Lingbeck Et Al Meat Science Liquid Smoke Review

Diunggah oleh

HoshiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Lingbeck Et Al Meat Science Liquid Smoke Review

Diunggah oleh

HoshiHak Cipta:

Format Tersedia

Meat Science 97 (2014) 197206

Contents lists available at ScienceDirect

Meat Science

journal homepage: www.elsevier.com/locate/meatsci

Review

Functionality of liquid smoke as an all-natural antimicrobial in

food preservation

Jody M. Lingbeck a, Paola Cordero b, Corliss A. O'Bryan b, Michael G. Johnson b,

Steven C. Ricke a,b,c, Philip G. Crandall a,b,

a

b

c

Sea Star International LLC., 2138 East Revere Place, Fayetteville, AR 72701, USA

Department of Food Science and Center for Food Safety, University of Arkansas, 2650 Young Ave., Fayetteville, AR 72704, USA

Department of Poultry Science, Division of Agriculture, University of Arkansas, Fayetteville, AR 72704, USA

a r t i c l e

i n f o

Article history:

Received 16 October 2013

Received in revised form 28 January 2014

Accepted 2 February 2014

Available online 9 February 2014

Keywords:

Liquid smoke

Antimicrobial

Listeria monocytogenes

Salmonella

a b s t r a c t

The smoking of foods, especially meats, has been used as a preservation technique for centuries. Today, smoking

methods often involve the use of wood smoke condensates, commonly known as liquid smoke. Liquid smoke is

produced by condensing wood smoke created by the pyrolysis of sawdust or wood chips followed by removal of

the carcinogenic polyaromatic hydrocarbons. The main products of wood pyrolysis are phenols, carbonyls and

organic acids which are responsible for the avor, color and antimicrobial properties of liquid smoke. Several

common food-borne pathogens such as Listeria monocytogenes, Salmonella, pathogenic Escherichia coli and

Staphylococcus have shown sensitivity to liquid smoke in vitro and in food systems. Therefore liquid smoke has

potential for use as an all-natural antimicrobial in commercial applications where smoke avor is desired.

This review will cover the application and effectiveness of liquid smoke and fractions of liquid smoke as

an all-natural food preservative. This review will be valuable for the industrial and research communities in

the food science and technology areas.

2014 Published by Elsevier Ltd.

Contents

1.

2.

3.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generation of liquid smoke from wood pyrolysis . . . . . . . . . . . .

Antimicrobial activity of liquid smoke . . . . . . . . . . . . . . . . .

3.1.

Possible mechanisms of antimicrobial action of liquid smokes . . .

3.2.

Activity of phenols . . . . . . . . . . . . . . . . . . . . . .

3.3.

Activity of carbonyls . . . . . . . . . . . . . . . . . . . . . .

4.

Antimicrobial activity of liquid smoke against Listeria . . . . . . . . . .

4.1.

In vitro effects on Listeria . . . . . . . . . . . . . . . . . . . .

4.2.

Antilisterial effects in ready-to-eat meats . . . . . . . . . . . .

4.3.

Genetic basis of the antimicrobial effects of liquid smoke on Listeria

5.

Effects of liquid smoke on Salmonella spp. . . . . . . . . . . . . . . .

6.

Effects of liquid smoke on E. coli . . . . . . . . . . . . . . . . . . . .

6.1.

In vitro effects of liquid smoke on E. coli . . . . . . . . . . . . .

6.2.

Effects of liquid smoke on E. coli in beef . . . . . . . . . . . . .

7.

Effect of liquid smoke on Staphylococcus . . . . . . . . . . . . . . . .

8.

Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

197

198

199

199

199

200

203

203

203

204

204

204

204

205

205

205

205

1. Introduction

Corresponding author at: 2650 Young Ave., Fayetteville, AR 72704, USA.Tel.: +1 479

575 7686.

E-mail address: crandal@uark.edu (P.G. Crandall).

http://dx.doi.org/10.1016/j.meatsci.2014.02.003

0309-1740 2014 Published by Elsevier Ltd.

Traditional smoking of foods, especially meats, has been used as

a preservation technique for centuries. Wood smoke, in addition to

198

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

preserving food quality with its antioxidant and antimicrobial properties, also imparts a desirable color, avor and aroma to smoked foods.

Application of liquid smoke requires less time than traditional smoking,

is more environmentally friendly, and eliminates potentially toxic compounds while still imparting the desired avors and aromas of traditional smoking. Use of condensates or liquid smoke allows the processor

to control the concentration of smoke being applied more readily than

generating smoke by burning of wood (Suen, Fernandez-Galian, &

Aristimuo, 2001). Liquid smoke is traditionally applied to meat, sh

and poultry and it has also been used to impart avor to non-meat

items such as cheese, tofu and even pet food. Because the smoke avor

is concentrated, application of liquid smoke is best suited for use in marinades, sauces or brines or topically to processed meat items such as hot

dogs, sausage, ham and bacon (Rozum, 2009).

According to an annual poll conducted by The Center for Food Integrity consumers have less condence in the safety and quality of the food

supply and are demanding more all-natural and minimally processed

foods with less synthetic chemical additives (Andrews, 2012). Consumers also have increased interest in organic foods because they believe they are healthier, better tasting, or fresher than conventional

products (Wier & Calverley, 2002). However, although free of synthetic

chemicals, organic and all-natural foods are not exempt from bacterial

contamination and may require the addition of an all-natural antimicrobial to insure their safety. All-natural antimicrobials including those

derived from plants, animals and bacteria have been shown to be effective in increasing the safety of food products by destroying or limiting

the growth of bacterial pathogens. Several reviews have been written

on all-natural antimicrobials from bacterial, plant and animal origin

(Davidson, Critzer, & Taylor, 2013; Juneja, Dwivedi, & Yan, 2012; Rai &

Chikindas, 2011), as well as their use in organic poultry and meat production (Ricke, Van Loo, Johnson, & O'Bryan, 2012; Sirsat, Muthaiyan,

& Ricke, 2009). However, these reviews contain little or no information

on the use of liquid smoke as an effective all-natural antimicrobial. The

review by Holley and Patel (2005) provides a nice overview on the use

of liquid smoke as well as its antimicrobial properties in food systems,

especially in sh. This review builds on the information presented in

Holley and Patel (2005) as well as provides a more detailed and up to

date discussion on the effectiveness of liquid smoke as an all-natural

preservative in food products. We will examine the effectiveness of

liquid smoke, including ranges of microbial susceptibility and factors

affecting antimicrobial action and discuss currently understood mechanisms of action.

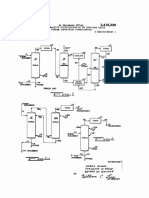

2. Generation of liquid smoke from wood pyrolysis

Liquid smoke is produced by condensing wood smoke created by the

controlled, minimal oxygen pyrolysis of sawdust or wood chips. The

wood is placed in large retorts where intense heat is applied, causing

the wood to smolder (not burn), releasing the gases seen in ordinary

smoke. These gases are quickly chilled in condensers, which liquees

the smoke. The liquid smoke is then forced through rening vats, and

then ltered to remove toxic and carcinogenic impurities. Finally, the

liquid is aged for mellowness. Fig. 1 shows a schematic of a typical liquid

smoke production facility. Factors inuencing the avor and antimicrobial properties of liquid smoke include the temperature of smoke generation, moisture content of the wood as well as the type of wood used to

generate the smoke (Simko, 2005). Common woods include hickory

and mesquite, but liquid smoke has also been prepared from rice hulls

(Kim et al., 2011, 2012), coconut shells (Zuraida, Sukarno, & Budijanto,

2011) and pecan shells (Van Loo, Babu, Crandall, & Ricke, 2012). In general, woods used to generate liquid smoke are roughly comprised of 25%

hemicellulose, 50% cellulose, and 25% lignins (Simko, 2005). See Table 1

for information about composition of specic woods. Pyrolysis occurs in

four stages starting with water evaporation, followed by decomposition

of hemicelluloses, cellulose decomposition and nally decomposition of

lignins. Pyrolysis of hemicellulose and cellulose occurs between 180 C

and 350 C and produces carboxylic acids and carbonyl compounds

while lignins are pyrolyzed between 300 C and 500 C and generate

phenols (Ramakrishnan & Moeller, 2002; Simko, 2005). Smoke avor

compounds, including phenols, are responsible for the smoke avor

and smoky aroma while carbonyl compounds impart a sweet aroma

and color to smoked meat products.

