Site Visit Report

Diunggah oleh

Kaushal PatelHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Site Visit Report

Diunggah oleh

Kaushal PatelHak Cipta:

Format Tersedia

1

DEPARTMENT OF CIVIL ENGINEERING

Report On:

Site Visit

Repair And Rehabilitation of Structures

Prepared by :

Patel.

Submitted to: Kaushal

Mrs.Niketa panchal

Page

1

D12CL067

Semester 7

Associate Proffesor

Civil department

CSPIT

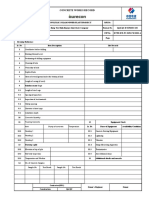

GENERAL DETAILS:

Date of visit

:18th September to 20th September, 2014

Name of site :

1)

B J Wadia Children Hospital, Parel, Mumbai

(Project Site of Structwel Designers and Consultants Pvt. Ltd)

2)

Structwel Designers and Consultants Pvt. Ltd., Turbhe, NaviMumbai(Main

Office and Laboratory)

3)

Ultratech Specialty Chemicals Ltd,Taloja

[Aditya Birla Science and Technology Company (ABSTC)]

4)

Global Vipassana Pagoda, Gevrai, Maharashtra.

Students: 4th Year B. Tech., Department of Civil Engineering

Objectives of Visit :

To explore real concrete investigation methods.

To interact with the practicing engineer and to get the knowledge of repair and

retrofitting techniques/ practice

To visit Pagoda dome - this was retrofitted under Heritage restoration

Guiding Faculties :

1) Mrs. Niketa Panchal

2) Dr. AV Thomas

Page

2

DAY 1(SEPTEMBER 18):

VISIT TO BJ WADIA CHILDREN HOSPITAL

On the first day, we visited the Bai Jerbai Wadia Children Hospital which was

built in 1928 and it is a heritage structure under 2-B category and is currently

undergoing extensive repair and retrofitting.

This project is being executed under the consultancy of Structwel Designers and

Consultants Pvt. Ltd. The hospital consists of five blocks A, B, C, D& E.The blocks B,

C & D were undergoing repair work at the time of our visit. The main aim of carrying

out the repair work is to increase the strength of the building while maintaining the same

architectural style and layout.

The building itself is an interesting structure. It is a load bearing structure (G+2).

The buildings looks like it has been made out of Stone Masonry but actually it is

constructed in brick masonry with Ashlar Stone Masonry Cladding. This was done to

give a very appealing architectural view to the building.

The building is made from 400 mm thick brick masonry with 4 inch thick Stone

Cladding. First of all we did External Condition Assessment of the building followed by

Internal Condition Assessment during which we also discussed various tests that were

carried out during the investigation phase and we were also made familiar with the

repair works that were being carried out in the structure.

During the External Condition Assessment, we noticed various distresses in the

structure such as severe cracks due to corrosion of reinforcement, deterioration of RCC

Weathershed (Spalling), CI pipe deterioration, Lintel Cracking (Caused due to corrosion

of Steel Reinforcement), Separation Cracks, Vegetation Growth, Unfinished through

holes for pipes (Potential entry way for water), Discoloration of stone masonry (Caused

due to Weathering).

Page

3

During the Internal Condition assessment, we noticed Spalling of concrete,

delamination, corrosion of steel, Dampness in the structure, Structural Cracksand

settlement of flooring.

We discussed the various tests such as Rebound Hammer Test, Ultrasonic Pulse

Velocity, Carbonation Test, Covermeter / Rebar Locator, Core Sampling and Endoscopy

that were carried out.

The whole structure of the hospital is quite interesting.There were no RCC

columns used. Stub columns and floating columns were used where needed. It consists

of a cantilever Open to sky which is supported by steel girders which are encased in

brick masonry.Also the slabs used in rooms are Pressed Coba type Slabs (8m to 10m

length) which consists only of Steel Girders and MB400 I-Sections and are designed as

per British standards. The passage slab is Simply Supported One Way slab.The ISections used and the design is based on British Standards.The structure also features

Roof Truss.

After performing these tests, a detailed report was generated from the analysis of

the test data. The extent of damage in the structure was graphically represented using

color coding, with each color representing a specific extent of damage.Based on the

extent of damage, the immediate actions to be taken and the type of repair works to be

carried out were suggested.

