Industrial Design Methods For Product Integrated Pem Fuel Cells

Diunggah oleh

Fachmi AgungJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Industrial Design Methods For Product Integrated Pem Fuel Cells

Diunggah oleh

Fachmi AgungHak Cipta:

Format Tersedia

NHA Annual Hydrogen Conference 2006, March 12-16

INDUSTRIAL DESIGN METHODS FOR PRODUCT

INTEGRATED PEM FUEL CELLS

dr. A. Reinders, prof. dr. ir. F.J.A.M. van Houten1

1. Introduction

In the next decade, proton exchange membrane fuel cells (PEM FC) will become an

energy technology of great importance for mobile applications. PEM fuel cells are not

only an environmentally sound alternative to high power internal combustion engines in

transportation; thanks to their modular structure they can also silently provide clean

electricity to products that are currently powered by batteries. Despite that current

technology already makes a broad range of applications possible, the use of PEM FC in

mass produced consumer products is still rare. Technical and financial challenges

related to fuel cell engineering may explain this in part. We believe, however, that the

need for modifications in design to adapt consumer products for use with PEM fuel

cells has also slowed down the product innovation process. Further, many product

designers are unaware of the benefits of using fuel cells in consumer products. In this

paper, we shall discuss how certain industrial design methods can be applied during the

product creation process in order to facilitate the integration of fuel cells in consumer

products. By virtue of their participation in product development, industrial designers

can serve as the connecting link between scientists, manufacturers and consumers,

helping to package new technology in a form useful to consumers. Moreover, feedback

from end-users and difficulties that appear during the conceptual design of technology

based products can help technology developers better focus their ongoing research. As

such, industrial designers could play a crucial role in making fuel cell technology fit for

consumer applications.

2. Industrial design methods

Industrial design is represented in Figure 1 as a four-leaf clover involving the following

four fields: technology, design & styling, human factors and marketing. In Figure 1,

Technology refers to product technologies and materials, as well as manufacturing

processes. Design & styling refers to the appearance of products and their image in the

market. Human factors cover the user context of consumer products and the physical

ergonomics. Marketing refers to market value costs and sales. We believe that all four

components of product development are equally important to the final success of a

product.

Both dr. Reinders and prof. dr. ir. van Houten are members of the Department of Design,

Production and Management, Faculty of Engineering Technology, University of Twente,

P.O.Box 217, NL-7500 AE Enschede, The Netherlands.

E-mail address for correspondence: a.h.m.e.reinders@utwente.nl

NHA Annual Hydrogen Conference 2006, March 12-16

Figure 1. Four-leaf clover model of industrial product design.

Industrial design methods (IDMs) play an important role in product development processes.

IDMs convert market needs into detailed information for products that can be

manufactured. They focus on the utility of consumer products. IDMs vary in their

approaches to problem-solving 2.A generally accepted approach is described in detail by

Pahl and Beitz [2] (see Figure 2). It consists in 4 phases:

1. Clarification of the task

2. Conceptual design

3. Embodiment design

4. Detail design

In the first three phases, product designers seek to optimize the working principle, i.e.

technology, of a product. The last three phases involve optimizing the layout and form of a

product. Thus, conceptual and embodiment design form the connecting links between

technology, on the one hand, and design and ergonomics, on the other. For the project

described in this paper, we used Pahl and Beitzs model as a blueprint for applying various

IDMs to the development of new products with PEM FC.

Figure 2. Flow chart respresenting the basic industrial design method of Pahl and Beitz.

2

In technological engineering design, design processes are generally viewed as heuristics [1]. That is to say,

we assume that design goals can be defined by carefully describing a problem prior to formulating possible

solutions to this problem. Through problem decomposition, the complexity of the problem is reduced. Next,

the designer evaluates how solutions to sub-problems can be merged into a solution composition that meets

the design goals. The embodiment of the solution is a product.

NHA Annual Hydrogen Conference 2006, March 12-16

In the automotive sector, design & styling is traditionally viewed as a decisive factor

for a cars success in the market. As a result, developers of fuel cell powered cars have

included design & styling early in the development process. Industrial product design,

however, has not yet become common practice for product integrated fuel cell systems.