In addition to carbonyls, acids, and phenols, pyrolysis of wood often

generates unfavorable compounds such as polycyclic aromatic hydrocarbons (PAH). Polycyclic aromatic hydrocarbons are families of compounds, some which are naturally occurring, others are the result of

incomplete burning and are typically formed at pyrolysis temperatures

between 500 C and 900 C (Simko, 2005). The level of PAH formation is

also inuenced by the wood source (Guilln, Sopelana, & Partearroyo,

2000). Some PAH compounds such as benzo(a)pyrene (B(a)P), have

Fig. 1. Flow diagram of typical liquid smoke production.

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

Table 1

Wood carbohydrate composition (%).

Wood

Cellulose

Hemicellulose

Lignin

Apple

Cherry

Chestnut

Hard maple

Hickory

Mesquite

Red oak

White oak

20.7

20.7

21.4

17.2

41.4

8.0

58.6

21.4

6.9

3.4

3.6

17.2

1.7

8.0

3.4

3.6

37.9

13.8

32.1

55.2

24.1

44.0

24.1

39.3

From Chen and Maga (1993).

been shown to cause birth defects when pregnant mice were exposed to

more than 300 ppm in food. Foods containing levels greater than

900 ppm led to liver and blood defects in test animals (EPA, 2008).

The European Union (EU) regulations limit the amount of PAH allowed

in food while the US Food and Drug Administration has not set an upper

limit for PAH exposure (Dolan, Matulka, & Burdock, 2010). Because data

has shown that it is possible to reach lower levels of B(a)P in smoked

meats, acceptable levels of regulated PAH, specically B(a)P, will drop

from 0.005 to 0.002 ppm in 2014 for these foodstuffs sold in the EU

((EC) No. 835/2011). The 2014 level of PAH is set 150,000 times

below the levels known to cause birth defects. Although PAH are extremely toxic, they have low water solubility which allows liquid

smoke manufacturers to easily separate out these compounds from

their nished products using phase separation and ltration techniques.

For more information on PAH in liquid smoke see Guilln and Sopelana

(2003) and Simon, de la Calle, Palme, Meier, and Anklam (2005).

3. Antimicrobial activity of liquid smoke

Different woods generate different levels of phenols, carbonyls and

organic acids upon pyrolysis which affect their antimicrobial properties

(see Table 2). Liquid smokes from 20 different types of woods including

redwood, black walnut, birch, hickory, aspen, white oak, cherry

and chestnut were assessed for their antimicrobial properties against

Staphylococcus aureus and Aeromonas hydrophila in broth culture

(Boyle, Sofos, & Maga, 1988; Sofos, Maga, & Boyle, 1988). It was found

that wood smoke generated from Douglas r sapwood was inhibitory

to both the bacterial strains in that it delayed initiation of growth and

growth rates of these organisms while smoke from mesquite or lodge

pole pine did little to inhibit these pathogens (Boyle et al., 1988; Sofos

et al., 1988). In a separate study, liquid smoke from white mangrove,

mahogany and abura were shown to inhibit S. aureus and Escherichia

coli. Red mangrove and alstonia were able to inhibit S. aureus, but not

E. coli, indicating that not only does the type of wood affect the antimicrobial properties of liquid smoke but also that pathogenic organisms

have varying degrees of sensitivity to the ingredients of the liquid

smoke (Asita & Campbell, 1990). The susceptibility of major food

borne pathogens Listeria monocytogenes, Salmonella, E. coli and Staphylococcus to liquid smoke in laboratory media as well as in model meat systems will be reviewed. Table 3 summarizes the in vitro results of liquid

smoke against several food borne pathogens while Table 4 is a summary

of the antimicrobial activity of liquid smoke against pathogens in model

food systems.

3.1. Possible mechanisms of antimicrobial action of liquid smokes

Gram-positive and Gram-negative organisms may behave differently to exposure to liquid smoke or fractions of liquid smoke and there

may be varying susceptibility within differing strains of the same organism thus making it difcult to identify the mechanism and compounds

responsible for microbial inhibition (Sofos et al., 1988). The amount of

phenols present in liquid smoke condensates has been reported to

be approximately 9.911.1 mg/mL (Ramakrishnan & Moeller, 2002).

199

Phenolic compounds are known to disturb the cytoplasmic membranes

of bacteria and cause the intracellular uids to leak (Davidson, 1997).

Carbonyls have been reported in liquid smokes in amounts of approximately 2.6 to 4.6% (Milly, Toledo, & Ramakrishnan, 2005). The efcacy

of carbonyls as an antimicrobial can be inferred based on the 133 different aldehydes and ketones present in liquid smoke (Montazeri, Oliveira,

Himelbloom, Leigh, & Crapo, 2013). Carbonyls inhibit microbial growth

by penetrating the cell wall and inactivating enzymes located in the

cytoplasm and the cytoplasmic membrane (Milly, 2003). Carbonyls act

by condensing with the free, primary amino-groups in the polypeptide

chains, primarily in the side-chains of basic amino-acids. These aminogroups may be an essential part of active site of the enzyme, or they

may function to bind the substrate by hydrogen-bonding (Painter,

1998). Even if the carbonyls cannot access the interior of a microbial

cell, they can still inhibit growth by interfering with the uptake of nutrients. There are 3 proposed mechanisms involved in this interference,

termed A, B and C types.

Type A inhibition entails the sequestration of amino acids or ammonia

by condensation with the carbonyl compounds, thus lowering the effective concentration in the growth medium (Painter, 1998). Some carbonyls, including -keto-carboxylic acids, enediols, 3-hydroxyketones

and 1,3-diones, can also remove essential metal cations by chelation

(Painter, 1998). Type B inhibition is active against putrefactive bacteria

or molds which excrete exocellular proteases or glycanases to break

down proteins or glycans into small fragments which can be taken up

by the cells. Carbonyl compounds either inactivate the enzymes as

described for type A inhibition, or by immobilizing them in insoluble

particles or a three-dimensional polymeric network which physically

isolates them from their substrates (Painter, 1998). Type C inhibition

involves direct chemical modication of a substrate itself, so that it becomes less accessible or susceptible to the microbial enzymes (Painter,

1998). Antimicrobial activity of phenols and carbonyls is discussed

further in the following sections.

3.2. Activity of phenols

Early studies on antimicrobial activity of liquid smoke on

L. monocytogenes and other pathogens attributed the activity to phenolic compounds. Faith, Yousef, and Luchansky (1992) evaluated several

liquid smoke fractions and common smoke phenols for antilisterial activity. A three strain cocktail of L. monocytogenes including isolates

Scott A, V7 and 101 M was incubated in hot dog exudate containing

0.2% or 0.6% of the liquid smoke fraction CharSol Supreme (Red Arrow

Company, Manitowoc, WI) at 25 C for up to 114 h. L. monocytogenes

levels decreased in liquid smoke treated samples with D-values of 36

h for exudate containing 0.2% liquid smoke and 4.5 h for 0.6% treated

samples. When eleven individual smoke phenols were evaluated for

their antilisterial activity against L. monocytogenes Scott A in Tryptose

Broth, only isoeugenol was able to delay growth. The addition of acetic

acid further enhanced inactivation due to its bactericidal activity

(Young & Foegeding, 1993).

