Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erection

Diunggah oleh

eldobie3Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erection

Diunggah oleh

eldobie3Hak Cipta:

Format Tersedia

Code

I.E.M.S.A

Inspection And Test

Plan For Piping

UAN (for QMHA)

Page

11-3090

1 of 5

INSPECTION AND TEST PLAN FOR

PIPING FABRICTION AND ERECTION

ACCORDING TO THE UHDE SPECIFICATION

Owner

: ENPC

Main contractor : Uhde

Project name

: AMMONIA UREA PROJECT

S : Surveillance

W : Witness

H : Hold

R : Report Review

A : Approval

00

First Issue

11/6/2010

Emad Omar

11/6/2010

Hassan Basha

Rev

Status

Description

Date

Prepared

Date

Checked

CC Category Code:

1 = for approval

2 = for review

3 = for information

4 = for internal use

AC Acceptance Code:

1 = approved / reviewed

2 = approved / reviewed as

noted

3 = not accepted

4 = received

Status Code:

A = Issued for Design

D = Issued for Inquiry

E = Issued for Order

F = Issued for Prefabrication

G = Issued for Construction /

Fabrication

H = Issue for Work

Preparation

I = As- built

Date

Approved

Acc.

Space for Bar Code label

M = General Issue

Copyright 2007 Uhde GmbH

Doc. ID-Code

PT-BM-G00-DC-00101

Category

1

Code

Inspection and test

plan for Piping

I.E.M.S.A

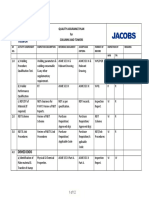

Ser

no.

Activates

Inspe

ction

%

Respon

sible

Control description

ENPC

IEMSA

UAN (for QMHA)

Page

11-3090

2 of 5

PTJ

UHDE

ENPC

W/R

W/R

W/R

W/R

W/R

R/A

R/A

All Members

Check level , orientation,

Verticality & Dimension

Check Parameter and WPS and

Statement

100

%

Control description and

dimension for DWG

100

%

100

%

100

%

Check construction Dwg. Revs

Check shop Dwg. Revs.

H

H

R

R

R

R

S

S

Remarks

1 - Qualification Of Welding Procedures

1.1

WPS

WPSs documents

1.2

Supported PQR

1.3

Issue All The Final

WPS's AND PQR'S

FOR Production

Welding Samples According to

WPS'S then NDT & If Accepted

then Mechanical Tests in

Approved Lab

Review and approve the

mechanical test reports and

procedure, qualification Records

2.1

Welder

Qualification

Make tests witnessed main

contractor

2.2

Welder

Certification

3.1

Receiving

Material From

Main

Contractor

Store

100

%

QC dep.

2 - Welders Qualification

100

%

Review The Qualification Record

QC dep.

Issue ID & Certificate

3 Material control

3.2

100

%

Material

traceability

Visual Inspection

Material

controll

er

Be Sure That Materials

Identification are Stamped or

Marked on All Parts

Report Will Be Attached To Each

be Identify The Heat Numbers

For All Parts

Mat.

Controll

er & QC

dep.

4 - Piping Supports

4.1

Drawings

4.2

Fit up

4.3

Erection

4.4

Welding

4.5

NDT

4.6

Repair

4.7

Dimension check

after welding

100

%

100

%

Check construction DWG. Revs

Tech.

Office

Check shop Dwg. Revs.

Check Weld Map & WPS

NDT

scop

e

100

%

QC dep.

Perform Required NDT

5 - Prefabrication Piping

5.1

Drawings

5.2

Fit up

5.3

Welding

5.4

NDT

NDT

SCOP

E

5.5

Repair

100

%

PWHT (if

required)

Proje

ct

5.6

Copyright 2007 Uhde GmbH

All Members

Tech.

Office

QC dep.

Check Weld Map & WPS

Welding Parameters

H

H

W

W

S/R

S

S

S

Perform Required NDT

W/R

Check Parameter , WPS and

statement

Check Parameter and Chart

Doc. ID-Code

PT-BM-G00-DC-00101

Rev.

00

Code

I.E.M.S.A

Ser

no.

