Slickline-Deployed Electromechanical Intervention System

Diunggah oleh

lulalala8888Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Slickline-Deployed Electromechanical Intervention System

Diunggah oleh

lulalala8888Hak Cipta:

Format Tersedia

Slickline-Deployed

Electromechanical

Intervention System

Slickline capabilities have expanded

beyond well remediation, maintenance, and pressure-control applications. Enhanced self-powered

slickline tools can perform diagnostic and conformance-control functions that require memory production logging. Applications that

require electrical initiation or

mechanical manipulation at the tool

interface can be performed with

slickline and battery power, insulating the tools from the surface equipment. Mechanical signals transmitted through the wire control the

tools start and stop functions and

provide real-time position telemetry.

Equipment Capabilities and Use

Measuring System. The surface electronic depth-measurement system

provides accurate depth and weight

measurements. When coupled with

the slickline collar locator, slickline

depth-measurement accuracy can be

compared with that of electricline measurements.

This article is a synopsis of paper

SPE

67201,

Slickline-Deployed

Electro-Mechanical Intervention System, a Cost-Effective Alternative to

Traditional Cased-Hole Services, by

Jerry Foster, Jack Clemens, and

Darrell Moore, Halliburton Energy

Services Inc., originally presented at the

2001 SPE Production and Operations Symposium, Oklahoma City,

Oklahoma, 2427 March.

Surface Data-Acquisition Systems.

The data/job logger provides a means

for recording the advanced-measuring-system data. Data supported by

this function include tool direction,

depth, line tension, line speed, time,

and units of measurement. By use of

real-time logging software, the

data/job logger can generate historical

job summaries, real-time slickline collar-locator logs, and can be used to

produce high quality American

Petroleum Inst. memory production

logs. The memory production surveys

can include gamma ray, spinner, pressure, temperature, fluid density, water

holdup, and post-fracture-treatment

radioactive tracers.

This information, coupled with

other components in the advanced

slickline service system, enables wireline personnel to do the following.

Generate real-time slickline collarlocator logs to correlate perforating,

setting of plugs and packers, and

dump-bailing operations.

Maintain a record of every slickline job performed for qualityimprovement processes.

Develop a wireline-usage database

that can be incorporated in a wirelinemanagement program.

Provide records for use in a training simulator to allow trainees to practice real-life situations without affecting well productivity.

Slickline Collar Locator. The slickline collar locator is a battery-powered

electromechanical device that provides

real-time indications of collar locations in the wellbore for accurate positioning of plugs and packers and for

perforating at exact zones. Used in

conjunction with the advanced measuring system and the data/job logger, it

can be used to generate prints and

enable viewing of the collar locations

in real time as the tool string is raised

through the wellbore. The tool uses a

standard casing-collar locator (CCL),

signal-conditioning assembly, and

drag mechanism to sense collars.

When a collar is passed, line tension

increases or decreases. These 50-lbf

tension changes are plotted against

depth by the surface equipment, and

the display on the computer screen

provides the operator with an accurate

real-time indication of collar location.

Downhole Power Unit. The downhole power unit is a battery-powered

electromechanical device designed to

produce a bi-directional linear force

for setting or retrieving downhole

tools without the use of explosives. A

gear motor operates a linear drive to

generate a gradual controlled axial

compressive or tensile force to optimize the setting of the slips and sealing

elements of monobore nippleless

locks, packers, and bridge plugs.

Electronic Triggering Device. This

battery-powered electromechanical

tool is designed to electrically detonate

an explosive charge downhole on

slickline. The primary uses of this tool

are perforating and cutting tubing and

casing, activating explosive-type setting tools for bridge plugs or packers,

and dump bailing. The compact electronic triggering device can provide a

quick response to situations needing

immediate attention.

We l l I n t e r v e n t i o n

Introduction

Traditionally, slickline servicing has

provided effective well maintenance by

use of high-speed mechanical deployment, manipulation, and retrieval of

downhole service tools in all types of

wells, including those with high-pressure and flowing-well conditions. Its

portability enables use of these services

in remote locations and on satellite

platforms. Combining electromechanical intervention tools with accurate

surface measuring instruments, as

shown in Fig. 1, has expanded slickline operations.

