Cycle Time and Idle Time Reduction in An Engine Assembly Line

Diunggah oleh

IJSTEJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cycle Time and Idle Time Reduction in An Engine Assembly Line

Diunggah oleh

IJSTEHak Cipta:

Format Tersedia

IJSTE - International Journal of Science Technology & Engineering | Volume 2 | Issue 05 | November 2015

ISSN (online): 2349-784X

Cycle Time and Idle Time Reduction in an Engine

Assembly Line

Amith J Prakash

PG Scholar

Department of Industrial Engineering & Management

Mangalam college of Engineeering Ettumanoor

Aneesh K S

Associate Professor

Department of Mechanical Engineering

Mangalam college of Engineeering Ettumanoor

Abstract

This paper focuses on productivity improvement of a tiller assembly line by using operational analysis and assembly line

balancing .The existing standard time in the assembly line is too old and inaccurate. A proposal of new standard time has been

given to reduce the ineffective time. A heuristic method called Ranked Positional Weighted method is used for assembly line

balancing. After the analysis of the existing time required for each tasks non value added time, value added time and production

time has been found using stop watch time study. Micro motion study is done to find the ineffective time in each operation.

Keywords: Idle Time, Standard Time Cycle Time, Line Balancing

________________________________________________________________________________________________________

I. INTRODUCTION

An important problem faced in the production system is that of determining the time it takes to produce a unit of product, in

order to thoroughly analyze the problem, the production process for each of product is analyzed. For every manufacturing

organization, price of the product primarily compromises of manufacturing cost and desired profit. If a company wishes to

increase its profit, one way is to reduce the manufacturing cost with maintaining the quality of the product. Waste reduction,

especially the time waste, is an important factor to reduce the manufacturing cost.

II. NEED FOR LINE BALANCING

In an Assembly Line if the workers are not utilized effectively then it results in less efficiency. If the Cycle Time of one work

station is high them it will affect the production rate of the whole product, if the line balancing is done in the assembly line. It

will result in smooth functioning of the plant without bottleneck. Here this paper focus to do Assembly Line Balancing by

heuristic method Rank Position Weighted method (RPW)

III. LITERATURE SUMMARY

Santosh T Ghutukade, Dr. Suresh M. Sawant, 2013 [1] explain a problem of line balancing in cashew nut shelling machine

production using ranked position weighted method. The main purpose of this paper is to represent use of RPW method to

develop the assembly line and balancing that line. With this study it is found that RPW method is useful when the less data is

available. According to Vrittika Pachghar, R. S.Dalu March, (2014) [2] This paper presents the reviews of assembly line

balancing methods and tries to find out latest developments and trends available in industries in order to minimize production

time. This paper highlights the contributions of various assembly line balancing methods for global optimum solution and gaps

in literature which discuss point have more attention from the study of assembly line balancing it is found that assembly lines are

flow-line production systems, where a series of workstations, on which interchangeable parts are added to a product. Riyadh

Mohammed Ali Hamza, Jassim Yousif Al-Manaa (2013) [3] In this paper A study imitating a procedure of a Two Stages Gear

Box (2SGB) assembly line layout is presented. Three balancing methods are studied in which 2SGB is assembled. These

methods are Rank position weight, larger candidate rate, and Column method. Mahbubur Rahman, Farjana Nur 2014 [4] explains

that Waste reduction, especially the time waste, is an important factor to reduce manufacturing cost. Purpose of paper is to

identify and address the ways to improve productivity and efficiency in domestic context. Line balancing job has been done by

the help of Candidate rule and Ranked Positional Weight Technique. Line Balancing is an effective tool to suggest ways to

reduce workstation number and increase the throughput of a manufacturing process. Satish Keru Raut 2014 [5] explains the time

of producing a unit of product is directly proportional to the number of production stages involved and the time spent at eac h

stage. Actual time of each operation is taken using time study and new times are proposed for improving productivity. This paper

discusses the use of industrial engineering tools used for the purpose of productivity improvement. Sandip K. Kumbhar, Niranjan

M. R [2014] [6] this paper is focusing on optimization of cycle time, reduction non value added work (3m-muda, muri, mura),

kaizen. In this paper focus given on the optimization of cycle time and reduction of non-value added activity. Improvement in the

productivity achieved and elimination of non value added activities has been done. The cost of operation is reduced considerably.

