Din 10029

Diunggah oleh

Sérgio AmorimHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Din 10029

Diunggah oleh

Sérgio AmorimHak Cipta:

Format Tersedia

Article: Tolerances to EN 10029 for hot rolled plate 3mm and above

Page 1 of 3

Tolerances to EN 10029 for hot rolled plate 3mm

General

This standard covers a wider group of steels than just stainless:

Non-alloy and alloy steels including stainless steels with:

1. Nominal thickness > 3mm < 250mm

2. Nominal width > 600mm

3. Specified minimum yield strength < 700 N/mm2

Tolerances on plate less than 600 mm wide shall be agreed at time of enquiry/order

Thickness tolerance

At the enquiry/order stage it is necessary to define which of 4 classes A-D is required.

Tolerances on nominal thickness 1)

Class A

Class B

Class C

Class D

Lower Upper Lower Upper Lower Upper Lower Upper

>3<5

-0.4 +0.8 -0.3 +0.9 -0

+1.2 -0.6 +0.6

>5<8

-0.4 +1.1 -0.3 +1.2 -0

+1.5 -0.75 +0.75

> 8 < 15

-0.5 +1.2 -0.3 +1.4 -0

+1.7 -0.85 +0.85

> 15 < 25

-0.6 +1.3 -0.3 +1.6 -0

+1.9 -0.95 +0.95

> 25 < 40

-0.8 +1.4 -0.3 +1.9 -0

+2.2 -1.1 +1.1

> 40 < 80

-1.0 +1.8 -0.3 +2.5 -0

+2.8 -1.4 +1.4

> 80 < 150 -1.0 +2.2 -0.3 +2.9 -0

+3.2 -1.6 +1.6

> 150 < 250 -1.2 +2.4 -0.3 +3.3 -0

+3.6 -1.8 +1.8

Nominal

thickness

1. These thickness tolerances apply outside ground areas

Maximum thickness difference within a plate

Nominal width

> 600 < 2000 > 2000 < 2500 > 2500 < 3000 > 3000 < 3500 > 3500 < 4000 > 4000

>3<5

0.8

0.9

0.9

------>5<8

0.9

0.9

1.0

1.0

----> 8 < 15

0.9

1.0

1.0

1.1

1.1

1.2

> 15 < 25

1.0

1.1

1.2

1.2

1.3

1.4

1.1

1.2

1.2

1.3

1.3

1.4

> 25 < 40

> 40 < 80

1.2

1.3

1.4

1.4

1.5

1.6

> 80 < 150 1.3

1.4

1.5

1.5

1.6

1.7

> 150 < 250 1.4

1.5

1.6

1.6

1.7

--Nominal

thickness

Thickness shall be measured at any point situated more than 25mm from the transverse o

the plate, other than locally ground areas.

For plates with untrimmed edges the measuring points shall be agreed at the time of orde

Ground areas

The standard governing surface defects and permissible ground areas of hot rolled plates

intended to publish an article on this standard on the website in the near future. For the tim

refer to the Stainless Steel Advisory Service.

Width tolerance

Nominal width

> 600 < 2000

> 2000 < 3000

> 3000

Tolerances

Lower Upper

0

+20

0

+25

0

+30

Width shall be measured perpendicular to the major axis of the plate.

Plates may be supplied with untrimmed edges, condition NK. In this case, width tolerance

the time of the enquiry and order.

http://www.bssa.org.uk/topics.php?article=289

05.11.2009

Article: Tolerances to EN 10029 for hot rolled plate 3mm and above

Page 2 of 3

Length tolerance

Nominal length

< 4000

>4000 < 6000

>6000 < 8000

>8000 < 10000

>10000 < 15000

>15000 < 200001)

Tolerances

Lower Upper

0

+ 20

0

+ 30

0

+ 40

0

+ 50

0

+ 75

0

+100

1. Tolerances on plates with a nominal length > 20000mm shall be agreed at the time

The length of the plate is the length of the largest rectangle contained within a plate.

Edge camber and out of squareness

Edge camber is the maximum deviation between one longitudinal edge and the straight lin

of this edge.

The out of squareness is the orthogonal projection of one transverse edge on one longitud

The edge camber and out of squareness of a plate shall be limited so that it shall be poss

rectangle with the dimensions of the ordered plate within the delivered size.