This may be because fuel cell systems are a new technology. Thus, when designing

products with integrated PEM fuel cells, it may be helpful to pay attention to issues

related generally to the implementation of innovative technology in conventional

product design processes [3] [4].

3. Integrating innovative technology in products

Theoretically, innovations improve product performance over time [5]. Introducing

major innovations such as PEM fuel cells, however, is not easy, owing to the dual effect

of innovations. On the one hand, people resist innovations because they render

corporate expertise and existing manufacturing structures obsolete. On the other hand,

innovations are essential because of the competitive significance resulting from

functional improvements and cost reductions [6].

PEM fuel cells are considered an innovative technology on the threshold between what

Little [7] refers to as packing and key technologies 3. Potential applications are

being assessed through research and development, and they are still in the process of

being integrated into products. Figure 3 shows how technological research and product

design may both contribute to innovations at this stage in the development of PEM FC.

On the one hand, the development of promising technologies may initiate product

design. On the other, problems with the design of products based on existing

technology may stimulate further technological research.

Figure 3. Innovative products result from the conjunction of technology research and

product design.

Arthur D. Little distinguishes four types of technologies depending on their level of

implementation in product development. Emerging technologies have not yet demonstrated clear

product potential. Scientists discover emerging technologies in the course of explaining working

principles. Next, packing technologies have demonstrated market potential and are the subject of

ongoing R&D to make them fit for applications. Finally, the purpose is to embed the technology in

products. Such key technologies may be patented. Technologies that have become common to all

competitors they are a commodity are called base technologies [7].

NHA Annual Hydrogen Conference 2006, March 12-16

Given that technological research has already suggested several marketable applications

for PEM fuel cells, it seems to us that an impetus from product designers may be

needed to exploit their market potential. Designers need to package existing technology

in a way appealing to consumers. Further, they need to assess the weaknesses of

products using established technologies, such as batteries, so as to focus future

technological research on solving those problems with PEM FC applications.

Design is often regarded as purely aesthetic or superficial. Recent research, however,

has highlighted the crucial role played by design in the economy of the Netherlands,

and in product innovation [8]. The Premsela Foundation study found that, with a value

added of 2.6 billion, design is on a par with such large sectors in the Dutch economy

as the petroleum industry (excluding mineral extraction) and the air transportation

industry. Design is both a service purchased by companies in the marketplace and an

activity carried out in-house on a large scale by companies, as part of their own

production and marketing processes. The Premsela Foundation study concluded that

companies combining technological innovation with new product design increase their

market share relative to other companies. It therefore seems likely that industrial

designers will provide significant added value to products with integrated PEM FC. Our

students case studies on product integrated PEM fuel cells, presented below, illustrate

how this may work.

4. Description of case studies

In the period from September to November of 2005, students in the masters program for

Emerging Technology Design of the School of Industrial Design Engineering at

University of Twente (the Netherlands) developed conceptual designs for consumer

products based on PEM fuel cell technology. Their goal was to use PEM FC in products

that would increase personal mobility. We present some of our students designs in

Section 5 below. Each product design is preceded by a brief discussion of the products

function and technology.

All students had graduated with a bachelors degree in Industrial Design Engineering.

Therefore, they had all had some experience in designing a product containing key and

base technologies. Seventeen pairs of students successfully completed the project. The

students began as laymen and were introduced to fuel cell technology by NedStack Fuel

Cell Technology, the Dutch PEM fuel cell manufacturer [9], and by reading literature

on the subject [10] [11] [12]. Students were informed about several methods for and

approaches towards innovative product design: innovation journey, lead user study,

innovation phase model, innovative design & styling, technology roadmapping by

TRIZ, platform driven product development, risk diagnosis and constructive technology

assessment. In Section 5, we illustrate how each of these methods informed the design

of a product by one pair of students.

