Build Mechanics Illustrated Kart

Diunggah oleh

Jim100%(5)100% menganggap dokumen ini bermanfaat (5 suara)

2K tayangan7 halamanPlans to build a go kart.

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniPlans to build a go kart.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

100%(5)100% menganggap dokumen ini bermanfaat (5 suara)

2K tayangan7 halamanBuild Mechanics Illustrated Kart

Diunggah oleh

JimPlans to build a go kart.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 7

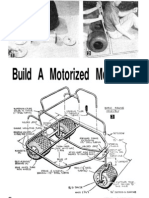

A 2-1/2,-hp lawn mower engine drives this kart at

more than 30 mph. It's Class A fun for anyone.

By S. Calhoun Smith

T HE "go kart" has taken the U. S. by

storm. A happy wedding of lawn

mower engine and steel tubing on four

hp karts are capable of 30 to 35 mph

with an adult aboard and more when

driven by a lightweight 10-year-old.

little wheels, it has become a craze Races are run on paved parking lots and

among kids and adults with a yen for small dirt ovals and regular sports car

racing or just plain driving fun. type raceways have been built with

Kart racing originated in California tracks four-tenths of a mile in length

and has spread eastward since 1956. and 20 feet wide. Such tracks incorpor-

Now the GKCA (Go Kart Club of ate eleven turns, both banked and flat.

America) is firmly established and has The MI Kart was designed and built

set up sensible rules governing design by Bob Peru of Red Bank, N. J. and

and power for stable, safe "karting." can be considered a basic Class A kart.

Even the lowest powered Class A, 2.5 It complies in all respects with GKCA

102 Mechanix Illustrated

specifications. Cost runs from $100 to saw, tin snips, files, hammer, large vise

$110 complete with an A-400 Clinton and an electric hand drill or drill press.

engine. Peru did the welding himself To help hold cost down, the frame is

but anyone not equipped to do it would made of thin-wall conduit, but more ex-

have to spend $20 to $30 extra. The pensive chrome-moly tubing could be

building time was about 25 hours and substituted throughout. Some parts,

the tools required were a square, hack the seat and steering hoops, steering

COMPLETED FRAME with axles installed; BELLY PAN and seat back are sheet steel;

a thin-wall conduit is used to reduce cost they're spot-welded to the conduit frame.

January, 1960 103

FRONT END view shows brake and throttle SPOT BRAKE pivots flush against inside

pedals and the simple steering mechanism. face of sprocket. Note engine mount plate.

104 Mecha.nlx Illustrated

yoke, front wheel spindle

b r a c k e t s and engine

mount plate, can be pur-

chased ready-formed from

v a r i o u s kart manufac-

turers. Their use will

speed building consider-

ably-

Begin construction by

drawing a side frame out-

line on a piece of scrap

lumber. Cut and flare the

tubing required and heat CLINTON 2-1/2-hp engine drives MI kart at more than 30

the lower piece to make mph with adult load; note throttle crank on seat hoop.

the bend. Fit the pieces

over the outline and clamp

them. Then tack weld all

joints and remove the

framing from the board.

Using the first side as a

pattern, clamp the parts of

the second to it and tack

weld them together. This

will insure uniformity.

Next fabricate the front

and rear axles. Bend

the front wheel spindle

brackets to shape and drill

them for the kingpin bolts.

Then weld them to the

front axle tube. Align

them carefully, square on

the tube ends and parallel

to each other. The rear

axle tube ends are bushed SPANKING NEW kart is ready to go. You can upholster

seat but boat cushion from marine supplier does nicely.

with a length of pipe to reduce the

inside diameter for the 5/8-inch

round stock axles. The axles are

held in the tube with a quarter-

inch bolt near each inner end.

They can be tapped for short bolts

or holes [Continued on page 150]

RECOIL STARTER is pulled as youthful driver

sits with his left foot depressing brake pedal.

