1188848

Diunggah oleh

Cristi BudauHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1188848

Diunggah oleh

Cristi BudauHak Cipta:

Format Tersedia

VI International Conference on Textile Composites and Inflatable Structures

STRUCTURAL MEMBRANES 2013

K.-U.Bletzinger, B. Krplin and E. Oate (Eds)

HIGH PRECISION LARGE SPACE STRUCTURES: CHALLENGES IN

CABLE NETWORKS DESGIN

STRUCTURAL MEMBRANES 2013

BIN WEI, DOMINIK MAGNER, STEPHAN ENDLER, HORST BAIER AND

LERI DATASHVILI

Institute of Lightweight Structures

Technische Universitt Mnchen

Boltzmann Strae 15, 85747 Garching bei Mnchen

Emails: wei@llb.mw.tum.de, datashvili@llb.mw.tum.de

Web page: http://www.llb.mw.tum.de

Key words: Large Space Structures, Cable Network, Form Finding, Structural Optimization,

Force Density Method, Dynamic Relaxation.

1

INTRODUCTION

Nowadays space missions such as Earth observation, telecommunication and science

require large antenna reflectors in the diameter range up to 20 meters or even larger for high

performances. The antenna reflector structure has to satisfy strict requirements like high

surface accuracy, low mass, high packaging efficiency, high reliability/stability in hazardous

space environments for a long service life among others. These requirements lead to great

challenges in developing large space deployable reflector (LDR) structures. One of the

challenges is related to providing the parabolic high accurate (sub-millimeter range) shape

with a minimum mass. Most of the flown reflectors known use cable networks suspended

circumferentially or radially over a deployable framework. The cable networks approximate a

parabolic surface with flat triangular facets, creating support for reflective material, e.g.

extremely flexible knitted metal mesh.

In some specific missions LDR of about 6 m shall operate in high radio-frequency band

(e.g. up to 30 GHz) [2]. This indicates a need of a fine facet size of the cable network of about

100 mm with a large number of cables and a strict surface error tolerance (around 0.1 mm).

Moreover, manufacturing and assembling of such complex cable network with high accurate

positioning and proper tensioning in cables is a quite challenging task as well. All above

mentioned aspects lead the cable network design to be a form finding and design optimization

problem with large number of variables, strict goal definition and multiple complex

constraints.

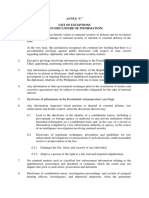

A mechanical architecture of a large deployable mesh reflector (Figure 1) contains a

deployable peripheral structure, which supports a cable network and a reflecting metal mesh.

The cable network usually consists of a front network, a rear network and tie cables between

them to form a so called tension truss (see also [12]).

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

Figure 1: A mechanical architecture of a mesh reflector [17]

The cable network is a kind of flexible structures, which generally have strong interactions

between their geometry and stresses. Different to conventional rigid structures, the

configurations of flexible structures are more likely to be found rather than to be designed.

The sustainable configurations of such structures are the equilibrium status among used

materials, stresses in structures, defined boundary conditions and external loads. From energy

point of view, the equilibrium status can be understood as a system with minimum total

potential energy, which is the same to minimum difference between internal strain energy to

external kinetic energy.

2

FORM FINDING AND STRUCTURAL OPTIMIZATION

Form finding is one of the classical problems in flexible tension structures like cable

networks and membranes. Two typical approaches used in form finding are force density

method (FDM) and dynamic relaxation (DR). Their basic principles are briefly explained in

the following.

The force density method is initialized by Linkwitz and Schek in early 70s, which is used

to design the cable-net roofs of Olympia stadium Munich (1972). The core of FDM is

linearizing the system of nonlinear equations by introducing a parameter called force density

(ratio of force to cable length). These linearized system equations enable an efficient and

accurate analytical approach to be performed for finding good initial geometry of flexible

structures. In later publications of Schek [1], he has given a more general understanding of

form finding and optimization about cable networks. Cable network design is understood as a

structural optimization, whose goal is finding an equilibrium initial geometry subjecting to

constrains like cable lengths, cable forces and point positions. The expression of the

optimization problem is:

( ( ) ( ) ( ) )

Goal:

Design variable:

Constraints:

min. system potential energy

force density (q) of each cable

cable lengths, cable forces and point positions

(1)

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

One of the simplest algorithms for solving the optimization problem is gradient based least

squares principle. The gradients and related Lagrange factors can be readily derived through

chain rules [1]. To improve the convergence behavior of a form finding design optimization

particularly in problems with large force densities or shape changing, damping factors are

added into functions as well.

