension & Weight Seating & Trimyusransyah100% (1)

- Pinout-Schematic DiagramsDokumen14 halamanPinout-Schematic DiagramsIvan RdzBelum ada peringkat

- Service Manual: Common Rail System For NISSAN YD1-K2 Type EngineDokumen40 halamanService Manual: Common Rail System For NISSAN YD1-K2 Type EngineBryan Edu Curay ZavalaBelum ada peringkat

- Toyota Hilux 2018 Overall EWD Vehicle Exterior Power Window (RHD All Door Jam Protection)Dokumen2 halamanToyota Hilux 2018 Overall EWD Vehicle Exterior Power Window (RHD All Door Jam Protection)gabrielzinho43Belum ada peringkat

- Diagrama Hiace 2kd 5le PDFDokumen48 halamanDiagrama Hiace 2kd 5le PDFantoniomecptBelum ada peringkat

- P0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedDokumen4 halamanP0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedBiniyam BekeleBelum ada peringkat

- 1ZZ-FE - 2ZZ-FE wiring (คันเร่งสาย)Dokumen84 halaman1ZZ-FE - 2ZZ-FE wiring (คันเร่งสาย)Mos stckrBelum ada peringkat

- Hyundai Chassis EPS - MDPS-Power SteeringDokumen99 halamanHyundai Chassis EPS - MDPS-Power SteeringDedi Suwasono100% (2)

- Serena 2003 Automatic Continuously Variable Transmission CVT Wiring Diagram & VoltagesDokumen4 halamanSerena 2003 Automatic Continuously Variable Transmission CVT Wiring Diagram & VoltagesrayBelum ada peringkat

- PG - Power Supply Ground & Circuit Elements PDFDokumen157 halamanPG - Power Supply Ground & Circuit Elements PDFAxxBelum ada peringkat

- DTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionDokumen9 halamanDTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionAndres AriasBelum ada peringkat

- 2az-Fe Engine Control System Sfi SystemDokumen6 halaman2az-Fe Engine Control System Sfi SystemMarcelo DecimaBelum ada peringkat

- DAewoo Matiz Engine Fault CodesDokumen5 halamanDAewoo Matiz Engine Fault CodesGerasimos FragopoulosBelum ada peringkat

- Ci P0500Dokumen2 halamanCi P0500David BenazeraBelum ada peringkat

- Sec5a4 Abs AsrDokumen94 halamanSec5a4 Abs AsrTadas PBelum ada peringkat

- Toshiba MG75J2YS45 DatasheetDokumen5 halamanToshiba MG75J2YS45 DatasheetGonzaloBelum ada peringkat

- Siemens MS43 PinoutDokumen5 halamanSiemens MS43 Pinoutzozo0424Belum ada peringkat

- Avensis Intake System PDFDokumen19 halamanAvensis Intake System PDFMladen VidovićBelum ada peringkat

- ECM Mitsubishi Pajero - FULL MOTORES CHECKDokumen5 halamanECM Mitsubishi Pajero - FULL MOTORES CHECKJuan Felipe Romero Rayo100% (1)

- 1KD EduDokumen5 halaman1KD EduMakokha Mumelo100% (1)

- Accent Engine Control SystemDokumen35 halamanAccent Engine Control Systemflash_24014910Belum ada peringkat

- Actyon A0 A06005Dokumen10 halamanActyon A0 A06005Arimbi GembiekBelum ada peringkat

- Ipd 66031Dokumen42 halamanIpd 66031HannOtto StoreBelum ada peringkat

- Part2 Engine Management System-PB-New F3-OkDokumen433 halamanPart2 Engine Management System-PB-New F3-OkAbel OviedoBelum ada peringkat

- PDF Isuzu Truck Fault Codes List PDF - CompressDokumen1 halamanPDF Isuzu Truck Fault Codes List PDF - CompressRodrigo Almanza NBelum ada peringkat

- System Component TestsDokumen18 halamanSystem Component TestsAnimemanuel MuñozBelum ada peringkat