Additionally, if agreed at the time of the enquiry and order, edge camber shall be limited to

length of the plate and out of squareness to 1% of the actual width of the plate. This extra

designated G.

http://www.bssa.org.uk/topics.php?article=289

05.11.2009

Article: Tolerances to EN 10029 for hot rolled plate 3mm and above

Page 3 of 3

Flatness tolerance

Flatness shall be measured as follows:

Place plate on a flat surface. Deviation from flatness shall be determined by measuring th

between the plates and a straight edge of 1000mm or 2000mm long which may be placed

Only the part between two points of contact between the straight edge and the plate shall

consideration. Deviations shall be measured at a point at least 25mm from the longitudina

distance of 200mm from the end for Normal tolerances or 100mm for Special tolerances

Flatness tolerances are either Normal, Class N, or Special, Class S. The tolerance also de

minimum yield strength of the steel. These are steel types L and H:

L - Products with a specified minumum yield strength < 460 N/mm2, neither quenched no

tempered.

H - Products with specified minumum yield strength > 460 N/mm2 and < 760 N/mm2 and

and quenched and tempered products

Note. Not in standard itself. For stainless steels the yield strength should be taken as the

material standard EN 10088-2 or EN 10028-7. The quenching which is often part of the he

solution annealing of austenitic stainless steels is NOT intended in these definitions. Most

steels will therefore fall into class L.

Normal flatness tolerances Class N

Steel type L Steel type H

Nominal thickness Measuring length

1000 2000 1000 2000

> 3< 5

9

14

12

17

> 5< 8

8

12

11

15

> 8 < 15

7

11

10

14

> 15 < 25

7

10

10

13

> 25 < 40

6

9

9

12

> 40 < 250

5

8

8

11

If the distance between the points of contact of the straight edge and the plate < 1000mm

deviation from flatness shall comply with the following requirements:

For steel type L a maximum of 1% and for steel type H a maximum of 1.5% of the distanc

contact on the plate between 300 and 1000mm but not exceeding the values in the above

Special flatness tolerances, Class S

Steel type L

Plate width

Steel type H

Nominal

< 2750

> 2750

thickness

Measuring length

1000 2000 1000 2000 1000

2000

>3<8 4

8

5

10 Shall be agreed at time of

enquiry and

6

3

6

> 8 < 250 3

order

Tighter tolerances for steel type L can be agreed at the time of enquiry and order.

If the distance between the points of contact of the straight edge and the plate < 1000mm

deviation from flatness shall comply with the following requirements:

A maximum of 0.5% of the distance between points of contact but not exceeding the value

and not < 2mm.

Excess mass

There is a rather complex table for excess mass and it is not intended to reproduce it in th

otherwise agreed at the time of the enquiry and order, excess mass shall not be a cause f

information on this particular issue, please refer to the Stainless Steel Advisory Service.

http://www.bssa.org.uk/topics.php?article=289

05.11.2009

Anda mungkin juga menyukai

- En 10029Dokumen3 halamanEn 10029hamoody_007100% (1)

- Hot Rolled Plate Standard EN 10029 Thickness TolerancesDokumen3 halamanHot Rolled Plate Standard EN 10029 Thickness TolerancesNuran ZorBelum ada peringkat

- Thikness TolerenceDokumen5 halamanThikness TolerencemuneeshwaraperumalBelum ada peringkat

- Standard EN10029Dokumen4 halamanStandard EN10029Florin JipaBelum ada peringkat

- Tolerante Table Groase Laminate La Cald EN 10029-2011 PDFDokumen2 halamanTolerante Table Groase Laminate La Cald EN 10029-2011 PDFDaniel C.Belum ada peringkat

- En 10051Dokumen2 halamanEn 10051sskamalakannanBelum ada peringkat

- En 10029 For Hot Rolled Plate 3mm and AboveDokumen4 halamanEn 10029 For Hot Rolled Plate 3mm and AboveIlkin hasanovBelum ada peringkat

- ToleranceDokumen9 halamanTolerancemarkom123Belum ada peringkat

- Tolerances To en 10051 For Continuously Rolled HotDokumen4 halamanTolerances To en 10051 For Continuously Rolled HotSorin LescaiBelum ada peringkat

