Chadwick 2010 K

Diunggah oleh

MarkusMakuAldoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Chadwick 2010 K

Diunggah oleh

MarkusMakuAldoHak Cipta:

Format Tersedia

OPERATION FOCUS Indonesia

Grasberg

block cave

John Chadwick concludes the mining side of the Freeport Indonesia story.

Access to the wealth of proven undeveloped underground deposits is

the key driving force to future production

hen the Grasberg open pit is depleted,

the Grasberg Block Cave (GBC) and

East Ertsberg Skarn System (EESS)

mines will become the primary ore sources. Last

months article on Big Gossan explained how the

Common Infrastructure Projects (CIP) AB Tunnels

will support the new underground mines providing

reliable gravity drainage, material handling,

ventilation, manpower and material access,

emergency egress, services line and maintenance

access. Currently, Redpath is developing the Lower

GBC mine terminal and DMLZ mine access spur.

The GBC mine terminal is a multi-heading

installation, providing a broad range of services to

mine development, construction and operation

groups. It lies at the underground end of AB

Tunnels GBC spur, some 6,000 m from its Ridge

Camp portal. This is the terminus for AB Tunnel rail

operations and the bottom station for the GBC

service shaft. Functions accommodated by the

terminal include:

Personnel handling and queuing for on/off

loading the man-cage at shift-change

Marshalling of material flat cars on the AB line

and shaft dollies in the shaft station

Handling loaded and empty material transport

containers and ISO-tainers, using the terminals

travelling bridge cranes

Intake ventilation, routed from AB Tunnels

through the terminal.

Redpath continues to work on the Grasberg

Terminal and had excavated more than 4,400 D

equivalent m to December 2009. D is the

standard drift size that Freeport Indonesia uses to

10 International Mining MARCH 2010

calculate equivalent metres for budgets, planning

and actual accomplished 4.4 m (wide) x 4.0 m

(high).

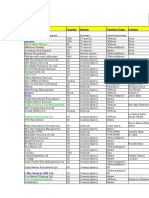

Secondary access to the GBC mine workings will

be provided by the inter-level ramp. This ramp is in

progress and will extend from the northwest end

of the GBC terminal at the 2,535 m elevation, up

to the Extraction Level near the shaft station at the

2,830 m elevation. From there, a short connection

extends the ramp access up to the Undercut Level

and hoist room. The inter-level ramp is also the

primary access to the crusher stations for

development, operations and maintenance. From

January to December 2009, Redpath excavated

more than 1,500 m D equivalent of inter-level

ramp access.

The GBC area will be supplied with air via

primary intake and exhaust drifts, collectively called

the Grasberg Ventilation Declines (GVDs). The goals

of these are to provide:

Sufficient ventilation for the GBC initial mine

development

An alternate access for GBC development

activities, notably during the nine- to 12-month

period where the GBC Spur will be blocked off

for rail installation

An alternate emergency egress from the AB

Tunnels

Knowledge of ground conditions for the benefit

of conveyor drifts to be developed later

Incorporation of the ventilation drifts into the

long term Ventilation Drift layout proposed.

This development is crucial for initial and longterm operation of the GBC mine, which will be

A rig move for PT Pontil (acquired by Major Drilling in

1997), which has a long-term contract to supply drilling

services to the mine and the exploration projects

ventilated with airflow of 1,700 m3/s via four intake

and four exhaust GVDs. These declines will come

to a portal close to the existing Amole drifts, each

with a length of 2,800 m and dimensions of 6.8 m

wide x 9.0 m high. The mine uses a negative

pressure system, pulling air through rather than

forcing it in from the intakes. Each main exhaust

fan motor is rated 2,200 kW. The GBC ventilation

system is both extensive and complex. It must be

implemented and expanded as mine development

proceeds so as to provide adequate mine ventilation

at all stages of mine development and production.

Of the eight ventilation drifts, GVD#1 and

GVD#2 will form the two most westerly drifts of

the ten drift arrangement. So far, GVD#2 has been

used as an air exhaust way, and GVD#1 as an

intake airway. After additional drifts are excavated

and permanent exhaust becomes operational,

GVD#2 will take on an intake role.

Redpath started this project on January 27, 2007

with the development of the first two GVD#1

and GVD#2. The declines provide access for

development of the remainder of the ventilation

and conveyor declines required for the GBC mine.

Total development expected for the ventilation and

conveyor declines is about 30,000 m.