Students could freely choose a product concept related to either transportation (7

concepts) or portable consumer products (10 concepts). Table 1 lists the products they

designed, sorted by type of application. The power of portable devices ranges from 0,7

Watt to 2 Watt. The power of vehicles ranges from 0,6 kW to 200 kW. Based on

NHA Annual Hydrogen Conference 2006, March 12-16

assumptions we gave them, the student designers predicted that their fuel cell powered

products would be commercially viable in certain niches of the market as early as 2007.

Table 1. Conceptual designs of products with integrated PEM FC

Product

Fuel*

(H/M)

Power

of FC

(Watt)

Market

ready

in**

Product

Fuel*

(H/M)

Power

of FC

(kWatt)

Market

ready

in**

Portables

Transportation

Communication

H

0,7

2014

Outboard motor

H

0,6

2007

device

Communication

H

2,5

2010

Moped

H

1,7

2010

device

Intelligent

M

3

2007

Sled

H

2

2007

clothing

Diving lamp

M

10

2007

Rickshaw

H

5

2010

Battery charger

H

10

2015

City car

H

40

2015

M

400

2010

Helicopter

H

45

2015

H2 backpack

Cooking unit

H

500

2010

Bus

H

200

2015

Brush cutter

H

1400

2008

Brush cutter

H

1800

2008

Backpack

H

2000

2008

blower

*) Fuel is either hydrogen (H) or methanol (M).

**) Year in which students have estimated the product would be commercially viable, assuming fuel cell

break-even costs of 45 / kW in 2010.

5. Evaluation of product concepts and IDMs used

In this paper, we present some of the students product designs, emphasizing the

portable consumer products. Each design illustrates one of the industrial design

methods or innovation theories set forth in Section 4.

5.1 Innovation journey

In the case of technology-based product design, product development often follows

certain patterns. By examining the so-called innovation journeys [13] of products in

different fields, one may gain tools for assessing the potential innovation journeys of

new products using PEM FC.

One pair of students used this approach to design an induction cooking device powered

by a PEM FC (see Figure 4). They evaluated the evolution of technologies for cooking

dinner, starting with plain fire and leading to the principles of electrical cooking.

Comparing plain electrical elements, ceramic, halogen, infrared and induction cooking,

they found the last method most suitable in relation to customers demands for an easyto-use and light-weight cooking device.

The black box in Figure 4 accommodates all electrical components, including a

replaceable hydrogen cartridge, a fuel cell of 500 Watts and an induction coil. The

black box fits snugly into the cubical case, which serves as a protective shell during

transportation. The device is operated by an ergonomic user interface.

NHA Annual Hydrogen Conference 2006, March 12-16

Figure 4. Induction cooking device powered by PEM FC. Right in compact carrying

case. Left, the product in use. Designed by Rick Tigchelhoff and Wouter Haanstra.

5.2 Lead user study

According to the theory of Von Hippel [6], lead users can provide useful

information to product designers. Lead users are those who are the first to face needs

that will eventually affect a larger market (see Figure 5). By identifying and

interviewing lead users, emerging market needs can be channeled into the development

of innovative products.

Figure 5. Positioning of lead users in product innovation diffusion curve, from [6].

Sixty percent of the product concepts developed by our students were based on a lead

user study. Figure 6 shows a communication device for cyclists powered by PEM FC

and developed on the basis of a lead user study. The students identified wireless

communication experts and bicycle couriers as lead users. From interviews, they

concluded that a device to improve routing for couriers was needed. The product also

NHA Annual Hydrogen Conference 2006, March 12-16

incorporates WIMAX communication technology to keep couriers in touch with the

office that directs the delivery of packages.

Figure 6. Communication device for bike messengers with integrated PEM FC. In this

figure, the device is mounted on a bicycles handlebars. Designed by Renske Schijvens

and Josselin Bode.

5.3 Innovation phase model

The innovation phase model [14] aims to combine the intrinsic value of technology

optimally with opportunities in the market. Divergence, selection and convergence of

search fields related to technology and markets lead to innovative technology-productmarket combinations. The creative process is supported by visual collages and written

mind maps. Figure 7 shows a communication device that has been developed by using a

mind map. Mind maps of a fuel cell (Figure 8) and of lead user hikers (Figure 9) are

combined to determine a suitable technology-product-market combination.