Build MI's Kart

[Continued from page 106]

can be drilled all the way through for bolts brackets of 1/4xl-in strip steel. Bend the

and nuts. steering shaft front end and drill it for the

The side frames, axles and crosspieces tie-rod bolt. Then bend the yoke to shape.

can now be assembled. Cut and flare the Put brackets and collars on the steering

pieces and tack weld them, using a try shaft and weld the yoke to the shaft end.

square to make sure they're aligned. Add Next slide the shaft through the top

the axles to the frame ends, squaring up bracket to spread out the collars and weld

the assembly as it progresses. Note that the bracket to the underside of the hoop

the front axle is rotated slightly in the side curve. Hold the lower end of the shaft at

frame ends so that the kingpin axis has a the proper angle to align the top bracket

7° rearward slant. The frame-axle assem- while welding. Finish by sliding the shaft

bly can now be completely welded at all into position and welding the front bracket

joints. As the last step, add the diagonal to the top of the front axle.

crosspiece at the rear. The tie-rod ends are threaded for about

The front wheel spindle units are made one inch to match the Heim ball end fit-

up next. Cut the kingpin bushing tubes to tings. Clevis end or Ford brake rod ends

fit snug inside the brackets. Then weld the could be substituted if the ball ends are

wheel spindle bolts to the sides of the bush- not readily available. Adjust the rod ends

ings. Follow this by welding the spindle at the center to align the wheel spindles

steering arm pieces to the bushings. Note at zero degrees. Toe-in or toe-out can be

that right- and left-hand units are required adjusted later when the kart's running

since the steering arm pieces slant inward. qualities have been checked. While work-

The steering and seat hoops are now ing on the front end, weld the pedal pivot

formed and cut to fit onto the frame. To bolts to the side frames.

make the curves, apply heat and bend a Drive and engine mount parts are next

little at a time so that the tubing will not on the list. The wheel hub is first fitted

deform. Tack weld the hoops in position with a large washer for bolting on the

after clamping them at the proper angles; large sprocket. This permits removal of the

then complete the welds. Next cut the sprocket if different sizes are to be fitted.

belly pan and seat back to shape, checking (If you do not wish to bother with removal,

the pieces against the frame for correct di- the sprocket can be welded flush to the

mensions. Tack weld the belly pan in place wheel hub inside face.) The large washer

on the bottom of the frame and then skip and sprocket are drilled for mounting

weld the pan edges to the frame. Welds bolts. Disassemble the wheel to make

should be about one inch long and two welding on the hub easier. The large

inches apart. Where the pan touches the washer is welded to the hub 3/16-in from

crosspiece at the steering hoop rosette, the inside face so that the hub forms a

welds can be used or the sheet and tubing shoulder for centering the sprocket. Weld

can be drilled for self-tapping sheet metal the washer from behind, aligning it care-

screws. To prevent the sheet steel from fully so that it and the sprocket will track

buckling during welding, use a chill block without any wobble. After assembly,

clamped about a quarter-inch from the mount the drive wheel and sprocket on the

edge along the area to be welded. The chill axle. Next bolt the engine to the mount

block can be a piece of 1/2xlx24-inch plate, install the clutch (if used) and the

steel bar stock. The seat back is skip chain. Now carefully align the chain and

welded to the front of the seat hoop in the sprockets, moving the engine and mount

same manner as the belly pan. Make half- on the frame. When set, mark the position

round cuts to clear the side frame tubes. and clamp the mount plate to the frame.

Sissy rails can now be bent to shape, fitted Then remove the engine and wheel and

to the sides and seat hoop and welded in weld the mount plate to the frame. The

place. engine mounting bolts should be in the

The steering assembly is made next. Cut center of the slots so that the engine can

and drill the steering shaft support be shifted to correct for wear on the chain

150 January, 1960

Build MI's Kart

and sprocket.

The spot brake is made and installed

next. Detail drawings are self-explanatory,

but follow this procedure for mounting on

the axle: mount drive wheel on axle;

mount brake on pivot bolt and tube; clamp

brake firmly to sprocket in "brake" posi-

tion (this will position pivot tube on bot-

tom of axle tube); then clamp and weld

pivot tube to axle.

The throttle linkage is made next. Cut

out and drill all parts shown on the detail

drawing. Then put the engine in place on

the mount so that the upper linkage parts

can be aligned with the engine throttle.

