Manhole Proof Load Test

Diunggah oleh

Asif HameedHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Manhole Proof Load Test

Diunggah oleh

Asif HameedHak Cipta:

Format Tersedia

Introduction

The following is a summary report of the evaluation of the ARPRO EPP Manhole

Grade Adjustment Ring application for HS-25 Static Loading.

Sanitary sewer systems necessitate that a manhole grade adjustment ring bear the load

requirements of the installation.

Load Requirements and Standard Testing Methods

The American Association of State Highway and Transportation Officials (AASHTO)

Standard Specification M306 identifies the proof-load testing required for drainage,

sewer, and related castings intended for use in traffic service. AASHTO M306 was

originally developed as a specification for cast iron, but the proof-load testing method

can also be applied to ARPRO Expanded Polypropylene (EPP) manhole grade rings. A

specifying agency or municipality may have established its own procedure that might

differ from this AASHTO specification; however it is likely that any method will require

the application of a specific load on a defined area. Any crack or detrimental permanent

deformation will cause the cover, grating, frame, or grade ring to be rejected.

The AASHTO Standard Specifications for Highway Bridges, 17th Edition, Section 3,

identifies two types of design vehicle loads. They represent categories of individual

vehicles and are routinely referred to as the H or HS truck. The H truck configuration

includes only two theoretical axles as in figure 1.

H-15

H-20

H-25

6,000 lbs.

8,000 lbs.

10,000 lbs.

24,000 lbs.

32,000 lbs.

40,000 lbs.

Figure 1 Standard H Trucks

Page 2 of 6

The information contained herein is based upon the results of limited laboratory tests on test samples of material molded from expanded polyolefin resin manufactured by JSP.

There can be no assurance that similar results will be achieved in simulated tests or actual use of commercial product molded by customers of JSP. Product performance may vary

substantially depending upon the particular application or processing involved. The listed properties are illustrative only and applications of JSP foam products can influence molded

part performance in many ways. Consequently, processors and/or users are advised that there may be a need to conduct independent tests and experiments in order for them to

determine the extent to which they may choose to rely upon such information in their business operations. JSP disclaims any liability in connection with the use of the information

and does not warrant against infringement by reasons of the use of its products in combination with other material or in any process.

The HS truck configuration represents the conventional semi- or tractor-trailer. It is

identical to the H truck, but with an extra axle representing the rear axle of the trailer, as

in figure 2.

H-15

H-20

H-25

6,000 lbs.

8,000 lbs.

10,000 lbs.

24,000 lbs.

32,000 lbs.

40,000 lbs.

24,000 lbs.

32,000 lbs.

40,000 lbs.

Figure 2 Standard HS Trucks

Results

Vehicular load testing was tested for JSP by the MGA Research Corporation, report

number C09H7-084.1 (Appendix A), in accordance with the proof-load testing standards

outlined by AASHTO M306, Section 6. Per AASHTO M306, Section 6, a proof-load

shall be applied to the drainage, sewer, utility, and all related castings. This proof load

represents a safety factor of 2.5 for H-20 or HS- 20 loading. A 50,000 lb. proof load will

be used to represent a safety factor of 2.5 for H-25 or HS-25 loading.

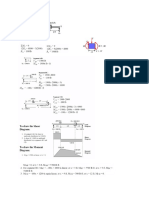

The proof-load test was conducted on one (1) standard ARPRO Expanded

Polypropylene (EPP) manhole 36-24GF-600 grade-finish ring. A standard 36-24GF-600

grade-finish ring has an outer diameter of 36 inches, an inner diameter of 24 inches,

and a starting height of 6.0 inches. The ring was placed onto a flat metal surface with

an East Jordan cast iron manhole frame and cover placed on top as it would be during

intended usage (figure 1). A servo hydraulic actuator was mounted to a crosshead

attached to two stanchions. The specified force was applied and held for a minimum of

1 minute at which time a maximum deflection was recorded at three locations on the

ring. Upon removal of the load, the sample was allowed to recover for 60 minutes then

the sample was inspected for cracks and detrimental permanent deformation. The

results are recorded in tables 1 and 2.

Page 3 of 6

The information contained herein is based upon the results of limited laboratory tests on test samples of material molded from expanded polyolefin resin manufactured by JSP.

There can be no assurance that similar results will be achieved in simulated tests or actual use of commercial product molded by customers of JSP. Product performance may vary

substantially depending upon the particular application or processing involved. The listed properties are illustrative only and applications of JSP foam products can influence molded

part performance in many ways. Consequently, processors and/or users are advised that there may be a need to conduct independent tests and experiments in order for them to

determine the extent to which they may choose to rely upon such information in their business operations. JSP disclaims any liability in connection with the use of the information

and does not warrant against infringement by reasons of the use of its products in combination with other material or in any process.