Figure 7. Communication device for hikers with integrated PEM FC. Right, front view.

Left, opened back view. Designed by Kyra Adolfsen and Benne Draijer.

NHA Annual Hydrogen Conference 2006, March 12-16

Figure 8. Mindmap of a PEM fuel cell. Selected search fields in green.

Figure 9. Mindmap of lead user hikers. Selected search fields in green.

NHA Annual Hydrogen Conference 2006, March 12-16

5.4 Innovative design & styling

Design & styling is an asset for technological innovation [15]. More specifically, cars,

modern durables, and consumer products require a high degree of integration between

functional and aesthetic aspects of design [16]. A market of products with integrated

PEM FC can be promoted by studying the image that potential users of a proposed

product wish to project and designing the product so that it meets those aesthetic

requirements. Figure 10 shows a design for a diving lamp with integrated direct

methanol FC. Technology is decisive in the high-end diving market, where users

require long burning-hours and reliability. In the larger market of so-called family

divers, however, design and styling (see Figure 11) are more important. The

ergonomics of diving with the lamp, as well as of re-filling it with methanol and air,

were also important considerations in designing this product.

Figure 10. Diving lamp powered by direct methanol fuel cells. Designed by Julia Garde

and Annelies Brummelman.

Figure 11. Design and styling of a diving lamp by diverging, categorizing and

converging in two phases. Drawing by Julia Garde and Annelies Brummelman.

NHA Annual Hydrogen Conference 2006, March 12-16

5.5 Technology roadmapping by TRIZ

A technology roadmap establishes a correlation between identified market needs and

trends with existing and emerging technologies for a specific industry sector [17].

Technology roadmaps usually cover 3 to 10 years and are used in strategic product

planning, research planning and business planning [18]. Figure 12 shows an example of

a TRM for intelligent clothing powered by direct methanol FC.

2006

2008

2010

2012

Fuel cells (lower costs, higher energy density)

Development

Product development (new applications, new advanced technologies)

Standards with

industry

Products

Segments

Advanced

electronics with

special purpose

(Heath generation,

protection)

Advanced

electronics in

textile

(Dynamic

colouring, Body

sensoring)

Basic electronics

in clothing

High performance

applications

High performance

applications

High performance

applications

Sports

Sports

(Cell phones,

LCD)

Fashion

Product launches

Figure 12. Technology roadmap of intelligent clothing powered by fuel cell technology,

by Casper Tromp and Olle Vos.

When defining a TRM, TRIZ can be applied to estimate the probability of technology

developments. TRIZ is a Russian acronym meaning Theory of Inventive Problem

Solving [19]. It is a comprehensive method based on long term patent research leading

to certain basic rules governing problem solving in product development. As the

method is complex, software has been developed to make it easier to use. Figure 13

shows in which fields TRIZ could improve product development.

NHA Annual Hydrogen Conference 2006, March 12-16

Figure 13. TRIZ Trends of Technology Evolution, from Souchkov [17].

Figure 14. Four views of a backpack containing PEM FC and hydrogen storage tank for

electrical gardening equipment.

5.6 Platform driven product development

A product platform defines a set of related products, a so-called product family, that can

be developed and produced in a time- and cost-efficient manner. Features of a product

platform are modularity, connecting interfaces and common standards [20]. By using a

product platform, companies can reach different markets (and customers) with less

effort than by developing separate products. In the case of PEM FC, product platforms

will help manufacturers more easily to access this relatively new technology and to

implement PEM FC in existing product development processes. Platform thinking is

applied to the conceptual design of PEM FC powered electrical gardening equipment,

such as blowers, hedgers and brush cutters. The main advantages of hydrogen

technology for the functions of gardening equipment are instant power supply with high

NHA Annual Hydrogen Conference 2006, March 12-16

energy density, low noise production and a new product experience. Figure 14 shows

the basic backpack, which provides power to gardening equipment.

