TOP LIRE - Corrosion Inspection and Management in OKTA Crude Oil Refinery

Diunggah oleh

LandryHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TOP LIRE - Corrosion Inspection and Management in OKTA Crude Oil Refinery

Diunggah oleh

LandryHak Cipta:

Format Tersedia

A.

ENOVAR

CORROSION INSPECTION AND MANAGEMENT IN OKTA CRUDE

ANDREJ ENOVAR

Professional paper

UDC:620.193.4:665.66

Corrosion inspection and management in OKTA crude oil refinery

The appearance of corrosion presents a major issue in the petroleum industry. The corrosive

deterioration is the main cause for the equipment and piping breakdown and failure, which reduces the

process efficiency and increases the costs significantly. Also, failures due to corrosion pose a threat

for the personnel, as well as for the environment. For these reasons, the corrosion inspection and

management is an essential aspect of the management of every petroleum refinery.

The subject of this paper is the analysis of the main causes and the most common types of corrosion

present in OKTA, as well as corrosion management. The corrosion detection is primarily done by

visual inspection. The condition of the material is inspected with ultrasonic thickness measurement and

defectoscopy, and hardness measurement. The equipment subjected to high-temperature conditions is

inspected with IR camera. The inspection reports are used for corrosion rate determination, remaining

life calculations and fitness for service.

Key words: refinery, corrosion, inspection, corrosion management

1. INTRODUCTION

Due to the different nature of the process fluids

and various enviroments found in petroleum refining,

corrosion is an inevitable part of the operating

proecss. The various aspects of corrosion and its

accompanying processes are responsible for the most

of the equipment failures and damage. In addition,

corrosion reduces the efficiency of the process and

increases the operating and maintenance costs significantly. Based on national and company surveys, the

cost in corrosion in refining ranges from $0.14/bbl to

$1.34/bbl, with an average value of $0.89/bbl [1].

As a result of the extremely hazardous nature of

the fluids and gases processed in refineries, the safety

and well being of both plant employees and the public

are put at risk by corrosion. Equipment failures could

result in severe damage to entire process units, as well

as the environment. It was determined that corrosion

was a factor in 21.5% of all reported accidents in

refineries [2,3].

The cost reduction, health and safety of the personnel, as well as the protection of the environment

are the three main causes for corrosion inspection and

management.

2. TYPES OF CORROSION

There are many systems for classifying corrosion,

but the most widely accepted categorization is the one

of M. Fontana [4], which includes the following types

Author's address: OKTA Crude Oil Refinery AD,

Skopje, Macedonia, e-mail: acesnovar@helpe.gr

Received for Publication: 19. 03. 2013.

Accepted for Publication: 15. 06. 2013.

of corrosion: uniform attack, galvanic (two-metal)

corrosion, pitting, crevice corrosion, intergranular

corrosion, selective leaching, erosion corrosion, stress

corrosion and hydrogen damage. The advantage of

this classification is that the corrosion type can be

indentified visually, without laboratory analysis.

The corrosion manual from NALCO categorizes

the corrosion according the chemical cause carbon

dioxide, oxygen, hydrogen sulfide, microorganism

influenced, hydrochloric acid and naphthenic acid

corrosion [5]. According to API RP 571, there are 63

different corrosion mechanisms occurring in refinery

equipment [6]. Regarding the form, there are 15 types

of corrosion in the petroleum industry [7].

However, there are several most common types of

corrosion that can be found in OKTA Crude Oil

Refinery: uniform corrosion, pitting, erosion and crevice corrosion. Crevice, galvanic, microbial corrosion

and other types have also been detected.

3. CORROSION INSPECTION

Corrosion is determined and inspected by the

following methods:

Visual inspection,

Ultrasonic thickness measurement,

Ultrasonic defectoscopy,

Hardness measurement,

Infrared thermography.