Based on the suggestions, repair works were being carried out in the structure by

B.N. Mistry Contractors. The repair work consisted of improving the strength of the

structure by providing additional girders to support the structure. The girders provided

for strengthening meticulously follow the original design philosophy of the structure.

Along with providing additional girders, the rust on existing girders and I-sections was

removed by extensive grinding on the top, bottom as well as the sides of the steel

members. After removal of rust, rusticide is applied to prevent any further corrosion

followed by 2 coats of paint. The thickness of the existing flooring in the building is

very high which added a lot of extra weight on the structure. Hence, in order to decrease

the weight on the floor, Foam concrete will be adopted in the flooring. Crack Sealing,

Water Proofing, and Epoxy grouting injection was also being carried out. We learnt that

Page

4

epoxy grouting should be carried out from bottom to top in the same member in order to

increase the efficiency of grouting. Micro-Concreting was also adopted in the structure

for high strength and durability. During the repair work the main aim of using micro

concreting was to give high strength in short period of time.

Later on we had an extensive Q&A session followed by lunch which was

graciously arranged for us by the Contractors. We then headed to our hotel and retired

for the day.

DAY 2 (SEPTEMBER 19):

VISIT TO STRUCTWEL DESIGNERS AND CONSULTANTS PVT. LTD.

Structwel Designers and Consultants is one of the premier consulting companies

in India in the field of Repair and Rehabilitation of structures.

We were given presentations regarding different type of instruments used during

assessment of structure. Along with the presentation we were also given demo of various

instruments used. Patil Sir gave the presentation of the various instruments and Vinayak

sir discussed the various instruments.

We discussed in depth, the Non-Destructive Tests such as Rebound

Hammer Test, Ultra-Sonic Pulse Velocity test, Core Cutting test, Covermeter test,

Carbonation test and Half-Cell Potential Test. We learned about the application,

interpretation and significance of each test.

Schmidt rebound hammer test:-

Page

5

Rebound hammer test is done to find out the compressive strength of concrete by

using rebound hammer as per IS: 13311 (Part 2) 1992. The rebound of an elastic mass

depends on the hardness of the surface against which its mass strikes. When the plunger

of the rebound hammer is pressed against the surface of the concrete, the pringcontrolled mass rebounds and the extent of such a rebound depends upon the surface

hardness of the concrete. The surface hardness and therefore the rebound is taken to be

related to the compressive strength of the concrete. The rebound value is read from a

graduated scale and is designated as the rebound number or rebound index. The

compressive strength can be read directly from the graph provided on the body of the

hammer.

Demonstration of rebound hammer at structwell laboratory

Some important notes:

Minimum number of rebounds for each face = 16

Minimum edge distance

= 25mm

Used only for OPC cement & up to M50 grade concrete.

Page

6

Correlation between rebound number and compressive strength is

given by below graph:

Graph to be used for correlation between rebound number and hardness

Ultrasonic pulse velocity test:This test is done to assess the quality of concrete by ultrasonic pulse

velocity

method

as

per

IS:

13311

(Part

1)

1992.

The method consists of measuring the time of travel of an ultrasonic pulse passing

through the concrete being tested. Comparatively higher velocity is obtained when

concrete quality is good in terms of density, uniformity, homogeneity etc.

Page

7

Demonstration of USVP

criteria for range of USVP

Covermeter:Page

8

This test is done to know the cover provided in the member or the

structure. This instrument is also used to identify the diameter of bar provided in

the member if the design drawings are not available. During the presentation, full

demonstation of how to operate a covermeter was given by vinayak sir.

Thermography:Thermography is used to determine the possible presence of moisture

but the differential thermal temperature when using a thermo graphic instrument

is used.

Page

9

10

Image produced due to thermography

This was followed by a presentation on Advanced Investigation Tools in which we

learned about various new instruments such as Endoscope, Ground Penetrating Radar

(GPR), and Infrared Survey using Thermography Survey.

GPR image & CORE sampling together to understand the structure of the core

Page

10

11

Ground penetrating radar (GPR)

Different diameter of cores by different core cutters

This was followed by snacks and then we visited their Laboratory and got

familiarized with the protocol followed by the company for testing of samples.