Figure 1 Proof-Load Test Set-up

Table 1 Proof-Load Test Results @ 40,000 Lbf

Post Test

Post Test

Permanent

+ 1 Hr.

Measurement

Set

Measurement

(in.)

(in.)

(in.)

5.658

5.693

0.000

Measurement

Location

Pre-Test

Measurement

(in.)

5.693

5.660

5.639

5.660

0.000

5.735

5.704

5.734

0.001

Remarks

No visible

deterioration

No visible

deterioration

No visible

deterioration

Page 4 of 6

The information contained herein is based upon the results of limited laboratory tests on test samples of material molded from expanded polyolefin resin manufactured by JSP.

There can be no assurance that similar results will be achieved in simulated tests or actual use of commercial product molded by customers of JSP. Product performance may vary

substantially depending upon the particular application or processing involved. The listed properties are illustrative only and applications of JSP foam products can influence molded

part performance in many ways. Consequently, processors and/or users are advised that there may be a need to conduct independent tests and experiments in order for them to

determine the extent to which they may choose to rely upon such information in their business operations. JSP disclaims any liability in connection with the use of the information

and does not warrant against infringement by reasons of the use of its products in combination with other material or in any process.

Table 2 Proof-Load Test Results @ 50,000 Lbf

Post Test

Post Test

Permanent

+ 1 Hr.

Measurement

Set

Measurement

(in.)

(in.)

(in.)

5.656

5.673

0.025

Measurement

Location

Pre-Test

Measurement

(in.)

5.698

5.703

5.657

5.673

0.030

5.687

5.651

5.656

0.031

Remarks

No visible

deterioration

No visible

deterioration

No visible

deterioration

Conclusions

Per ASSHTO M306, Section 6, upon removal of the proof load, the test specimen shall

be examined for cracks or detrimental permanent deformation. Permanent deformation

shall not exceed 3.2 mm (0.125 inch). Any cracks shall be cause for rejection.

Based upon the above proof load test results, it is apparent that the ARPRO Expanded

Polypropylene (EPP) Manhole Grade Adjustment Rings, when installed properly, can be

utilized in traffic environments where H-20, HS-20, H-25, and HS-25 vehicle loading is

expected.

Page 5 of 6

The information contained herein is based upon the results of limited laboratory tests on test samples of material molded from expanded polyolefin resin manufactured by JSP.

There can be no assurance that similar results will be achieved in simulated tests or actual use of commercial product molded by customers of JSP. Product performance may vary

substantially depending upon the particular application or processing involved. The listed properties are illustrative only and applications of JSP foam products can influence molded

part performance in many ways. Consequently, processors and/or users are advised that there may be a need to conduct independent tests and experiments in order for them to

determine the extent to which they may choose to rely upon such information in their business operations. JSP disclaims any liability in connection with the use of the information

and does not warrant against infringement by reasons of the use of its products in combination with other material or in any process.

Appendix A

Page 6 of 6

The information contained herein is based upon the results of limited laboratory tests on test samples of material molded from expanded polyolefin resin manufactured by JSP.

There can be no assurance that similar results will be achieved in simulated tests or actual use of commercial product molded by customers of JSP. Product performance may vary

substantially depending upon the particular application or processing involved. The listed properties are illustrative only and applications of JSP foam products can influence molded

part performance in many ways. Consequently, processors and/or users are advised that there may be a need to conduct independent tests and experiments in order for them to

determine the extent to which they may choose to rely upon such information in their business operations. JSP disclaims any liability in connection with the use of the information

and does not warrant against infringement by reasons of the use of its products in combination with other material or in any process.

mga research corporation

JSP

MAN-HOLE CONSTRUCTION

VERTICAL STATIC LOAD TEST SERIES

(PO# P39807)

446 executive drive troy, mi 48083

248 / 577-5001 fax 248 / 577-5025

www.mgaresearch.com

mga research corporation

TEST REPORT

MGA REPORT NO.:

C09H7-084.1 Rev. 1 (Revised 10/13/09)

TEST (S) PERFORMED ON:

October 7, 2009

TEST DESCRIPTION:

Vertical Static Load

ITEM DESCRIPTION:

Man-Hole Construction

(PO# P39807)

MGA PROCEDURE:

MGATPDUR_HF

TEST REFERENCE NUMBER (S):

VE9655 656

TEST LABORATORY:

MGA Research Corporation

446 Executive Drive

Troy, Michigan 48083

SUBMITTED TO:

Rob Doerr

JSP

1443 East 12 Mile Road

Madison Heights, MI 48071

TEST REPORT DATE:

October 12, 2009

MGA PERSONNEL:

Gerald Roesser

Project Leader

Test Personnel:

Ali Kaafarani

* The results presented in this report relate only to the specified test items.