The system uses an electronic

counter and proprietary correction

algorithms to perform continuous

high-speed depth adjustments that

result in an accuracy of 5 ft/10,000 ft

of measured depth. The combination

depth- and line-tension counter system was designed to increase wire life

through nonreverse bending of the

wire and use of large-diameter measuring wheels. When used with the realtime slickline collar locator, depth

accuracy of less than 1 ft can be

achieved at any depth.

Wireline-Set Inflatable Bridge Plugs.

Inflatable bridge plugs (also referred to

as inflatable packers) provide reliability when used as through-tubing bridge

plugs at up to a 3:1 expansion ratio

[casing inside diameter (ID)/packer

outside diameter (OD)]. Well conditions (bottomhole temperature and

25

JUNE 2001

We l l I n t e r v e n t i o n

pressure) as well as wellbore fluids (gas, oil, and

mud) affect reliability;

therefore, these conditions must be evaluated

before attempting to use

an inflatable bridge plug

in any application.

The wireline setting

tool used to set the

inflatable bridge plug

comprises a 28-V DC

motor driving a lowpressure/high-volume

hydraulic gear pump

with typical output of

0.4 gal/min at maximum

pressure of 250 psi. This

pump system provides

sufficient output to

inflate a typical packer

application to 200-psi

inflation pressure in less

than 15 minutes. Once

the packer is in contact

with the casing wall and

capable of holding an

overpull from the wireline, a pull intensifier is

stroked by alternately

slacking off and applying overpull with the

wireline to intensify the

inflation pressure to typical values of 1,000 to

1,500 psi.

Bridge-plug inflation is

achieved by use of either

liquids from the wellbore

or liquids carried into

the well as part of the

tool string. When using

wellbore liquids, a highefficiency filter component assures that clean

Fig. 1A typical slickline service unit.

liquid is fed to the pump,

even in wells with sandIn deviated wells, the surface

laden fluids. For wells without liquid

in the wellbore, water is carried into weight-indicator measurement is

the well in pressure-compensated reduced by the friction effects when

chambers and used as the plug infla- running into the hole and is increased

when pulling out of the hole. The

tion fluid.

friction effects depend on the well

geometry. Unlike vertical wells, it is

General Operational

possible for the weight-indicator

Strategies

Deployment in Deviated Wells. reading to show less than the tool

Intervention operations in deviated weight when the tool string

wells must be planned meticulously. approaches the target depth. Software

Downhole friction can mask some of is available for analysis of the downthe surface tension signals. Thus, it is hole mechanics that are characteristic

important that extensive prejob plan- of deviated wells. This design tool is

ning be performed to identify the fric- used to provide a graphical model of

tion effects.

the forces that the tool and wire will

encounter and can predict whether

the gravity-deployed tools will be

able to reach the target zone.

Any dynamic force associated with

acceleration will affect the surface tension. Buoyancy, viscous drag, mechanical friction, and stuffing-box packing

friction also affect the surface weightindicator readings. Even though speed

changes may seem small, significant

weight-indicator changes can occur at

the surface. The software models

buoyancy, drag friction, pressure and

stuffing-box friction.

The software algorithms are extensions of those developed for coiled-

26

JUNE 2001

tubing modeling. The wireline version

differs from the coiled-tubing version

by taking into account that wire cannot support compressive loads.

To apply the analytical capabilities

to a well scenario efficiently, well

designers need all pertinent data.

Usually, these data include the directional survey; a completion schematic

with the ID of the tubulars and location of restrictions; tool-string length,

weight, OD, and location of knuckle

joints; wire size and type; annulus

fluid weight; surface pressure; and

production rates (if the well is allowed

to flow). Numerous simulations can

be performed to evaluate the sensitivity to changes in the expected

input parameters.

Physical-Property Measurement.

Generally, physical-property measurements are concerned with temperature, pressure, and fluid-velocity

measurements. The temperature tool

is particularly useful for identifying

fluid-entry points and locating fluid

movement behind the casing, and

determining the elevation of the top of

cement behind the casing.

Pressure tools use a quartz-gauge

sensor to provide signals that are converted to pressure and temperature

data. These pressure measurements are

useful in reservoir characterization.