Project challenges:

Development rates are high

Development is passing through areas of known

difficult geotechnical ground conditions

OPERATION FOCUS Indonesia

GBC ramp access layout

Intercepting areas with high pressure and high

volume water inflows

Numerous geological contacts between

limestone, sandstone and diorite

Decline development, increasing complications

from any water flows encountered

Breakthrough for ventilation at the highly

congested Amole portals area.

GBC the stalwart

The GBC mine will be the main source of mill feed

after the open pit becomes exhausted. At that

time, the district-wide underground ore reserves

will be on the order of 1,700 Mt, of which the

GBC mine comprises more than half 1,000 Mt at

a grade of 1.0% Cu and 0.8 g/t Au. As we have

already seen, development of the access adits was

initiated in 2004 in order to access and develop this

mine in time for the open pit completion.

Block cave mining was chosen as the most

applicable method for mining the deposit, with

production rates of up to 160,000 t/d being

considered. It is a large footprint (1 km by 1 km) to

develop. The ores average uniaxial compressive

strength is about 110 MPa, with some variation

depending on mineralogy and alteration between

70 and 140 MPa. The principal in-situ stress is in

the northeast direction and corresponds to the

regional structural geology (about 40 MPa). The

principal horizontal stress is approximately equal to

the overburden stress.

The rock mass rating (RMR), used to establish

mine design parameters (hydraulic radius and

ground support), is good for the development

levels, the lower 50 m of the mineable zone, and

for the central Kali intrusive. In general, primary

fragmentation in the GBC is expected to be coarse,

with more than 76% of the tonnage being in

blocks greater than 2 m3. The secondary

fragmentation curves indicate that at ore column

heights greater than 250 m, 23% of the rock will

have a volume of more than 2 m3. The estimated

hydraulic radius required for sustained caving is 33

12 International Mining MARCH 2010

m. Rock burst potential does exist and has to be

evaluated in more detail. The assumed draw rates

range from 0.13 m/d during the initial 100 m of

column height, up to 0.30 m/d at a column height

greater than 200 m.

Wet muck has been a problem in the DOZ mine

(January article) but at GBC, the risk from wet

muck is thought to be relatively low, particularly for

the early years of mining. The predicted coarse

in-situ grain size should inhibit significant wet

muck, despite the relatively high volumes of

predicted passive groundwater inflow. However,

comminution of the High Sulphide Zone (HSZ see

February article), fines from adjacent open pit

overburden stockpiles reporting to the cave, or

secondary fragmentation of limestone derived from

pit walls may all eventually report to the drawpoints

and present a wet muck problem.

GBCs Extraction Level is to be at the 2,815 m

elevation. The primary access to the mine will be

via the AB adits, 6 km in length, that have been

developed from surface at the 2,500 m level by

Redpath, as noted earlier. Undercutting is to be

initiated in 2015, peak production is forecast by

2021, and closure estimated in about 2041.

The Extraction Level will use an El Teniente style

layout, used previously in the Ertsberg District at the

now-exhausted IOZ mine. Spacing of the panels is

30 m with drawpoint spacing of 20 m. The current

mine layout is a very large footprint with a

diameter of about 1 km (700,000 m2) and contains

more than 2,500 drawpoints.

In order to develop and mine this size of

footprint, the panels and drawpoints are to be

broken down into five to six manageable

production blocks, each containing between 250

and 550 drawpoints. Each panel section within

those blocks contains an orepass and a vent raise,

located in adjacent pillars. Extending the drawpoint

through the drawbell to the next panel allows the

creation of an open access and can be used as a

short-term or pseudo fringe drift.

The sections allow for an LHD to access both

orepasses located north and south of the section.

This improves tramming efficiencies, with the

longest tram being about 150 m. It also gives the

flexibility of a back-up orepass in case one is down

for repair or maintenance.

PTFI selected an advance undercut approach,

with the leading edge of the undercut a minimum

of 20 m ahead of drawbelling on the Extraction

Level. A crinkle cut undercut system is planned as

is being used at the currently operating DOZ block

cave mine. Undercut headings will be directly

above and parallel to the extraction level panels.

The draw column heights are expected to average

460 m, and great care will be taken to protect the

integrity of the extraction level drawpoints.

Each drawbell will be mined out once the

undercut has passed by a minimum of a single

drawbell ahead and the bell is clear of abutment

OPERATION FOCUS Indonesia

Grasberg block cave layout

geometry of the production blocks and mining

sequence. The lines gather into a northeasttrending fringe drift that runs over the coarse ore

bin dumps. There are two intake and two exhaust

drifts parallel to each of the lines.