- En 10029 PDFDokumen5 halamanEn 10029 PDFmanuela vilas boasBelum ada peringkat

- En 10029Dokumen5 halamanEn 10029manuela vilas boasBelum ada peringkat

- Bulb Flats Dimensions GuideDokumen11 halamanBulb Flats Dimensions GuideMd. Rafique HassanBelum ada peringkat

- Technical specifications for welded round precision steel tubesDokumen1 halamanTechnical specifications for welded round precision steel tubessalimmalmaliBelum ada peringkat

- Tolerances To EN 10029 For Hot Rolled Plate 3mm and Above: GeneralDokumen5 halamanTolerances To EN 10029 For Hot Rolled Plate 3mm and Above: GeneralKumar NawneetBelum ada peringkat

- Tolerances To BS en 10296Dokumen4 halamanTolerances To BS en 10296matteo2009Belum ada peringkat

- Standard Sheetmetal Slitting TolerancesDokumen11 halamanStandard Sheetmetal Slitting TolerancessudarshanBelum ada peringkat

- Parkers: BS EN 10051: 1992Dokumen2 halamanParkers: BS EN 10051: 1992christos032Belum ada peringkat

- Hot Strip Mill Product TolerancesDokumen9 halamanHot Strip Mill Product TolerancesAyman Al AnsaryBelum ada peringkat

- S355MCDokumen2 halamanS355MCRodrigo Eduardo GomesBelum ada peringkat

- Seamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Dokumen8 halamanSeamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00refeiBelum ada peringkat

- En 10051 PDFDokumen4 halamanEn 10051 PDFmanuela vilas boasBelum ada peringkat

- En 10029 Quarto Plate TolerancesDokumen4 halamanEn 10029 Quarto Plate TolerancesDiyanto AntoBelum ada peringkat

- Al - 1050ADokumen2 halamanAl - 1050Adejo1986100% (1)

- Cold Rolled Steel StripDokumen40 halamanCold Rolled Steel StripshelarsanjayBelum ada peringkat

- En 10143Dokumen3 halamanEn 10143Anonymous JoB5ZxgBelum ada peringkat

- Stramit Monoclad: Product Technical ManualDokumen8 halamanStramit Monoclad: Product Technical Manualchillerz69Belum ada peringkat

- Z Plates: Hot-Rolled Steel Sheets, Plates and CoilsDokumen4 halamanZ Plates: Hot-Rolled Steel Sheets, Plates and CoilsSteven MaynardBelum ada peringkat

- Hot Dip GalvanisedDokumen20 halamanHot Dip Galvanisedepsa333100% (1)

- Rolled Alloys Astm A480 Plate Thickness Flatness TolerancesDokumen2 halamanRolled Alloys Astm A480 Plate Thickness Flatness TolerancesAli YasirBelum ada peringkat

- Hot-rolled steel product catalogueDokumen30 halamanHot-rolled steel product catalogueShankar PranavBelum ada peringkat

- QStE 380 TM PDFDokumen2 halamanQStE 380 TM PDFJetesh DevgunBelum ada peringkat

- AISI 4140 - AISI 4142mod.: Product DescriptionDokumen3 halamanAISI 4140 - AISI 4142mod.: Product Description2shaenBelum ada peringkat

- Welding Tolerance StandardsDokumen6 halamanWelding Tolerance StandardsSowmen_CBelum ada peringkat

- Cold Rolling MillDokumen4 halamanCold Rolling MillArslan BohioBelum ada peringkat

- Is Iso 16160 2005Dokumen11 halamanIs Iso 16160 2005Amber HudsonBelum ada peringkat

- Din 1615Dokumen5 halamanDin 1615David FonsecaBelum ada peringkat

- Qste 340 TMDokumen2 halamanQste 340 TMJuan José Viñas MéndezBelum ada peringkat

- Sae 4140Dokumen3 halamanSae 4140Anurag JainBelum ada peringkat

- Winding Wires Standards and TestsDokumen71 halamanWinding Wires Standards and TestsMaria BellBelum ada peringkat

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDokumen4 halamanDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraBelum ada peringkat

- Fine-Grain Structural Steels, Normalised Rolled: Mechanical PropertiesDokumen2 halamanFine-Grain Structural Steels, Normalised Rolled: Mechanical PropertieswentropremBelum ada peringkat

- SSAB General Product Information Strenx Hardox Armox Toolox 2018 PDFDokumen11 halamanSSAB General Product Information Strenx Hardox Armox Toolox 2018 PDFAslam ShaikhBelum ada peringkat