The dynamic relaxation (DR) is an explicit solution technology based on finite difference

method. Day [13] introduced this method in 60s to tidal flow computation and later Barnes

extended it to solve design problems of flexible structures [15]. It traces step-by-step for small

time increments of the motion of each node of the structure until it reaches the static

equilibrium due to damping. Since the objective is to find the equilibrium status rather than

trace the real dynamic behavior, the mass is fictitious here and is set to optimal convergence.

In addition, better numerical stability of the analysis can be reached by taking kinetic

damping instead of viscous damping. According to Newtons second law, the residuals

between external loads and internal loads cause motion of a system and the velocity and

displacement of each node can be obtained by integrating time steps. The update of geometry

is performed on each node step-by-step based on center finite difference method. So their

computation costs in DR are significantly less than stiffness matrix inversion calculations in

FDM. In kinetic damping method, once the maximal kinetic energy of a system is detected,

the analysis has to be restarted at the current geometry configuration with zero residuals and

acceleration for the next iteration (Figure 2).

(2)

(3)

(4)

( )

(5)

There are three aspects of requirements to the cable network design. First is the high

surface accuracy requirement. Generally the surface shape accuracy is characterized by

systematic and random errors. Triangular faceted approximation of the parabola determines

the extent of systematic errors, which can be controlled by the facet size. The random error is

the deviation of the achieved point positions from the nominal positions, which depends on

the design and manufacturing quality. The second aspect of requirements is related to tensions

in the cables. The cables are to be tensioned and, for the reason of manufacturing

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

simplification, to be uniform in magnitude. Last but not least, the cable network must be in

equilibrium configuration with satisfying the above two aspects of requirements

simultaneously.

Variation of kinetic energy to iterations

Kinetic energy

10

x 10

8

6

4

2

0

0

10

20

30

40

50

60

70

80

Number of iterations

Figure 2: A typical curve of variation of kinetic energy to iterations

The above mentioned two approaches of form finding are integrated into a structural

optimization code of cable networks. Two types of examples are used as testing benchmarks

to compare these two design approaches. One uses the frame structure as in Figure 1 and has a

front to rear symmetric networks. The other uses a conical ring structure (Figure 3) and has a

front to rear asymmetric networks.

Figure 3: Conical ring structure [ESA patent 568]

DESIGN OF CABLE NETWORKS USING FORCE DENSITY METHOD

In the design approach using FDM, FDM is used for form finding and gradient based

algorithm (least square) is used for structural optimization. The performance and features of

this method are discussed through design examples.

There are lots of design examples of symmetric cable networks in references [4, 6, 8, and

9]. Since it has a symmetric construction, simplifications e.g. using half of cable network,

using vertical forces to instead of tie cables are taken in designs. Further simplifications like

considering only the internal regular cable network while ignoring the interface cables, frame

structures as well as their interactions are taken in these examples. In [9], Morterolle

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

presented a simple design approach using FDM to design parabolic and uniform tensioned

cable networks. In his approach, Z coordinates of points are directly given by analytical

parabolic functions according to their in-plane positions and tie forces are calculated by

relating to tensions in cables and points positions. Therefore a 3D design problem is

simplified to be a 2D design problem with only tension constraints. In his later publication

[14], he demonstrated this method works also for offset parabolic configurations and other

facets like square and hexagon.

Generally, those methodologies in literature have number of simplifications, which in fact

have to be followed more accurately. For example, behavior of an interface between internal

cable network to interface cables (Figure 4) is better to be taken into account. The over

simplified problem leads to difficulties in applying this method to practice applications

directly. Therefore in [14], a stepwise approach is performed to design the interface cables

based on designed internal cable networks. But actually, the interface cables belong to the

same structure as well, whose design can be implemented similarly and simultaneously to the

internal cable network.