The brackets, rods and cranks can be as-

sembled by brazing. Complete the throttle

and brake linkage by making the pedals

and push rods. Note that there are right-

and left-hand pedals. Remember to slide

the fairleads and stop tubes onto the push

rods before bending the S ends. Rods can

be fitted with clevis ends if desired so that

adjustments can be made. Fit one end of

the rod to the brake at the rear and put the

pedal on the other end. Next put the pedal

on the pivot bolt at the front, clamp the

fairleads to the side frames and braze them

in place. Braze the stop to the rod ahead of

the fairlead with the brake off and clear of

the sprocket. The throttle push rod and

pedal are assembled in a similar manner.

Last, make and install return springs on

both pedals.

This completes the metal work on the

kart. All welds should be wire brushed.

Welding splatters and braze flux should be

chipped off all metal surfaces and the

metal cleaned before painting. It's a good

idea to clean up the welds during fabrica-

tion for easy access to the tight corners.

The Clinton engine, of course, is not the

only one which can be used; West Bend,

Briggs & Stratton, Continental, Power

Products and McCulloch engines fill the

bill with slight mount modifications. The

builder who wishes to customize his kart

will find such items as mufflers, drum

brakes, chromed tanks, steering wheels

and racing slicks available from the many

kart manufacturers. You can add what-

ever your pocketbook will allow—but sim-

ple or dressed up, the MI kart is a kartload

of fun. •

Anda mungkin juga menyukai

- Technical Manual-Go KartDokumen13 halamanTechnical Manual-Go Kartmichaelmaness1168290% (2)

- Chassis Design Archive at Kartbuilding BlogDokumen9 halamanChassis Design Archive at Kartbuilding BlogMuhammad Arij100% (1)

- Radio SimplifiedDokumen94 halamanRadio SimplifiedJim100% (3)

- Pedalmatic 1951Dokumen3 halamanPedalmatic 1951Jim100% (4)

- Midget Sports CarDokumen7 halamanMidget Sports CarJim100% (8)

- The Boy's Book of Crystal SetsDokumen36 halamanThe Boy's Book of Crystal SetsJim100% (9)

- Maytag RoadsterDokumen5 halamanMaytag RoadsterJim100% (3)

- Receive Short W A V E Onyour HomeradioDokumen5 halamanReceive Short W A V E Onyour HomeradioJim100% (9)

- Suburban Runabout Three Wheel ScooterDokumen14 halamanSuburban Runabout Three Wheel ScooterJim100% (8)

- Fat-Tire Scooter For SportsmenDokumen5 halamanFat-Tire Scooter For SportsmenFrenchwolf420Belum ada peringkat

- Breeze Baby Sailboat PlansDokumen5 halamanBreeze Baby Sailboat PlansJim100% (5)

- Vintage Go Kart Mini Bike Plans-1950sDokumen95 halamanVintage Go Kart Mini Bike Plans-1950sJanne FredrikBelum ada peringkat

- Mineral Vegetable and Animal LifeDokumen4 halamanMineral Vegetable and Animal LifeJim86% (7)

- Bull Frog Go KartDokumen15 halamanBull Frog Go KartJim100% (3)

- 1901 Half Scale TruckDokumen10 halaman1901 Half Scale TruckJim89% (9)

- Red Bug Complete Plans SetDokumen72 halamanRed Bug Complete Plans Setmantuga92% (26)

- Wren Minibike PlansDokumen7 halamanWren Minibike PlansJim100% (5)

- Wren Minibike PlansDokumen7 halamanWren Minibike PlansJim100% (5)

- Vintage Playground Plans 1950s PDFDokumen39 halamanVintage Playground Plans 1950s PDFAlexandre Mello100% (1)

- An Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverDari EverandAn Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverBelum ada peringkat

- Popular Mechanics Plans-Small Horizontal Steam EngineDokumen5 halamanPopular Mechanics Plans-Small Horizontal Steam Enginebogtudor100% (2)

- Fee Jee PMFM47Dokumen7 halamanFee Jee PMFM47Jim100% (3)

- Air Cooled Hot Air EngineDokumen6 halamanAir Cooled Hot Air EngineJim50% (2)

- Make Antique Auto Children Battery PoweredDokumen5 halamanMake Antique Auto Children Battery PoweredAmy Reed83% (6)

- Brush Buggy, Build An ExcitingDokumen5 halamanBrush Buggy, Build An ExcitingJim88% (8)

- Homemade ATVDokumen67 halamanHomemade ATVJim100% (7)

- ScooterDokumen7 halamanScooterBuyuangKota100% (1)