5.7

5.8

5.9

5.1

0

Activates

NDT after PWHT

Inspe

ction

%

requir

e

ment

Inspection and test

plan for Piping

Respon

sible

Control description

ENPC

UAN (for QMHA)

Page

11-3090

3 of 5

IEMSA

PTJ

UHDE

ENPC

W/R

R/A

All Members

Check Weld Map & WPS

Welding Parameters

W/R

R/A

Check Parameter , WPS and

statement

Check Parameter and Chart

S/R

R/A

Perform Required NDT

W/R

R/A

Perform Required NDT

Repair after

PWHT (if any)

Dimension check

after welding

100

%

Check Parameter and WPS

and statement

Control description and

dimension for DWG

Release for

painting

100

%

Check that all required NDT

are Carried Out

Remarks

6- Site ( Field ) Activities

6.1

Install pipes or

spools

100

%

Adjust spools location.

Dimension , level and fit up of

field joints

Choose the suitable WPS to be

used

Check Field Weld Parameter

6.2

Fit up

100

%

100

%

NDT

scop

e

100

%

6.3

Welding

6.4

NDT

6.5

Repair

6.6

PWHT (if

required)

6.7

NDT after PWHT

Code

requir

e

ment

6.8

Repair after

PWHT (if any)

100

%

Check Parameter and WPS

and statement

6.9

Dimension check

after welding

100

%

Control description and

dimension for DWG

Inspect and approve

Check calibration certificates

Review operator qualification

W/R

W/R

QC dep.

Perform Required NDT

7 NDT

100

%

7.1

Test Equipment

7.2

NDT Operators

( UT, RT, MT,PT&

Hardness)

7.3

NDT After Joint

Weld Out

100

%

RT, UT, MT and PT, or

combination as per NDT Scope

7.4

NDT After PWHT

(When PWHT is

Required

100

%

UT, MT as indicated on weld

marks Dwg's and project

procedures + Hardness.

W/R

W/R

7.5

NDT after repair

NDT

scop

e

Perform as original test

W/R

W/H

Copyright 2007 Uhde GmbH

QC dep.

Doc. ID-Code

PT-BM-G00-DC-00101

Rev.

00

Code

I.E.M.S.A

Ser

no.

Activates

Inspe

ction

%

Inspection and test

plan for Piping

Respon

sible

Control description

ENPC

IEMSA

UAN (for QMHA)

Page

11-3090

4 of 5

PTJ

UHDE

ENPC

Remarks

8- PWHT (If Required)

8.1

Equipment

100

%

Inspect and approve

8.2

Release for PWHT

100

%

Check that all required NDT

are carried out

Check member suitably

supported

8.3

Before treatment

100

%

8.4

During treatment

Rand

om

8.5

After treatment

100

%

W/R

Verify parameters

Sign off and review chart

Check calibration certificates

Check thermocouple quantity

and locations

PWHT

ENG.

Check pads and insulation

Prevent Machine Faces with

dexoy paint

Sign on chart

9-Pressure Test

9.1

Test Equipment

9.2

Release for

Hydro test

9.3

Before Test

100

%

100

%

100

%

Inspect and approve

Check calibration certificates

S/R

Approved Test Package

S/R

S/R

H/R

Review test package

R/A

Confirm pressuring up time

Confirm test pressure

Check for leaks

Confirm test duration

Confirm depressurization

rate

Sign off and review chart

Confirm reinstatement of

removed items

H

H

H

W

W

W

W

W

S

W

W

W

H

H

H

W

W

H

S

S

W/R

S

S

W/R

Confirm pre-test inspection is

complete including test media

Check vents and drains

Confirm item removals /for

test purposes

Confirm test limits

Sign on chart

9.4

During test

100

%

100

%

9.5

After test

10.

1

10.

2

10.

3

Fit up

NDT

NDT

SCOP

E

10.

4

PWHT (if

required)

Proje

ct

Hydro

test

Eng.

10- Golden joint

Welding

100

%

100

%

Copyright 2007 Uhde GmbH

All Members

Check Weld Map & WPS

Welding Parameters

Perform Required NDT

-100% visual inspection for

every pass

- Perform PT after root and

hot pass

-Perform PT on cap

-Perform RT or UT (After PWHT

if required)

Check Parameter and Chart

QC dep.

Doc. ID-Code

PT-BM-G00-DC-00101

Rev.

00

Code

I.E.M.S.A

Ser

no.

10.