- CMP (Phase) MuranoDokumen8 halamanCMP (Phase) MuranoGuillermo RojasBelum ada peringkat

- Toyota Inputs & SensorsDokumen22 halamanToyota Inputs & Sensorsfasdomingo100% (1)

- P1128-Closed Loop Fueling Not Achieved - Bank 1 - WH, XH, Ka, KK - 2007-2010Dokumen9 halamanP1128-Closed Loop Fueling Not Achieved - Bank 1 - WH, XH, Ka, KK - 2007-2010Karl Heinz KerzenschuhBelum ada peringkat

- P0100 Mass Air Flow CircuitDokumen7 halamanP0100 Mass Air Flow CircuitDaniel rodriguez alayoBelum ada peringkat

- Fuse: Locations High Current Battery Junction Box (BJB)Dokumen1 halamanFuse: Locations High Current Battery Junction Box (BJB)julio797Belum ada peringkat

- 4WD JM PDFDokumen32 halaman4WD JM PDFjulio797Belum ada peringkat

- Fusibles Escape 2013Dokumen1 halamanFusibles Escape 2013julio797Belum ada peringkat

- Relay Baterry Escape2010Dokumen2 halamanRelay Baterry Escape2010julio797Belum ada peringkat

- Vehicle: Electrical Diagrams Antilock Brakes / Traction Control SystemsDokumen4 halamanVehicle: Electrical Diagrams Antilock Brakes / Traction Control Systemsjulio797Belum ada peringkat

- Data SheetDokumen227 halamanData Sheetjulio797Belum ada peringkat

- TM CVT Nissan NoteDokumen257 halamanTM CVT Nissan Notejulio797100% (1)

- l438 Dual RegulatorDokumen13 halamanl438 Dual Regulatorjulio797Belum ada peringkat

- BMW 325 1Dokumen1 halamanBMW 325 1julio797Belum ada peringkat

- Ec Nissan Sentra 2002 PDFDokumen1.854 halamanEc Nissan Sentra 2002 PDFjulio79750% (2)

- 2005 - MD - C - Elec Duty C Series PDFDokumen321 halaman2005 - MD - C - Elec Duty C Series PDFjulio797Belum ada peringkat

- 62TE, Tech Info, Solenoid ID & Connector Pin OutDokumen1 halaman62TE, Tech Info, Solenoid ID & Connector Pin Outjulio79780% (5)

- Aim Bosch 100 EngDokumen36 halamanAim Bosch 100 Engjulio797Belum ada peringkat

- Four-Wheel Drive Systems - Electronic Shift: Special Tool(s)Dokumen24 halamanFour-Wheel Drive Systems - Electronic Shift: Special Tool(s)julio797Belum ada peringkat

- Vehicle: Connector Views C175TDokumen2 halamanVehicle: Connector Views C175Tjulio797Belum ada peringkat

- Center Differential Lock Power SourceDokumen1 halamanCenter Differential Lock Power Sourcejulio797Belum ada peringkat

- Fuses Instrument Panel Amarok 13Dokumen7 halamanFuses Instrument Panel Amarok 13julio797Belum ada peringkat

- Thectsc Mechatronic ReplacementDokumen22 halamanThectsc Mechatronic Replacementjulio797Belum ada peringkat

- System Wiring Diagrams 1.6L DOHC, Engine Performance Circuits (1 of 3)Dokumen1 halamanSystem Wiring Diagrams 1.6L DOHC, Engine Performance Circuits (1 of 3)julio797Belum ada peringkat

- Fuses Batery AmarokDokumen6 halamanFuses Batery Amarokjulio797Belum ada peringkat

- DSO Nano V3 User's ManualDokumen15 halamanDSO Nano V3 User's Manualjulio797Belum ada peringkat

- Class VIII Science Question Bank For SUMMATIVE ASSESMENTDokumen7 halamanClass VIII Science Question Bank For SUMMATIVE ASSESMENTApex Institute100% (2)

- Trimec FullrangeDokumen24 halamanTrimec FullrangeSaravanan MathiBelum ada peringkat