Caliper tools provide a diameter

measurement required to aid interpretations of the flowmeter logs because

changes in diameter will affect the

fluid velocity. Current versions of log-

Conclusions

Use of these tools enhances job-site and

environmental safety by eliminating the

need for surface electrical isolation.

Slickline capabilities enable contingency

planning for intelligent-well-completion techniques. Elec-tromechanical

intervention tools extend the operational envelope beyond traditional slick-

line services and provide cased-hole

information and data. The cost efficiency provided by slickline is enhanced

because the resources traditionally used

for such operations as perforating can

be used for other operations.

JPT

Please read the full-length paper for

additional detail, illustrations, and references. The paper from which the synopsis has been taken has not been peer

reviewed.

We l l I n t e r v e n t i o n

Memory Production Logging. Slickline memory production logging provides a method for storing data in logging tools that can be retrieved when

the logging tools are recovered from

the well. The tools can be run on nonconducting slickline or coiled tubing.

Often, slickline units are in place on

the platforms. Thus, logistical concerns as well as personnel requirements are reduced. The typical memory-production-logging system is

PC-based with graphical interfacing.

The tools use lithium batteries to

provide high power and low self-drain

at more extreme downhole temperatures. The batteries are available with

300, 330, and 350F ratings. Some of

the tools used in the logging system

include the depth/time recorder,

depth-correlation tools, and fluid

monitoring tools.

analysis software require this information as input for calculations.

27

JUNE 2001

Anda mungkin juga menyukai

- SPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDokumen16 halamanSPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDen YogaBelum ada peringkat

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDari EverandHydraulics and Pneumatics: A Technician's and Engineer's GuidePenilaian: 4 dari 5 bintang4/5 (8)

- Celda de CargaDokumen18 halamanCelda de CargaronainteBelum ada peringkat

- Force Balance Sensor TechnologyDokumen5 halamanForce Balance Sensor TechnologyAngela Maribel Valdez NeyraBelum ada peringkat

- Practical Methods for Analysis and Design of HV Installation Grounding SystemsDari EverandPractical Methods for Analysis and Design of HV Installation Grounding SystemsPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Vertical Shaft Laser AlignmentDokumen0 halamanVertical Shaft Laser AlignmentDelfinshBelum ada peringkat

- SPE 116474 Completion Design For Sandface Monitoring of Subsea WellsDokumen8 halamanSPE 116474 Completion Design For Sandface Monitoring of Subsea WellsYerbolSultanbayevBelum ada peringkat

- 2 Logging SystemsDokumen17 halaman2 Logging SystemsArdita S IrwanBelum ada peringkat

- Automated Drilling Algorithms ImplementationDokumen11 halamanAutomated Drilling Algorithms ImplementationnanlingjigongBelum ada peringkat

- Instrumentation in TunnelsDokumen14 halamanInstrumentation in Tunnelssravan_ruby100% (2)

- Zakho Drilling Report Answers PDFDokumen11 halamanZakho Drilling Report Answers PDFSirajBelum ada peringkat

- (TP0V002) Design of Displacement ProversDokumen7 halaman(TP0V002) Design of Displacement ProversRoberto Carlos Teixeira100% (1)

- Modified AC Wheatstone Bridge Network For Accurate Measurement of Pressure Using Strain Gauge Type Pressure SensorDokumen3 halamanModified AC Wheatstone Bridge Network For Accurate Measurement of Pressure Using Strain Gauge Type Pressure SensorMukul RBelum ada peringkat

- Silo Weigh PDFDokumen7 halamanSilo Weigh PDFOleg AndrisanBelum ada peringkat

- Equipo para Correr Registros Electricos-Clase Unacar Ing Petrolera PDFDokumen14 halamanEquipo para Correr Registros Electricos-Clase Unacar Ing Petrolera PDFYuriko LagunaBelum ada peringkat

- Practical Flow EssentialsDokumen8 halamanPractical Flow EssentialsAyman TermaniniBelum ada peringkat

- 38 Peter BlanzDokumen10 halaman38 Peter BlanzClaudio Del Pino VásquezBelum ada peringkat