** This report shall not be reproduced except in full, without the written approval of the laboratory.

446 executive drive troy, mi 48083

248 / 577-5001 fax 248 / 577-5025

www.mgaresearch.com

0850-01

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Page 2 of 11

Introduction

MGA Research is to perform test and provide testing results for the JSP Expanded Polypropylene manhole grade

adjustment ring. The test is to prove that the manhole construction will withstand typical ASHTO HS 20 and HS 25

loading conditions.

ASHTO Loading Conditions

The AASHTO Standard Specifications for Highway Bridges, 17th Edition, Section 3, identifies two types of

design vehicle loads. They represent categories of individual vehicles and are routinely referred to as the H

or HS truck. The H truck configuration includes only two theoretical axles as in figure 1.

H-15

6,000 lbs.

24,000 lbs.

H-20

8,000 lbs.

32,000 lbs.

H-25

10,000 lbs.

40,000 lbs.

Figure 1 Standard H Trucks

The HS truck configuration represents the conventional semi- or tractor-trailer. It is identical to the H

truck, but with an extra axle representing the rear axle of the trailer, as in figure 2.

H-15

6,000 lbs.

24,000 lbs.

24,000 lbs.

H-20

8,000 lbs.

32,000 lbs.

32,000 lbs.

H-25

10,000 lbs.

40,000 lbs.

40,000 lbs.

Figure 2 Standard HS Trucks

Load Calculations

The 40,000 lbf proof loads represent a safety factor of 2.5 for H-20 or HS- 20 loading on one tire patch.

36,600 lb rear axel / 2 tire patches * 2.5 safety factor = 40,000 lbf proof load

A 50,000 lb. proof load will be used to represent a safety factor of 2.5 for H-25 or HS-25 loading on one

tire patch.

40,000 lb rear axel / 2 tire patches * 2.5 safety factor = 50,000 lbf proof load

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Page 3 of 11

Test Procedure

1.

2.

3.

4.

5.

Test Samples were loaded under compression

Sample #1 was loaded to 40,000 lbf @ 400 lbf/sec. load was held for 1 minute.

Sample #2 was loaded to 50,000 lbf @ 400 lbf/sec. load was held for 1 minute.

Pre, instant post and 1 hour post test deflection measurements were taken.

Pre and Post test photos were taken.

Test Results

VE9655 Sample#1 @ 40K Lbf

Location

1

2

3

Location

1

2

3

Pre-Test

Measurements (in)

5.693

5.66

5.735

Post-Test

Measurements (in)

5.658

5.639

5.704

1-Hour Post-Test

Measurements (in)

5.693

5.66

5.734

VE9656 Sample#2 @ 50K Lbf

Pre-Test

Post-Test

Measurements (in)

Measurements (in)

5.698

5.656

5.703

5.657

5.687

5.651

1-Hour Post-Test

Measurements (in)

5.673

5.673

5.656

Additional Information can be found in the following appendices

Appendix A System Calibration Information ................................................................................................................4

Appendix B Test Data Plots and Photographs...............................................................................................................7

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Appendix A

System Calibration Information

Page 4 of 11

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Page 5 of 11

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Page 6 of 11

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Appendix B

Test Data Plots and Photographs

Page 7 of 11

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Page 8 of 11

MGA Research

JSP

ManHole

Vertical Static Loading @40K Lbf

Sample#1

VE9655

45000

40000

35000

Force (Lbf)

30000

25000

20000

15000

10000

5000

0

-0.05

0.05

0.1

0.15

0.2

0.25

0.3

0.35

Displacement (in)

MGA Research

JSP

ManHole

Vertical Static Loading @40K Lbf

Sample#1

VE9655

45000

40000

35000

Force (sec)

30000

25000

20000

15000

10000

5000

0

0

20

40

60

80

Time (sec)

100

120

140

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Page 9 of 11

Test #VE9655 Pre-Test Photos

Photo #1

Photo #2

Photo #3

Photo #4

Photo #5

Photo #6

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Page 10 of 11

Test #VE6955 Post-Test Photos

Photo #1

Photo #2

Photo #3

Photo #4

Photo #5

Photo #6

MGA Report No.: C09H7-084.1 Rev. 1

Test Type: Vertical Static Load

Customer: JSP

Program: Man-Hole Construction

Page 11 of 11

Test #VE9556 Post-Test Photos

Photo #1

Photo #2

Photo #3

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- LEC - 25 Buckling of Columns - Part 1Dokumen29 halamanLEC - 25 Buckling of Columns - Part 1Asif HameedBelum ada peringkat