Grade control

software to confirm production and secondary

breakage equipment requirements, ore haulage

and requirements for the AB adits to handle all

development activities. The results to achieve

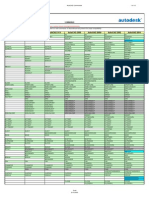

output of 160,000 t/d produced the following:

45 operating LHDs

>1,000 active drawpoints

Six medium hang-up rigs

36 secondary blasting rigs

Six haulage trains consisting of 24 x 30-t ore cars

Three 60" x 89" crushers.

The service level (2,785 m) provides intake and

exhaust to the undercut and extraction levels and is

the primary ore handling level. The rail haulage

system has four lines that run under the orebody in

a generally northwest orientation that match the

Switch TTL T90076 R&D

stress. This will be achieved with a portable Alimak

nest and climber used to drive a 2 x 2 m vertical

raise, 9.5 m long. Once the raise is in place and

secure the drawbell will be drilled and a mobile

emulsion charging unit will be employed to load

the blastholes. Variable density emulsion and

electronic detonators will be used to fire the bell in

a single shot.

Maximum drawbell opening rates are expected

to be eight per month and maximum draw rates

0.30 m/d. The plan assumes that the cave will be

developed initially in two separate mining blocks

simultaneously. The sequence has been designed to

maximise grade and minimise dilution effects from

the toppling of the pit material.

Simulations were performed using Arena

Sampling underground has been very important

and will be so in the new mines. Last year, proper

sampling had resulted in a decrease of the grade

variance between the Underground report and the

Mill report from 12% in 2008 to 4% in 2009.

Sampling results are also used to calculate the

Underground grade actual reconciliation with the

Mill.

Sampling in the underground mines is done

twice a day, involving six Underground crew

members. It is undertaken to control and optimise

the economic value of the mineral reserve during

production planning by providing the actual grade

value, which provides clear direction when drafting

the production plan.

Average samples collected amount to 100 bags

per day; they are then taken to the Mill 74

laboratory. The results will help provide the value of

actual grade, assist in drafting the production plan,

and aid in determining the actual economic value

of the mined ore.

Wealth Unearthed

We inhabit a special planet. One that sustains life. A planet that is abundant in hidden riches. AEL is

dedicated to creating explosives technology that allows us to unearth wealth. We meticulously supply

carefully controlled energy solutions needed by our mines to extract the bounty of our planet.

As the world evolves, so do we. Our 100 year heritage in the mining industry would not have been

possible without continuous innovation born from world class research and development. Take our Hot

Hole Monitor for example: This innovative technology tests hot hole temperatures before blasting, so

our clients can determine whether it is safe to blast; saving time, money and lives in the coal industry.

Tel: +27 11 606 0000 email: mail@ael.co.za web: www.aelminingservices.com

MARCH 2010 International Mining 13

OPERATION FOCUS Indonesia

Sampling underground has been very important and

will be so in the new mines. Last year, proper

sampling had resulted in a decrease of the grade

variance between the Underground report and the

Mill report from 12% in 2008 to 4% in 2009

Searching for more

These underground mines should have attractive

operating profiles when compared with other

mines around the world. Their development will

provide the opportunity for Freeport Indonesia to

realise significant value beyond the life of the open

pit, allowing the operation to leverage synergies of

existing mill facilities and infrastructure and

providing long-term incremental cash flows.

As the mine plan is driven by exploration,

exploration activities could add near-term

production and/or extend mine life even further.

Boart Longyear has been involved with

Financial benefits to Indonesia

Freeport Indonesia provides direct economic

benefits for the central, provincial, and local

governments of Indonesia, as well as the local

economy of Papua and the nation as a whole.

PTFI is the largest private employer in Papua

and one of the largest taxpayers in Indonesia.

From January to December 2009, PTFI

paid its financial obligations to the

Government of Indonesia in the sum of $1.4

billion. Under its financial obligations as set

out in the 1991 Contract of Work, from

1992 to 2009, PTFI has paid a total of $9.5

billion to the Government of Indonesia.

PTFI also has a strong commitment to the

local community and a portion of revenues

goes to benefit the local community through

the Freeport Partnership Fund for

Community Development. In 2009,

contributions to the Partnership Fund

totalled nearly $69 million, with total

contributions to the fund reaching nearly

$398 million since its inception in 1996.