5

Activates

NDT after PWHT

Inspe

ction

%

requir

e

ment

Copyright 2007 Uhde GmbH

Inspection and test

plan for Piping

Control description

Perform Required NDT

Respon

sible

ENPC

UAN (for QMHA)

Page

11-3090

5 of 5

IEMSA

PTJ

UHDE

ENPC

W/R

R/A

Doc. ID-Code

PT-BM-G00-DC-00101

Remarks

Rev.

00

Anda mungkin juga menyukai

- Larsen & Toubro underground piping inspection planDokumen4 halamanLarsen & Toubro underground piping inspection planBhavani PrasadBelum ada peringkat

- 4 1 - 16 10 Lws Preventers Installation and OperationDokumen28 halaman4 1 - 16 10 Lws Preventers Installation and Operationcrni roko100% (1)

- ITP-001 Steelwork Fabrication Rev ADokumen5 halamanITP-001 Steelwork Fabrication Rev AMarcus Cox100% (2)

- Itr Ew 01a - EngDokumen2 halamanItr Ew 01a - Engwassim nasriBelum ada peringkat

- Sample QAPDokumen3 halamanSample QAPsniperiBelum ada peringkat

- Saudi Aramco Welding Consumables ChecklistDokumen5 halamanSaudi Aramco Welding Consumables ChecklistAnsuman KalidasBelum ada peringkat

- Method Statement: Al-Khafji FDP Phase-I Onshore FacilitiesDokumen8 halamanMethod Statement: Al-Khafji FDP Phase-I Onshore FacilitiesSiddiqui Muhammad AshfaqueBelum ada peringkat

- Repair and Modification ITPDokumen8 halamanRepair and Modification ITPShewale PravinBelum ada peringkat

- Training The ABC's of Perfumery: Stephen V. Dowthwaite PerfumersWorldDokumen27 halamanTraining The ABC's of Perfumery: Stephen V. Dowthwaite PerfumersWorldSteve100% (16)

- ITP Format For New PVDokumen8 halamanITP Format For New PVDavid LambertBelum ada peringkat

- ITP Heat ExchangerDokumen1 halamanITP Heat Exchangersarmad009Belum ada peringkat

- PT BM 183 DC 00005 VT ProcedureDokumen6 halamanPT BM 183 DC 00005 VT Procedureeldobie3Belum ada peringkat

- Weld Repair ProcedureDokumen15 halamanWeld Repair Proceduremohd as shahiddin jafriBelum ada peringkat

- X-Ray Room Setup Method StatementDokumen19 halamanX-Ray Room Setup Method StatementJervino RuahBelum ada peringkat

- Inspection and Test Plan For Piping (PP/FRP Piping)Dokumen2 halamanInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDokumen13 halamanSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289Belum ada peringkat

- 30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingDokumen21 halaman30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingkilioBelum ada peringkat

- Quality Assurance PlanDokumen6 halamanQuality Assurance Planvkrishnamoorthy100% (2)

- ItpDokumen7 halamanItpJose Sherin100% (1)

- Fit Up ReportDokumen41 halamanFit Up ReportFendik NewbieBelum ada peringkat

- Hydraulic Seal PDFDokumen88 halamanHydraulic Seal PDFharoldBelum ada peringkat

- QW 406 Asme CodeDokumen3 halamanQW 406 Asme CodeMardeOpamenBelum ada peringkat

- Rotating Itp 1Dokumen4 halamanRotating Itp 1abdul aziz100% (1)

- Hydrotesting of PipelineDokumen14 halamanHydrotesting of PipelineJWC Sales & Services :100% (1)

- MIP17-MS-2012 Method Statement For Fabrication and Installation of PipingDokumen23 halamanMIP17-MS-2012 Method Statement For Fabrication and Installation of PipingAmeerHamzaWarraichBelum ada peringkat

- WPS Pipe 08'' SHD 40 SMAW REV02Dokumen2 halamanWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejBelum ada peringkat

- Piping Fabrication Installation QCP On SiteDokumen1 halamanPiping Fabrication Installation QCP On SiteTarun PatelBelum ada peringkat

- Jurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover SheetDokumen14 halamanJurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover Sheettomj9104Belum ada peringkat

- Contractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationDokumen5 halamanContractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationSergey KichenkoBelum ada peringkat