The ultrasonic thickness measurement is done

with 4 thickness gauges, Krautkramer DM4, the ultrasonic defectoscopy is done with phased array ultrasonics, Krautkramer Phasor XS, the hardness measu-

ZATITA MATERIJALA 54 (2013) broj 3

291

A. ENOVAR

CORROSION INSPECTION AND MANAGEMENT IN OKTA CRUDE

rement is conducted with hardness metrer, Krautkramer DynaMIC, and the IR inspection is done with a

camera, FLIR T-200.

The listed inspection methods are, usually, done

in combination with each other, following the pattern

showed of figure 1. The purpose of using of multiple

methods is the obtaining of a more complete picture

of the inspected equipment.

of external and internal visual inspection are given on

fig. 2, showing the surface affected by corrosion

under insulation on a heat exchanger head and the

product-induced corrosion in a distillation column,

respectively.

Figure 1 - Scheme for conducting equipment

inspection

The first step is the visual inspection, which

represents the basis for determinig whether a

corrosion problem exists or not. If a problem is found,

the next step is the inspection is the ultrasonic

thickness meausrement. Depending of the

temperature environment of the equipment, for hightemperature conditions, hardness measurements or IR

inspection is done. If the problem is more complex,

ultrasonic defectoscopy or phased array are applied.

In many cases, the corrosion damage of the

equipment is internal. Then, the ultrasonic thickness

measurement is the first step for detection of

corrosion. The following steps are the same as the

ones regarding external corrosion.

a) External

3.1. Visual inspection

The visual control is the first, basic step, but also

it is the most important activity done on every

inspection. The successfulness of the inspection

depends primarily on the quality of the visual

inspection; it is a determining factor of the direction

which the inspection will take. After the visual

inspection, it is decided whether additional activities

are needed.

Depending of the type of equipment, accessibility, operating environment, etc., the visual

inspection can be done externally or internally. The

inspection of the external side reveals the corrosion

caused by environmental influences, and the internal

inspection can determine corrosive damage caused by

the fluid used.

During the inspection, every evidence of

corrosion is photographed, and the appearance and

location of the surface in question is noted. Examples

292

b) Internal

Figure 2 - Examples of visual inspection

The visual control, as a method of inspection, is

standard practice in all of the API (American

Petroleum Institute) inspection standards [8-12],

which are used in OKTA.

3.2. Ultrasonic thickness measurement

The ultrasonic thickness measurement is a basic

method for determining a thickness reduction as a

result of erosion or corrosion of the metal material.

The thickness measurement is done on the most

critical locations on the equipment, on specifically

determined places. The determining of these locations

is done both by experience (on equipment with

previously established corrosion problems) and by the

inspection standard requirements.

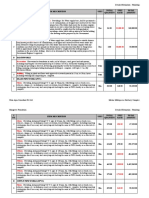

These ultrasonic thickness measurement results

are not only providing an insight in the current state

of the equipment, but the thickness chronology can

also serve for determining of the corrosion rates, i.e.

metal wall loss during operation, as well as for

ZATITA MATERIJALA 54 (2013) broj 3

A. ENOVAR

CORROSION INSPECTION AND MANAGEMENT IN OKTA CRUDE

prediction of the remaining life of the vessel. An

example of an ultrasonic thickness measurement

report is given on figue 3.

Figure 3 - Ultrasonic thickness measurement report for a pressure vessel

The ultrasonic thickness inspection is regulated

with the standard EN 583 [13], while the characterristic inspection areas on each type of equipment are

separately given in the API standards [8-12].

Because of this, the inspection of the hardness is

an important, if non-direct, method for assessment of

corrosion damage.

3.3. Ultrasonic defectoscopy

Another non-conventional method for corrosion

detection used in OKTA is the infrared thermography.

Its primary use is for detection of thinned walls on

pipes, compressors, etc. operating under high-temperature conditions. The advantage of the IR thermography is that it enables us to scan the pipes relatively

fast and detect the locations with reduced thickness

via the higher temperatures reported in these areas.