Page

11

12

Afterwards we took leave from there and headed to Ultratech Specialty Chemicals

Ltd situated inside Aditya Birla Science and Technology Company Limited, MIDC,

Taloja.

VISIT TO ULTRATECH SPECIALTY CHEMICALS LIMITED

Ultratech Specialty Chemicals Limited is situated inside the Aditya

Birla Science and Technology Company (ABSTC) located at MIDC, Taloja. ABSTC is

the primary R&D facility for the Aditya Birla Group Companies.

Ultratech Specialty Chemicals limited is the R&D Company of Ultratech Cement

Limited.

In the First Session we were given three different presentations.

The First presentation was delivered by Dr. Mohan Medhe. We were familiarized with

the Manufacturing process of Portland cement. We also learned the chemistry of cement

manufacturing. During this presentation a case was discussed that how the Ultratech

Cement Limited lost a tender due to the problem in their own raw material and how the

solved the problem after the detailed study carried out by the available high tech

instruments in their research laboratory.

The Second Presentation familiarized us with the Standards and Specifications in

Cement Manufacturing. We learned how the specifications and standards are met by the

manufacturers and how it relates to the Producer, Seller and Consumer.

Page

12

13

The third presentation was delivered by Dr. Suresh K., which dealt with Problem

Solving in Concrete. We were also familiarized with the research work conducted by the

company regarding the application of Nano technology in the cement industry.

This was followed by a Second Session in which we visited their laboratory and

got acquainted with the state of the art instruments used by the company for their

research work.

Afterwards, we had high tea and snacks after which we headed to our hotel and

retired for the day.

DAY 3 (SEPTEMBER 20)

VISIT TO GLOBAL VIPASSANA PAGODA

On the third and final day of our visit, we checked out from our hotel in the

morning and headed to Global Vipassana Pagoda before leaving for home.

The center of the Global Vipassana Pagoda contains the world's largest stone

dome built without any supporting pillars. The height of the dome is approximately 29

metres. External diameter of the largest section of the dome is 97.46m and the shorter

section is 94.82m. Internal diameter of the dome is 85.15m. The inside of the pagoda is

hollow and serves as a very large meditation hall with an area covering more than 6000

m2 (65,000 ft2). The foundation of the dome consists of basalt, while the dome itself is

made from sandstone imported from Rajasthan. The individual blocks of sandstone

weigh 600700 kg each and are kept in place due to the unique design of the bricks.

Each of the bricks interlock with the ones adjacent to it and lime mortar is used to fill in

Page

13

14

any remaining gaps. The top keystone itself weighs 10 tons.The whole dome is

supported by a ring beam which holds the structure in place.

The spire of the dome is covered in real gold, while the rest of the pagoda is

covered in gold paint. The spire is topped with a special ornamental umbrella piece

donated by the Burmese. The main doors to the pagoda are wooden and hand-carved in

Myanmar. After wards, we spent some leisure time on the beach and then headed

towards our hometown.

Page

14

15

CONCLUSION:

This site visit was an enriching experience and we gained a lot of knowledge

onthe engineering practices and current trends in the field of Repair and Rehabilitation

of Structures. We got a huge amount of exposure to the current industrial practices being

followed in this sector. The involvement and enthusiasm of Mrs. Niketa Panchal and Dr.

AV Thomas was immense and really commendable. I heartily thank Niketa Panchal

mam for arranging such an extraordinary visit.

Page

15

Anda mungkin juga menyukai

- Concrete and asphalt aggregate element chartDokumen4 halamanConcrete and asphalt aggregate element chartsaber2s22ahmadBelum ada peringkat

- 12 Form WorkDokumen7 halaman12 Form WorkAkhilesh KumarBelum ada peringkat

- Earthworks Subfolder PK 61.30 - PK 75 - 14th July 2021 En.Dokumen546 halamanEarthworks Subfolder PK 61.30 - PK 75 - 14th July 2021 En.Adrian FrantescuBelum ada peringkat

- 30.99.97.1616 Rev. 1 - ITP For Civil WorksDokumen26 halaman30.99.97.1616 Rev. 1 - ITP For Civil Worksshajahan eBelum ada peringkat

- Civil Works Inspection and Test PlanDokumen6 halamanCivil Works Inspection and Test PlanWalid AmdouniBelum ada peringkat