Figure 4: A design example of a symmetric cable network with uniform tension

The fact that the number of support truss points is usually less than the number of the edge

points of the internal cable network determines the need in having interface cables. The

interface cables connect several internal network points to a single truss point. As proved by

numerical tests, it is infeasible to find an equilibrium form with identical tensions in all

internal and interface cables. Therefore, modification of constraints with respect to the

interface cables has to be implemented. It can be done in two ways. One is maintaining

uniform tension in interface cables while allowing varying their positions. Then the tensions

in interface cables can be allowed to be larger than in the internal cables. The other is

maintaining the rim points positions of the internal network while varying tensions in

interface cables. Examples of using the first modification can be found in [16] and examples

of using the second modification are explained in the following.

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

The simplified method of Morterolle is not capable to handle these multi-types constraints.

Therefore the general method described by Schek [11], which is a gradient based

optimization, is used. Different gradients from position constraints (internal cable network

edge points) and tension constraints (internal cables) are linearly combined by weighting

factors for iterative update of the force densities. Four design examples using edge point

position constraints are demonstrated in Figure 5. The first two have the same number of

points and cables while different edge points positions. The latter two contain large number

of members and complex interface cable connections.

Figure 5: Design examples of using edge points positions constraints

All these four designs are achieved with uniform tension in internal cables and predefined

positions of the edge points are maintained. One highlight of these designs is the narrow

varied facet size, which is preferred for surface accuracy reason. The tensions in interface

cables vary adding some complexities in manufacturing and assembling.

Different to the symmetric design, the simplifications due to symmetric conditions are not

valid and design approaches are to be updated correspondingly in case of asymmetric network

designs (Figure 3) [16].

As the number of points and cables increase (the largest number of points is 733 and cables

is 2214 in Figure 5) in designs, the computation cost increases dramatically. Besides this, the

convergence behavior is not stable due to multiple types of constraints. Damping factors must

be appropriately selected to find a compromise between computation robustness and cost. For

instance, the last example with proper selected damping factors took around 3 hours for

computation on a high performance computer. To find these proper damping factors, several

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

trial and error tests are needed, which consumes extra time as well.

For high RF applications, the cable networks of medium class LDR require around 4000 to

6000 cable elements for achieving an acceptable level of systematic shape errors. The

gradient based optimization with FDM seems quite complicated to accomplish this

challenging task due to the following main drawbacks. The first is related to the stiffness

matrix inversion in each iteration in the gradient calculation, which is generally time

consuming and inaccurate. The second is related to the multiple types of constraints in

optimization, which generate multiple gradients and they are difficult to be combined properly

for updates. Both drawbacks belong to the used FDM but they can be avoided using DR

method addressed in the following.

4

DESIGN OF CABLE NETWORKS USING DYNAMIC RELAXATION

Form finding with dynamic relaxation has significantly lower computation cost especially

when using the kinetic damping method, which ensures a rapid and stable convergence of the

analysis. DR method for form finding and structural optimization is implemented and tested

through different examples discussed below.

Found shapes for several examples with front and rear symmetric networks are presented

in Figure 6. Optimization constraints of internal cable network edge points are set to maintain

their positions in a very narrow range while varying tensions in interface cables. Given

examples in the figure contain different number of support truss points and intermediate

points as well as the number of cables, which varies between 4000 and 6000.

Different to the iteratively updated design parameters to approach the goal using FDM, the

targeted cable forces and positions are directly assigned to the initial network to cause

oscillations (geometry changes) until reaching the equilibrium due to damping. The

convergence criterion is set to force residuals on nodes, which determines the accuracy of

results and computation cost.

Computation cost of the both design methods discussed has been compared using the same

cable network with the same convergence criterions (tension residuals). This particular

investigation shows that the FDM needs around 180 minutes for computation, while using the

DR 10 minutes are sufficient. Additionally, the point position error in using DR is

significantly smaller than it in using FDM (refer to the similar constraints). The design

method using DR has shown attractive features of computation efficiency and robustness,

which is appropriate to accomplish tasks of designing cable networks for high precision LDR

for high radio frequencies.