- FInal QAP HDPE WeldingDokumen2 halamanFInal QAP HDPE Weldingkannagi198Belum ada peringkat

- NDE PROCESS CONTROL Rev 1Dokumen15 halamanNDE PROCESS CONTROL Rev 1eldobie3Belum ada peringkat

- NRP QapDokumen10 halamanNRP QapKevin Mathew100% (1)

- Id35 Honda GX630 GX660 GX690Dokumen20 halamanId35 Honda GX630 GX660 GX690RodrigoChaves0% (1)

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDokumen1 halamanField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoBelum ada peringkat

- Fit-Up Preparation and Acceptance Criteria As Per Project RequirementsDokumen6 halamanFit-Up Preparation and Acceptance Criteria As Per Project RequirementsAbdülHak ÖZkaraBelum ada peringkat

- Method Statement For For Cable Tray and Conduit Installation With Risk AssesmentDokumen9 halamanMethod Statement For For Cable Tray and Conduit Installation With Risk Assesmentobasiigwe8499Belum ada peringkat

- Precision Storage Vessels PVT LTD: Pressure Test ReportDokumen2 halamanPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Pressure Vessel ITP Rev 0Dokumen10 halamanPressure Vessel ITP Rev 0SLC HosurBelum ada peringkat

- Cooling Gel Safety ReportDokumen15 halamanCooling Gel Safety ReportJacek Stanislawski100% (1)

- Spec - WeldingDokumen6 halamanSpec - Weldingprasad_kcpBelum ada peringkat

- Material Inspection Report: Project Name Date InspDokumen22 halamanMaterial Inspection Report: Project Name Date InspRafiqKuBelum ada peringkat

- WPS - Smaw - 2Dokumen6 halamanWPS - Smaw - 2Harkesh RajputBelum ada peringkat

- API 510 PC Final Exam ClosedDokumen12 halamanAPI 510 PC Final Exam ClosedAbdel-Rahman Taha Merdan100% (1)

- PT BM 183 DC 00007 PWHT ProcedureDokumen7 halamanPT BM 183 DC 00007 PWHT Procedureeldobie3100% (1)

- PT BM 183 DC 00006 Ut ProcedureDokumen6 halamanPT BM 183 DC 00006 Ut Procedureeldobie3Belum ada peringkat

- OneSteel Pipe Fittings CatalogueDokumen48 halamanOneSteel Pipe Fittings Cataloguebmacavanza100% (6)

- Mechanical and Piping Inspector HDokumen3 halamanMechanical and Piping Inspector HHafiz Shabbir HussainBelum ada peringkat

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Dokumen4 halamanInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaBelum ada peringkat

- Pt-bm-183-Dc-00009 Welding Consumable Handling & StorageDokumen6 halamanPt-bm-183-Dc-00009 Welding Consumable Handling & Storageeldobie3Belum ada peringkat

- PT BM 183 DC 00008 Preheat ProcedureDokumen5 halamanPT BM 183 DC 00008 Preheat Procedureeldobie3Belum ada peringkat

- Checklist For Fabrication & Erection of Structural Steel WorkDokumen1 halamanChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuBelum ada peringkat

- 1.13 Inspection & Test PlansDokumen1 halaman1.13 Inspection & Test Plansabimanyubawono100% (2)

- Wps For Smaw06-001 (Pipe 6g CS)Dokumen10 halamanWps For Smaw06-001 (Pipe 6g CS)walitedisonBelum ada peringkat

- 2.8.2. Indicative QAP - ColumnsDokumen12 halaman2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- QC FORMDokumen3 halamanQC FORMRicardo LourençoBelum ada peringkat

- Painting & Inspection FormatDokumen1 halamanPainting & Inspection FormatABEC Trombay siteBelum ada peringkat

- RFI For 18.03.2014 Piping, Welding at SESA FabDokumen4 halamanRFI For 18.03.2014 Piping, Welding at SESA Fabmuhammedemraan100% (1)

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDokumen12 halamanSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Shaik Yousufuddin (Welding Inspector)Dokumen3 halamanShaik Yousufuddin (Welding Inspector)Mohamed AdelBelum ada peringkat

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDokumen10 halamanFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- QCP 040 QCP CrmsDokumen7 halamanQCP 040 QCP Crmsarockiyathass100% (1)

- Hydraulic crash barriers ITPDokumen4 halamanHydraulic crash barriers ITPmoytabura96Belum ada peringkat