- QCP - BuildingsDokumen4 halamanQCP - BuildingsMitendra Kumar ChauhanBelum ada peringkat

- CH - Ash Pond Lining With Geomembrane, NelloreDokumen3 halamanCH - Ash Pond Lining With Geomembrane, NellorePa Dadang0% (1)

- Qap PDFDokumen11 halamanQap PDFNirajan MarwaitBelum ada peringkat

- Mitp For Surveying Setting Out ApprovedDokumen4 halamanMitp For Surveying Setting Out ApprovedMogu MohanBelum ada peringkat

- Central Expressway ConstructionDokumen23 halamanCentral Expressway ConstructionJayaratneBelum ada peringkat

- EXW P006 0000 MQ SHC MS 00024 SubmittalDokumen47 halamanEXW P006 0000 MQ SHC MS 00024 SubmittalRaheelHashmiBelum ada peringkat

- Yjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654knDokumen56 halamanYjack - Ms 20170211 - BD For Bp600mm Wl2827kn Tl5654knKS Lee100% (1)

- Initial Pile Load Test Report - TP 3Dokumen11 halamanInitial Pile Load Test Report - TP 3skumarsr100% (1)

- Checklist For RE Wall InspectionDokumen1 halamanChecklist For RE Wall InspectionsanilBelum ada peringkat

- Precast Post-Tensioned Beam Construction MethodDokumen13 halamanPrecast Post-Tensioned Beam Construction MethodMAYMODERN STEELBelum ada peringkat

- INSPECTION AND TESTING PLANDokumen2 halamanINSPECTION AND TESTING PLANjitendraBelum ada peringkat

- FP - Method of Statement - Al PheniqDokumen9 halamanFP - Method of Statement - Al PheniqelbaraniBelum ada peringkat

- S.O.R. Bridge WorksDokumen48 halamanS.O.R. Bridge WorksUmar KarimiBelum ada peringkat

- Soil Investigation and Topographical Works RFPDokumen5 halamanSoil Investigation and Topographical Works RFPRiko Bin ZulkifliBelum ada peringkat

- Method Statement - Post Tensioning WorksDokumen15 halamanMethod Statement - Post Tensioning WorksMirzojon MirzoevBelum ada peringkat

- NCR 060816Dokumen2 halamanNCR 060816David Web0% (1)

- Tdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)Dokumen1 halamanTdoc 014 REV.01 - ITP FOR EXCAVATION & COMPACTION (ITP 002)mBelum ada peringkat

- J910-DH02-P0ZEN-049002 - B - ITP For Fence and GateDokumen12 halamanJ910-DH02-P0ZEN-049002 - B - ITP For Fence and GateAdrianus Hindradjaja100% (2)

- 06-Earthwork in ExcavationDokumen7 halaman06-Earthwork in ExcavationAkhilesh KumarBelum ada peringkat

- Checklist-Structural Concrete Post PouringDokumen1 halamanChecklist-Structural Concrete Post Pouringajit karandikarBelum ada peringkat

- M.S & R.S For Soil Investigation WorksDokumen14 halamanM.S & R.S For Soil Investigation WorksAL BASTAKI CONTRACTING L.L.C.100% (1)

- Piling and Foundation Works for Multipurpose Warehouse and Bulk Warehouse - Phase II at Arshiya Northern FTWZ Limited Thurga Hist Bulandshahar Uttar PradeshDokumen4 halamanPiling and Foundation Works for Multipurpose Warehouse and Bulk Warehouse - Phase II at Arshiya Northern FTWZ Limited Thurga Hist Bulandshahar Uttar PradeshAjay MalikBelum ada peringkat

- Excavation Work ProcedureDokumen11 halamanExcavation Work ProcedureResearcher100% (1)

- Checklist For Fence Work Rev.2Dokumen9 halamanChecklist For Fence Work Rev.2Ikhsan BakhrullohBelum ada peringkat

- Cico QapDokumen126 halamanCico QapAdrian FrantescuBelum ada peringkat

- KOC-CGCC-BRANTON-GC15 Test Package DocumentsDokumen13 halamanKOC-CGCC-BRANTON-GC15 Test Package DocumentsVISHNUPRASAD ARAKKAL MOHANDASBelum ada peringkat