- Application Notes Bearing Monitoring Equipment For Gear Driven Paper Machines Bo0072Dokumen4 halamanApplication Notes Bearing Monitoring Equipment For Gear Driven Paper Machines Bo0072AndysBelum ada peringkat

- Otc 20933 MS PDokumen7 halamanOtc 20933 MS PAliBelum ada peringkat

- Analysis of Load Monitoring System in Hydraulic MoDokumen11 halamanAnalysis of Load Monitoring System in Hydraulic Mochzakiabbas5250Belum ada peringkat

- Irrigation Evaluation 2Dokumen29 halamanIrrigation Evaluation 2Emanuel FuenzalidaBelum ada peringkat

- Liquid Measurement Station DesignDokumen10 halamanLiquid Measurement Station Designsigit.kurniadiBelum ada peringkat

- Current Sensors Expand Precision Motion Control CapabilitiesDokumen2 halamanCurrent Sensors Expand Precision Motion Control CapabilitiesRamesh RoyBelum ada peringkat

- Actuator DesignDokumen7 halamanActuator DesignAnkit KumarBelum ada peringkat

- Smart Valve Flow ConditionersDokumen4 halamanSmart Valve Flow ConditionersMuzammil HussainBelum ada peringkat

- Design of Entry Strip Thickness Controls For Tandem Cold MillsDokumen13 halamanDesign of Entry Strip Thickness Controls For Tandem Cold Millstorinomg100% (1)

- A New Generation of Wireline Formation Tester: Y. Manin, A. Jacobson, J.R. Cordera, SchlumbergerDokumen7 halamanA New Generation of Wireline Formation Tester: Y. Manin, A. Jacobson, J.R. Cordera, SchlumbergerIan DonaldBelum ada peringkat

- Shot Flow ControlDokumen13 halamanShot Flow ControlRAJIV GandhiBelum ada peringkat

- d323 Chapter 6Dokumen46 halamand323 Chapter 6Prajjwal AnuragiBelum ada peringkat

- Acoustic Pressure Transient Testing CIM 2008Dokumen16 halamanAcoustic Pressure Transient Testing CIM 2008sameer bakshiBelum ada peringkat

- Electro HydraulicDokumen20 halamanElectro HydraulicAnkit KumarBelum ada peringkat

- Quality Assurance ProcedureDokumen13 halamanQuality Assurance ProcedureRahil PiraniBelum ada peringkat

- ET205 Densimeter RepairDokumen191 halamanET205 Densimeter RepairFredyMirreBelum ada peringkat

- NDT2012 2a2 PDFDokumen12 halamanNDT2012 2a2 PDFIvan MauricioBelum ada peringkat

- WP Select Calibrate TurbineDokumen9 halamanWP Select Calibrate Turbinekvvp94Belum ada peringkat

- 51W 10540 1Dokumen16 halaman51W 10540 1Mitrofan AnduBelum ada peringkat

- NG112-06 Technical InformationDokumen20 halamanNG112-06 Technical InformationyaasinBelum ada peringkat

- Smart Wells & Nodal AnalysisDokumen50 halamanSmart Wells & Nodal AnalysisWilfred ThomasBelum ada peringkat

- Fluid Mechanics Lab-I (Report)Dokumen18 halamanFluid Mechanics Lab-I (Report)Mohammad Usman HabibBelum ada peringkat

- Wastewater Flow Meter Design GuidelineDokumen94 halamanWastewater Flow Meter Design GuidelineJomy AugustineBelum ada peringkat

- An Indicating Tachometer For Oceanographic Use: Ocean EngngDokumen3 halamanAn Indicating Tachometer For Oceanographic Use: Ocean EngngSusilo Adi PutraBelum ada peringkat

- Wireline ServicesDokumen21 halamanWireline ServicesweldsvBelum ada peringkat

- CF RT - : Monitoring of Rock Movements Using Probe Inclinometer - GuidelinesDokumen10 halamanCF RT - : Monitoring of Rock Movements Using Probe Inclinometer - GuidelinesRoshanRSVBelum ada peringkat

- Subsea Corrosion/Erosion Monitoring: Young Technology ShowcaseDokumen4 halamanSubsea Corrosion/Erosion Monitoring: Young Technology Showcaselulalala8888Belum ada peringkat