The determined areas can then be evaluated in terms

of thickness reduction with ultrasonics. However, this

method is limited only to high-temperature, uninsulated equipment, which is not common in the oil

refineries. Also, the corrosion damage on the walls

has to be sufficient, so that a temperature gradient

appears, which can be recorded with an IR camera.

The infrared thermography can also be used as a

method for corrosion prevention. Its ability for detecting temperature differences enables us to find poorly insulated areas on the piping, which, if not

repaired, can lead to collecting and trapping of water.

This, in turn, can cause appearance of corrosion.

This ultrasonic defectoscopy is used for determining of the type of defect, after it is found by

another inspection method. This method allows us to

discover defects in the base material and especially in

the welds. The phased array mode of operation is an

advanced inspection technique; it produces a 3D imaging of the defect, which gives a real representation

of its type and location.

Sometimes, the thickness gauge records a thickness reduction in the metal, which is actually due to

defect in the base material (inclusion, pore, etc.) and

not a result of corrosion damage. In these cases, the

ultrasonic defectoscope enables us to determine the

true cause of the obtained thickness reduction result.

3.4. Hardness measurement

The measurement of the hardness is used when

inspecting equipment exposed to high-temperature

operating conditions. The hardness itself is not a

direct indication of corrosion; however, the increase

of the hardness results in increasing of the tensile

strength and decreasing of the toughness and ductility

of the metal. The impairment of some of the

mechanical properties means that the calculated

minimal thickness of the equipment is no longer

valid. In fact, it could be drastically higher than the

one calculated for a material not affected by hightemperature conditions.

3.5. Infrared thermography

4. CORROSION PREDICTION AND INSPECTION

PLANNING

The information regarding the equipment corrosion are collected, analyzed and stored in the Technical Inspection database. In the electronic database,

there is a file referring to each piece of process

equipment, containing the following information:

ZATITA MATERIJALA 54 (2013) broj 3

293

A. ENOVAR

CORROSION INSPECTION AND MANAGEMENT IN OKTA CRUDE

1. Technical data. This section contains the

technical and technological data of the vessel production year, steel grade, maximal operating temperature, operating and test pressure, type of product,

etc. Also, the types of corrosion affecting the vessel

according to API 571 [6], as well as the aggressiveness of the fluid, are included.

2. Technical drawing. The drawing contains the

dimensional properties of the vessel, as well as the

measuring locations.

3. Chronology of thickness measurements. This

section contains the measuring locations, design

thickness, minimal allowed thickness, and a column

with the measured thickness and the date of the measurement. The minimal thickness is calculated according to ASME Code, Section VIII Division 1 [14].

4. Graphic presentation of the data. Here, the

measured values, i.e., one measurement from every

characteristic location on the vessel (head, shell,

nozzle, etc.) with the largest thickness reduction are

taken as reference points. An example of the graphic

presentation of the chronological thickness data is

given on fig. 4.

5. Vessel history data. This section contains

several basic types of information, but it is designed

to accommodate any type of data that is considered

important. For instance, information such as the dates

of the vessel hydro-testing, inspections done by thirdparty companies, repairs of the insulation and/or paint

coating, installing, replacement or repair on major

vessel parts (or minor ancillary equipment), etc. are

included here.

Figure 4 - Graphic presentation of thickness reduction on the shell and head of a pressure vessel

This data can serve for scheduling of the inspection activities, as well as for risk-based inspection.

Risk-based inspection (RBI) is a method for using

risk as a basis for prioritizing and managing the

efforts of an inspection program, in accordance with

the risk associated with a certain piece of equipment

[15]. When the risk of a vessel is calculated, multiple

factors should be taken in consideration corrosion

rate, operating conditions, the aggressiveness/hazardousness of the fluid, etc. Usually, a vessel is con294

sidered to be of medium or high risk when, according

to the other conditions and the corrosion rate, the

inspection interval should be shorter than the one

given in the inspection standards.