- Procedure - Concrete Pouring & CuringDokumen12 halamanProcedure - Concrete Pouring & CuringjabpunBelum ada peringkat

- SOP RoadsDokumen207 halamanSOP RoadsPratik Raj MishraBelum ada peringkat

- Environmental Management PlanDokumen38 halamanEnvironmental Management PlanRayBelum ada peringkat

- Mix Design M-25 GradeDokumen9 halamanMix Design M-25 Gradeenjoy begening lifeBelum ada peringkat

- MS Format-Tata Projects HosurDokumen19 halamanMS Format-Tata Projects HosurSukhdeb BiswakarmaBelum ada peringkat

- Itp Transfer Tower - Xls (Bvi Comment)Dokumen52 halamanItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoBelum ada peringkat

- Inspection & Testing Plan For AggregatesDokumen2 halamanInspection & Testing Plan For Aggregatesjerin sam kurian100% (1)

- METHOD - STATEMENT - FOR D Wall and Guide WallDokumen6 halamanMETHOD - STATEMENT - FOR D Wall and Guide WalldhruvBelum ada peringkat

- RV RAN GTI 412 1 Rev 1Dokumen46 halamanRV RAN GTI 412 1 Rev 1BIPL REPORTBelum ada peringkat

- Method Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)Dokumen11 halamanMethod Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)MAYMODERN STEEL100% (1)

- ITP For Pile Splicing Work & Miscellaneous WorkDokumen3 halamanITP For Pile Splicing Work & Miscellaneous WorkMuthu Barathi ParamasivamBelum ada peringkat

- Sew Infrastructutre LTD: Calibration of Sand Pouring CylinderDokumen1 halamanSew Infrastructutre LTD: Calibration of Sand Pouring CylinderRayudu VVSBelum ada peringkat

- Larsen & Toubro Limited Grouting SpecificationDokumen11 halamanLarsen & Toubro Limited Grouting Specificationirshad khanBelum ada peringkat

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDokumen16 halamanRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanBelum ada peringkat

- Quality Assurance PlanDokumen14 halamanQuality Assurance PlanBiswasBelum ada peringkat

- Method Statement - PilingDokumen65 halamanMethod Statement - PilingNaseer IsmailBelum ada peringkat

- MS For Chamber ConstructionDokumen17 halamanMS For Chamber ConstructionWilliam C. Pasamonte100% (1)

- 3009 - Method Statement For Administration Building Construction PDFDokumen38 halaman3009 - Method Statement For Administration Building Construction PDFNjilou LagaticBelum ada peringkat

- Geotechnical Report - PreliminaryDokumen29 halamanGeotechnical Report - PreliminaryAyoola OluwadotunBelum ada peringkat

- MS For Survey Works (Draft) R5Dokumen47 halamanMS For Survey Works (Draft) R5Tegar Pilar RamadhanBelum ada peringkat

- YJACK - MS 20170211 - BD For BP600mm WL2827kN TL5654kN (Yjackpiletest@Gmail - Com)Dokumen55 halamanYJACK - MS 20170211 - BD For BP600mm WL2827kN TL5654kN (Yjackpiletest@Gmail - Com)KS Lee100% (1)

- Blockwork and Plastering - HalulDokumen14 halamanBlockwork and Plastering - HalulDindo QuintanBelum ada peringkat

- Cb2 Q Zen 05 60211 Itp For Earth Work - Rev.bDokumen6 halamanCb2 Q Zen 05 60211 Itp For Earth Work - Rev.bAnonymous wIPMQ5rhBelum ada peringkat

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDokumen2 halamanQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialBelum ada peringkat

- 2111-122-QVC-G-001 - Civil Works FQP For DSTPS FGD Package-Proposed PDFDokumen22 halaman2111-122-QVC-G-001 - Civil Works FQP For DSTPS FGD Package-Proposed PDFMANNABelum ada peringkat

- PCC WorksDokumen4 halamanPCC WorksRounak MaheshwariBelum ada peringkat

- Kalyani Expressway RFPDokumen116 halamanKalyani Expressway RFPAjay JainBelum ada peringkat