Figure 15 shows the effect of platform driven product development in a matrix of

customer value perception vs. enabling technology. For a manufacturer of gardening

equipment, an FC powered blower would be a breakthrough product, enhancing its

portfolio of conventionally powered equipment. Thus, the risk of integrating the new

PEM FC technology in products can be distributed over ongoing product development

activities.

Figure 15. Product platform for gardening equipment, B1) Blower on hydrogen energy,

B2) Blower with noise reduction system, B3) Blower standard, C1) Cutter with flexible

drive shaft, C2) Cutter standard, S1) Chainsaw with automatic balancing system, S2)

Chainsaw standard.

5.7 Risk diagnosis

Companies must take risks to launch new products speedily and successfully. In this

scope Risk Diagnosing Methodology (RDM) aims to identify and evaluate

technological, organizational and business risk in product innovation [21]. This

methodology has been developed and applied at Philips and Unilever, and is fit for

product development in diverse areas such as automobile industry, printing equipment,

landing gear systems and fast-moving consumer goods such as shampoo and margerine.

The risks evaluated by RDM are related to product family and brand positioning,

technology, manufacturing, intellectual property, supply chain and sourcing, consumer

acceptance, project management, public acceptance, screening & appraisal, trade

customers, competitors and commercial viability.

One pair of students applied RDM to another product platform of PEM FC powered

gardening equipment, and drew the following conclusions:

The main risk is acceptance of the new, unknown, fuel cell technology by

users

NHA Annual Hydrogen Conference 2006, March 12-16

Most risks related to the production, manufacturing and distribution of the new

product can be mitigated or eliminated by forming a joint venture with several

stakeholders

A design process that involves the participation of end-users can be used to

create a higher degree of acceptance for new products

5.8 Constructive technology assessment

In innovation journeys many actors play a role. New products must be promoted by

manufacturers and retailers, must be approved by a competent authority in accordance

with industry rules and standards, and must meet with acceptance from consumers.

Constructive technology assessment focuses on these processes and how to improve

them [22]. The dynamics of technological development involve a series of exchanges

between technology and society. Social projects such as those shown in Figure 16 foster

the acceptance of new products by teaching people about the benefits of technology for

society.

Figure 16. PEM FC powered rickshaw. Designed by Simon Brandenburg and Werner

Helmich.

In Asian metropolises, transportation has always been a difficult problem. Owing to

outdated engine technologies, private taxies (referred to locally as rickshaws, tuk-tuks

and bajajs, etc.) are a primary source of air pollution and noise. Because they require

little powerabout 5 kW rickshaws could be an interesting application for PEM fuel

cells. A positive social impact would result from the decrease of harmful emissions and

increased comfort due to decreased noise. As a side benefit, PEM fuel cells could

supply the rickshaws with electric power, enabling end-users to operate air

conditioning, stoves and refrigerators from them. Moreover the rickshaw, as an icon of

transportation cherished by many residents, might serve as a catalyst to accelerate social

acceptance of fuel cell technology.

6. Conclusion and recommendations

The use of carefully chosen and applied industrial design methods in our project led, we

believe, to fresh and unexpected product concepts. The results of this experiment have

persuaded us that industrial design methods could help manufacturers to integrate PEM

NHA Annual Hydrogen Conference 2006, March 12-16

FC into some their products, and begin to exploit a market with great potential for

growth. Further, we believe the innovation process could be facilitated if PEM FC were

integrated into products that offer a functionality and appearance that consumers

perceive as novel.

In the interest of facilitating the integration of PEM FC technology into new products

industry wide, we recommend the following:

Education of Industrial Designers. A better understanding of how PEM fuel cells

are made, and what uses they may be put to, is crucial to winning acceptance of this

new technology by manufacturers. Industrial designers, however, should not be

burdened with more technical instruction than is necessary for the design process:

the students participating in our project had no experience with PEM FC, and yet

they proved quite capable of developing product concepts with this relatively new

technology. It would be worthwhile, therefore, to focus attention on the

development of design tools that provide easily accessible information about PEM

FC. One could think about plug-ins for CADCAM models that provide information

about the sizing of PEM FC and fuel storage in relation to the energy requirements

of a product.