The graphically presented data can show the

condition of the equipment from aspect of corrosion.

With the adding of a mathematical trendline,

depending of the obtained curves, the remaining life

of the equipment can be easily calculated. This is

presented on figure 5.

ZATITA MATERIJALA 54 (2013) broj 3

A. ENOVAR

CORROSION INSPECTION AND MANAGEMENT IN OKTA CRUDE

(shell)

(thickness) [mm]

8.5

8

7.5

7

(measured)

(design)

6.5

(minimal)

6

5.5

5

4.5

4

1988

1992

1996

2000

2004

2008

2012

2016

2020

2024

(year)

Figure 5 - Calculation of remaining life of a pressure vessel

Often, the data points are not forming even curves

some of the points can be higher, in comparison to

the expected values by the overall trend of the curve.

This is due to the nature of the ultrasonic measurement; it is very difficult to make the measurement

on the identical location as previously. This variation

of the thickness can present a problem for calculating

of the remaining life, if there are not sufficient history

data for the vessel. However, in most of the cases, the

data from the previous years of measurement is more

than enough for establishing the correct remaining

life.

Nonetheless, this method of collecting and presenting of the thickness reduction data gives invaluable information regarding the corrosion. In turn, the

information is essential for inspection planning.

The managing of corrosion is done mainly by

identifying and minimizing of the causes. For this

purpose, the previously collected and analyzed

corrosion data are used.

Analysis of the equipment data, which involves a

few steps. First, the corrosion rate is determined, by

comparing the latest and previously collected data

regarding the equipment in question. Then, considering the corrosion rate, amongst other risk factors,

the risk category of the equipment is determined.

Based on the corrosion rate, the remaining life of the

equipment is calculated. Finally, depending on the

previous two activities, it is decided whether the

equipment is fit for service.

The following of this procedure for inspection

and data analysis gives us a detailed picture of the

current state of the equipment, as well as a good idea

for the future measures and activities that should be

taken for prevention and minimizing of corrosion and

corrosion-related issues.

REFERENCES

5. CONCLUSION

[1] R. Tems, A. M. Al Zaharani, Cost of Corrosion in

Oil Production and Refining, Saudi Aramco Journal

of Technology, 2006, 2-14.

The corrosion inspection of the equipment in

OKTA Crude Oil Refinery is one of the key factors

for providing continuous production process and safe

working environment. The corrosion inspection and

management is accomplished with the following

activities:

[2] M. H. Wood, Corrosion Accidents in Refineries,

Preliminary Finding from a Study of Recent Accidents in OECD/EU countries, European Commission Joint Research Centre, Major Accident Hazards

Bureau, 2010.

Inspection of the equipment, which includes quantitative and qualitative assessment of the corrosion

and corrosion associated damage i.e., is corrosion

present and what is the degree of its severity.

[3] R. Manojlovic, A.Cesnovar, Zastita materijala 53

(2012) 4, 365-371

[4] M. G. Fontana, Corrosion Engineering, McGrawHill Book Company. 3rd edition, 1985.

ZATITA MATERIJALA 54 (2013) broj 3

295

A. ENOVAR

CORROSION INSPECTION AND MANAGEMENT IN OKTA CRUDE

[5] NALCO, Corrosion in the Petroleum Industry,

Nalco Company, 2004.

[10] API RP 572 Inspection of Pressure Vessels, 2nd

ed., American Petroleum Institute, 2001.

[6] API RP 571 - Damage Mechanisms Affecting Fixed

Equipment in the Refining Industry, American

Petroleum Institute, 2003.

[11] API RP 574 Inspection Practices for Piping

System Components, 2nd ed., American Petroleum

Institute, 1998.

[7] R. Heiderbach, Metallurgy and Corrosion Control in

Oil and Gas Production, John Wiley & Sons, Inc.,

2011.