All rights reserved by www.ijste.org

139

Cycle Time and Idle Time Reduction in an Engine Assembly Line

(IJSTE/ Volume 2 / Issue 05 / 027)

Patange Vidyut Chandra, [2013] [7] this paper focuses on the crucial area of productivity improvement with the use of work

study technique mixed with modern soft skills. Knowing what is unnecessary is important than knowing what is the most

important in production and operation. Based on those, we can eliminate insignificant tasks and non-productive activities.

Management needs to understand its application not just from angle of Production improvement or finance improvement or

resource utilization, but also should address critically the soft side of workers psychology to give the best to not only for

accepting the productivity solutions, but also be a part on fore front during actual implementation to make the study really worth

its time and effort. Prathamesh P Kulkarni [2014] [8] the objective of this paper is to present an overview on a new combined

methodology for the efficient improvement in productivity with the help of various Work Study Methods associated with Lean

Manufacturing Principles & Tools. S.H Eryuruk [2008] [9] explains two heuristic assembly line balancing techniques known as

the Ranked Positional Weight Technique, and the Probabilistic Line Balancing Technique, were applied to solve the

problem of multi-model assembly line balancing in a clothing company for two models. The aim of this article is the comparison

of the efficiencies of two different procedures applied for the first time to solve line balancing in a clothing company. S.A. Oke

[2006] [10] The studys most important finding is that the time of producing a unit of product is directly proportional to the

number of production stages involved and the time spent at each stage. In this paper, the time study concept in a production

process is modeled mathematically

IV. PROBLEM IDENTIFICATION AND PROBLEM STATEMENT

The After observation and analyzing production department the production rate of Power Tiller is reducing yearly, and not able

to meet the required demand. The following are the main problems observed which cause this.

1)

Idle times occurring in the assembly line is not controlled

2)

The existing time standards are too old and inaccurate in present practices

3)

The cycle time is not reduced in the assembly line

Problem Statement - Excessive cycle time and uncontrolled idle time increases waste of time and reduce the productivity of

a firm

V. PROBLEM DEFINITION

The production department consists of three Assembly sections. Transmission Assembly section, Engine assembly section and

KMB-series section. The main problem of firm is the inability to meet the current demand of Power tillers. Production and

demand details for the past three years are shown in the table below.

Table - 1

Production and Demand details for past three years

YEAR

DEMAND PRODUCTION

2012

9800

7200

2013

8200

5700

2014

7500

5525

2015 (TILL AUG)

4500

2400

When the Production and demand for the past few years was analyzed, it is clear that the production is showing a down trend

and not able to meet the demand. The table II shows the present Basic time of each section in the existing plant.

Table - 2

Time taken of sub-assemblies for Transmission assembly in 2 shifts

Day

No: of sub Shift 1 Shift 2 Total Time

assembly

(hr)

(min

Day 1

10

4:30

4.41

9:11

551

Day 2

10

4:35

4.38

9:13

553

Day 3

8

4:25

4.45

9:10

550

Day 4

10

4:40

4.35

9:15

555

Day 5

8

4:38

4.30

9:08

548

Total

46

22:48 23:09 45:57 2757

Average

9.2

9:114 551.4

Basic time = Average actual time/Average no: of sub-assemblies completed

=570/19.2 =29.68 min for one sub assembly

Table - 3

Time taken for sub-assemblies for KMB series in 2 shifts

No: of sub

Total Time

Day

Shift 1 Shift 2

assembly

(hr)

(min

Day 1

23

4:42

4:47

9:39

579

Day 2

25

4:35

4:32

9:07

547

Day 3

22

4:44

4:55

9:39

579

Day 4

20

4:50

4:43

9:33

573

All rights reserved by www.ijste.org

140

Cycle Time and Idle Time Reduction in an Engine Assembly Line

(IJSTE/ Volume 2 / Issue 05 / 027)

Day 5

Total

25

115

Average

23

4:32

23:23

4:36

23:33

9:08

46:56

548

2816

9:23

563.2

Basic time = Average actual time/Average no: of part Assemblies completed

=563.2/23 = 24.48 min for one sub assembly

Table - 4

Time taken for sub-assemblies in Engine Assembly line

No: of sub

Total Time

Day

Shift 1 Shift 2

assembly

(hr)