Improvements in Methodology. Improvements in methodology may also help

speed the market acceptance of PEM FC. This was our first experiment with

product design using integrated PEM FC. Our results show clearly that industrial

design methods tailored specially to PEM FC could have a significant beneficial

impact on the market acceptance of this technology; but these methods can be

improved. In light of our experience with the first group of master students, we

intend to focus specifically on improving our application of TRIZ, platform driven

product development and risk diagnosis to product integrated PEM FC.

Taking Full Advantage of the Computer. In this project, students recorded the

results of their creative processes during product development with pen and paper.

This procedure is relatively slow and does not offer much flexibility. Since the end

of 2005, a new product development laboratory has been available at the University

of Twente. This facility is outfitted with advanced programs for computer supported

brainstorming and interactive visualization of product concepts. For our next

project, we intend to meet with students in this new laboratory, and include virtual

prototyping, scenario-based design and gaming [23] [24] as part of the curriculum.

Acknowledgements

We acknowledge with deep gratitude the idea formulating support of Eric von Hippel of

MIT Sloan School of Management in Boston. At the University of Twente, I am greatly

indebted to Arie Rip and Joop Halman, who both provided valuable information on

innovation processes. We are all much obliged to Erik Middelman of Nedstack, who

has championed fuel cell technology so warmly and so eloquently. I am also grateful to

Idpartners Jacques Stevens and Valeri Souchkov for their help in the fields of design

NHA Annual Hydrogen Conference 2006, March 12-16

and styling and TRIZ theory. Also I am pleased to acknowledge the extraordinary

translation talent of Darrell Wilkins. Finally, I thank all the students whose work in our

masters class forms the basis of this paper. Their enthusiastic participation resulted in

scintillating classroom discussions, as well as many interesting product concepts.

References

1. M. J. French, Conceptual Design for Engineers (Second edition), London Design Council, 1985.

2. Gerhard Pahl, Wolfgang Beitz, Engineering Design, London Design Council, 1984

3. Angle Reinders, Remko Akkerman, Design, Production and Materials of PV Powered Consumer

Products - The Case of Mass Production, Proceedings of the 20th European Photovoltaic Solar Energy

Conference and Exhibition, Barcelona, 2005

4. Arthur Eger, Andr de Boer, Emerging Technology Design, Proceedings of Engineering and Product

Design Education Conference, Edinburgh, 2005

5. Robert A. Burgelman, Clayton M. Christensen, Steven C. Wheelwright, Strategic Management of

Technology and Innovation, McGrawHill, 2004

6. Eric von Hippel, The Sources of Innovation, Oxford University Press, 1988 and Democratizing

Innovation, The MIT Press, 2005

7. Arthur D. Little, The Strategic Management of Technology, European Management Forum, 1981

8. TNO, Design in the Creative Economy A Summary, Premsela Foundation, The Netherlands, 2005

9. Erik Middelman, Fuel Cell Technology, Nedstack Fuel Cell Technology, 2005

10. Frank de Bruijn, The Current Status of Fuel Cell Technology for Mobile and Stationary Applications,

Green Chemistry (7), 2005

11. James Larminie, Andrew Dicks, Fuel Cell Systems Explained, John Wiley & Sons Ltd, 2003

12. National Research Council, The Hydrogen Economy Opportunities, Costs, Barriers, and R&D

Needs, The National Academies Press, 2004

13. Arie Rip, Technological Innovation In Context, Meeting of Lowlands Innovation Research

Network, January 2003

14. Jan Buijs: Modeling Product Innovation Processes, from Linear Logic to Circular Chaos, Creativity

and innovation management, June 2003

15. Jens F. Christensen, Asset Profiles for Technological Innovation, Research Policy (24) 1995

16. Jacques Stevens, Innovative Technology But What Should It Look Like?, Idpartners, University of

Twente, 2005

17. Valeri Souchkov, TRIZ-based Innovation Roadmapping, University of Twente, 2005

18. Robert Phaal, Clare Farrukh, David Probert, Technology Roadmapping: Linking Technology

Resources to Business Objectives, University of Cambridge, 2001

19. Genrich Altshuller, And Suddenly the Inventor Appeared, Technical Innovation Centre, 1984

20. Johannes I.M. Halman, Adrian P. Hofer, Wim van Vuuren: Platform-Driven Development of Product

Families: Linking Theory with Practice, Journal of Product Innovation Management (20), 2003