Suen (1998) measured the antimicrobial activity of seven different smoke fractions used in the Spanish food industry against

L. monocytogenes and other pathogenic microorganisms. The MIC values

were determined using an agar dilution technique with smoke extracts

prepared in buffer, pH adjusted to 7 and used at concentrations up to 2

the maximum level recommended by the manufacturer. Antimicrobial

activity was directly related to phenol concentrations in that extracts

possessing a high concentration of phenols (94 to 153 mg/kg)

corresponded to the fractions with the strongest antimicrobial properties. However, the fraction containing the highest concentration of

phenols was not the most active. The most active fraction, in addition

to having a high level of phenols (21 mg/kg), also contained the highest

concentration of acids (34 mg/kg) which may have contributed to the

antimicrobial action of this fraction.

200

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

Table 2

Chemical properties of commercial liquid smokes.

Liquid smoke tested

Manufacturer

pH

Titratable acidity as percent

acetic acid (wt/wt)

Phenol content

(mg/mL)

Carbonyl content

(g/100 mL)

References

Charsol Supreme

2.12.6

1416

1825

2025

Vitt et al. (2001)

2.22.8

No data

2.12.6

2.02.4

3.04.0

7.38.1

Not listed

2.53.3

1416

No data

10.512

1315

4.0 maximum

No data

1011

3.55.6

1523

2530

1015

914

3742

No data

916 mg/g

1.7 maximum

2430

No data

1213

1620

No data

No data

1216

1922

AM-3

Red Arrow Company

(Manitowoc, WI)

Red Arrow Company

Red Arrow Company

Red Arrow Company

Red Arrow Company

Red Arrow Company

Red Arrow Company

Red Arrow Company

Mastertaste, Inc.

(Monterey, TN)

Mastertaste, Inc.

4.254.85

1.82.1

0.30.8

1620

AM-3

Mastertaste, Inc.

4.3

2.2

Not detected

Not listed

List-A-Smoke

Mastertaste Inc.

2.02.5

7.08.0

1.754.25

58

Code 10-Poly

Mastertaste Inc.

2.3

10.3

3.22

Not listed

AM-10

Mastertaste Inc.

4.2

2.3

Not detected

Not listed

1291

Mastertaste Inc.

5.7

0.7

0.1

Not listed

Code V

Hickory Specialties

(Brentwood, TN)

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

Mastertaste Inc.

2.0

6.87.8

1.44.0

2.07.0

Paranjpye et al. (2004)

Faith et al. (1992)

Vitt et al. (2001)

Vitt et al. (2001)

Vitt et al. (2001)

Vitt et al. (2001)

Paranjpye et al. (2004)

Gedela, Escoubas, et al. (2007)

and Gedela, Gamble, et al. (2007)

Gedela, Escoubas, et al. (2007)

and Gedela, Gamble, et al. (2007)

Montazeri, Himelbloom, et al. (2013);

Montazeri, Oliveira, et al. (2013b)

Gedela, Escoubas, et al. (2007) and

Gedela, Gamble, et al. (2007)

Montazeri, Himelbloom, et al. (2013)

and Montazeri, Oliveira, et al. (2013)

Montazeri, Himelbloom, et al. (2013)

and Montazeri, Oliveira, et al. (2013)

Montazeri, Himelbloom, et al. (2013)

and Montazeri, Oliveira, et al. (2013)

EstradaMuoz et al. (1998)

23

6.17.0

23.0

4.15.0

23.0

23.0

5.16.0

6.17.0

6.17.0

23

33.2

4.14.3

67.4

4.55.9

01.4

6.07.4

3.04.4

6.07.4

6.07.4

1.52.9

01.4

01.4

4.55.9

3.43.7

1.51.8

01.4

05

05

05

20.125.0

05

05

05

05

05

0.30.6

0.30.6

0.30.6

0.30.6

151200.9

101150.9

101150.9

050.9

101150.9

51100.9

51100.9

101150.9

51100.9

151200

120132

110120

100110

Milly et

Milly et

Milly et

Milly et

Milly et

Milly et

Milly et

Milly et

Milly et

Milly et

Milly et

Milly et

Milly et

Charsol Supreme

Charsol Supreme

Charsol H-10

Charsol LFB Supreme Poly

Aro-Smoke P-50

CharOil

C-10

Zesti B

F1

F2

F3

F4

F5

F6

F7

F8

F9

S1

S2

S3

S4

Other studies suggest that the antimicrobial properties of liquid

smoke are not attributed to their phenol composition. Smoke fractions

from the Spanish food industries (L1, L2, L3 and S) were evaluated for

their antimicrobial properties at low temperature against A. hydrophila,

Yersinia enterocolitica and L. monocytogenes (Suen et al., 2001).

The pH of the liquid smokes was adjusted to neutrality and used at the

maximal concentration recommended by the manufacturer (0.4 to 4%)

and were subsequently incubated with 4 to 5 log10 CFU/mL of pathogen

for up to 21 days at 4 C in broth culture. All four extracts were effective

at eliminating or suppressing growth of A. hydrophila after 21 days.

Fractions L1 and S were bacteriostatic against Y. enterocolitica while fractions L2 and L3 were ineffective at reducing Y. enterocolitica numbers.

The most effective fraction against L. monocytogenes was fraction S

(3.2 log10 CFU/g reduction after 21 days) while fractions L1 and L2

exhibited slight inhibition by reducing cell counts by 2.1 log10 CFU/mL

and 1.9 log 10 CFU/mL, respectively. Fraction L3 did not inhibit

L. monocytogenes growth. The most active fraction, fraction S, was lowest in phenol concentration (23 mg/kg), but high in acid concentration

(23 mg/kg), while the least effective fraction L3 contained a high level

of phenols (99 mg/kg) suggesting that phenol concentration is not

indicative of the antimicrobial activity of liquid smoke.

3.3. Activity of carbonyls

Carbonyl compounds have also been suggested to contribute to the

antimicrobial properties of liquid smoke. Milly et al. (2005) determined

minimal inhibitory concentration (MIC) values of low phenolic liquid

smoke fractions against Listeria innocua M1 and several Gramnegative bacteria. The MIC values were determined for nine liquid

al. (2005)

al. (2005)

al. (2005)

al. (2005)

al. (2005)

al. (2005)

al. (2005)

al. (2005)

al. (2005)

al. (2008)

al. (2008)

al. (2008)

al. (2008)

smoke fractions (F19), eight of which had a phenol concentration of

0 to 5 mg/mL so that the antimicrobial effect of the non-phenolic compounds (i.e. carbonyl compounds and organic acids) could be evaluated.

The fraction F1 was found to be the most effective against the Gramnegative cocktail mixture with an MIC value of 1.5%. Fraction F1 had a

pH range of 2 to 3 and had the highest carbonyl content at 151 to

200.9 mg/mL. Fractions F3, F5 and F6 had MIC values of 2%, were similar

to F1 in pH and phenol level, but were lower in carbonyl content (101 to

150.9 mg/mL for F3 and F5; 51 to 100.9 mg/mL for F6). Fraction F4

which had a phenol content of 20.1 to 25.0 mg/mL, a pH of 4.1 to 5.0

and a carbonyl content of 0 to 50.9 mg/mL produced an MIC value of

3%. The least effective fractions, F7 (MIC 5%) and F9 (MIC 9%) contained

the same carbonyl level (51 to 100.9 mg/mL) but differed slightly in pH.

Fraction F7 with a lower pH range of 5.1 to 6.0 compared to that of F9,

pH 6.1 to 7.0, exhibited signicantly improved antimicrobial properties.

In assessing the antimicrobial properties of different liquid smoke

fractions, these data demonstrate the importance of knowing the concentrations of carbonyl compounds, acids and the pH values of these

products.

Three rened liquid smoke fractions along with a full strength fraction, Code 10-Poly (Kerry Ingredients and Flavors, Monterey, TN) were

tested in vitro for antilisterial properties. The three rened liquid

smoke fractions 1291, AM-10 and AM-3 possessed little to no phenols.