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

Figure 6: Design examples using DR

One of the key points in asymmetric network design process using DR is the way of

determination of the tensions in tie cables. The tensions in tie cables are updated in each

iteration to be the difference between the actual tensions and out-of-plane residuals in front

network points. The purpose of this action is adjusting the tensions in tie cables to set

residuals in front network points to zero. So their pre-defined positions can be maintained.

The rear network points have almost no position constraints and their geometry is simply

updated according to updated residuals.

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

Figure 7: Asymmetric cable networks designs using DR

Various cable networks designs have been investigated using the described method.

Results of these investigations show that computation cost is usually higher in designing

asymmetric cable networks than symmetric ones due to configuration differences. The front

networks of asymmetric cases have no significant configuration difference from the

symmetric ones however their facet sizes vary wider than in symmetric cases for smaller rear

network constructions.

5. INFLUENCE OF COMPLIANCE OF FRAME STRUCTURES

In above test examples, cable networks are attached to idealized rigid frame structures. A

simplified truss frame structure, which is made from carbon fiber reinforced plastic (CFRP)

tubes, is implemented to figure out the influence of its compliance to cable networks (Figure

8). The used cable network contains 1670 points and 5815 cables and its convergence

criterion for design optimization is set to residual to be less than 1% of tension in cables.

Subject to an idealized rigid frame, the point position error of the designed network in

FEM analysis is insignificant (6.2e-5 mm under 1% residuals). With considering the

compliance of the frame structure under radially symmetric and statically determinate

constraints in FEM, the point position error is increased significantly (Table 1).

The compliance of the frame structure can be reduced by increasing its bending stiffness.

For instance, increasing the CFRP tubes diameter by about 25%, the maximal deformation of

the frame structure is reduced by 30% and the surface error is also marginally reduced. This

example has shown increasing bending stiffness of the frame structure is a useful but not an

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

efficient method.

Figure 8: A cable network and its frame structure

On the other hand, the compliance problem can be solved by an iterative method. The

deformation of the frame structure indicates the boundary conditions of the cable network

have been changed. Therefore an update design of the cable network according to updated

boundary conditions is required. The resulting acting forces due to cable network updates

change deformation of the frame and in the end influences are reflected back to the cable

network design. The iterative procedure is continued until either change of the reaction forces

or deformations of the frame are small enough. Using this iterative method, the point position

error is close to the value of rigid frame model.

Table 1: Methods and effect of solving the compliance problem of the frame structure

Relative point

position error

Rigid frame

model

(reference)

Compliant frame

model

Increasing

bending stiffness

of the frame

structure on 25%

Iterative update

frame structure

and cable

network

114

92

1.1

Though the relative change of point position error due to compliance of frame structures is

large, its absolute value can be not critical and be accepted in applications. With a sufficient

high stiff frame structure, the compliance influence can be ignored even. These investigations

have shown another fact of the designed networks, they are quite sensitive to their positioning

and small deviations in points locally may cause a relatively large overall point position error.

6. CONCLUSIONS

In this paper, two approaches of cable networks design optimization for high precision

LDR were discussed and compared. The design method using DR with kinetic damping is

much more efficient and robust as compared to the FDM. This is especially the case when

networks contain large number of members and have complex configurations.

A negative influence of the compliance of the frame structure on surface accuracy can be

10

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

maintained acceptable, if setting the convergence criteria sufficiently small. On the other

hand, relative error increases at least on two orders of magnitude as compared to the assumed

rigid boundary. This can be still reduced by the established iterative procedure of taking into

account the frame deformations during the optimization process.

In practice, manufacturing and assembling of such high accurate structures is another

challenging task. The cable networks accuracy is quite sensitive to deviations of point

positioning, which indicates difficulties in implementing the high accurate designs. As a part

of future work, the uncertainty study of used material properties, points positioning and

tensions in cables will be investigated.