21. Jimme A. Keizer, Johannes I.M. Halman, Michael Song: From Experience, Applying the Risk

Diagnosing Methodology, Journal of Product Innovation Management (19), 2002

22. Jasper Deuten, Arie Rip, Jaap Jelsma, Societal Embedding and Product Creation Management,

Technology Analysis & Strategic Management (9), 1997

23. Mary B. Rosson, John M. Carroll, Usability Engineering: Scenario-based Development of HumanComputer Interaction, Academic Press, San Diego, 2002

24. Dick Arnold, The Virtual Innovator, Perspectief Communicatieprojecten, Almelo, The Netherlands

2005

NHA Annual Hydrogen Conference 2006, March 12-16

Biographies

Dr. Angle Reinders

Dr. Angle Reinders is currently assistant professor in the Department of Design,

Production and Management of the University of Twente (UT) in the Netherlands. Her

research focuses on innovative product design for integrated sustainable energy

technologies. She also teaches in the masters studies program of Industrial Design

Engineering. Throughout her career, dr. Reinders has had an abiding interest in

sustainable energy. Prior to joining UT in 2002 she worked at Delft University (NL),

where she investigated direct methanol fuel cells for portable applications. In 2001, Dr.

Reinders worked as a scientific advisor in the Asia Alternative Energy Program of the

World Bank in Washington D.C. From 1993 to 2000, she was associated with Utrecht

University (NL), where she investigated, among other things, energy consumption of

households in the European Union. She received her doctoral degree from the Faculty

of Chemistry at Utrecht University in 1999. Her Ph.D. dissertation covers the analysis

of the field performance of photovoltaic solar energy systems. Dr. Reinders completed a

masters degree in Experimental Physics in 1993 at Utrecht University, specializing in

Material Physics and Energy Physics.

Prof. dr. ir. Fred van Houten

Prof. dr. ir. Fred van Houten is full professor in Design Engineering, Director of the

National Research School on Integral Manufacturing Innovation (IPV) and member of

the management team of the Faculty of Engineering Technology of the University of

Twente. He is head of the Department of Design, Production and Management, which

comprises the Divisions of Production Technology, Surface Technology and Product

Design. At the Department of DPM about 40 staff members and 25 PhD students are

active in a wide area of research in the field of Integrated Design Engineering and

Design Process Modeling.

Prof. dr. ir. Fred van Houten is also responsible for the educational program of the

studies of Industrial Design Engineering and the international masters program

Industrial Design and Manufacturing. Furthermore, he is chairing the Editorial

Committee of the International Institution for Production Engineering Research.

Anda mungkin juga menyukai

- Panduan PenggunaDokumen1 halamanPanduan PenggunaIbu Sri JakartaBelum ada peringkat

- Workstation cycle time analysisDokumen34 halamanWorkstation cycle time analysisFachmi AgungBelum ada peringkat

- Eoc Training ModuleDokumen28 halamanEoc Training ModuleFachmi AgungBelum ada peringkat

- Result Cheat CodeDokumen2 halamanResult Cheat CodeFachmi AgungBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- LEADSDokumen122 halamanLEADSBlessy Ruth BismonteBelum ada peringkat

- IKEA Chest of Drawers Product Recall List 2017Dokumen3 halamanIKEA Chest of Drawers Product Recall List 2017gdfeiu dionwdnBelum ada peringkat

- Furninova Selection 2014Dokumen66 halamanFurninova Selection 2014Dot MobelBelum ada peringkat

- D&B CatalogueDokumen43 halamanD&B CataloguejalloeBelum ada peringkat

- Gus Modern - Spring 2015 Furniture Collection - Modern Furniture Made SimpleDokumen76 halamanGus Modern - Spring 2015 Furniture Collection - Modern Furniture Made SimplegusmodernBelum ada peringkat