- How To Build A Mini ChopperDokumen25 halamanHow To Build A Mini ChopperAshleigh Kuykendall0% (1)

- Electric Scooter PlansDokumen6 halamanElectric Scooter PlansJim88% (8)

- Electric Scooter PlansDokumen6 halamanElectric Scooter PlansJim88% (8)

- Suitcase PowercycleV2Dokumen13 halamanSuitcase PowercycleV2Jim67% (3)

- Beep Plans CompleteDokumen9 halamanBeep Plans Completetaxmac80% (5)

- Model Hot Air EngineDokumen4 halamanModel Hot Air EngineJim100% (4)

- PowerCycle With SideCarDokumen7 halamanPowerCycle With SideCarJim100% (2)

- Candle Powered EngineDokumen2 halamanCandle Powered EngineJimBelum ada peringkat

- Homebuilt Car With Wood Frames - Practical MechanicsDokumen39 halamanHomebuilt Car With Wood Frames - Practical Mechanicssjdarkman1930100% (3)

- DIY Plans - Model Steam Marine EngineDokumen5 halamanDIY Plans - Model Steam Marine Enginemigss107483% (6)

- Listening LoopsDokumen2 halamanListening LoopsJim75% (4)

- Suburba Car, Chassis For ADokumen7 halamanSuburba Car, Chassis For AJim100% (9)

- King Midget ArticleDokumen8 halamanKing Midget ArticleJim100% (10)

- Building One Lung KartsDokumen7 halamanBuilding One Lung KartsJim100% (5)

- Foxhole RadioDokumen2 halamanFoxhole RadioJim89% (9)

- Wooden Scooter and PopcycleDokumen6 halamanWooden Scooter and PopcycleJim75% (4)

- 1901 TruckDokumen10 halaman1901 TruckGary B. Watts100% (3)

- Six Wheeled ATV by Mechanix IllustratedDokumen7 halamanSix Wheeled ATV by Mechanix IllustratedJim100% (6)

- Auto Union Cycle Kart Pg. 2 RevisedDokumen1 halamanAuto Union Cycle Kart Pg. 2 Revisedsjdarkman1930Belum ada peringkat

- 2706 Building SpeedsterDokumen10 halaman2706 Building Speedstersjdarkman1930100% (1)

- By Emile Alline: Technical Art by Fred WolffDokumen4 halamanBy Emile Alline: Technical Art by Fred WolffJim100% (3)

- Mite Cycle by Mechanix IllustratedDokumen7 halamanMite Cycle by Mechanix IllustratedJim100% (3)

- Bicycle MinibikeDokumen6 halamanBicycle MinibikeJim100% (1)

- Super Scooter by Mechanix IllustratedDokumen12 halamanSuper Scooter by Mechanix IllustratedJim100% (3)

- Super Scooter by Mechanix IllustratedDokumen12 halamanSuper Scooter by Mechanix IllustratedJim100% (3)

- Relive the romance of early automobiles with a half-size 1901 Packard replicaDokumen8 halamanRelive the romance of early automobiles with a half-size 1901 Packard replicaDillon Hartsyker100% (1)

- Build The Ison Race KartDokumen8 halamanBuild The Ison Race KartJim100% (2)

- Plywood ScooterDokumen7 halamanPlywood ScooterJim100% (4)

- Micro TransportationDokumen6 halamanMicro TransportationJim100% (3)

- Kid-Powered "Squaris" WheelDokumen6 halamanKid-Powered "Squaris" WheelzebrazeroBelum ada peringkat

- Space Age Crystal SetDokumen3 halamanSpace Age Crystal SetJim100% (3)

- Magnetic BaseDokumen3 halamanMagnetic BaseJim100% (2)

- Polliwog Sailboat PlansDokumen6 halamanPolliwog Sailboat PlansJim100% (4)

- Construir Moto ChopperDokumen7 halamanConstruir Moto ChopperAngel Dure100% (2)

- A Crystal Set For The Boy BuilderDokumen3 halamanA Crystal Set For The Boy BuilderJim100% (4)

- Sidewalk Play Car: by Elmer V. ClarkDokumen5 halamanSidewalk Play Car: by Elmer V. ClarkJimBelum ada peringkat