[12] API 653 Tank Inspection, Repair, Alteration and

Reconstruction, ADD 3, American Petroleum

Institute, 2008

[8] API 510 Pressure Vessel Inspection Code: InService Inspection, Rating and Alteration, 9th ed.,

American Petroleum Institute, 2006.

[13] EN 583, Non-destructive testing Ultrasonic

examination.

[9] PI 570 Piping Inspection Code: Inspection,

Repair, Alteration and Rerating of In-Service Piping

Systems, American Petroleum Institute, ADD 4,

2006.

[14] ASME Boiler and Pressure Vessel Code (BPVC),

Section VIII Division 1, American Society of

Mechanical Engineers, 2010.

[15] API 581 Risk-Based Inspection Base Resource

Document, American Petroleum Institute, 2000.

IZVOD

INSPEKCIJA I UPRAVLJANJE KOROZIJOM U RAFINERIJI NAFTE OKTA

Pojava korozije predstavlja veliki problem u naftenoj industriji. Oteenja usled korozije su glavni

razlog za pojavu defekata opreme i cevovoda, to utie na smanjenje efikasnosti procesa i znaajno

uveava trokove. Takoe, defekti prouzrokovani korozijom predstavljaju opasnost za zaposlene, kao i

za okolinu. Zbog ovoga, inspekcija i upravljanje korozijom pretstavljaju kljuni aspekat menadmenta

svake rafinerije nafte.

Tema ovog rada je analiza glavnih uzroka i najeih tipova korozije koji se sreu u rafineriji OKTA,

kao i upravljanje korozijom. Detekcija korozije se uglavnom obavlja putem vizuelne kontrole. Stanje

materijala se ispituje ultrazvunim merenjem debljine i defektoskopijom kao i merenjem tvrdoe, dok

se oprema podloena visokotemperaturnim uslovima ispituje infracrvenom kamerom. Inspekcijski

izvetaji se koriste za odreivanje brzine korozije, proraune preostalog vremena upotrebe opreme i

ispitivanje pogodnosti za korienje.

Kljune rei: rafinerija, korozija, inspekcija, upravljanje korozijom

Struni rad

Primljeno za publikovanje: 19. 03. 2013.

Prihvaeno za publikovanje: 15. 06. 2013.

296

ZATITA MATERIJALA 54 (2013) broj 3

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Church of God Is Zhang Gil-Ja's Congregation!Dokumen7 halamanThe Church of God Is Zhang Gil-Ja's Congregation!LandryBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Corr AccDokumen100 halamanCorr AccNaveen KumarBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Prabhupada Interview2Dokumen14 halamanPrabhupada Interview2LandryBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- SabbathDokumen6 halamanSabbathLandry100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- VeilDokumen5 halamanVeilLandryBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- X1 - Who Were The Original Jews and HebrewsDokumen4 halamanX1 - Who Were The Original Jews and HebrewsLandry0% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Tree of Life and Christ AhnsahnghongDokumen4 halamanThe Tree of Life and Christ AhnsahnghongLandry100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Environmental Issues of Petroleum ExplorationDokumen3 halamanEnvironmental Issues of Petroleum ExplorationMarcus Skookumchuck Vannini100% (1)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- TOP Risk - The Latest On Damage Mechanisms in The Petrochemical IndustryDokumen4 halamanTOP Risk - The Latest On Damage Mechanisms in The Petrochemical IndustryLandryBelum ada peringkat

- X1 - Circumcisions and CovenantsDokumen4 halamanX1 - Circumcisions and CovenantsLandryBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- XXI Paper 084Dokumen8 halamanXXI Paper 084yogolainBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Physical PlantDokumen2 halamanPhysical PlantLandryBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- x1 - Zion and JahrusalemDokumen8 halamanx1 - Zion and JahrusalemLandryBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- PFC3d Manual ContentsDokumen3 halamanPFC3d Manual ContentsLandryBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Plastics Engineering NewDokumen4 halamanPlastics Engineering NewyogolainBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Corrosion Management - OffshoreDokumen76 halamanCorrosion Management - OffshoreZarra Fakt100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Kern Method Heat ExchangerDokumen30 halamanKern Method Heat ExchangerCS100% (3)