- Surveying NotesDokumen39 halamanSurveying NotesInhen Yero75% (4)

- Electroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneDokumen48 halamanElectroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneShweta KateBelum ada peringkat

- Fidic Timeline (Final)Dokumen1 halamanFidic Timeline (Final)Asif Hameed81% (16)

- Estimation of The ProjectDokumen89 halamanEstimation of The ProjectNaga PrasanthBelum ada peringkat

- IRE ETS: Uc Davis Fire Prevention Self Inspection ChecklistDokumen3 halamanIRE ETS: Uc Davis Fire Prevention Self Inspection ChecklistAsif HameedBelum ada peringkat

- Fidic Assignment FinalDokumen53 halamanFidic Assignment FinalAsif Hameed100% (1)

- Labour Productivity Journal PaperDokumen22 halamanLabour Productivity Journal PaperAsif HameedBelum ada peringkat

- Labour Productivity Journal PaperDokumen22 halamanLabour Productivity Journal PaperAsif HameedBelum ada peringkat

- (2014) Colour and Technology in Historic Decorated Glazes and Glasses PDFDokumen117 halaman(2014) Colour and Technology in Historic Decorated Glazes and Glasses PDFtariq.toffa4760Belum ada peringkat

- Metro Train-Induced Vibrations On Historical BuildingDokumen12 halamanMetro Train-Induced Vibrations On Historical BuildingAsif HameedBelum ada peringkat

- 18 A FYP Stakeholder ManagementDokumen10 halaman18 A FYP Stakeholder ManagementAsif HameedBelum ada peringkat

- 1 s2.0 S0950061814001160 Main PDFDokumen15 halaman1 s2.0 S0950061814001160 Main PDFsanjithr619Belum ada peringkat

- Hec Self Assessment ManualDokumen47 halamanHec Self Assessment ManualHaseeb JatoiBelum ada peringkat

- MANE 4240 & CIVL 4240 Introduction To Finite Elements: Prof. Suvranu deDokumen28 halamanMANE 4240 & CIVL 4240 Introduction To Finite Elements: Prof. Suvranu deskkskBelum ada peringkat

- Ms Research ProposalDokumen8 halamanMs Research ProposalAsif HameedBelum ada peringkat

- Effect of Various Supplementary Cementitious Materials On RheologicalDokumen10 halamanEffect of Various Supplementary Cementitious Materials On RheologicalAsif HameedBelum ada peringkat

- Bashandy A Self-Curing 2 2016Dokumen16 halamanBashandy A Self-Curing 2 2016Asif HameedBelum ada peringkat

- SCC AplicationDokumen392 halamanSCC AplicationTeguh Farid Nurul ImanBelum ada peringkat

- SF BM SafeerDokumen3 halamanSF BM SafeerAsif HameedBelum ada peringkat

- ASCE Near-Surface-Mounted Composite System For Repair Axial Load and Biaxial BendingDokumen13 halamanASCE Near-Surface-Mounted Composite System For Repair Axial Load and Biaxial BendingAsif HameedBelum ada peringkat

- Effect of Chemical and Mineral Admixtures OnDokumen77 halamanEffect of Chemical and Mineral Admixtures OnAsif HameedBelum ada peringkat

- Edu WabashBridgeDesignDokumen69 halamanEdu WabashBridgeDesignNiels HaelewynBelum ada peringkat

- Critical Success Factors in Implementing Process-Oriented Knowleddge Management in KoreaDokumen154 halamanCritical Success Factors in Implementing Process-Oriented Knowleddge Management in KoreaAsif HameedBelum ada peringkat

- Vishay Linear Displacement SensorsDokumen4 halamanVishay Linear Displacement SensorsAsif HameedBelum ada peringkat

- Group 1 2 Semester Section A CIVIL 2012 Booker Name: Roll No. 2012-CIV-09Dokumen8 halamanGroup 1 2 Semester Section A CIVIL 2012 Booker Name: Roll No. 2012-CIV-09Asif HameedBelum ada peringkat

- Finding ESL Example 11.2Dokumen2 halamanFinding ESL Example 11.2Asif HameedBelum ada peringkat

- Chapter 2 - Factors, Effect of Time & Interest On MoneyDokumen33 halamanChapter 2 - Factors, Effect of Time & Interest On MoneyAsif HameedBelum ada peringkat