Using a disk diffusion assay it was determined that all fractions with

the exception of 1291 were effective against L. innocua. The largest inhibition zones were seen with Code 10-Poly which had a pH of 2.3, 10.3%

titratable acidity and total phenol content of 3.22 mg/mL. Fractions AM10 and AM-3 were also able to reduce the counts of L. innocua in culture

media tests, despite their having undetectable phenol levels suggesting

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

201

Table 3

Efcacy of liquid smoke as an antimicrobial against select bacteria in vitro.

Fraction

Concentration

Bacteria

Method

Results

Reference

Aro Smoke P-50,

CharOil,

Charsol H-10,

Charsol LFB Supreme

Poly,

Charsol Supreme

Nine commercial LS from

Mastertaste F1F9

0100%

Listeria monocytogenes

ATCC 19115

Listeria innocua

ATCC 33090

MIC values determined by a

broth dilution method in BHI

Vitt et al. (2001)

100.5%

L. innocua M1

MICs determined by a broth

dilution method

100%

75%

50%

25%

Up to 2

manufacturers

recommended

concentration

0.4% L1

0.6% L2

4% L3

1% S

10.2%

L. innocua ATCC 33090

Disk diffusion

L. monocytogenes

CECT 932,

L. innocua CECT 4030

Agar dilution

L. monocytogenes

CECT 932

Flask containing LS were

inoculated and incubated at 4 C.

MIC values

Aro Smoke P-50 = 2.5%

CharOil = 5%

Charsol H-10 = 1.25%

Charsol LFB Supreme Poly = 1.25%

Charsol Supreme = 0.5%

MIC Values

F1 = 1.25%

F2 = 2%

F3 2%

F4 = 2%

F5 = 2%

F6 = 2%

F7 = 4%

F8 = 2%

F9 = 6%

Larger zones of inhibition were seen with

increasing LS concentration. Code 10-Poly

was the most effective fraction at all

conditions while 1291 was least effective.

Fractions L1, L4, S1 and S3 were not

effective. Fraction L2 was inhibitory at

0.6%, L3 at 8% for L. innocua and N8% for

L. monocytogenes, S2 at 1%

L1 and reduced Listeria by ~2 log CFU/mL

S reduced Listeria by 3.2 log CFU/mL and L3

was ineffective at reducing Listeria

Code 10-Poly

AM-3

AM-10

1291

Seven fractions from

Spanish food industry

L1, L2, L3, L4, S1, S2, and

S3 (all pH 7)

Four fractions from

Spanish food industry

L1, L2, L3, and S

Rice hull smoke extract

Four water based

commercial samples

and four concentrated

extracts from

commercial sources

Nine commercial LS from

Mastertaste F1F9

960.375%

100.5%

Lab generated from pyrolysis 1%0.05%

of beachwood chips

Four water based

960.375%

commercial samples and

four concentrated extracts

from commercial sources

Lab generated from pyrolysis 1%0.05%

of beachwood chips

Four water-based

commercial samples and

four concentrated extracts

from commercial sources

960.375%

Salmonella Typhimurium MICs were determined in

ATCC 14028

nutrient broth with phenol in a

microtiter plate

Salmonella Enteritidis

MICs were determined by a

PT 13A

microdilution method in

microtiter plates at 37 C.

MIC of rice hull smoke

condensate = 0.822%

Milly et al. (2005)

Montazeri, Himelbloom,

et al. (2013) and

Montazeri, Oliveira, et al.

(2013)

Suen (1998)

Suen et al. (2001)

Kim et al. (2012)

MIC values were 6% for 3 of the 4 water

Van Loo et al. (2012)

based samples and 12% for the fourth

sample. MICs were 0.5% for 3 of the 4

concentrated extracts; the nal concentrated

extract had an MIC value of 3%.

Gram negative cocktail of MIC values were determined

MIC Values

Milly et al. (2005)

Salmonella Muenster,

by a broth dilution method

F1 = 1.25%

Salmonella Seftenburg,

at 37 C.

F2 2%

Salmonella Typhimurium

F3 = 2%

and Escherichia coli 8677

F4 = 3%

F5 = 2%

F6 = 2%

F7 = 5%

F8 = 2%

F9 = 9%

E. coli ATCC 14948-K12

Smoke condensates were mixed Growth was delayed by 1 day at 0.125%, by Fretheim et al. (1980)

with nutrient broth agar followed 1.5 days at 0.166% and no growth was

by spread plating of E. coli. Plates observed at concentrations above 0.25%

were incubated at 30 C for

2 weeks.

E. coli O157:H7

MICs were determined by a

MIC were 6% for the water based samples Van Loo et al. (2012)

ATCC 43888

microdilution method in

and 0.5% for 3 of the 4 concentrated

microtiter plates

extracts, the nal concentrated extract had

an MIC value of 6%

Staphylococcus aureus

Smoke condensates were mixed No growth was observed at concentrations Fretheim et al. (1980)

ATCC 25923

with nutrient broth agar followed above 0.1%

by spread plating of E. coli. Plates

were incubated at 30 C for

2 weeks.

S. aureus ATCC 25923

MICs were determined by a

MIC were 6% for the water based samples Van Loo et al. (2012)

ATCC 6538

microdilution method in

and ~0.38% for concentrated extracts.

Mu50, MRSA

microtiter plates

Col, MRSA

that organic acids or carbonyls rather than phenols were involved in the

antilisterial properties of liquid smoke products they tested (Montazeri,

Himelbloom, Oliveira, Leigh, & Crapo, 2013).

Milly, Toledo, and Chen (2008) used high-end turkey rolls which

were whole parts of turkey breast formed to have no more than 40%

binders and broth added, low-end turkey rolls which were minced turkey breast parts with up to 60% binders and broth added before forming

and cooking, as well as roast beef cuts to evaluate low phenolic liquid

smoke fractions for antimicrobial properties. Turkey rolls and roast

beef cuts were rst inoculated with L. innocua M1, subsequently treated

with four different liquid smoke fractions (Mastertaste Inc., Brentwood,

TN), vacuum packed and refrigerated at 4 C for up to four weeks of storage. Samples were treated with 2 log10 CFU/25 cm2 of L. innocua M1 and

evaluated at 2 and 4 weeks of storage. Samples treated with smoke fractions S1, S2 and S3 had levels below the detection limit for L. innocua at

all the sampling times. Samples treated with S4 remained positive after

202

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

Table 4

Efcacy of liquid smoke as an antimicrobial against several bacteria in food systems.

Liquid smoke fraction

Liquid smoke

concentration

Strain

Processing parameters

Result

Reference

CharSol Supreme

0.6% and 0.2%

Listeria monocytogenes

Scott A, V7, 101 M

60%

Listeria innocua

AM-3

AM-10

0.9%

L. innocua ATCC 33090

Listeria counts decreased after 3 days.

Estimated D-values are 4.5 h at 0.6% and

36 h for 0.2%

A 15 s dip resulted in a 3 log reduction

greater reductions were seen with

longer dip times

Both fractions reduced L. innocua to

b2 log CFU/g after 2 weeks.

Faith et al. (1992)

Charsol Supreme

Hot dog exudates containing LS were

inoculated with Listeria and incubated

at 25 C for up to 114 h.

100 g chum salmon samples were

brined, dipped for 5 min in LS,

inoculated and dried in a smoke house

Salmon strips were treated with LS,

inoculated, vacuum sealed, and stored

at 4 C for up to 49 days.

Fractions from

Spanish food

industries L1, L2,

L3 and S

100%, 1 min dip

L. monocytogenes CECT

932

Filets were brined, inoculated, treated

with LS and stored at 4 C for 21 days

CharSol C-10

100%

50%

25%

10%

dipped

L. monocytogenes strains

4121 and 1455

Salmon lets were brined, treated with

LS, inoculated and heat processed.