- Whitepaper Laser-Tracker Hydro Jan09Dokumen7 halamanWhitepaper Laser-Tracker Hydro Jan09Sagar PatkiBelum ada peringkat

- Method Statement - Instrumented MLT With Strain GaugesDokumen3 halamanMethod Statement - Instrumented MLT With Strain Gaugesjbmune66830% (1)

- Excitation Frequency MagfloDokumen4 halamanExcitation Frequency Magfloyokogawa_barodaBelum ada peringkat

- Spe 111465Dokumen16 halamanSpe 111465HSEQ AZUL ENERGYBelum ada peringkat

- Vibration Measuring InstrumentsDokumen8 halamanVibration Measuring InstrumentsSardar Wasif Ashraf KhanBelum ada peringkat

- Digital SlicklineDokumen10 halamanDigital SlicklineAli mohammadBelum ada peringkat

- Maximizing Revenue Using Abb'S Aquamaster FlowmetersDokumen4 halamanMaximizing Revenue Using Abb'S Aquamaster FlowmetersHelosman FigueiredoBelum ada peringkat

- Chapter 3 Position, Speed and Acceleration MeasurementDokumen18 halamanChapter 3 Position, Speed and Acceleration MeasurementMohamed ZahranBelum ada peringkat

- De-Embedding Using A VnaDokumen6 halamanDe-Embedding Using A VnaA. VillaBelum ada peringkat

- SPE Swab Surge Field Validations PDFDokumen5 halamanSPE Swab Surge Field Validations PDFAbhayBelum ada peringkat

- Ground Check Monitors For Underground Power SystemsDokumen8 halamanGround Check Monitors For Underground Power SystemsjorgeayreBelum ada peringkat

- Design and Implementation of Closed Loop Soft Switching Boost Converter Using PI ControllerDokumen9 halamanDesign and Implementation of Closed Loop Soft Switching Boost Converter Using PI ControllerAnonymous lPvvgiQjRBelum ada peringkat

- DA NotesDokumen8 halamanDA Notesdrmsrmurty9473Belum ada peringkat

- Great Health Direct: A Medical Plan To Protect You Against Life's UncertaintiesDokumen9 halamanGreat Health Direct: A Medical Plan To Protect You Against Life's Uncertaintieslulalala8888Belum ada peringkat

- Streaming Potentials at Hydrocarbon Reservoir ConditionsDokumen14 halamanStreaming Potentials at Hydrocarbon Reservoir Conditionslulalala8888Belum ada peringkat

- Mto - F.Dokumen36 halamanMto - F.lulalala8888Belum ada peringkat

- SPE-174567-MS A Novel Technique For Enhanced Oil Recovery: In-Situ CO - Emulsion GenerationDokumen13 halamanSPE-174567-MS A Novel Technique For Enhanced Oil Recovery: In-Situ CO - Emulsion Generationlulalala8888Belum ada peringkat

- SPMSDokumen7 halamanSPMSlulalala8888Belum ada peringkat

- Rent.: Emulsion. DemulsifirsDokumen3 halamanRent.: Emulsion. Demulsifirslulalala8888Belum ada peringkat

- Numerical Simulation of Emulsion Flow Through Porous Media M.R. Islam S.M. Farouq AliDokumen12 halamanNumerical Simulation of Emulsion Flow Through Porous Media M.R. Islam S.M. Farouq Alilulalala8888Belum ada peringkat

- Eor/Ior Additional Reading Available at TheDokumen1 halamanEor/Ior Additional Reading Available at Thelulalala8888Belum ada peringkat

- OTCbservationDokumen9 halamanOTCbservationlulalala8888Belum ada peringkat

- Simulation of O/W Emulsion Flow in Alkaline/Surfactant Flood For Heavy Oil RecoveryDokumen13 halamanSimulation of O/W Emulsion Flow in Alkaline/Surfactant Flood For Heavy Oil Recoverylulalala8888Belum ada peringkat

- MAJOR14Dokumen14 halamanMAJOR14swathi100% (1)