- Crystal Radio LampDokumen4 halamanCrystal Radio LampJim100% (2)

- Light Ball-Bearing Column GrinderDokumen2 halamanLight Ball-Bearing Column GrinderFernando Morocho100% (1)

- Tom Thumb Mini BikeDokumen4 halamanTom Thumb Mini Bikemysteriousracerx100% (7)

- Plans For Steam Marine EngineDokumen5 halamanPlans For Steam Marine EngineGeorge LunguBelum ada peringkat

- Highway Kart by Mechanix IllustratedDokumen10 halamanHighway Kart by Mechanix IllustratedJim100% (1)

- Vintage Transistor RadioDokumen4 halamanVintage Transistor RadioJim100% (1)

- Vintage Transistor RadioDokumen4 halamanVintage Transistor RadioJim100% (1)

- Star Lite SailboatDokumen13 halamanStar Lite SailboatJim100% (8)

- Free Electric Power WindmillDokumen3 halamanFree Electric Power WindmillJim100% (4)

- Dynapac Ca250 t3 Service TrainingDokumen197 halamanDynapac Ca250 t3 Service TrainingDushan Alwis100% (3)

- Build A Scintillometer Uranium Detector For ProspectingDokumen11 halamanBuild A Scintillometer Uranium Detector For ProspectingJim80% (5)

- Flashlight RadioDokumen5 halamanFlashlight RadioJim67% (3)

- Power BikeDokumen4 halamanPower BikeGreg AnguishBelum ada peringkat

- Magnetic Current PamphletDokumen9 halamanMagnetic Current PamphletJim100% (2)

- War Toys For BoysDokumen48 halamanWar Toys For BoysJim100% (2)

- Exhibitor ListDokumen5 halamanExhibitor ListLeo Events WorldwideBelum ada peringkat

- 3 Wheel Dune BuggyDokumen5 halaman3 Wheel Dune BuggyyukitadaBelum ada peringkat

- Drill Pipe 5 VX-57Dokumen2 halamanDrill Pipe 5 VX-57Henry Garavito RamirezBelum ada peringkat

- Homemade Bandsaw From Pipe Fittings and Auto PartsDokumen4 halamanHomemade Bandsaw From Pipe Fittings and Auto PartsJan Steinman100% (2)

- Minibeep Mba80bDokumen14 halamanMinibeep Mba80bAparecido Nascimento Dos SantosBelum ada peringkat

- Build Your Own Mini Bike PlansDokumen8 halamanBuild Your Own Mini Bike Plansmawan_jogjaBelum ada peringkat

- Unit 2 Safety and Emergency ProceduresDokumen10 halamanUnit 2 Safety and Emergency ProceduresmarpelBelum ada peringkat

- Aircarflighttesting: by Angus LaidlawDokumen3 halamanAircarflighttesting: by Angus LaidlawJimBelum ada peringkat

- Build a DIY Motorized Mountain BuggyDokumen5 halamanBuild a DIY Motorized Mountain Buggyjii_907001Belum ada peringkat

- Load-Equalizing Trailer Hitch You Can Make IDokumen4 halamanLoad-Equalizing Trailer Hitch You Can Make IFrenchwolf420Belum ada peringkat

- 3 Wheel Go KartDokumen5 halaman3 Wheel Go KartLucas BrasilBelum ada peringkat

- Step-By-Step Building Instructions For the B19 and B20 Gyro СoptersDokumen8 halamanStep-By-Step Building Instructions For the B19 and B20 Gyro СopterspuchemBelum ada peringkat

- 12thpak InstrutionsDokumen5 halaman12thpak InstrutionsJavier Rodriguez PaezBelum ada peringkat

- Dorothy 24 Foot Sailing CruiserDokumen11 halamanDorothy 24 Foot Sailing CruiserJim92% (12)

- O Livro de Ouro Dos Experimentos Químicos (RARIDADE)Dokumen114 halamanO Livro de Ouro Dos Experimentos Químicos (RARIDADE)Davidson De Oliveira Lima100% (1)

- BAYLX UL16 UL18 UL20 2015 ULTRALITE-SPREADER-v3Dokumen32 halamanBAYLX UL16 UL18 UL20 2015 ULTRALITE-SPREADER-v3Jonah RagleBelum ada peringkat