- Report On Plate Load Test Along With Trial Pit: Project Name Repowering Project of Ghorasal Unit #3Dokumen12 halamanReport On Plate Load Test Along With Trial Pit: Project Name Repowering Project of Ghorasal Unit #3Mehedi HasanBelum ada peringkat

- After Fire ForensicDokumen8 halamanAfter Fire ForensicJun CrisostomoBelum ada peringkat

- Bio-Filtration For Air Pollution Control: M.Tech. Environmental Engineering Seminar - IiDokumen25 halamanBio-Filtration For Air Pollution Control: M.Tech. Environmental Engineering Seminar - IiKaushal PatelBelum ada peringkat

- Research Paper PDFDokumen7 halamanResearch Paper PDFKaushal PatelBelum ada peringkat

- (Research Paper) KaushalDokumen7 halaman(Research Paper) KaushalKaushal PatelBelum ada peringkat

- Final CO2 Capture and Storage (CCS)Dokumen34 halamanFinal CO2 Capture and Storage (CCS)Kaushal PatelBelum ada peringkat

- Sanitary System of Chandigarh1 PDFDokumen11 halamanSanitary System of Chandigarh1 PDFKaushal PatelBelum ada peringkat

- Legislative Power of GovernorDokumen14 halamanLegislative Power of GovernorKaushal PatelBelum ada peringkat

- Bio Filtration For Air Pollution ControlDokumen19 halamanBio Filtration For Air Pollution ControlKaushal Patel80% (5)

- Requirement of Effective Project Report and It EconomicDokumen10 halamanRequirement of Effective Project Report and It EconomicKaushal PatelBelum ada peringkat

- Kaushal - Pneumonia DiseaseDokumen10 halamanKaushal - Pneumonia DiseaseKaushal PatelBelum ada peringkat

- Final CO2 Capture and Storage (CCS)Dokumen34 halamanFinal CO2 Capture and Storage (CCS)Kaushal PatelBelum ada peringkat

- Comparision Od swm1 PDFDokumen26 halamanComparision Od swm1 PDFKaushal PatelBelum ada peringkat

- Karamsad Report1 PDFDokumen14 halamanKaramsad Report1 PDFKaushal PatelBelum ada peringkat

- Solid Waste Management in Vallabh VidhyanagarDokumen16 halamanSolid Waste Management in Vallabh VidhyanagarKaushal PatelBelum ada peringkat

- Oil Refinery Industry1 PDFDokumen12 halamanOil Refinery Industry1 PDFKaushal PatelBelum ada peringkat

- Light and VentilationDokumen25 halamanLight and VentilationKaushal PatelBelum ada peringkat

- 11 GroundwaterDokumen13 halaman11 GroundwaterKaushal PatelBelum ada peringkat

- TEXTILE INDUSTRY Report PDFDokumen12 halamanTEXTILE INDUSTRY Report PDFKaushal PatelBelum ada peringkat

- Automobile PollutionDokumen23 halamanAutomobile PollutionKaushal Patel100% (3)

- A Training Report PresentationDokumen22 halamanA Training Report PresentationKaushal PatelBelum ada peringkat

- Sanitary System of Chandigarh1 PDFDokumen11 halamanSanitary System of Chandigarh1 PDFKaushal PatelBelum ada peringkat

- Kaushal - Pneumonia DiseaseDokumen10 halamanKaushal - Pneumonia DiseaseKaushal PatelBelum ada peringkat

- Management Study BookDokumen30 halamanManagement Study BookKaushal PatelBelum ada peringkat

- Automobile PollutionDokumen23 halamanAutomobile PollutionKaushal Patel100% (3)

- Project ReportDokumen18 halamanProject ReportKaushal PatelBelum ada peringkat

- Management Study BookDokumen30 halamanManagement Study BookKaushal PatelBelum ada peringkat

- Rainwater HarvestingDokumen98 halamanRainwater HarvestingKaushal Patel100% (2)

- Automobile PollutionDokumen28 halamanAutomobile PollutionKaushal PatelBelum ada peringkat

- Rainwater HarvestingDokumen52 halamanRainwater HarvestingKaushal Patel100% (1)

- Training ReportDokumen119 halamanTraining ReportKaushal PatelBelum ada peringkat