14 International Mining MARCH 2010

exploration at Ertsberg and Grasberg for many

years. Between 1974 and 1978, Longyear was

drilling on the original Ertsberg project, using three

drills rigs (one LY44 and two LY38s) the project was

managed by Longyear Australia.

Between 1979 and 2003, PT Freeport Diamond

Drilling Division operated with Boart Longyear as its

preferred supplier for tooling and for underground

equipment four LM37s, seven LM55s and seven

LM75s. Boart Longyear was also the preferred

supplier for surface exploration equipment, with

five LF70 drilling rigs in operation.

From 1997 to 2003 PT Pontil (acquired by Major

Drilling in 1997) was contracted to supply both

underground and specialised surface drills to

support Freeport Indonesias own Diamond Drilling

Division, PT Pontil supplied both LM underground

drills and Universal drill rigs for surface operations.

During this period PT Pontil successfully completed

a number of 700 m Surface to Underground

directionally drilled holes that were cased with 203mm stainless steel casing on completion.

In 2003 PT Pontil acquired the assets of

Freeports Diamond Drilling Division and signed a

long term contract to supply drilling services to the

mine and the exploration projects. This contract has

been recently extended. PT Pontil has an office

situated in Jakarta and is fully established in

Indonesia to support its operations there.

Boart Longyear still provides the majority of

equipment and consumables on site as the

product of choice from the current contractor.

Major Drilling is a Global Account of Boart

Longyear and receives 100% support worldwide.

Major Drilling has committed to use modern and

technically sound equipment in this remote

environment. PT Pontil uses a variety of drills to

support its Freeport operations, including Sandvik,

Boart Longyear and Duralite drills.

Freeport Indonesias mineral exploration in Papua

poses unique challenges due to the limited geological

data, severe terrain, lack of road access, and the

wet and rapidly changing weather conditions. To

effectively explore large areas Freeport pioneered

Boart Longyear LF70 exploration drill at surface

OPERATION FOCUS Indonesia

Continuous pilot core drilling is currently being used in the high speed drill and

blast excavation of twin AB access tunnels for the CIP

the use of helicopter hoisting to allow geologists to access and sample remote

areas quickly and safely. To date, Freeport affiliates have invested over $300

million on exploration in Papua and made several discoveries that are being

evaluated.

Continuous pilot core drilling is currently being used in the high speed drill

and blast excavation of twin AB access tunnels for the CIP.

These deep access tunnels will have a total planned length of 18.6 km. An

innovative technique allows them to safely probe ahead of the face to warn of

bad ground and high pressure water compartments. They are using 650 m long

HQ core borings drilled from remucking alcoves along the tunnels. They are able

to achieve 30 m/d of core drilling using Boart Longyear LM75 hydraulic drills. IM

Thanks are due to Redpath for a great deal of the input to this article.

References

1.Freeport McMoRan Copper and Gold Inc., Common Infrastructure Phase 3 Grasberg

Block-Cave Ventilation and Access Decline Feasibility Report, Unpublished report for PT

Freeport Indonesia, October 2005.

2.Freeport McMoRan Copper and Gold Inc., Common Infrastructure Study, Unpublished

report for PT Freeport Indonesia, August 2003.

3.Freeport McMoRan Copper and Gold Inc., Feasibility Study for the Grasberg Block Cave

Mine - Volume I Executive Summary and Report, Unpublished report for PT Freeport

Indonesia, May 2005.

4.Freeport McMoRan Copper and Gold Inc., Grasberg Block Cave Feasibility Update

Presentation, March 2007

5.Brannon, C., Casten, T. and Johnson M. Design of the Grasberg block cave mine, Massin

2004, Santiago, Chile, August 2004.

For more on the great achievements of Freeport Indonesia, this series of

articles started in August 2009 and there has been an article on aspects

of this operation published every month since.

MARCH 2010 International Mining 15

Anda mungkin juga menyukai

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- Underground Railway TunnelingDokumen38 halamanUnderground Railway TunnelingSudeep SharmaBelum ada peringkat

- Coal Mining Methods - EMFI SummaryDokumen0 halamanCoal Mining Methods - EMFI SummaryCharles BinuBelum ada peringkat

- DAF Superstructures BodyBuilders - GuideDokumen34 halamanDAF Superstructures BodyBuilders - GuideЮлия Дам100% (1)

- 205 Paper 350 - Design of The SMART Project-ADokumen12 halaman205 Paper 350 - Design of The SMART Project-Aodri5Belum ada peringkat