- Bieleschweig4 Folien KuhnDokumen17 halamanBieleschweig4 Folien KuhnDave CBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Risk Based Inspection ApplicationDokumen12 halamanRisk Based Inspection Applicationelvis hidalgoBelum ada peringkat

- Am S 01200602Dokumen10 halamanAm S 01200602Kinger Bin KingeeBelum ada peringkat

- TOP Risk - Enterprise Risk Management Handbook (Complete)Dokumen37 halamanTOP Risk - Enterprise Risk Management Handbook (Complete)LandryBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- TOP Risk - Operational Risk Assessment of Chemical Industries by Exploiting Accident DatabasesDokumen46 halamanTOP Risk - Operational Risk Assessment of Chemical Industries by Exploiting Accident DatabasesLandryBelum ada peringkat

- HSE TOP TOP - Skelton - Process SafetyDokumen9 halamanHSE TOP TOP - Skelton - Process SafetyLandryBelum ada peringkat

- Fundamentals of Metallic Corrosion in Fresh WaterDokumen18 halamanFundamentals of Metallic Corrosion in Fresh Waterkklucher1Belum ada peringkat

- WroughtAndCastHeatResistantStainlessSteelsNickelAlloysRefiningPetrochemical 10071Dokumen16 halamanWroughtAndCastHeatResistantStainlessSteelsNickelAlloysRefiningPetrochemical 10071Jacildo Soares Cavalcante CavalcanteBelum ada peringkat

- TOP LIRE - NACE TOP LIRE Corrosion Control in The Refining Industry - Sept2012Dokumen3 halamanTOP LIRE - NACE TOP LIRE Corrosion Control in The Refining Industry - Sept2012LandryBelum ada peringkat

- Corrosion Integrity EngineerDokumen2 halamanCorrosion Integrity EngineeryogolainBelum ada peringkat

- WroughtAndCastHeatResistantStainlessSteelsNickelAlloysRefiningPetrochemical 10071Dokumen16 halamanWroughtAndCastHeatResistantStainlessSteelsNickelAlloysRefiningPetrochemical 10071Jacildo Soares Cavalcante CavalcanteBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- TheRoleofChlorineinHigh TemperatureCorrosioninWaste To EnergyPlants 14045Dokumen14 halamanTheRoleofChlorineinHigh TemperatureCorrosioninWaste To EnergyPlants 14045Yogaisan RamasawmyBelum ada peringkat

- TOP LIRE - Predictsw20 - Flyer - Honeywell Solutions For CorrosionDokumen2 halamanTOP LIRE - Predictsw20 - Flyer - Honeywell Solutions For CorrosionLandryBelum ada peringkat

- Funny AcronymsDokumen6 halamanFunny AcronymsSachinvirBelum ada peringkat

- Bruno (2005) Approximating The Bias of The LSDV Estimator For Dynamic Unbalanced Panel Data ModelsDokumen6 halamanBruno (2005) Approximating The Bias of The LSDV Estimator For Dynamic Unbalanced Panel Data Modelsvincus27Belum ada peringkat

- Dell PowerEdge M1000e Spec SheetDokumen2 halamanDell PowerEdge M1000e Spec SheetRochdi BouzaienBelum ada peringkat

- NV 2Dokumen2 halamanNV 2Joshua ApongolBelum ada peringkat

- 03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019Dokumen52 halaman03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019samir bendreBelum ada peringkat

- Spark - Eastern Peripheral Road Project (Epr) Weekly Quality MeetingDokumen6 halamanSpark - Eastern Peripheral Road Project (Epr) Weekly Quality Meetingengr.s.a.malik6424Belum ada peringkat