(min

Day 1

10

4:30

4.41

9:11

551

Day 2

10

4:35

4.38

9:13

553

Day 3

8

4:25

4.45

9:10

550

Day 4

10

4:40

4.35

9:15

555

Day 5

8

4:38

4.30

9:08

548

Total

46

22:48 23:09 45:57 2757

Average

19.2

9:114 551.4

Basic time = Average actual time/Average no: of part assemblies completed

=551.4/9.2 =59.93 min for one sub assembly

After calculation of overall basic time of the three sections in assembly line it is clear that the bottleneck is occurring in the

Engine Assembly line. If the cycle time, idle time is reduced and the standard time is modified in these sections then the

productivity can be improved.

Sl No

Table - 5

Idle Time Occurring in Engine Assembly Line and precautions suggested

Idle Time Category

Precautions

1

2

Repair/Breakdown Of Equipment

No Tools

Preventive Maintenance

Arrange Spare Tools As Reserve

3

4

No Job

Waiting For Assistant

Keep Sufficient Jobs For Work

Immediate Assistance Should Be Arranged

5

6

Waiting Crane/Handling Equipment

Waiting For Inspection

Effective Utilization Without Delay

Prompt Inspection At Right Time

7

8

Machine Cleaning

Accident Injury

Clean In Non-Working Time

Safety Precautions, Good Housekeeping

9

10

Power Failure

Official Permission

Arrange Generator Facility

Give Prompt Permission If Relevant

11

Personal Permission

Give Prompt Permission If Relevant

VI. PROCEDURE

A. Stage 1

In this stage the existing Assembly Line is studied to know whether it is efficient or not. Observation method and stop watch

time study is used to check overall time of each section. In this stage the idle time is also noted. The existing process sheet is

analyzed to find the area to be improved. Operation analysis is done in the present engine assembly line in order to find the NonValue added time, Value added time and production time which will help to reduce the wastage of time.

B. Stage 2

In this stage the standard time for E1, E2 and ET found by giving a rating factor of 6% of which 3% is skill and effort rating

factor and 3% is performance rating factor, and an Allowance of 10% is given of which 6% is personal allowance and 4% is

fatigue allowance. Standard time calculation in ET has shown in the table below.

SL

NO

1

2

3

Table 7

Standard time calculation of Engine testing (ET)

BASIC

FATIGUE

PRESENT

RATING

TASK

TIME

ALLOWANCE

TIME

FACTOR

(MIN)

(4%)

MOUNT ENGINE ON TEST BED

4.5

1.06

4.77

0.1908

CONNECT FUEL LINE TO DIESEL

3

1.06

3.18

0.1272

FILTER AND BLEED

FILL WATER IN RADIATOR

2.5

1.06

2.65

0.106

PERSONAL

ALLOWANCE

(6%)

0.2862

STD

TIME

5.247

0.1908

3.498

0.159

2.915

All rights reserved by www.ijste.org

141

Cycle Time and Idle Time Reduction in an Engine Assembly Line

(IJSTE/ Volume 2 / Issue 05 / 027)