- Genie Service Manual TML-4000 & TML-4000NDokumen78 halamanGenie Service Manual TML-4000 & TML-4000NPrejit RadhakrishnaBelum ada peringkat

- PerforationDokumen45 halamanPerforationCatur Nila Pratiwi75% (4)

- Operation and Maintenance Manual: Panel Mount PRO/portionerDokumen32 halamanOperation and Maintenance Manual: Panel Mount PRO/portionerAAR143Belum ada peringkat

- Duty Specification FOR Hot Oil System Package Unit: GeneraDokumen5 halamanDuty Specification FOR Hot Oil System Package Unit: GeneraSuchart TarasapBelum ada peringkat

- Ata 28Dokumen7 halamanAta 28Jose Cruz candidoBelum ada peringkat

- Hydrocarbon Production From Fractured Basement FormationsDokumen40 halamanHydrocarbon Production From Fractured Basement FormationsSyaiful Alam100% (1)

- WC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemDokumen7 halamanWC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemryneleeBelum ada peringkat

- HazardEX Novembro 2019 PDFDokumen48 halamanHazardEX Novembro 2019 PDFGabriel BonaroskiBelum ada peringkat

- Calculation of Dew Point of Flue Gas 4x135 MW Jindal, AngulDokumen2 halamanCalculation of Dew Point of Flue Gas 4x135 MW Jindal, AngulAshitava SenBelum ada peringkat

- Nissan CD17Dokumen3 halamanNissan CD17jose luis calixto requisBelum ada peringkat

- High Bulk DensityDokumen2 halamanHigh Bulk DensityallbenattiBelum ada peringkat

- Riding MowerDokumen68 halamanRiding Mowerfmpeb1Belum ada peringkat

- Wavistrong Supplemental Installation InstructionsDokumen13 halamanWavistrong Supplemental Installation Instructionsmg4myBelum ada peringkat

- Water Chiller SystemDokumen19 halamanWater Chiller SystemAlok kumar92% (24)

- SSP 604 - Audi 30l v6 Tdi Biturbo Engine EngDokumen23 halamanSSP 604 - Audi 30l v6 Tdi Biturbo Engine Engfrancois.garcia31100% (1)

- PC7000-6 Loading Shovel PC7000-6 BackhoeDokumen9 halamanPC7000-6 Loading Shovel PC7000-6 BackhoeDerek VerdejoBelum ada peringkat

- Catalogo Bombas CorkenDokumen12 halamanCatalogo Bombas CorkenDanielBelum ada peringkat

- Detroit DD15 Engine: Horsepower LB-FT Torque LitersDokumen10 halamanDetroit DD15 Engine: Horsepower LB-FT Torque LitersDeyviJavierIpanaqueEspinozaBelum ada peringkat

- Petrochemical Industry ListDokumen3 halamanPetrochemical Industry Listsachin bajpaiBelum ada peringkat

- 6284 2 20 PDFDokumen3 halaman6284 2 20 PDFnpsBelum ada peringkat

- Grundfos Pump Dissasemble PDFDokumen420 halamanGrundfos Pump Dissasemble PDFkokkiBelum ada peringkat

- Wartsila 32 DF PDFDokumen16 halamanWartsila 32 DF PDFKeivinMC100% (1)

- 4 G 69Dokumen18 halaman4 G 69dhikomo100% (2)

- lm75 SpecDokumen4 halamanlm75 SpecheberBelum ada peringkat

- Bunkering Check List: Yacht InformationDokumen3 halamanBunkering Check List: Yacht InformationMarian VisanBelum ada peringkat

- Presentation by Mr. Amit Chaturvedi and Mr. Rajesh Rawat, Reliance IndustriesDokumen18 halamanPresentation by Mr. Amit Chaturvedi and Mr. Rajesh Rawat, Reliance Industriesswaggeroni yololoBelum ada peringkat

- Kohler Courage SV710-SV740 & Courage Pro SV810-SV840 Service ManualDokumen76 halamanKohler Courage SV710-SV740 & Courage Pro SV810-SV840 Service ManualEric OlsonBelum ada peringkat