- 05 High Voltage CablesDokumen27 halaman05 High Voltage Cablesdaegerte100% (5)

- Pipeline Landfall - Cofferdam PDFDokumen7 halamanPipeline Landfall - Cofferdam PDFdndudcBelum ada peringkat

- Ryan Donnelly - Artificial Intelligence in GamingDokumen12 halamanRyan Donnelly - Artificial Intelligence in GamingJavier Pardo MuñozBelum ada peringkat

- Design of TBM Work Shaft and TBM Launching Chamber SingaporeDokumen8 halamanDesign of TBM Work Shaft and TBM Launching Chamber SingaporeLuis Zhan100% (1)

- Underground Haulage Selection: Shaft or Ramp For A Small-Scale Underground MineDokumen6 halamanUnderground Haulage Selection: Shaft or Ramp For A Small-Scale Underground MineluisparedesBelum ada peringkat

- EMI EMC Project ReportDokumen55 halamanEMI EMC Project ReportAshish Agarwal80% (5)

- Tauranga City Council Waterfront Project Construction MethodologyDokumen11 halamanTauranga City Council Waterfront Project Construction MethodologyVivek KalaBelum ada peringkat

- Ground Support in Deep Underground MinesDokumen27 halamanGround Support in Deep Underground MinesMarkusMakuAldoBelum ada peringkat

- Underground Mine DesignDokumen47 halamanUnderground Mine Designalfri121Belum ada peringkat

- Kavvadas Monitoring and PDFDokumen19 halamanKavvadas Monitoring and PDFAndyara DuarteBelum ada peringkat

- Long-Life Xlpe Insulated Power Cable PDFDokumen6 halamanLong-Life Xlpe Insulated Power Cable PDFbitconceptsBelum ada peringkat

- District Revised HMIS Manual UpdatedDokumen289 halamanDistrict Revised HMIS Manual UpdatedWaqar Asmat0% (1)

- Cable Laying SpecificationDokumen16 halamanCable Laying SpecificationdavidgarciavazquezBelum ada peringkat

- Cable Laying SpecificationDokumen16 halamanCable Laying SpecificationdavidgarciavazquezBelum ada peringkat

- Aspen Plus Model For Moving Bed Coal GasifierDokumen30 halamanAspen Plus Model For Moving Bed Coal GasifierAzharuddin_kfupm100% (2)

- Excavation of 17 KM Long Head Race Tunnel For 1000mw KarchamDokumen12 halamanExcavation of 17 KM Long Head Race Tunnel For 1000mw KarchamkhjkfjhsdklajBelum ada peringkat

- Ismailia Road Tunnel Crossing The Suez Canal PDFDokumen8 halamanIsmailia Road Tunnel Crossing The Suez Canal PDFRonald HeijmansBelum ada peringkat

- Pipeline Defect Assessment ManualDokumen18 halamanPipeline Defect Assessment Manualalexrodriguezabc100% (4)

- CableBolt TDSDokumen2 halamanCableBolt TDSMarkusMakuAldoBelum ada peringkat

- Design of The Highest RCC Dam Gibe 3Dokumen9 halamanDesign of The Highest RCC Dam Gibe 3dce_40Belum ada peringkat

- Pipe Jacked TunnelsDokumen10 halamanPipe Jacked Tunnelsretk0801Belum ada peringkat

- MassMin2012 - PT Freeport Indonesia - Transitioning To 240,000 TPD From Underground MiningDokumen9 halamanMassMin2012 - PT Freeport Indonesia - Transitioning To 240,000 TPD From Underground MiningÁALBelum ada peringkat

- A Major Step For A Pipeline: Crossing The Serra Do Mar State Park in BrazilDokumen11 halamanA Major Step For A Pipeline: Crossing The Serra Do Mar State Park in BrazilDheeraj Chowdary DhanekulaBelum ada peringkat

- EM202385MAR523ENGGDokumen7 halamanEM202385MAR523ENGGRose BachBelum ada peringkat

- Underground Haulage Selection 1Dokumen6 halamanUnderground Haulage Selection 1Zusica WigunnaBelum ada peringkat

- Submitted To: Dr. Ali Shamim: Submitted By: Usman Naeem (11-CE-156)Dokumen12 halamanSubmitted To: Dr. Ali Shamim: Submitted By: Usman Naeem (11-CE-156)KanjarvarBelum ada peringkat

- Const. Methodology Hirong HE ProjectDokumen28 halamanConst. Methodology Hirong HE ProjectVaibhav JainBelum ada peringkat