- What Is Creep in RailDokumen2 halamanWhat Is Creep in RailGulzar HussainBelum ada peringkat

- MGA Prices PDFDokumen2 halamanMGA Prices PDFrenger20150303Belum ada peringkat

- API6D1Dokumen37 halamanAPI6D1Angga ErlanggaBelum ada peringkat

- UMS Check ListDokumen2 halamanUMS Check ListMarc AlfredBelum ada peringkat

- Merlo Turbofarmer Modular Tf30 9 To Tf65 9 Service Manuals deDokumen30 halamanMerlo Turbofarmer Modular Tf30 9 To Tf65 9 Service Manuals derickywilliams080102sxg99% (102)

- Market Segmentation PDFDokumen51 halamanMarket Segmentation PDFJoeBelum ada peringkat

- Operations and Service Manual 69NT40-541-500 To 599: Container RefrigerationDokumen164 halamanOperations and Service Manual 69NT40-541-500 To 599: Container Refrigerationfran namiuchiBelum ada peringkat

- Ohlins Motorcycle Road Track Catalogue 2021 - 210x210mm - SpreadsDokumen39 halamanOhlins Motorcycle Road Track Catalogue 2021 - 210x210mm - SpreadsTiago ZeferinoBelum ada peringkat

- Synchromesh Gearbox Definition Construction Working Principle Advantages Application Notes PDFDokumen9 halamanSynchromesh Gearbox Definition Construction Working Principle Advantages Application Notes PDFMelanie MartinssonBelum ada peringkat

- CDN Side Slip Test - Automotive Testing Equipment - VamagDokumen2 halamanCDN Side Slip Test - Automotive Testing Equipment - Vamagguenadi abdoellahBelum ada peringkat

- 20ft Electric Single Man Lift JLGDokumen4 halaman20ft Electric Single Man Lift JLGJoshuaBelum ada peringkat

- Additive manufacturing of an automotive brake pedal by metal fused deposition modellingDokumen5 halamanAdditive manufacturing of an automotive brake pedal by metal fused deposition modellingseran ünalBelum ada peringkat

- United States Patent (19) 4,513,568: BajulazDokumen9 halamanUnited States Patent (19) 4,513,568: BajulazQwerty UiopBelum ada peringkat

- McCormick X70 Series Tier 4 (2012-2013) - RPE1 - X70.50 Tractor Service Repair Manual PDFDokumen28 halamanMcCormick X70 Series Tier 4 (2012-2013) - RPE1 - X70.50 Tractor Service Repair Manual PDFfjkkekmdmBelum ada peringkat

- University of Kerala: Syllabus For Iv Semester Mechanical EngineeringDokumen20 halamanUniversity of Kerala: Syllabus For Iv Semester Mechanical EngineeringRahul RetnakaranBelum ada peringkat

- What is Full Voltage Starter and Reducing Starter MachineDokumen3 halamanWhat is Full Voltage Starter and Reducing Starter MachineRoselle SambajonBelum ada peringkat

- Renault ThermostatDokumen28 halamanRenault Thermostat方程式Belum ada peringkat

- Congestion Pricing in London and StockholmDokumen12 halamanCongestion Pricing in London and StockholmN3N5YBelum ada peringkat

- Gazetted List of Pioneer Industries and ProductsDokumen23 halamanGazetted List of Pioneer Industries and ProductsscokoyeBelum ada peringkat

- 737 Landing Gear NotesDokumen13 halaman737 Landing Gear NotesDanielBelum ada peringkat

- Website Clutch ExedyDokumen1 halamanWebsite Clutch ExedyEleazar Pavon0% (1)

- Spare Parts Catalog: 16 S 2230 TO Material Number: 1367.002.045 Current Date: 26.04.2017Dokumen80 halamanSpare Parts Catalog: 16 S 2230 TO Material Number: 1367.002.045 Current Date: 26.04.2017Wang Sze Shian100% (1)

- CJZC Engine Coolant SystemDokumen35 halamanCJZC Engine Coolant SystemDanielBelum ada peringkat

- GX13Dokumen537 halamanGX13Richard GodoyBelum ada peringkat

- Hyva Moves Your World: Hyva International B.VDokumen2 halamanHyva Moves Your World: Hyva International B.VDaniel SolomonBelum ada peringkat