Zesti-B

100% dipped for 1

or 5 s or sprayed

L. monocytogenes Scott

A-2, V7-2, 39-2, 383-2

Zesti-B

100% sprayed

L. monocytogenes Scott

A-2, V7-2, 39-2, 383-2

Frankfurters formulated without lactate

and diacetate were dipped or sprayed in

LS, inoculated, vacuum packed and

stored at 1.7 C for 10 weeks.

Frankfurters formulated without lactate

and diacetate were sprayed in LS,

inoculated, vacuum packed and stored at

6.1 C for 10 weeks.

Fractions L1 and L2 immediately reduced

L. m to below detectable levels. Fraction

S slowly reduced Listeria and was below

detectable levels by 21 days. Fraction L3

did not show any inhibitory affects.

Internal minimum lethality temperatures

were N82.8 C in untreated salmon steaks,

67.2 C generated smoke was applied

throughout the entire smoking process

or N 80 C when smoke was only applied

during the last half of the process, 58.9 C

when dipped in 100% CharSol C-10 and

62.8 C, 68.9 C and 72.8 C with 50%, 25%

and 10% LS.

L. m. was reduced to undetectable

numbers after 4 weeks with all

treatments

Zesti-B AM-3

100%, 1 s dip

L. monocytogenes Scott

A-2, V7-2, 39-2, 383-2

AM-3

100% sprayed to

equal 1.8 mL per

frank

CharSol-10

100%, dipped

Zesti Smoke

Formulated into

franks at 10, 5,

and 2.5% (wt/wt)

L. monocytogenes ARS

V67, ARS V72, ARS V113,

ARS V125, ARS V105,

LCDC 81861

L. monocytogenes LCDC

81861, M1, M2, M5, C6,

serotype 4b derived

ATCC 19115

L. monocytogenes

Zesti-B

100%, 1 s dip

L. monocytogenes Scott

A-2, V7-2, 39-2, 383-2

Four commercial

LS from Mastertaste

S1, S2, S3 and S4

100%, 60s dip

L. innocua M1

Four commercial

LS from Mastertaste

S1, S2, S3 and S4

100%, 60s dip

L. innocua M1

Frankfurters were formulated without

lactate or diacetate, dipped in LS,

inoculated, vacuum sealed, heat

pasteurized for 1 min at 37 C, chilled

and stored at 6.1 C for 10 weeks

Frankfurters were formulated without

lactate or diacetate, sprayed with LS,

inoculated, sealed and stored at 4 C for

140 days.

Frankfurters were inoculated, dipped in

LS, vacuum packed and stored at 4 C for

72 h.

Frankfurters were inoculated, vacuum

packed and stored at 4 C for 12 weeks.

Deli turkey formulated without lactate or

diacetate were dipped in LS, inoculated,

vacuum packed, heat pasteurized 60s at

93.3 C, chilled and stored at 6.1 C for

10 weeks

High end turkey rolls (containing

less-than 40% binders and broth added),

low end turkey rolls (up to 60% binders

and broth added) were dipped in LS,

inoculated with L. i. in a marked 25 cm2

area, vacuum sealed and stored at 4 C

for 4 weeks.

Roast beef cuts were dipped in LS, inoculated with L. i. in a marked 25 cm2 area,

vacuum sealed and stored at 4 C for

4 weeks.

Vitt et al. (2001)

Montazeri,

Himelbloom, et al.

(2013) and

Montazeri, Oliveira,

et al. (2013)

Suen et al. (2003)

Poysky et al. (1997)

Gedela, Escoubas

et al. (2007)

L. m. was reduced to undetectable levels

after 1 week at log 1 inoculum levels, at

log 2 the levels declined slowly and were

undetectable after 4 weeks. The log 3

inoculum slowly increased over 10 weeks

to 0.8 logs higher that inoculum while

control increased by 7 logs

L. m. levels were undetectable after

3 weeks with both Zesti-B and AM-3

fractions

Gedela, Escoubas

et al. (2007)

L. m. was reduced by nearly 3 logs after

30 days and continued to slowly decline

for up to 130 days

Martin et al. (2010)

L. m. was reduced initially by at least

1 log and was undetectable after 72 h.

Messina et al. (1988)

Frankfurters formulated with 2.5% LS

saw a 0.5 log CFU/mL reduction when

inoculated at high L. m. levels and ~2 log

CFU/mL when inoculated with lower

levels of Listeria. Frankfurters formulated

with 5% LS saw greater reductions and

were listericidal after 6 weeks. 10% LS

was listericidal after 4 weeks.

L. m. levels were reduced by 2 logs after

2 weeks and remained low after

10 weeks

Morey et al. (2012)

L. i. levels were reduced to undetectable

levels after 2 and 4 weeks of storage on

both high and low end turkey rolls with

all LS samples tested, with the exception

of S4 on low end rolls. Only a small

reduction was seen after two weeks

(0.53 log CFU) but was not detected after

4 weeks.

L. i. levels were reduced to undetectable

levels after 2 and 4 weeks of storage with

all fractions tested.

Milly et al. (2008)

Gedela, Gamble,

et al. (2007)

Gedela, Gamble,

et al. (2007)

Milly et al. (2008)

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

203

Table 4 (continued)

Liquid smoke fraction

Liquid smoke

concentration

Strain

Processing parameters

Result

Reference

Code V

8%

Escherichia coli O157:H7

Growth was reduced by 2.3 log CFU/g

Estrada-Muoz et al.

(1998)

C10

Staphylococcus aureus

Charsol Supreme

75%

No reduction after 5 days

None detected after 5 days

None detected after 3 days

None detected after 3 days

1.7 log reduction after 3 h compared to

control

No reduction after 15 h compared to

control, however no enterotoxins were

present in LS treated samples

0.74 log reduction and no enterotoxins

were detected

Paranjpye et al.

(2004)

Charsol Supreme

25%

50%

75%

100%

1.25%

Beef trimmings were inoculated and

treated with LS after which they were

ground and formed into 7090 g patties.

Patties were packaged, and stored at 4 C

for 3 days.

Brined strips were dipped for 1 min,

inoculated, and processed at 30 C for

35 days

Cocktail mixture of

S. aureus ATCC 27664

(enterotoxin E), ATCC

13565 (enterotoxin A),

and ATCC 12660

Cocktail mixture of

S. aureus ATCC 27664

(enterotoxin E), ATCC

13565 (enterotoxin A),

and ATCC 12660

Inoculated, ground pork bellies were

treated with LS and heated to 50 C over

6 h followed by cooling to 7.2 C for

315 h

50 g pieces were inoculated and heated

to 50 C over 6 h. LS was sprayed at

hours 4 or 5. Sample were cooled to

7.2 C for 15 h.

both two and four weeks of cold storage. All liquid smoke fractions tested contained similar phenol concentrations (0.3 to 0.6 mg/mL) while

carbonyl concentrations ranged from 110 to 200 mg/mL for fractions

S1, S2 and S3 and from 100 to 110 mg/mL for S4. Fraction S4 was also

lower in acidity (0 to 1.4%) and higher in pH (6 to 7.4) than the other

samples (acidity range1.5 to 5.9% and pH 2 to 4.3). Again, the data

suggest that phenols contribute little to the bacteriostatic properties of

liquid smoke and that carbonyl compounds and acidity levels are

important in assessing the antimicrobial properties of liquid smoke

products. The authors also reported that food product composition

also plays an important role in bacterial survival in that the lower end

turkey rolls were apparently able to support bacterial growth better

than the high end turkey rolls or roast beef cuts (Milly, Toledo, &

Chen, 2008).

Liquid smoke has demonstrated ability at reducing foodborne

pathogens including L. monocytogenes, E. coli, S. aureus and Salmonella

in RTE foods and other food products. The exact mechanism of action

is unknown, and both phenolic compounds and carbonyl compounds

are thought to contribute to its antimicrobial properties. Table 4 lists

the chemical components of several commercial liquid smokes and

other liquid smoke fractions discussed below.