- Offshore Marinetech PVT - LTD: Electrode Baking RegisterDokumen3 halamanOffshore Marinetech PVT - LTD: Electrode Baking RegisterPrathamesh OmtechBelum ada peringkat

- ITP Plan - FF PDFDokumen7 halamanITP Plan - FF PDFAltaf KhanBelum ada peringkat

- Hydrotest QI304-sampleDokumen3 halamanHydrotest QI304-sampleHanuman Rao100% (1)

- Pneumatic Test ProcedureDokumen3 halamanPneumatic Test Procedurevijay padale50% (2)

- Transmittal SampleDokumen1 halamanTransmittal SamplekokocdfBelum ada peringkat

- Wps Mig PDF FreeDokumen3 halamanWps Mig PDF Freehanz bermejoBelum ada peringkat

- ITP For Mild Steel Pipe WorksDokumen4 halamanITP For Mild Steel Pipe WorksKumar AbhishekBelum ada peringkat

- Chemical Resistance (LLDPE) PDFDokumen24 halamanChemical Resistance (LLDPE) PDFrubyshreeBelum ada peringkat

- Field Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectDokumen12 halamanField Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectbasukiBelum ada peringkat

- Itp - 002 - Duct Installation - IfrDokumen3 halamanItp - 002 - Duct Installation - IfrMari BelajarBelum ada peringkat

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDokumen14 halamanPPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqBelum ada peringkat

- Ogpd-Lrf-Tr-00336 Tie-In Procedure ApproveDokumen2 halamanOgpd-Lrf-Tr-00336 Tie-In Procedure Approveeldobie3Belum ada peringkat

- Method of Statement For Hydro Test ProcedureDokumen11 halamanMethod of Statement For Hydro Test Procedureeldobie3100% (1)

- Process Control of TemperatureDokumen1 halamanProcess Control of Temperatureeldobie3Belum ada peringkat

- Pene Trant Testing MaterialsDokumen3 halamanPene Trant Testing Materialseldobie3Belum ada peringkat

- Emulsifier SDokumen2 halamanEmulsifier Seldobie3Belum ada peringkat

- Pene Trant Removal ProcessDokumen3 halamanPene Trant Removal Processeldobie3Belum ada peringkat

- Pen Et RantsDokumen1 halamanPen Et Rantseldobie3Belum ada peringkat

- Dimensional Threshold of FluorescenceDokumen2 halamanDimensional Threshold of Fluorescenceeldobie3Belum ada peringkat

- Preparing Parts for Penetrant InspectionDokumen2 halamanPreparing Parts for Penetrant Inspectioneldobie3Belum ada peringkat

- Introduction and History of Penetrant Inspection: Capillary ActionDokumen1 halamanIntroduction and History of Penetrant Inspection: Capillary Actioneldobie3Belum ada peringkat

- Nature of The DefectDokumen3 halamanNature of The Defecteldobie3Belum ada peringkat

- Developers: Developer FormsDokumen3 halamanDevelopers: Developer Formseldobie3Belum ada peringkat

- Color and Fluorescent BrightnessDokumen2 halamanColor and Fluorescent Brightnesseldobie3Belum ada peringkat

- Common Uses of Liquid Pene Trant InspectionDokumen2 halamanCommon Uses of Liquid Pene Trant Inspectioneldobie3Belum ada peringkat

- Common Uses of Liquid Pene Trant InspectionDokumen2 halamanCommon Uses of Liquid Pene Trant Inspectioneldobie3Belum ada peringkat

- PT BM 183 DC 00001 Itp BoilerDokumen5 halamanPT BM 183 DC 00001 Itp Boilereldobie30% (1)

- Density or Specific GravityDokumen1 halamanDensity or Specific Gravityeldobie3Belum ada peringkat

- PT BM 183 DC 00002 MT ProcedureDokumen7 halamanPT BM 183 DC 00002 MT Procedureeldobie3Belum ada peringkat

- API 510 PC 20 31 Aug05 Final Open AnswerDokumen1 halamanAPI 510 PC 20 31 Aug05 Final Open Answereldobie3Belum ada peringkat

- PT BM 183 DC 00003 PT ProcedureDokumen6 halamanPT BM 183 DC 00003 PT Procedureeldobie3Belum ada peringkat