- S235J2 NDokumen1 halamanS235J2 Npraveenmenon86Belum ada peringkat

- American StandardDokumen24 halamanAmerican StandardmitulfavsBelum ada peringkat

- Lasercut WB 100 enDokumen0 halamanLasercut WB 100 enfbp81Belum ada peringkat

- ABB DP 4Dokumen1 halamanABB DP 4schiff22Belum ada peringkat

- Bs en 485-4 1994 Gruix Tolerancies AluminiDokumen6 halamanBs en 485-4 1994 Gruix Tolerancies AluminiAlbert Solsona100% (1)

- S235J0Dokumen1 halamanS235J0serzo75Belum ada peringkat

- ThyssenKrupp - XABO 500Dokumen3 halamanThyssenKrupp - XABO 500Yesid Javier Martelo EllesBelum ada peringkat

- Parkers: BS 970: Part 1: 1996Dokumen2 halamanParkers: BS 970: Part 1: 1996strganeshkumarBelum ada peringkat

- Is 16162Dokumen11 halamanIs 16162Parthasarathi Paul100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDari EverandWeld Like a Pro: Beginning to Advanced TechniquesPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDari EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyBelum ada peringkat

- Petroleum Engineering Diploma Engineering MCQDari EverandPetroleum Engineering Diploma Engineering MCQPenilaian: 1 dari 5 bintang1/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- Denah Pembalokan Dek Lt. 2 Proyek Bumi Menara InternusaDokumen1 halamanDenah Pembalokan Dek Lt. 2 Proyek Bumi Menara Internusamuhammad chilmiBelum ada peringkat

- Torque Chart For ASTM A193 Grade B7 StudsDokumen3 halamanTorque Chart For ASTM A193 Grade B7 Studsmuhammad chilmiBelum ada peringkat

- BRT CP GD 001 Cutting Plan GirderDokumen1 halamanBRT CP GD 001 Cutting Plan Girdermuhammad chilmiBelum ada peringkat

- Torque Chart For ASTM A193 Grade B7 StudsDokumen3 halamanTorque Chart For ASTM A193 Grade B7 Studsmuhammad chilmiBelum ada peringkat

- Pib STDDokumen1 halamanPib STDmuhammad chilmiBelum ada peringkat

- ASMEDokumen1 halamanASMEmuhammad chilmiBelum ada peringkat

- HandrailDokumen1 halamanHandrailmuhammad chilmiBelum ada peringkat

- BRT HPH004 DW 002Dokumen1 halamanBRT HPH004 DW 002muhammad chilmiBelum ada peringkat

- Diagram shows temperature holding process over timeDokumen1 halamanDiagram shows temperature holding process over timemuhammad chilmiBelum ada peringkat

- General ArrangementDokumen1 halamanGeneral Arrangementmuhammad chilmiBelum ada peringkat

- Pib STDDokumen1 halamanPib STDmuhammad chilmiBelum ada peringkat

- 595 C +/-10 C Diagram Holding Temperatur 1" THK / HourDokumen1 halaman595 C +/-10 C Diagram Holding Temperatur 1" THK / Hourmuhammad chilmiBelum ada peringkat

- Detail of Pipe DavitDokumen1 halamanDetail of Pipe Davitmuhammad chilmiBelum ada peringkat

- Assembly 14V108Dokumen1 halamanAssembly 14V108muhammad chilmiBelum ada peringkat

- Top Ladder Detail Rev.0Dokumen2 halamanTop Ladder Detail Rev.0muhammad chilmiBelum ada peringkat

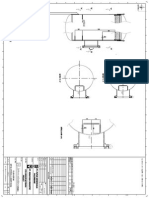

- General Arrangement Platform Fa - 604: (Liquid Ammonia Flash Drum)Dokumen2 halamanGeneral Arrangement Platform Fa - 604: (Liquid Ammonia Flash Drum)muhammad chilmiBelum ada peringkat

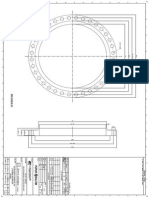

- Body Flange Fa 602Dokumen1 halamanBody Flange Fa 602muhammad chilmiBelum ada peringkat

- Ladder Rung - 1Dokumen1 halamanLadder Rung - 1muhammad chilmiBelum ada peringkat