4

5

6

7

8

9

10

11

12

13

14

COUPLE DYNAMOMETER TO ENGINE

FLY WHEEL

FIX BREAK SHOES AND WATER PIPES

1.06

4.24

0.1696

0.2544

4.664

3.5

1.06

3.71

0.1484

0.2226

4.081

START ENGINE

FILL ENGINE TEST RECORD ON

VERIFICATION

LOAD ENGINE GRADUALLY IN STEP 2

AND RUN ENGINE

1.06

4.24

0.1696

0.2544

4.664

4.5

1.06

4.77

0.1908

0.2862

5.247

1.06

5.3

0.212

0.318

5.83

ADJUST LOAD,CORRESPONDING TO

RPM,RECORD TIME AND FUEL

CONSUMPTION

4.5

1.06

4.77

0.1908

0.2862

5.247

1.06

4.24

0.1696

0.2544

4.664

4.5

1.06

4.77

0.1908

0.2862

5.247

1.06

4.24

0.1696

0.2544

4.664

3.5

1.06

3.71

0.1484

0.2226

4.081

2.5

1.06

2.65

0.106

0.159

2.915

CALCULATE AND RECORD SPECIFIC

FUEL CONSUMPTION

LOAD THE ENGINE FOR MAXIMUM

AND RECORD MAX HP

INCASE OF VARIATION REPORT TO

SUPERIORS FOR RECTIFICATION

CHECK CYLINDER HEAD BOLT AND

VALVE-CLEARANCE

WRITE THE TAG ,CLOSE AIR

CLEAANER FLANGE

TIME FOR ONE ENGINE

54 min

63 min

C. Stage 3

1) Final Stage

In this stage the assembly line balancing is done in E1 and E2 by the aid of a heuristic method Rank positional weighted method.

The table below shows the balanced Assembly line E1with a reduced cycle time 38 minutes instead of 52 minutes in the existing

case. Similarly the line balancing in E2 is also done

TASK NO:

2

3

4

7

Total

Table 6

Balanced Assembly line in E1

TIME SUM OF TIME

ELEMENT

(Min)

(Min)

A

7

36

K

8

C

6

R

8

D

3

G

4

B

32

35

L

3

S

28

36

H

8

E

24

36

I

7

T

5

J

15

34

M

6

N

8

V

5

U

8

37

O

18

W

4

X

7

Y

16

38

P

7

F

7

Q

8

252

NO: OF WORKERS

1

1

1

1

7

All rights reserved by www.ijste.org

142

Cycle Time and Idle Time Reduction in an Engine Assembly Line

(IJSTE/ Volume 2 / Issue 05 / 027)

SECTION

E1

E2

ET

TOTAL

Table 8

Present Vs Proposed standard time

STADARD

NON VALUE

PRESENT TIME

TIME PROPOSED ADDED TIME

158.6

58.8

12

158.6

62.2

13

63

54

14

392.2

191.14

39

VII. RESULT

The existing system was analyzed using Method Study and Time Study. Found that there is bottleneck in E1 and E2 engine

assembly sections. In order to avoid that standard time has been proposed along with operational analysis and Line balancing is

done in the E1, E2 assembly sections which ultimately helps to improve productivity

VIII. CONCLUSION

Detailed study in the existing assembly line shows that the engine assembly line should improve in order to achieve yearly

demand. So time standards are proposed and it can be used to reduce cycle time in the current assembly line. The idle times

occurring in the assembly line also need to control with the suggested precautions. Cycle time of E1 and E2 is reduced so as to

meet the yearly demand. The study shows that Engine Testing (ET) and Engine finishing (EF) need not modify. And the

bottleneck is occurring in Engine section one (E1) and section two (E2)

REFERENCES

[1]

Santosh T Ghutukade, Dr. Suresh M. Sawant, The use of Ranked Position weighted Method for Assembly Line

Balancing, Ghutukade, International

Journal of Advanced Engineering Research and Studies E-ISSN

22498974, Int. J. Adv. Engg. Res. Studies / II/ IV/July-Sept., 2013/01-03

[2] Vrittika Pachghar, R. S. Dalu The Review of assembly line balancing methods, International Journal of Science and Research (IJSR) March, ISSN

(Online): 2319-7064,Volume 3 Issue 3, March , (2014)

[3] Riyadh Mohammed Ali Hamza, Jassim Yousif Al-Manaa, A study imitating a Procedure Of A Two Stages Gear Box (2SGB) Assembly Line, Global

Perspectives On Engineering Management, Vol.2, Issue 2,pp.70-81(2013)

[4] Mahbubur Rahman, Farjana Nur An Integrated Framework of Applying Line Balancing In Apparel Manufacturing Organization: A Case Study, Journal of

Mechanical Engineering, Vol ME 44, NO. 2, DECEMBER 2014

[5] Satish Keru Raut, A Case Study of Productivity Improvement by using IE Tools, International Journal Of Innovations in Engineering Research and

Technology Volume 1, Issue 1 November, [2014]

[6] Sandip K Khumbhar, Niranjan M R, Sanjay T Satpute, Assembly Line production improvement by optimization of cycle time, Proceedings of 10th IRF

International Conference, 1st June, [2014]

[7] Patange Vidyut Chandra, An Effort to Apply Work And Time Study Techniques in a Manufacturing Unit for Enhancing Productivity, International a