- Proportional Directional Valves: Series LVS08 and LVS12 - Preferred Products ProgrammeDokumen66 halamanProportional Directional Valves: Series LVS08 and LVS12 - Preferred Products ProgrammealeksandrBelum ada peringkat

- (Routledge Library Editions - Urban Planning) Brian Field, Bryan Macgregor (Editor) - Forecasting Techniques For Urban and Regional Planning-Routledge (2018)Dokumen241 halaman(Routledge Library Editions - Urban Planning) Brian Field, Bryan Macgregor (Editor) - Forecasting Techniques For Urban and Regional Planning-Routledge (2018)OMAR SANCHEZ100% (1)

- Oracle Database 11g Transparent Data EncryptionDokumen40 halamanOracle Database 11g Transparent Data EncryptionYelena BytenskayaBelum ada peringkat

- Handwritten English Alphabet RecognitionDokumen8 halamanHandwritten English Alphabet RecognitionIJRASETPublicationsBelum ada peringkat

- Oral Histology & Embryology-FikreDokumen240 halamanOral Histology & Embryology-FikreHeran A AlhadiBelum ada peringkat

- 50 Input Output Practice Questions 1606810110009 OBDokumen17 halaman50 Input Output Practice Questions 1606810110009 OBJavid QuadirBelum ada peringkat

- Upcoming: Advisor Webcast: Oracle Database Resource ManagerDokumen41 halamanUpcoming: Advisor Webcast: Oracle Database Resource ManagerLayne MoránBelum ada peringkat

- EARTH AND LIFE SCIENCE II Answer KeyDokumen4 halamanEARTH AND LIFE SCIENCE II Answer Keyjelena jorgeoBelum ada peringkat

- Whitepaper 10G Ethernet 10-08Dokumen16 halamanWhitepaper 10G Ethernet 10-08Bogdan IhnatiucBelum ada peringkat

- How To Read An ODBC Trace FileDokumen13 halamanHow To Read An ODBC Trace FileganeshharidasBelum ada peringkat

- Assignment 176020307045 PDFDokumen82 halamanAssignment 176020307045 PDFnikita gohelBelum ada peringkat

- Flue Gas Analysis in IndustryDokumen150 halamanFlue Gas Analysis in Industryblack_knight728Belum ada peringkat

- Inform: Extending PhoenicsDokumen42 halamanInform: Extending PhoenicsrsigorBelum ada peringkat

- How Microprocessors Work PDFDokumen2 halamanHow Microprocessors Work PDFdanielconstantin4Belum ada peringkat

- Lecture 4: Expert Systems: What Is An Expert System?Dokumen5 halamanLecture 4: Expert Systems: What Is An Expert System?Zerihun BekeleBelum ada peringkat

- Rpzf2: Product Data SheetDokumen4 halamanRpzf2: Product Data SheetJosé RincónBelum ada peringkat

- System Administration JakartaDokumen347 halamanSystem Administration JakartaLorena Castillero80% (10)

- 07 Bubble BreakDokumen25 halaman07 Bubble BreakWeb LogueandoBelum ada peringkat

- United States: (12) Patent Application Publication (10) Pub. No.: US 2004/0132474 A1Dokumen17 halamanUnited States: (12) Patent Application Publication (10) Pub. No.: US 2004/0132474 A1BukBelum ada peringkat

- Manual Prevention An Control of Lost Cir PDFDokumen222 halamanManual Prevention An Control of Lost Cir PDFAna Maria TovarBelum ada peringkat

- Digital Control SystemDokumen34 halamanDigital Control SystemLaxman Koirala100% (3)

- Shared Memory ArchitectureDokumen2 halamanShared Memory ArchitectureNeethu RajeshBelum ada peringkat

- Nylon Bag BisDokumen13 halamanNylon Bag Bisbsnl.corp.pbBelum ada peringkat

- Packet Life BookDokumen28 halamanPacket Life BookboucheravBelum ada peringkat

- Wood Conserving StovesDokumen117 halamanWood Conserving Stovesalitoparana100% (1)

- Performance Evaluation of Existing Sunshine-Based Computing Models For Estimating Global Solar Radiation at Lagos, NigeriaDokumen12 halamanPerformance Evaluation of Existing Sunshine-Based Computing Models For Estimating Global Solar Radiation at Lagos, NigeriasamuelBelum ada peringkat