- Mil Pointers 2ND QuarterDokumen6 halamanMil Pointers 2ND QuarterStephanie Gail P. SimonBelum ada peringkat

- Rates of Teakwood FurnitureDokumen3 halamanRates of Teakwood FurnitureaajkalBelum ada peringkat

- Bamboo FurnitureDokumen25 halamanBamboo FurnitureTrisha Thapar0% (1)

- Shipment Manifest / Packing ListDokumen3 halamanShipment Manifest / Packing ListZahid MahmoodBelum ada peringkat

- Karta Pracy Prepositions of Place PLDokumen12 halamanKarta Pracy Prepositions of Place PLhhbflatBelum ada peringkat

- Low-Veroty Kantor - BleedDokumen108 halamanLow-Veroty Kantor - BleedCrystal Printing LombokBelum ada peringkat

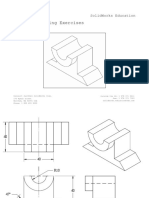

- Detailed Drawing Exercises: Solidworks EducationDokumen51 halamanDetailed Drawing Exercises: Solidworks EducationNiraj NaviBelum ada peringkat

- Seminar Presentation: Mentor: Dr. D.B.KarunakarDokumen14 halamanSeminar Presentation: Mentor: Dr. D.B.KarunakarPrashant KumarBelum ada peringkat

- Prepositions of Place. Reading Comprehension Activity.Dokumen7 halamanPrepositions of Place. Reading Comprehension Activity.JHONATANBelum ada peringkat

- NID Kurukshetra Admissions Open for 2018Dokumen8 halamanNID Kurukshetra Admissions Open for 2018prasannaBelum ada peringkat

- Design Thinking - Combined FDP - PPSXDokumen35 halamanDesign Thinking - Combined FDP - PPSXChirag PatilBelum ada peringkat

- Wassily ChairDokumen4 halamanWassily Chairresearcher9110% (1)

- A. Read The Text, Then Answer Some Questions! Architectural DesignerDokumen2 halamanA. Read The Text, Then Answer Some Questions! Architectural DesignerfujionoBelum ada peringkat

- Industrial Design Test PaperDokumen3 halamanIndustrial Design Test PaperJephthah Jude Tadeo GaleosBelum ada peringkat

- A MESSY ROOM - Furniture and Prepositions WorksheetDokumen3 halamanA MESSY ROOM - Furniture and Prepositions WorksheetIreneBelum ada peringkat

- BZ090Dokumen3 halamanBZ090ImronBelum ada peringkat

- Mixed results for FDMC 300 in pandemic yearDokumen15 halamanMixed results for FDMC 300 in pandemic yearUMESH JANGIRBelum ada peringkat

- ITEMS LIST R ANJEET - Error - Report - CSV - 0.odsDokumen328 halamanITEMS LIST R ANJEET - Error - Report - CSV - 0.odsdan webdeveloperBelum ada peringkat

- Directory For JobsDokumen3 halamanDirectory For Jobsmehtasahil21Belum ada peringkat

- Visionnaire 2011 Jewel-Like Colours For A Luxurious-CocoonDokumen65 halamanVisionnaire 2011 Jewel-Like Colours For A Luxurious-CocoontifonlineBelum ada peringkat

- CFR127 B1 CFR127 Cut SheetDokumen1 halamanCFR127 B1 CFR127 Cut SheetHenrique MilanesBelum ada peringkat

- Catalogue RZF Final PDFDokumen60 halamanCatalogue RZF Final PDFadyarman11Belum ada peringkat

- Free Holland Code Assessment ReportDokumen13 halamanFree Holland Code Assessment Reportnhan thanhBelum ada peringkat

- (D) WhereNet RPT 2022-02-11Dokumen276 halaman(D) WhereNet RPT 2022-02-11Kenan KudićBelum ada peringkat

- Loake Aw18 CollectionDokumen2 halamanLoake Aw18 Collectionmartin9947Belum ada peringkat