Journal of Innovative Research in Science, Engineering And Technology, Vol. 2, Issue 8, August [2013]

[8] Prathamesh P Kulkarni, Sagar S Kshire, Kailas V Chandratre, Productivity Improvement Through Lean Deployememnt And Work Study Methods,

International Journal Of Research And Technology, Feb[2014]

[9] S.H Eryuruk, S. H Eryuruk, A Research On The Effect Of Method Study On Production Volume And Assembly Line Efficiency, [2014]

[10] S A Oke [2006] S A Oke, A Case Study Application of Time Study Model in an Aluminium Company, The Pacific Journal Of Science and Technology,

Vol 7 Number 2, November [2006]

All rights reserved by www.ijste.org

143

Anda mungkin juga menyukai

- Design and Analysis of Magneto Repulsive Wind TurbineDokumen7 halamanDesign and Analysis of Magneto Repulsive Wind TurbineIJSTEBelum ada peringkat

- Automatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"Dokumen8 halamanAutomatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"IJSTEBelum ada peringkat

- RFID Based Toll Gate AccessDokumen5 halamanRFID Based Toll Gate AccessIJSTEBelum ada peringkat

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDokumen7 halamanPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTEBelum ada peringkat

- Multipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationDokumen9 halamanMultipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationIJSTEBelum ada peringkat

- FPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignDokumen4 halamanFPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignIJSTEBelum ada peringkat

- Optimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryDokumen8 halamanOptimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryIJSTEBelum ada peringkat

- Optimization of Treatability by FACCO For Treatment of Chemical Industry EffluentDokumen9 halamanOptimization of Treatability by FACCO For Treatment of Chemical Industry EffluentIJSTEBelum ada peringkat

- A Mixture of Experts Model For ExtubationDokumen4 halamanA Mixture of Experts Model For ExtubationIJSTEBelum ada peringkat

- A Cloud Based Healthcare Services For Remote PlacesDokumen4 halamanA Cloud Based Healthcare Services For Remote PlacesIJSTEBelum ada peringkat

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDokumen9 halamanEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTEBelum ada peringkat

- A Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemDokumen6 halamanA Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemIJSTEBelum ada peringkat

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDokumen6 halamanDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTEBelum ada peringkat

- Enriching Gum Disease Prediction Using Machine LearningDokumen6 halamanEnriching Gum Disease Prediction Using Machine LearningIJSTEBelum ada peringkat

- App-Based Water Tanker Booking, Monitoring & Controlling SystemDokumen6 halamanApp-Based Water Tanker Booking, Monitoring & Controlling SystemIJSTEBelum ada peringkat

- The Bicycle As A Mode Choice - A Gendered ApproachDokumen4 halamanThe Bicycle As A Mode Choice - A Gendered ApproachIJSTEBelum ada peringkat

- A Radar Target Generator For Airborne TargetsDokumen8 halamanA Radar Target Generator For Airborne TargetsIJSTEBelum ada peringkat

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDokumen5 halamanAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTEBelum ada peringkat

- Interstage Construction Techniques For Mass Gain: An OverviewDokumen5 halamanInterstage Construction Techniques For Mass Gain: An OverviewIJSTEBelum ada peringkat

- Optimum Placement of DG Units Using CPF MethodDokumen6 halamanOptimum Placement of DG Units Using CPF MethodIJSTEBelum ada peringkat

- Comparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridDokumen7 halamanComparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridIJSTEBelum ada peringkat

- Onerider The Bike TaxiDokumen3 halamanOnerider The Bike TaxiIJSTEBelum ada peringkat

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDokumen6 halamanWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTEBelum ada peringkat

- Technology Advancement For Abled PersonDokumen9 halamanTechnology Advancement For Abled PersonIJSTEBelum ada peringkat

- Duplicate Detection Using AlgorithmsDokumen3 halamanDuplicate Detection Using AlgorithmsIJSTEBelum ada peringkat

- Optimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersDokumen4 halamanOptimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersIJSTEBelum ada peringkat

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDokumen6 halamanUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTEBelum ada peringkat

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDokumen6 halamanResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTEBelum ada peringkat

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDokumen5 halamanAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTEBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- BECED S4 Motivational Techniques PDFDokumen11 halamanBECED S4 Motivational Techniques PDFAmeil OrindayBelum ada peringkat