- Reducing The Efficiency Gap by Optimal Allocation Using Modified Assignment Problem For Apparel Industry in Sri LankaDokumen1 halamanReducing The Efficiency Gap by Optimal Allocation Using Modified Assignment Problem For Apparel Industry in Sri LankaShivam BhandariBelum ada peringkat

- Minihydro GANZ enDokumen5 halamanMinihydro GANZ enRade NovakovicBelum ada peringkat

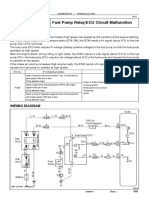

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDokumen4 halamanDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealBelum ada peringkat

- Generative AI: The Insights You Need from Harvard Business ReviewDari EverandGenerative AI: The Insights You Need from Harvard Business ReviewPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Cyber War: The Next Threat to National Security and What to Do About ItDari EverandCyber War: The Next Threat to National Security and What to Do About ItPenilaian: 3.5 dari 5 bintang3.5/5 (66)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyDari EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyPenilaian: 3.5 dari 5 bintang3.5/5 (111)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldDari EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldPenilaian: 4.5 dari 5 bintang4.5/5 (55)

- Algorithms to Live By: The Computer Science of Human DecisionsDari EverandAlgorithms to Live By: The Computer Science of Human DecisionsPenilaian: 4.5 dari 5 bintang4.5/5 (722)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andDari EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andPenilaian: 4.5 dari 5 bintang4.5/5 (709)

- The Future of Geography: How the Competition in Space Will Change Our WorldDari EverandThe Future of Geography: How the Competition in Space Will Change Our WorldPenilaian: 4 dari 5 bintang4/5 (6)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyDari EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyPenilaian: 4 dari 5 bintang4/5 (51)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDari EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyBelum ada peringkat

- System Error: Where Big Tech Went Wrong and How We Can RebootDari EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootBelum ada peringkat

- Alibaba: The House That Jack Ma BuiltDari EverandAlibaba: The House That Jack Ma BuiltPenilaian: 3.5 dari 5 bintang3.5/5 (29)

- Mini Farming: Self-Sufficiency on 1/4 AcreDari EverandMini Farming: Self-Sufficiency on 1/4 AcrePenilaian: 4 dari 5 bintang4/5 (76)

- AI Superpowers: China, Silicon Valley, and the New World OrderDari EverandAI Superpowers: China, Silicon Valley, and the New World OrderPenilaian: 4.5 dari 5 bintang4.5/5 (399)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumDari EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumPenilaian: 3 dari 5 bintang3/5 (12)

- Excel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceDari EverandExcel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceBelum ada peringkat

- HBR's 10 Must Reads on AI, Analytics, and the New Machine AgeDari EverandHBR's 10 Must Reads on AI, Analytics, and the New Machine AgePenilaian: 4.5 dari 5 bintang4.5/5 (69)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDari EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindBelum ada peringkat

- Learn Python Programming for Beginners: Best Step-by-Step Guide for Coding with Python, Great for Kids and Adults. Includes Practical Exercises on Data Analysis, Machine Learning and More.Dari EverandLearn Python Programming for Beginners: Best Step-by-Step Guide for Coding with Python, Great for Kids and Adults. Includes Practical Exercises on Data Analysis, Machine Learning and More.Penilaian: 5 dari 5 bintang5/5 (34)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveDari EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveBelum ada peringkat

- Evaluation of Some SMS Verification Services and Virtual Credit Cards Services for Online Accounts VerificationsDari EverandEvaluation of Some SMS Verification Services and Virtual Credit Cards Services for Online Accounts VerificationsPenilaian: 5 dari 5 bintang5/5 (2)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldDari EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldPenilaian: 4.5 dari 5 bintang4.5/5 (107)

- Solutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesDari EverandSolutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesBelum ada peringkat

- The Bitcoin Standard: The Decentralized Alternative to Central BankingDari EverandThe Bitcoin Standard: The Decentralized Alternative to Central BankingPenilaian: 4.5 dari 5 bintang4.5/5 (41)

- 100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziDari Everand100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziBelum ada peringkat