- Psychomotor For ComputerDokumen22 halamanPsychomotor For ComputerAsif HameedBelum ada peringkat

- Effect of Inert and Pozzolanic Materials On Flow andDokumen12 halamanEffect of Inert and Pozzolanic Materials On Flow andAsif HameedBelum ada peringkat

- VibrationDokumen84 halamanVibrationAsif HameedBelum ada peringkat

- Effect of fly ash and silica fume on compressive strength of self-compacting concreteDokumen8 halamanEffect of fly ash and silica fume on compressive strength of self-compacting concretegeostaterBelum ada peringkat

- Ecotek DesignManual v2015 02Dokumen44 halamanEcotek DesignManual v2015 02benBelum ada peringkat

- Manual Direct Fired 160h Through 800h PN 54000 07-12-13 - 1Dokumen53 halamanManual Direct Fired 160h Through 800h PN 54000 07-12-13 - 1Fer YamashitaBelum ada peringkat

- Presentation by Harshal Sethiya N Mitul UpadhyayDokumen26 halamanPresentation by Harshal Sethiya N Mitul Upadhyaysanket jain100% (1)

- BE AMC-34-All Branches With IndexDokumen223 halamanBE AMC-34-All Branches With IndexSrikanth RangdalBelum ada peringkat

- Coordinated Voltage and Reactive Power Control Strategy With Distributed Generator For Improving The Operational EfficiencyDokumen8 halamanCoordinated Voltage and Reactive Power Control Strategy With Distributed Generator For Improving The Operational EfficiencyRaphael NgenyiBelum ada peringkat

- BRP-1 Final Report Borjan Private LimitedDokumen38 halamanBRP-1 Final Report Borjan Private LimitedArsalan IqbalBelum ada peringkat

- Central Sterile ServiceDokumen75 halamanCentral Sterile ServiceSUBHENDU SIKDAR100% (1)

- M7 Lab: Sedimentary RocksDokumen10 halamanM7 Lab: Sedimentary RocksEssay NationBelum ada peringkat

- 842e In001 - en PDokumen4 halaman842e In001 - en PNilson Eduardo TorresBelum ada peringkat

- ACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualDokumen164 halamanACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualNutan PowerBelum ada peringkat

- Compro Saj 2023 - 22052023Dokumen58 halamanCompro Saj 2023 - 22052023Ahmad FauziBelum ada peringkat

- Vikas KumarDokumen4 halamanVikas Kumarsanju sharmaBelum ada peringkat

- Emc SCADA PresentationDokumen36 halamanEmc SCADA Presentationerode els erodeBelum ada peringkat

- The Fundamental Building Block: The CellDokumen12 halamanThe Fundamental Building Block: The CellTanish JenaBelum ada peringkat

- Single Point Earthing and Equipotential Planes for Sensitive Electronic EquipmentDokumen30 halamanSingle Point Earthing and Equipotential Planes for Sensitive Electronic EquipmentDeepak GuptaBelum ada peringkat

- MCA-12 Web DesigningDokumen204 halamanMCA-12 Web DesigningLittaBelum ada peringkat

- Donna's Score During The Third Quarter ExaminationDokumen7 halamanDonna's Score During The Third Quarter ExaminationGeraldine Valdez CacabilosBelum ada peringkat

- Um Centuris Pro Li900b1 - enDokumen70 halamanUm Centuris Pro Li900b1 - enOsires Ferreira100% (1)

- Unit V Cellular Manufacturing and Flexible Manufacturing System (FMS)Dokumen32 halamanUnit V Cellular Manufacturing and Flexible Manufacturing System (FMS)manuBelum ada peringkat

- Raúl Edgardo Macchiavelli: Raul - Macchiavelli@upr - EduDokumen53 halamanRaúl Edgardo Macchiavelli: Raul - Macchiavelli@upr - EduDhaval patelBelum ada peringkat

- Crude Fiber Lab ReportDokumen10 halamanCrude Fiber Lab ReportNurbatrisyia NawiBelum ada peringkat

- Sachin KotianDokumen4 halamanSachin Kotianapi-3699646Belum ada peringkat

- Leadership Theory Application and Skill Development 5th Edition Lussier Test Bank 1Dokumen36 halamanLeadership Theory Application and Skill Development 5th Edition Lussier Test Bank 1douglasbrownyipsmrgkob100% (29)

- Assignment On Computer HardwareDokumen9 halamanAssignment On Computer HardwareMuktadirhasan100% (1)

- MetabolismDokumen21 halamanMetabolismNagendra NayakBelum ada peringkat

- Weeder SynopsisDokumen8 halamanWeeder SynopsisParas ChauhanBelum ada peringkat