4. Antimicrobial activity of liquid smoke against Listeria

L. monocytogenes is a Gram-positive food borne bacterium. Listeria

has the ability to grow to infective doses at low temperatures, high

salt concentrations, and under acidic and microaerophilic conditions,

which make it difcult to control on many ready-to-eat (RTE), refrigerated foods. The infective dose of L. monocytogenes is dependent upon

several factors including the bacterial strain and susceptibility of the individual to the bacterium, but it can be as low as 1000 bacteria (SchmidHempel & Frank, 2007). Consumption of an infective dose of Listeria

may lead to the food borne infection, listeriosis, in humans especially

in older adults or persons who are immunocompromised as well as

pregnant women and newborns. Symptoms of listeriosis include fever,

muscle aches, nausea or diarrhea and may result in meningitis, premature labor, miscarriage or even death. In the US, 1651 cases of listeriosis

and 292 deaths or fetal losses as a result of Listeria infection were reported between 2009 and 2011 (CDC, 2011).

4.1. In vitro effects on Listeria

Pittman et al. (2012) studied the effects of individual stressors of

cold smoking including freezing, thawing, salt exposure, exposure to

liquid smoke and cold storage on virulent and avirulent Listeria. Two

Taormina and

Bartholomew (2005)

Taormina and

Bartholomew (2005)

strains, virulent HCC7 and avirulent HCC23, both in mid-log growth

were examined by transmission electron microscopy (TEM) to identify

changes in cell wall integrity due to exposure to a simulated cold

smoking process in brain heart infusion (BHI) culture medium. Bacteria

were subjected to a sequence of stresses: a freeze thaw cycle (20 C

for 2 h followed by room temperature thawing for 1 h); exposure to

6% NaCl at 30 C for 1 h, exposure to 0.6% liquid smoke at 30 C for 1 h

and nally anaerobic storage at 2 C for 16 h. The authors found that

the avirulent strain was more susceptible than the virulent strain to all

of the above conditions of the cold-smoking process; the virulent strain

was only signicantly affected by application of liquid smoke and anaerobic storage. The results suggested that these two different strains

utilize different mechanisms to adapt to the above stresses. More importantly, they found that both strains can survive the effects of this

simulated cold smoking process, emphasizing the need for additional

effective but all-natural antimicrobial interventions to control this pathogen (Pittman et al., 2012).

4.2. Antilisterial effects in ready-to-eat meats

Ready-to-eat (RTE) meats such as luncheon meat and frankfurters treated with liquid smoke have shown reduced levels of

L. monocytogenes. Beef franks were inoculated by immersion into a

3 log10 CFU/mL cocktail of six strains of L. monocytogenes. After air

drying, frankfurters were dipped in full strength CharSol-10, air dried,

vacuum packed and stored at 4 C. After 72 h, frankfurters treated

with CharSol-10 exhibited a 3 log10 reduction in L. monocytogenes

counts compared to control samples whose bacterial count remained

unchanged (Messina, Ahmad, Marchello, Gerba, & Paquette, 1988).

Spray application of liquid smoke was also successful in reducing

L. monocytogenes levels on frankfurters formulated without the typical

Listeria growth inhibitors of sodium lactate and sodium diacetate.

Frankfurters were sprayed with the commercial liquid smoke fraction AM-3 followed by inoculation with a six strain cocktail of

L. monocytogenes at a concentration of 5 log10 CFU/mL. Frankfurters

were stored at 4 C and bacterial levels were monitored at 2, 24 and

48 h. Liquid smoke treated samples showed a continuous decline of

L. monocytogenes with time until no detectable levels were seen at 48

h (Martin et al., 2010). An extended shelf life study in which lactate/

diacetate free frankfurters were sprayed with AM-3 and inoculated

with a cocktail of L. monocytogenes, showed that liquid smoke could

suppress L. monocytogenes on frankfurters vacuum packed and stored

at 4 C for up to 130 days (Martin et al., 2010). In a similar study

lactate/diacetate free frankfurters were inoculated with 3 log10 CFU/mL

of a four strain cocktail of L. monocytogenes, sprayed with the liquid

204

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

smoke fraction Zesti B (Mastertaste, Monterey, TN) and stored at

the abuse temperature of 6.1 C for up to 10 weeks. Levels of

L. monocytogenes decreased after one week of storage, but thereafter increased by only 0.8 log10 CFU/g above the initial inoculum level by the

end of the 10 weeks as compared to a 7 log10 increase in untreated

franks (Gedela, Escoubas, & Muriana, 2007). The authors also tested

the effectiveness of a dip application of liquid smoke to frankfurters.

Retail franks (containing lactate and diacetate) which had previously

been shown to permit growth of L. monocytogenes at 1.7 C after

6 weeks were dipped in Zesti-B liquid smoke for 1 to 90 s followed by

inoculation with 1 log10 CFU of a Listeria cocktail. Viable counts were

reduced to below the detection level after 4 weeks of storage for all

dip times tested whereas untreated controls showed a greater than

4 log10 increase (Gedela, Escoubas, et al., 2007; Gedela, Gamble, et al.,

2007).

A combination of post-process heat pasteurization and a liquid

smoke containing reduced acid levels and low phenolic concentrations

was able to reduce L. monocytogenes on frankfurters and deli turkey. Of

two smoke extracts tested, the product coded as Zesti-B had 3.5 to 5.6%

acidity, a pH 2.5 to 3.3, with a maximum of 1.7 mg/mL of phenols and a

carbonyl concentration of 19 to 22 g/100 mL while the product coded as

AM-3, a fraction lighter in color and reduced smoke avor, contained

1.8 to 2.1% acidity, a pH 4.25 to 4.85, with a 0.3 to 0.8 mg/mL phenol

concentration and a carbonyl concentration of 16 to 20 g/100 mL.

Frankfurters were formulated without lactate/diacetate and dipped for

1 s into Zesti-B or AM-3, inoculated with a four strain mixture of

L. monocytogenes at 5 log10 CFU/sample, vacuum packed, pasteurized

at 73.9 C for 1 min and stored at the mild abuse temperature of 6.1 C

for up to 10 weeks. No Listeria was detected immediately after processing and L. monocytogenes levels remained below detectable limits during 10 weeks of storage. Turkey breast chubs formulated without

lactate/diacetate or nitrate underwent similar treatment. Samples

treated with liquid smoke 60 to 30 s post-process pasteurization resulted in 2 to 3 log 10 reductions of Listeria by week two.

L. monocytogenes levels remained consistently low for the remainder of

the experiment (Gedela, Gamble, Macwana, Escoubas, & Mariana, 2007).

The use of liquid smoke as an ingredient, as opposed to topical application, has also been shown to be effective in reducing L. monocytogenes.

Frankfurters, formulated with 2.5%, 5% or 10% (wt/wt) of the liquid

smoke fraction Zesti Smoke (Kerry Ingredients and Flavors, TN), were

inoculated with either 4 or 8 log10 CFU/mL of L. monocytogenes, vacuum

packed and stored at 4 C for 12 weeks. At select sampling times the

frankfurters were rinsed and the rinsates were plated on Modied

Oxford agar to detect the presence of Listeria. The liquid smoke incorporated as an ingredient in frankfurters was able to suppress the growth of

L. monocytogenes inoculated at both high (8 log10 CFU/mL) and low inoculation levels (4 log10 CFU/mL) at its lowest concentration (2.5%)

compared to untreated samples. Inoculated frankfurters not formulated

with liquid smoke permitted growth of L. monocytogenes up to more

than 8 log10 CFU/mL in 12 weeks for both high and low inoculation

levels. The addition of 2.5% liquid smoke to the frankfurters reduced

L. monocytogenes levels compared to control levels to 6.2 log10 CFU/mL

for the low inoculation level and 7.47 log10 CFU/mL for the high level

inoculation. Further suppression was seen with increasing liquid

smoke concentrations. However, frankfurters containing 10% liquid

smoke were somewhat less acceptable in sensory panel tests as compared to frankfurters containing 2.5% or 5% liquid smoke (Morey,

Bratcher, Singh, & McKee, 2012).