- 20 X 70Dokumen102 halaman20 X 70MatAlengBelum ada peringkat

- Exercise 3 - Binary Coded DecimalDokumen3 halamanExercise 3 - Binary Coded DecimalNaiomi RaquinioBelum ada peringkat

- Azar Mukhtiar Abbasi: Arkad Engineering & ConstructionDokumen4 halamanAzar Mukhtiar Abbasi: Arkad Engineering & ConstructionAnonymous T4xDd4Belum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- ManagementLetter - Possible PointsDokumen103 halamanManagementLetter - Possible Pointsaian joseph100% (3)

- MEETING 12 - Additional CasesDokumen25 halamanMEETING 12 - Additional CasesJohn Michael VidaBelum ada peringkat

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDokumen6 halaman29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaBelum ada peringkat

- Brand Plan - SingulairDokumen11 halamanBrand Plan - Singulairshashank100% (2)

- SPMT Stability of Hydraulic EngDokumen4 halamanSPMT Stability of Hydraulic Engparamarthasom1974Belum ada peringkat

- Indian Chief Motorcycles, 1922-1953 (Motorcycle Color History)Dokumen132 halamanIndian Chief Motorcycles, 1922-1953 (Motorcycle Color History)Craciun Sabian100% (6)

- Witness Affidavit of Emeteria B, ZuasolaDokumen4 halamanWitness Affidavit of Emeteria B, ZuasolaNadin MorgadoBelum ada peringkat

- Life Lessons AssignmentDokumen5 halamanLife Lessons Assignmentapi-332560669Belum ada peringkat

- MC1413 D PDFDokumen8 halamanMC1413 D PDFAnonymous oyUAtpKBelum ada peringkat

- How To Start A Fish Ball Vending Business - Pinoy Bisnes IdeasDokumen10 halamanHow To Start A Fish Ball Vending Business - Pinoy Bisnes IdeasNowellyn IncisoBelum ada peringkat

- PROCEMAC PT Spare Parts ManualDokumen27 halamanPROCEMAC PT Spare Parts ManualMauricio CruzBelum ada peringkat

- Overview 6T40-45 TransmissionDokumen14 halamanOverview 6T40-45 TransmissionLeigh100% (1)

- Australian Car Mechanic - June 2016Dokumen76 halamanAustralian Car Mechanic - June 2016Mohammad Faraz AkhterBelum ada peringkat

- Among Us Hack Mod Menu Mod AlwaysDokumen4 halamanAmong Us Hack Mod Menu Mod AlwaysC JBelum ada peringkat

- Consultant Agreement PDFDokumen6 halamanConsultant Agreement PDFRathore&Co Chartered AccountantBelum ada peringkat

- c15 ldn01610 SchematicDokumen4 halamanc15 ldn01610 SchematicJacques Van Niekerk50% (2)

- EconiQ High Voltage Roadmap 1629274842Dokumen1 halamanEconiQ High Voltage Roadmap 1629274842Daniel CaceresBelum ada peringkat

- Fss Operators: Benchmarks & Performance ReviewDokumen7 halamanFss Operators: Benchmarks & Performance ReviewhasanmuskaanBelum ada peringkat

- EU MEA Market Outlook Report 2022Dokumen21 halamanEU MEA Market Outlook Report 2022ahmedBelum ada peringkat

- Risk Management GuidanceDokumen9 halamanRisk Management GuidanceHelen GouseBelum ada peringkat

- UNV EZAccess Datasheet - V1.2-EN - 883121 - 168459 - 0Dokumen3 halamanUNV EZAccess Datasheet - V1.2-EN - 883121 - 168459 - 0Agus NetBelum ada peringkat

- Transformed: Moving to the Product Operating ModelDari EverandTransformed: Moving to the Product Operating ModelPenilaian: 4 dari 5 bintang4/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsDari EverandDesign for How People Think: Using Brain Science to Build Better ProductsPenilaian: 4 dari 5 bintang4/5 (8)