REFERENCES

[1] H.-J. Schek, The force density method for form finding and computation of general

networks, Journal of Computer methods on applied mechanics and engineering, volume 3

(1974) 115-134.

[2] Gunnar Tibert, Deployable tensegrity structures for space applications, doctoral thesis of

Royal Institute of Technology, ISSN 0348-467X, 2002.

[3] A. Meguro, S. Harada and M. Watanabe, Key technologies for high-accuracy large mesh

antenna reflector, Acta Astronautica 53 (2003) 899-908

[4] M.W. Thomson, AstroMesh deployable reflectors for Ku-and Ka-band commercial

satellites, AIAA-2002-2032.

[5] L. Grndig E. Moncrieff, P. Singer and D. Stroebel, A history of the principal

developments and applications of the force density method in Germany 1970-1999, Fourth

international colloquium on computation of shell & spatial structures, 2000, Greece.

[6] D.W. Yang, H. Bao, Force balance characteristics and pretension design of asymmetric

cable net parabolic antenna, Journal of mechanical engineering, 2009, 45(8): 308-312.

[7] P K Agrawal, M S Anderson, M F Card, Preliminary design of large reflectors with flat

facets, IEEE transactions on antennas and propagation, 1981, 29(4): 56-63.

[8] B. Li, G.W. Hu and F. Huang, Form-finding optimization of flexible cable net of

AstroMesh deployable reflector by force-density method, Journal of Guilin University of

electronic technology, Vol. 29, No. 5, 2009.

[9] S. Morterolle, B. Maurin. J. Quirant, Recherche de Forme dun Reflecteur Parabolique

<Geotensoid>, 10th colloque national en calcul des structures, 2011, Presauile de Giens.

[10] L. Datashvili, H. Baier, E. Wehrle, T. Kuhn, J. Hoffmann, Large shell-membrane space

reflectors, 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and

Materials Conference, 12 - 15 April 2010 2010, Orlando, Florida, USA.

[11] J. Ruze, Antenna Tolerance Theory A Review, Proceedings of the IEEE, Vol. 54, No. 4,

1966.

[12] K. Miura, and Y. Miyazaki, Concept of the tension truss antenna. AIAA Journal 28, 6

(1990), 10981104.

[13] M. R. Barnes, Form finding and analysis of tension structures by dynamic relaxation,

International Journal of space structures, Vol. 14, No.2, 1999.

[14] S. Morterolle, B. Maurin, J. Quirant and C. Dupuy, Numberical form-finding of

geotensoid tension truss for mesh reflector, Acta Astronautica 76 (2012) 154-163.

11

B. Wei, D. Magner, S. Endler, H. Baier and L. Datashvili.

[15] W J Lewis, Tension structures form and behavior, Thomas Telford Publishing, ISBN: 0

7277 3236 6, 2003.

[16] B. Wei, L. Datashvili, Cable web design for precision large deployable reflectors,

Proceedings of the Workshop on Large Deployable Antennas 2012, Noordwijk, Holland.

[17] L. Datashvili, S. Endler, H. Baier, H. Langer, M. Friemel, N. Tsignadze, J. SantiagoProwald, Study of Mechanical Architectures of Large Deployable Space Antenna

Apertures: From Design to Tests, Proceedings of the ESA/ESTEC Antenna Workshop

2012, Noordwijk.

12

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- AFAR Problems PrelimDokumen11 halamanAFAR Problems PrelimLian Garl100% (8)

- Where To Eat PizzaDokumen3 halamanWhere To Eat PizzaLiliancitaLcJsBelum ada peringkat

- Eurocode 7 Geotechnical Design Worked ExamplesDokumen172 halamanEurocode 7 Geotechnical Design Worked ExamplesJevgenijs Kolupajevs100% (1)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Study For 33KV Sub-Marine Cable Crossings PDFDokumen80 halamanStudy For 33KV Sub-Marine Cable Crossings PDFOGBONNAYA MARTINSBelum ada peringkat

- Data MiningDokumen721 halamanData MiningAuly Natijatul AinBelum ada peringkat

- Claim Age Pension FormDokumen25 halamanClaim Age Pension FormMark LordBelum ada peringkat