4.3. Genetic basis of the antimicrobial effects of liquid smoke on Listeria

Liquid smoke has a demonstrated success at limiting the growth of

Listeria. Using proteomics Guilbaud et al. (2008) examined the effects

of liquid smoke on L. monocytogenes. Listeria was exposed to 30 g/mL

of phenol for 2 h which resulted in the upregulation of ClpP-2, a subunit

of the general stress protein ClpP which is required for virulence

expression in L. monocytogenes. Also affected were proteins involved

in metabolic pathways including Lmo355 and Lmo2829, proteins involved in membrane bioengineering and lipid metabolism, suggesting

that liquid smoke affects the synthesis of the cell membrane. In addition

liquid smoke reduced the hemolytic activity of Listeria and may reduce

the virulence of Listeria. This may partially explain the extremely limited

number of food borne outbreaks involving cold-smoked sh.

5. Effects of liquid smoke on Salmonella spp.

Salmonella is a Gram-negative food borne bacterium. Salmonella contamination is especially prevalent in raw poultry and eggs, but the organism can contaminate a wide variety of different foods including dairy,

meat and raw vegetables and fruits and animal feeds (Maciorowski,

Jones, Pillai, & Ricke, 2004; Foley et al., 2011; Howard, O'Bryan,

Crandall, & Ricke, 2012; Finstad, O'Bryan, Marcy, Crandall, & Ricke,

2012). The infectious dose of Salmonella is approximately 5 log10

organisms (Schmid-Hempel & Frank, 2007). Symptoms of Salmonella

infection include fever, cramps, vomiting and diarrhea. Generally symptoms only last a few days and leave no lasting effects; however, in some

cases life threatening complications may arise (Ricke, Koo, Foley, &

Nayak, 2013).

A liquid smoke generated from the pyrolysis of rice hulls was shown

to be bactericidal against Salmonella Typhimurium in a disk diffusion

assay at concentrations ranging from 0.1% to 1%. Larger zones of inhibition were seen at higher rice hull liquid smoke concentrations. The MIC

was 0.822% (v/v) as determined by a broth dilution assay. Interestingly,

rice hull liquid smoke also enhanced survival of mice infected with a

lethal dose of Salmonella. The Balb/c mice were fed a commercial

chow diet containing 1% rice hull liquid smoke for 14 days after which

they were injected with 5 log10 CFU of Salmonella Typhimurium. Mice

fed rice hull liquid smoke survived twice as long (about14 days)

compared to mice that were fed the untreated diet who survived approximately 7 days (Kim et al., 2012).

Van Loo et al. (2012) determined the MICs of seven commercial

liquid smoke samples from three commercial manufacturers against S.

Typhimurium using a microdilution method. The liquid smoke samples

were separated into two groups. Group I contained water based liquid

smokes extracted from woods of hickory, mesquite, apple and pecan.

Group II were concentrated liquid smokes extracted from hickory and

mesquite. Group II liquid smokes were more effective at reducing

Salmonella with MIC values ranging from 0.5% to 4%. Group I was less

effective and produced MIC values from 6% to 12%. Similar results

were seen with nine commercial liquid smoke samples (Mastertaste,

Brentwood, TN) on a cocktail of Gram-negative bacteria consisting of

S. Muenster, S. Seftenburg, S. Typhimurium and E. coli. MIC values

ranged from 1.5% to 9% (Milly et al., 2005).

6. Effects of liquid smoke on E. coli

E. coli is a Gram-negative bacterium found in the intestines of most

animals including humans. Although most strains of E. coli are innocuous, some strains such as the Shiga toxin producing strain O157:H7

(STEC) and non O157:H7 Shiga toxin producing strains can cause illness

if ingested (Jaeger, 1999). E. coli O157:H7 is infectious at concentrations

as low as 10 organisms (Schmid-Hempel & Frank, 2007). Complications

arising from STEC strains of E. coli infections include cramps, vomiting,

bloody diarrhea, and blood in the urine, with severe infections leading

to kidney failure (Belongia et al., 1991). Contamination with STEC strains

of E. coli is often found in undercooked meat especially beef, unpasteurized dairy products and raw fruits and vegetables.

6.1. In vitro effects of liquid smoke on E. coli

The antimicrobial properties of smoke condensates in concentrations ranging from 0.05% to 1% were evaluated against STEC strains of

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

E. coli. These strains were able to grow in up to 0.1% smoke while at

0.125%, growth was delayed by 1 day and at 0.25% no growth was

observed (Fretheim, Granum, & Vold, 1980). Values for MICs for several

commercial liquid smokes against E. coli O157:H7 were reported by Van

Loo et al. (2012). Effective concentrations ranged from 6% to as low as

0.75% depending upon the commercial brand of liquid smoke.

205

avor and also has inhibitory effects on food borne pathogens. The

preservative effect of liquid smokes is achieved by antimicrobial and

antioxidant compounds such as aldehydes, carboxylic acids and phenols.

Liquid smoke also has several advantages over traditional smoking techniques including ease of application, speed of smoking process, good reproducibility of desired characteristics obtained in the nal smoked

food, and omission of hazardous polycyclic aromatic hydrocarbons.

6.2. Effects of liquid smoke on E. coli in beef

The effects of liquid smoke on E. coli in a model meat system have

been reported. Beef trimmings were inoculated with 7 log10 CFU/g of

the STEC strain E. coli O157:H7 and treated with a nal concentration

of 8% of the liquid smoke fraction Code V (Hickory Specialties,

Brentwood, TN). Trimmings were then ground, formed into patties,

heat sealed and stored at 4 C. Liquid smoke treated trimmings showed

a 2.3 log10 CFU/g reduction after three days of refrigerated storage compared to untreated samples (Estrada-Muoz, Boyle, & Marsden, 1998).

7. Effect of liquid smoke on Staphylococcus

Staphylococcus is a Gram-positive spherical-shaped bacterium

appearing in grape-like clusters (Betts, 2010). S. aureus is salt tolerant

and produces heat-stable enterotoxins which are responsible for

staphylococcal foodborne illnesses. Foodborne illness due to S. aureus

is a result of eating foods contaminated with toxins produced by the

bacteria as opposed to consumption of the bacteria itself (Betts,

2010); it is generally agreed that populations of S. aureus need to

reach 5 to 6 log10 organisms for toxin production to occur (SchmidHempel & Frank, 2007). Symptoms of S. aureus infection include nausea,

vomiting and diarrhea which generally last 1 to 3 days. Foods commonly contaminated with S. aureus are prepared foods that require no additional cooking such as salads of tuna, egg, chicken, potato and macaroni,

sandwiches, bakery products containing a cream lling as well as meat,

poultry and eggs (Betts, 2010).

Bacon has been shown to also harbor staphylococci (Taormina &

Bartholomew, 2005). In order to validate that bacon processing does

not permit the growth of S. aureus, cured, raw pork bellies were ground

and inoculated with a cocktail of S. aureus followed by application of

Charsol Supreme to a nal concentration of 1.25%. Samples were slowly

heated over the course of 6 h to 50 C, the peak smoking temperature

for bacon, and cooled to 7.2 C in 3 h to simulate smoking and blast chilling that occurs in commercial plants. S. aureus populations increased by

only 0.68 log10 CFU/g in liquid smoke treated samples, when compared

to control samples which had an increase of 2.38 log10 CFU/g. When

cooling times were increased from 6 to 15 h S. aureus grew by 4 log10

CFU/g in both smoke treated and untreated samples, however no

enterotoxins were detected in samples treated with liquid smoke. In a

separate experiment, whole pork bellies were sliced into 50 g pieces

and inoculated by injection of the bacterial cocktail to a nal inoculation

concentration of approximately 2 log10 CFU/g. The pieces were then

subjected to simulated smoking. A 75% solution of Charsol Supreme

was sprayed after 4 and 5 h of the smoking process after which the

samples were cooled to 7.2 C over the course of 15 h and bacterial populations were enumerated. After simulated smoking and extended

cooling S. aureus populations were reduced to 0.74 0.53 log10 CFU/g

and samples were negative for staphylococcal enterotoxins (Taormina

& Bartholomew, 2005).