- Types of Chemical Reactions: Synthesis and DecompositionDokumen3 halamanTypes of Chemical Reactions: Synthesis and DecompositionAlan MartínBelum ada peringkat

- Supply List & Resource Sheet: Granulation Techniques DemystifiedDokumen6 halamanSupply List & Resource Sheet: Granulation Techniques DemystifiedknhartBelum ada peringkat

- str-w6754 Ds enDokumen8 halamanstr-w6754 Ds enAdah BumbonBelum ada peringkat

- FT2020Dokumen7 halamanFT2020Sam SparksBelum ada peringkat

- Topic One ProcurementDokumen35 halamanTopic One ProcurementSaid Sabri KibwanaBelum ada peringkat

- BPS C1: Compact All-Rounder in Banknote ProcessingDokumen2 halamanBPS C1: Compact All-Rounder in Banknote ProcessingMalik of ChakwalBelum ada peringkat

- .CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADODokumen782 halaman.CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOMarcelo JesusBelum ada peringkat

- Basic Terms/Concepts IN Analytical ChemistryDokumen53 halamanBasic Terms/Concepts IN Analytical ChemistrySheralyn PelayoBelum ada peringkat

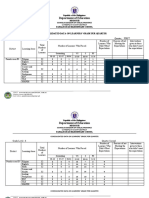

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDokumen4 halamanDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaBelum ada peringkat

- Atmel 46003 SE M90E32AS DatasheetDokumen84 halamanAtmel 46003 SE M90E32AS DatasheetNagarajBelum ada peringkat

- Probation Period ReportDokumen17 halamanProbation Period ReportMiranti Puspitasari0% (1)

- Department of Ece, Adhiparasakthi College of Engineering, KalavaiDokumen31 halamanDepartment of Ece, Adhiparasakthi College of Engineering, KalavaiGiri PrasadBelum ada peringkat

- Polysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Dokumen1 halamanPolysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Carlos JiménezBelum ada peringkat

- Management Accounting by Cabrera Solution Manual 2011 PDFDokumen3 halamanManagement Accounting by Cabrera Solution Manual 2011 PDFClaudette Clemente100% (1)

- Job Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeDokumen16 halamanJob Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeNaveen KumarBelum ada peringkat

- Engineering Ethics in Practice ShorterDokumen79 halamanEngineering Ethics in Practice ShorterPrashanta NaikBelum ada peringkat

- MLX90614Dokumen44 halamanMLX90614ehsan1985Belum ada peringkat

- Executive Summary: 2013 Edelman Trust BarometerDokumen12 halamanExecutive Summary: 2013 Edelman Trust BarometerEdelman100% (4)

- Logistic RegressionDokumen7 halamanLogistic RegressionShashank JainBelum ada peringkat

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDokumen9 halamanDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaBelum ada peringkat

- Object Oriented ParadigmDokumen2 halamanObject Oriented ParadigmDickson JohnBelum ada peringkat

- Understanding The Contribution of HRM Bundles For Employee Outcomes Across The Life-SpanDokumen15 halamanUnderstanding The Contribution of HRM Bundles For Employee Outcomes Across The Life-SpanPhuong NgoBelum ada peringkat

- Installing Surge Protective Devices With NEC Article 240 and Feeder Tap RuleDokumen2 halamanInstalling Surge Protective Devices With NEC Article 240 and Feeder Tap RuleJonathan Valverde RojasBelum ada peringkat

- Banking Ombudsman 58Dokumen4 halamanBanking Ombudsman 58Sahil GauravBelum ada peringkat

- Importance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesDokumen61 halamanImportance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesjrtnBelum ada peringkat

- Chapter 01 What Is Statistics?Dokumen18 halamanChapter 01 What Is Statistics?windyuriBelum ada peringkat

- JO 20221109 NationalDokumen244 halamanJO 20221109 NationalMark Leo BejeminoBelum ada peringkat

- Configuration Guide - Interface Management (V300R007C00 - 02)Dokumen117 halamanConfiguration Guide - Interface Management (V300R007C00 - 02)Dikdik PribadiBelum ada peringkat

- CE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationDokumen32 halamanCE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationPROSPEROUS LUCKILYBelum ada peringkat