- Perform Ace of Trench Less TechniquesDokumen20 halamanPerform Ace of Trench Less TechniquesWilson MokBelum ada peringkat

- Design of Grand Ethiopian Renaissance, RCC Main DamDokumen10 halamanDesign of Grand Ethiopian Renaissance, RCC Main DamabrahamBelum ada peringkat

- Design and Construction of Rion Antirion 'Charilaos TrikoupisDokumen17 halamanDesign and Construction of Rion Antirion 'Charilaos TrikoupisApoorva SinghBelum ada peringkat

- Breast Stoping Lay OutDokumen4 halamanBreast Stoping Lay OutTinozivasheBelum ada peringkat

- CH116 PDFDokumen8 halamanCH116 PDFMercedez BenzBelum ada peringkat

- Site Selection of An Incline or Pit:: R FurtherDokumen6 halamanSite Selection of An Incline or Pit:: R FurtherSatyajeet ParidaBelum ada peringkat

- 16-27 - 735 - HkieDokumen12 halaman16-27 - 735 - HkieWilson MokBelum ada peringkat

- ShaftsDokumen9 halamanShaftsSumit JainBelum ada peringkat

- Viable TBM Applications For Short Tunnel Drives 900 MetersDokumen11 halamanViable TBM Applications For Short Tunnel Drives 900 MetersPaloma CortizoBelum ada peringkat

- Longwall MiningDokumen6 halamanLongwall MiningGiancarlo Calderon AmesquitaBelum ada peringkat

- Report 2Dokumen3 halamanReport 2madherchodgroup1Belum ada peringkat

- Aplicationo of Open Pit and Underground Mining Technology For Residual Coal of End SlopesDokumen5 halamanAplicationo of Open Pit and Underground Mining Technology For Residual Coal of End SlopeskellyllBelum ada peringkat

- Home Assignment 1Dokumen5 halamanHome Assignment 1victory shahbazBelum ada peringkat

- Budget Level Cost Estimates 1Dokumen41 halamanBudget Level Cost Estimates 1Nati100% (2)

- Case Study of AlpDokumen17 halamanCase Study of AlpluckyBelum ada peringkat

- CFRD Siah-BisheDokumen8 halamanCFRD Siah-BisheSamoon IbrahimBelum ada peringkat

- MassMin 2016 Conference Proceedings Grasberg Underg 2 (1-4)Dokumen4 halamanMassMin 2016 Conference Proceedings Grasberg Underg 2 (1-4)catalina ramirezBelum ada peringkat

- MassMin 2016 Conference Proceedings Grasberg Underg 2Dokumen9 halamanMassMin 2016 Conference Proceedings Grasberg Underg 2catalina ramirezBelum ada peringkat

- 30 - Crook Oyu TolgoiDokumen12 halaman30 - Crook Oyu TolgoiMik SerranoBelum ada peringkat

- Ground Deformations Above A Large Shallow Tunnel EDokumen10 halamanGround Deformations Above A Large Shallow Tunnel ECarlos ValdésBelum ada peringkat

- 11 Tunnelling With Hidraulic Drills at Abajora Hidro Eletric Plant in NorwayDokumen0 halaman11 Tunnelling With Hidraulic Drills at Abajora Hidro Eletric Plant in Norwaycastille1956Belum ada peringkat

- Curve Jacking - Paper Bangkok T-1ThorenDokumen10 halamanCurve Jacking - Paper Bangkok T-1ThorenCheng KimHuaBelum ada peringkat

- Boring MachinesDokumen2 halamanBoring MachinesidonotspammeBelum ada peringkat

- Bi 012008 EngDokumen3 halamanBi 012008 EngSivaramanBelum ada peringkat

- Detailed Design of The Lai Chi Kok Drainage Tunnels CHUI, Eric H. M., CHAN, Ray W. K. & VERMAN, PiersDokumen11 halamanDetailed Design of The Lai Chi Kok Drainage Tunnels CHUI, Eric H. M., CHAN, Ray W. K. & VERMAN, PierscoldplateBelum ada peringkat

- Application of Surface Pre-Grouting For Shaft SinkingDokumen3 halamanApplication of Surface Pre-Grouting For Shaft SinkingAnonymous qTP5oq7gBelum ada peringkat

- Construction Methods in SiahBishe CFRDSDokumen19 halamanConstruction Methods in SiahBishe CFRDSArmin AtmajayaBelum ada peringkat