- IASS98Dokumen8 halamanIASS98Cristi BudauBelum ada peringkat

- 04 TensileDokumen69 halaman04 TensileCristi BudauBelum ada peringkat

- 73 FTP PDFDokumen17 halaman73 FTP PDFCristi BudauBelum ada peringkat

- Math T 2Dokumen13 halamanMath T 2Sarman TamilselvanBelum ada peringkat

- 73 FTP PDFDokumen17 halaman73 FTP PDFCristi BudauBelum ada peringkat

- Dynamic Analysis of Cable Roofs Under Transient Wind: A Comparison Between Time Domain and Frequency Domain ApproachesDokumen5 halamanDynamic Analysis of Cable Roofs Under Transient Wind: A Comparison Between Time Domain and Frequency Domain ApproachesCristi BudauBelum ada peringkat

- 0354 51801503651RDokumen10 halaman0354 51801503651RCristi BudauBelum ada peringkat

- Arwade Schafer Paper 09Dokumen16 halamanArwade Schafer Paper 09Cristi BudauBelum ada peringkat

- Extended Force Density Method and Its ExpressionsDokumen17 halamanExtended Force Density Method and Its ExpressionsGhada KhalilBelum ada peringkat

- 592009.full Paper PetraDokumen8 halaman592009.full Paper PetraCristi BudauBelum ada peringkat

- 2013062068087193Dokumen8 halaman2013062068087193Cristi BudauBelum ada peringkat

- Nonlinear Analysis of Cable Systems With Point Based Iterative MethodDokumen14 halamanNonlinear Analysis of Cable Systems With Point Based Iterative MethodKtk ZadBelum ada peringkat

- 6 2 Hegyihinczmiktex v6n2Dokumen17 halaman6 2 Hegyihinczmiktex v6n2Cristi BudauBelum ada peringkat

- 2012 Ijss Veenendaal Block 1380094819Dokumen13 halaman2012 Ijss Veenendaal Block 1380094819denis1808scribdBelum ada peringkat

- Tents, Cable Nets and Grid Shells PDFDokumen69 halamanTents, Cable Nets and Grid Shells PDFCristi BudauBelum ada peringkat

- 267 MS10 Abs 1954Dokumen8 halaman267 MS10 Abs 1954Cristi BudauBelum ada peringkat

- IASS Fabric PaperDokumen8 halamanIASS Fabric PaperCristi BudauBelum ada peringkat

- C 0706Dokumen10 halamanC 0706Cristi BudauBelum ada peringkat

- What Is New V.3.7: Designing With FormfinderDokumen26 halamanWhat Is New V.3.7: Designing With FormfinderPierre BadiaBelum ada peringkat

- Bletzinger 162Dokumen13 halamanBletzinger 162Cristi BudauBelum ada peringkat

- Airsculpt Tensile DownloadDokumen6 halamanAirsculpt Tensile DownloadCristi BudauBelum ada peringkat

- Cable Structure With Load-Adapting Geometry: Julich@enpc - Lami.fr Caron@enpc - Lami.fr Baverel@Dokumen8 halamanCable Structure With Load-Adapting Geometry: Julich@enpc - Lami.fr Caron@enpc - Lami.fr Baverel@Cristi BudauBelum ada peringkat

- 5Dokumen16 halaman5Cristi BudauBelum ada peringkat

- CIB10896Dokumen5 halamanCIB10896Cristi BudauBelum ada peringkat

- 786 Ce014Dokumen10 halaman786 Ce014Cristi BudauBelum ada peringkat

- Sistem Desktop Serioux Power V11 Cu Procesor Intel® Core™ I5-4460 3.2GHz Haswell, 8GB RAM, 1TB HDD, NVIDIA GTX 750 OC 2GB - eMAGDokumen2 halamanSistem Desktop Serioux Power V11 Cu Procesor Intel® Core™ I5-4460 3.2GHz Haswell, 8GB RAM, 1TB HDD, NVIDIA GTX 750 OC 2GB - eMAGCristi BudauBelum ada peringkat