- Assignment 2Dokumen2 halamanAssignment 2Hashir AmeenBelum ada peringkat

- Distribution System Grounding FundamentalsDokumen17 halamanDistribution System Grounding FundamentalsJose Alberto RodriguezBelum ada peringkat

- Bearing CapacityDokumen20 halamanBearing CapacityAbdirizak HussienBelum ada peringkat

- Project Dossier: Main IndexDokumen11 halamanProject Dossier: Main IndexAbdullah Javed100% (1)

- Circuitos Electroneumaticos NewDokumen29 halamanCircuitos Electroneumaticos NewDaniel PantojaBelum ada peringkat

- Mohammed Nasir Iqbal Senior Mechanical Engineer: PersonalinformationDokumen4 halamanMohammed Nasir Iqbal Senior Mechanical Engineer: PersonalinformationMohd HaroonBelum ada peringkat

- White Book C04 S05 Partitions GypWall QUIET SFDokumen33 halamanWhite Book C04 S05 Partitions GypWall QUIET SFPavaloaie Marian ConstantinBelum ada peringkat

- Fatigue Analysis GuideDokumen17 halamanFatigue Analysis GuideAna RuxandraBelum ada peringkat

- Aplication Pipe and Tube - Nippon SteelDokumen29 halamanAplication Pipe and Tube - Nippon Steelmatheus david100% (1)

- Abb K6 22Z 01Dokumen2 halamanAbb K6 22Z 01YudhaPrawiraBelum ada peringkat

- Lrbics ManualDokumen146 halamanLrbics ManualOdessa Fortu Landicho75% (4)

- FTA QualityAssurance QualityControl GuidelinesDokumen278 halamanFTA QualityAssurance QualityControl GuidelinesViky Asolibe AmaBelum ada peringkat

- Functions of An EngineerDokumen4 halamanFunctions of An EngineerKurt Francis AcostaBelum ada peringkat

- Presentation 20859 SIM20859 Potts AU2016Dokumen39 halamanPresentation 20859 SIM20859 Potts AU2016Sony JsdBelum ada peringkat

- Killeshal Lintels SpecificationDokumen4 halamanKilleshal Lintels Specificationgdug27Belum ada peringkat

- Heap Leach Facility Liner Design - LupoDokumen25 halamanHeap Leach Facility Liner Design - LupoAbraham FIgueroa ARevaloBelum ada peringkat

- Acm C A03: Project Management Systems and TechniquesDokumen77 halamanAcm C A03: Project Management Systems and Techniquesben hurBelum ada peringkat

- ASME Y14-24 99 Types y Aplications of Engineering DrawingsDokumen83 halamanASME Y14-24 99 Types y Aplications of Engineering DrawingsAlex Bolaños100% (1)

- Method of Statement Plumbing WorksDokumen3 halamanMethod of Statement Plumbing Workshasan_6764896160% (1)

- Unit-1 Value EngineeringDokumen4 halamanUnit-1 Value Engineering2K21 B652Anand JhaBelum ada peringkat

- Plain & Reinforced Concrete-1: Lecture # 1Dokumen48 halamanPlain & Reinforced Concrete-1: Lecture # 1Adil Javed Chaudhary100% (1)

- Safety Standard For Belt Manlifts: ASME A90.1-2009Dokumen34 halamanSafety Standard For Belt Manlifts: ASME A90.1-2009Marko's Brazon'Belum ada peringkat

- Fan VibrationDokumen8 halamanFan Vibrationlafondejs100% (1)

- Summer Training Project Report - PLCDokumen28 halamanSummer Training Project Report - PLCNitish Bhardwaj84% (19)

- Circular Slabs - PpsDokumen19 halamanCircular Slabs - PpssrivaruniBelum ada peringkat

- wwwww123 PDFDokumen4 halamanwwwww123 PDFChandu CKBelum ada peringkat

- Rio Tinto Alcan Gove G3 Experience On Pre-Assembled ModulesDokumen5 halamanRio Tinto Alcan Gove G3 Experience On Pre-Assembled ModulesRogerio CannoniBelum ada peringkat

- Marshall Test 2x75 TumbukanDokumen10 halamanMarshall Test 2x75 TumbukanMalik AzizBelum ada peringkat

- Instrument Air SupplyDokumen8 halamanInstrument Air SupplyMohammad Amini100% (1)