- Nant de Drance PDFDokumen8 halamanNant de Drance PDFsoftminestudioBelum ada peringkat

- Min 019 RG CSDokumen16 halamanMin 019 RG CSfenderlimaBelum ada peringkat

- The Asphalt Lining of A Large Water Reservoir Near Bengazi - SchmidDokumen6 halamanThe Asphalt Lining of A Large Water Reservoir Near Bengazi - Schmidmivos4Belum ada peringkat

- 2013 WTC2013Geneve-ChuquicamataUnderground PDFDokumen9 halaman2013 WTC2013Geneve-ChuquicamataUnderground PDFIvo FritzlerBelum ada peringkat

- 002 Basha DamDokumen6 halaman002 Basha DamBilal Nawaz KiyaniBelum ada peringkat

- EM202357MAR510ENGGDokumen9 halamanEM202357MAR510ENGGRosalie BachillerBelum ada peringkat

- 2008 XX XX Ehrbar Gotthard Base Tunnel Experiences With Different Tunnelling MethodsDokumen14 halaman2008 XX XX Ehrbar Gotthard Base Tunnel Experiences With Different Tunnelling MethodsAnonymous qTP5oq7gBelum ada peringkat

- Extreme Excavation in Fault Zones and Squeezing Ground at The Kargi HEPP in TurkeyDokumen11 halamanExtreme Excavation in Fault Zones and Squeezing Ground at The Kargi HEPP in TurkeynishantBelum ada peringkat

- CP Unit 2Dokumen184 halamanCP Unit 2Dhanashri Patil100% (1)

- Transactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159Dari EverandTransactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159Belum ada peringkat

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The North River Tunnels. Paper No. 1155Dari EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The North River Tunnels. Paper No. 1155Belum ada peringkat

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The Cross-Town Tunnels. Paper No. 1158Dari EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The Cross-Town Tunnels. Paper No. 1158Belum ada peringkat

- Longwall Mining at Shallow Depth of Cover in IndiaDari EverandLongwall Mining at Shallow Depth of Cover in IndiaBelum ada peringkat

- Scientific American Supplement, No. 384, May 12, 1883Dari EverandScientific American Supplement, No. 384, May 12, 1883Belum ada peringkat

- England - Premier League England - League 2Dokumen2 halamanEngland - Premier League England - League 2MarkusMakuAldoBelum ada peringkat

- Sika Technologies For MiningDokumen5 halamanSika Technologies For MiningMarkusMakuAldoBelum ada peringkat

- 8-Vol6No1Mar2013 - Yoszi Mingsi AnapertaDokumen22 halaman8-Vol6No1Mar2013 - Yoszi Mingsi AnapertaekaBelum ada peringkat

- Tunnel r06 PDFDokumen6 halamanTunnel r06 PDFMarkusMakuAldoBelum ada peringkat

- Ground Support 2013Dokumen13 halamanGround Support 2013Ignacio PadillaBelum ada peringkat

- 1 s2.0 S088677981530225X MainDokumen14 halaman1 s2.0 S088677981530225X MainMarkusMakuAldoBelum ada peringkat

- Lay OutDokumen1 halamanLay OutMarkusMakuAldoBelum ada peringkat

- Panitia Expo Dies Natalis 2017Dokumen2 halamanPanitia Expo Dies Natalis 2017MarkusMakuAldoBelum ada peringkat

- Panitia Expo Dies Natalis 2017Dokumen2 halamanPanitia Expo Dies Natalis 2017MarkusMakuAldoBelum ada peringkat

- NelsonDokumen51 halamanNelsonMarkusMakuAldoBelum ada peringkat

- Tunnelling and Underground Space Technology: Masood Hajali, Ali Alavinasab, Caesar Abi ShdidDokumen9 halamanTunnelling and Underground Space Technology: Masood Hajali, Ali Alavinasab, Caesar Abi ShdidMarkusMakuAldoBelum ada peringkat

- Manual 31 en Rock StabilityDokumen8 halamanManual 31 en Rock StabilityMarkusMakuAldoBelum ada peringkat

- Install GuideDokumen5 halamanInstall GuideMarkusMakuAldoBelum ada peringkat

- Dywidag Systems International - Mechanical Anchors and Rebar Rock Bolts (DSI, 2013)Dokumen16 halamanDywidag Systems International - Mechanical Anchors and Rebar Rock Bolts (DSI, 2013)sandycastleBelum ada peringkat