- 385Dokumen14 halaman385Cristi BudauBelum ada peringkat

- Vol7no4 1Dokumen17 halamanVol7no4 1Cristi BudauBelum ada peringkat

- A Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingDokumen22 halamanA Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingPl TorrBelum ada peringkat

- KL1508 KL1516: 8/16-Port Cat 5 High-Density Dual Rail LCD KVM SwitchDokumen5 halamanKL1508 KL1516: 8/16-Port Cat 5 High-Density Dual Rail LCD KVM SwitchnisarahmedgfecBelum ada peringkat

- Millets: Future of Food & FarmingDokumen16 halamanMillets: Future of Food & FarmingKIRAN100% (2)

- User Custom PP Install74Dokumen2 halamanUser Custom PP Install74Zixi FongBelum ada peringkat

- Project Cost ContingencyDokumen9 halamanProject Cost ContingencyniroshniroshBelum ada peringkat

- Assignment 03 Investments in Debt SecuritiesDokumen4 halamanAssignment 03 Investments in Debt SecuritiesJella Mae YcalinaBelum ada peringkat

- Case Title: G.R. No.: Date: Venue: Ponente: Subject: TopicDokumen3 halamanCase Title: G.R. No.: Date: Venue: Ponente: Subject: TopicninaBelum ada peringkat

- Order 49Dokumen14 halamanOrder 49NURADRIANA OMAR BAHSIRBelum ada peringkat

- ShinojDokumen4 halamanShinojArish BallanaBelum ada peringkat

- Upload 1 Document To Download: Ergen DedaDokumen3 halamanUpload 1 Document To Download: Ergen DedakBelum ada peringkat

- Kudla Vs PolandDokumen4 halamanKudla Vs PolandTony TopacioBelum ada peringkat

- Dolby Atmos Specifications PDFDokumen24 halamanDolby Atmos Specifications PDFVanya ValdovinosBelum ada peringkat

- 671 - BP Well Control Tool Kit 2002Dokumen19 halaman671 - BP Well Control Tool Kit 2002Ibama MirillaBelum ada peringkat

- Defination of ValuesDokumen11 halamanDefination of ValuesDipannita GhoshBelum ada peringkat

- Resume (Suyash Garg)Dokumen1 halamanResume (Suyash Garg)Suyash GargBelum ada peringkat

- BP Azspu Driver Fatigue & Tiredness Management ProcedureDokumen11 halamanBP Azspu Driver Fatigue & Tiredness Management ProcedureEl Khan100% (1)

- RS485 ManualDokumen7 halamanRS485 Manualndtruc100% (2)

- ANNEX C LIST OF EXCEPTIONS (Non-Disslosure of Information)Dokumen3 halamanANNEX C LIST OF EXCEPTIONS (Non-Disslosure of Information)ryujinxxcastorBelum ada peringkat

- Solar Power Plant in Iit HyderabadDokumen9 halamanSolar Power Plant in Iit HyderabadHimanshu VermaBelum ada peringkat

- Nepal CountryReport PDFDokumen64 halamanNepal CountryReport PDFnickdash09Belum ada peringkat

- Wheel CylindersDokumen2 halamanWheel Cylindersparahu ariefBelum ada peringkat

- Risk, Return & Capital BudgetingDokumen18 halamanRisk, Return & Capital BudgetingMuhammad Akmal HussainBelum ada peringkat

- Mobilcut 102 Hoja TecnicaDokumen2 halamanMobilcut 102 Hoja TecnicaCAGERIGOBelum ada peringkat

- Hardening'-Australian For Transformation: A Monograph by MAJ David J. Wainwright Australian Regular ArmyDokumen89 halamanHardening'-Australian For Transformation: A Monograph by MAJ David J. Wainwright Australian Regular ArmyJet VissanuBelum ada peringkat

- CERES News Digest - Week 11, Vol.4, March 31-April 4Dokumen6 halamanCERES News Digest - Week 11, Vol.4, March 31-April 4Center for Eurasian, Russian and East European StudiesBelum ada peringkat