- PT BM 183 DC 00004 RT ProcedureDokumen6 halamanPT BM 183 DC 00004 RT Procedureeldobie3Belum ada peringkat

- API 510 PC Mid Session Exam Open Book Attempt SheetDokumen1 halamanAPI 510 PC Mid Session Exam Open Book Attempt Sheeteldobie3Belum ada peringkat

- API 510 PC Final Exam Closed Book Attempt SheetDokumen1 halamanAPI 510 PC Final Exam Closed Book Attempt Sheeteldobie3Belum ada peringkat

- 41 42Dokumen4 halaman41 42alfa alfaBelum ada peringkat

- Solid Rivet - MS20470Dokumen2 halamanSolid Rivet - MS20470Manoj ManoharanBelum ada peringkat

- Microalgae To Biofuels Promising' Alternative and Renewable EnergyDokumen13 halamanMicroalgae To Biofuels Promising' Alternative and Renewable EnergyJeevan KumarBelum ada peringkat

- Research Article: Synthesis of New Benzofuran-2-Carboxylic Acid DerivativesDokumen8 halamanResearch Article: Synthesis of New Benzofuran-2-Carboxylic Acid Derivativesfatriani smakBelum ada peringkat

- EOSIN STAINING ALCOHOL SOLUTION MSDSDokumen11 halamanEOSIN STAINING ALCOHOL SOLUTION MSDSfitrisya luckyBelum ada peringkat

- ICARUS' Trunnion Mounted Ball Valve Design GuideDokumen36 halamanICARUS' Trunnion Mounted Ball Valve Design GuidezayerirezaBelum ada peringkat

- MSDS Dynamic DescalerDokumen4 halamanMSDS Dynamic DescalerEurotech Tra TranBelum ada peringkat

- Oxynitrox MsdsDokumen4 halamanOxynitrox MsdscapdesuroBelum ada peringkat

- Investigating Oxygen and Carbon Dioxide Levels in Inhaled and Exhaled AirDokumen2 halamanInvestigating Oxygen and Carbon Dioxide Levels in Inhaled and Exhaled AirAdy Phanterz100% (1)

- Introduction To Cell BiologyDokumen43 halamanIntroduction To Cell BiologyEllemrac GageloniaBelum ada peringkat

- Improve Salt Purity With New Washery UnitDokumen7 halamanImprove Salt Purity With New Washery UnitABelum ada peringkat

- Criteria air pollutants: Sources, health effects and control of particulate matterDokumen8 halamanCriteria air pollutants: Sources, health effects and control of particulate matterSumaiya ImamBelum ada peringkat

- Mat & Sat-04Dokumen32 halamanMat & Sat-04RamNagalBelum ada peringkat

- Cemtec AL PU CoatingDokumen2 halamanCemtec AL PU CoatingAhmad ElghazolyBelum ada peringkat

- Ferroelectricity in HfO2Dokumen6 halamanFerroelectricity in HfO2Basharat AhmadBelum ada peringkat

- Nuclear-Grade Boron Carbide Powder: Standard Specification ForDokumen3 halamanNuclear-Grade Boron Carbide Powder: Standard Specification ForAnilBelum ada peringkat

- Color Reactions Intact Protein (Gluten) Basic HydrolysisDokumen6 halamanColor Reactions Intact Protein (Gluten) Basic HydrolysisJennifer CamaBelum ada peringkat

- MechanizationDokumen82 halamanMechanizationDeorene PulmanoBelum ada peringkat

- Report Filed by The APPCBDokumen30 halamanReport Filed by The APPCBhcbbBelum ada peringkat

- MayonnaiselabreportDokumen15 halamanMayonnaiselabreportapi-375920722Belum ada peringkat

- CLS 7, Atomic Structure, WSDokumen2 halamanCLS 7, Atomic Structure, WSEmerooBelum ada peringkat

- SECTION 15081: Duct Insulation 15081Dokumen5 halamanSECTION 15081: Duct Insulation 15081fatREVITBelum ada peringkat

- ABB CorrosionDokumen8 halamanABB CorrosionForexFFBelum ada peringkat

- An Introductory Course Bioinformatics-I: A Student HandoutDokumen320 halamanAn Introductory Course Bioinformatics-I: A Student HandoutWaryam MuhammadBelum ada peringkat