- Manual 30 CZ Import-Dxf-1Dokumen17 halamanManual 30 CZ Import-Dxf-1Mark EdowaiBelum ada peringkat

- Lateralk User'S Manual (Novo Tech Software LTD.)Dokumen10 halamanLateralk User'S Manual (Novo Tech Software LTD.)MarkusMakuAldoBelum ada peringkat

- CatalogueDokumen230 halamanCatalogueOsama_Othman01100% (1)

- GroundRules Geology 11 13Dokumen22 halamanGroundRules Geology 11 13MarkusMakuAldoBelum ada peringkat

- 236885e5fe4c044 EkDokumen226 halaman236885e5fe4c044 Ekcrls_marcosBelum ada peringkat

- Chadwick 2010 KDokumen5 halamanChadwick 2010 KMarkusMakuAldoBelum ada peringkat

- 12references PDFDokumen21 halaman12references PDFMarkusMakuAldoBelum ada peringkat

- Surfer 10 GuideDokumen60 halamanSurfer 10 GuideRodry100% (1)

- Savitha S. Panikar, PH.DDokumen4 halamanSavitha S. Panikar, PH.Diboorose7Belum ada peringkat

- F1160 1479757-1Dokumen8 halamanF1160 1479757-1Thaweekarn ChangthongBelum ada peringkat

- SATR-J - 6802 - Rev 0 PDFDokumen3 halamanSATR-J - 6802 - Rev 0 PDFAdel KlkBelum ada peringkat

- Autocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004Dokumen12 halamanAutocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004veteranul13Belum ada peringkat

- Ram 100Dokumen2 halamanRam 100MAT-LIONBelum ada peringkat

- Topic 1 Valve and Instrumentation SymbolsDokumen8 halamanTopic 1 Valve and Instrumentation SymbolshatiniBelum ada peringkat

- J030 J032 Eu Aa V1.00Dokumen41 halamanJ030 J032 Eu Aa V1.00gkalman_2Belum ada peringkat

- Company Name Country Service Function/Type Contact: RigzoneDokumen4 halamanCompany Name Country Service Function/Type Contact: RigzonekokabawaBelum ada peringkat

- Total PDFDokumen35 halamanTotal PDFMauricio ThanatosBelum ada peringkat

- GeothermalenergyDokumen2 halamanGeothermalenergyapi-238213314Belum ada peringkat

- An Overview of Transceiver SystemsDokumen11 halamanAn Overview of Transceiver SystemssurvivalofthepolyBelum ada peringkat

- GM 302 - Update - 10-2004Dokumen26 halamanGM 302 - Update - 10-2004Naser JahangiriBelum ada peringkat

- Fire Hydrant - WikipediaDokumen9 halamanFire Hydrant - WikipediaVaibhav SawantBelum ada peringkat

- Clubhouse Rental FormDokumen8 halamanClubhouse Rental FormAmanda MillerBelum ada peringkat

- SSPL Catalog Regular - Resize PDFDokumen25 halamanSSPL Catalog Regular - Resize PDFusman379Belum ada peringkat

- How To Update SoftwareDokumen4 halamanHow To Update SoftwareNayarit TianguisBelum ada peringkat

- Describe in Detail The Method You Use To Parallel The Alternator and Share LoadDokumen4 halamanDescribe in Detail The Method You Use To Parallel The Alternator and Share LoadDen EdiBelum ada peringkat

- のわる式証明写真メーカー|PicrewDokumen1 halamanのわる式証明写真メーカー|PicrewpapafritarancheraBelum ada peringkat

- JDokumen4 halamanJapi-299173937Belum ada peringkat

- 12 008 00 (01) Vibrating Drum Smooth (Group 1) (nd104240)Dokumen4 halaman12 008 00 (01) Vibrating Drum Smooth (Group 1) (nd104240)DAVID ORLANDO MURCIA BARRERABelum ada peringkat

- PT 100 Operators ManualDokumen15 halamanPT 100 Operators ManualSerhiiBelum ada peringkat

- 03-Instruction Set ArchitectureDokumen40 halaman03-Instruction Set ArchitectureccoccoheadBelum ada peringkat

- Axial Piston Fixed Motor AA2FM Series 6x: AmericasDokumen30 halamanAxial Piston Fixed Motor AA2FM Series 6x: AmericasKaian OliveiraBelum ada peringkat

- Shot Blasting Machines: Laser PeeningDokumen2 halamanShot Blasting Machines: Laser Peeningrahul srivastavaBelum ada peringkat