8. Conclusions

Liquid smoke is an effective antimicrobial against an array of bacterial pathogens as demonstrated in both broth culture and food systems.

Commercial use of liquid smoke in the food industry may satisfy consumer demand for all-natural foods while still maintaining their safety.

Liquid smoke is being used more frequently in preserving protein-based

foods, namely meat, sh, and cheese, because it imparts a pleasant

References

Acheson, D. W. K., & Jaeger, J. L. (1999). Shiga toxin-producing Escherichia coli. Clinical

Microbiology Newsletter, 21, 183188.

Andrews, J. (2012, October 29). Poll shows food safety condence slightly decreased this

year. Food Safety News. Retrieved July 10, 2013 from http://www.foodsafetynews.

com/2012/10/u-s-lost-condence-in-food-safety-since-last-year/#.Ud14eTsqZnk

Asita, A. O., & Campbell, I. A. (1990). Anti-microbial activity of smoke from different

woods. Letters in Applied Microbiology, 10, 9395.

Belongia, E. A., Macdonald, K. L., Parham, G. L., White, K. E., Korlath, J. A., Lobato, M. N.,

Strand, S. M., Casale, K. A., & Osterholm, M. T. (1991). An outbreak of Escherichia

coli O157:H7 colitis associated with consumption of precooked meat patties. Journal

of Infectious Diseases, 164, 338343.

Betts, R. (2010). Microbial update Staphylococcus aureus. International Food Hygiene, 21,

1213.

Boyle, D. L., Sofos, J. N., & Maga, J. A. (1988). Inhibition of spoilage and pathogenic microorganisms by liquid smoke from various woods. Lebensmittel-Wissenschaft &

Technologie, 21, 5458.

CDC (2011). Vital Signs: Listeria Illnesses, Deaths, and Outbreaks - United States, 2009

2011. Morbidity and Mortality Weekly Reports, 62, 448452.

Chen, Z., & Maga, S. A. (1993). Wood smoke composition. In G. Charalambous (Ed.), Food

avors, ingredients, and composition (pp. 10011007). New York, NY: Elsevier.

Davidson, P. M. (1997). Chemical Preservatives and Natural Antimicrobial Compounds. In

M. P. Doyle, L. R. Beuchat, & T. J. Montville (Eds.), Food Microbiology: Fundamentals and

Frontiers (pp. 520556). Washington, DC: American Society for Microbiology.

Davidson, P. M., Critzer, F. J., & Taylor, T. M. (2013). Naturally occurring antimicrobials for minimally processed foods. Annual Review of Food Science and

Technology, 4, 163190.

Dolan, L. C., Matulka, R. A., & Burdock, G. A. (2010). Naturally occurring food toxins. Toxins,

2, 22892332.

EPA (2008). Environmental Protection Agency. Polycyclic Aromatic Hydrocarbons. http://

www.epa.gov/osw/hazard/wastemin/minimize/factshts/pahs.pdf

Estrada-Muoz, R., Boyle, E. A. E., & Marsden, J. L. (1998). Liquid smoke effects on

Escherichia coli O157:H7, and its antioxidant properties in beef products. Journal of

Food Science, 63, 150153.

Faith, N. G., Yousef, A. E., & Luchansky, J. B. (1992). Inhibition of Listeria monocytogenes by

liquid smoke and isoeugenol, a phenolic compound found in smoke. Journal of Food

Safety, 12, 303314.

Finstad, S., O'Bryan, C. A., Marcy, J. A., Crandall, P. G., & Ricke, S. C. (2012). Salmonella and

broiler production in the United States: Relationship to foodborne salmonellosis. Food

Research International, 45, 789794.

Foley, S., Nayak, R., Hanning, I. B., Johnson, T. L., Han, J., & Ricke, S. C. (2011). Population

dynamics of Salmonella enterica serotypes in commercial egg and poultry production.

Applied and Environmental Microbiology, 77, 42734279.

Fretheim, K., Granum, P. E., & Vold, E. (1980). Inuence of generation temperature on the

chemical composition, antioxidative, and antimicrobial effects of wood smoke.

Journal of Food Science, 45, 9991002.

Gedela, S., Escoubas, J. R., & Muriana, P. M. (2007). Effect of inhibitory liquid smoke fractions on Listeria monocytogenes during long-term storage of frankfurters. Journal of

Food Protection, 70, 386391.

Gedela, S., Gamble, R. K., Macwana, S., Escoubas, J. R., & Mariana, P. M. (2007). Effect of inhibitory extracts derived from liquid smoke combined with postprocess pasteurization for control of Listeria monocytogenes on ready-to-eat meats. Journal of Food

Protection, 70, 27492756.

Guilbaud, M., Chafsey, I., Pilet, M. -F., Leroi, F., Prvost, H., Hbraud, M., & Dousset, X.

(2008). Response of Listeria monocytogenes to liquid smoke. Journal of Applied

Microbiology, 104, 17441753.

Guilln, M. D., & Sopelana, P. (2003). PHA's in diverse foods, Chapter 8. In J. F. Felix

D'Mello (Ed.), Food safety: Contaminants and toxins. Cambridge, MA: CABI Publishing.

Guilln, M. D., Sopelana, P., & Partearroyo, M. A. (2000). Polycyclic aromatic hydrocarbons

in liquid smoke avorings obtained from different types of wood. Effect of storage in

polyethylene asks on their concentrations. Journal of Agricultural and Food Chemistry,

48, 50835087.

Holley, R. A., & Patel, D. (2005). Improvement in shelf-life and safety of perishable

foods by plant essential oils and smoke antimicrobials. Food Microbiology, 22,

273292.

Howard, Z. R., O'Bryan, C. A., Crandall, P. G., & Ricke, S. C. (2012). Salmonella Enteritidis in

shell eggs: Current issues and prospects for control. Food Research International, 45,

755764.

Juneja, V. K., Dwivedi, H. P., & Yan, X. (2012). Novel natural food antimicrobials. Annual

Review of Food Science and Technology, 3, 381403.

Kim, S. P., Kang, M. Y., Park, J. C., Nam, S. H., & Friedman, M. (2012). Rice hull smoke extract inactivates Salmonella Typhimurium in laboratory media and protects infected

mice against mortality. Journal of Food Science, 71, M80M85.

206

J.M. Lingbeck et al. / Meat Science 97 (2014) 197206

Kim, S. P., Yang, J. Y., Kang, M. Y., Park, J. C., Nam, S. H., & Friedman, M. (2011). Composition of liquid rice hull smoke and anti-inammatory effects in mice. Journal of

Agricultural and Food Chemistry, 59, 45704581.

Maciorowski, K. G., Jones, F. T., Pillai, S. D., & Ricke, S. C. (2004). Incidence and control of

food-borne Salmonella spp. in poultry feeds A review. World's Poultry Science

Journal, 60, 446457.

Martin, E. M., O'Bryan, C. A., Lary, R. Y., Jr., Grifs, C. L., Vaughn, K. L. S., Marcy, J. A., Ricke, S.

C., & Crandall, P. G. (2010). Spray application of liquid smoke to reduce or eliminate

Listeria monocytogenes surface inoculated on frankfurters. Meat Science, 85, 640644.

Messina, M., Ahmad, H. A., Marchello, J. A., Gerba, C. P., & Paquette, M. W. (1988). The effect of liquid smoke on Listeria monocytogenes. Journal of Food Protection, 51, 629631.

Milly, P. J. (2003). Antimicrobial properties of liquid smoke fractions. Masters Thesis.

http://athenaeum.libs.uga.edu/bitstream/handle/10724/7046/milly_paul_j_200312_

ms.pdf?sequence=1

Milly, P. J., Toledo, R. T., & Chen, J. (2008). Evaluation of liquid smoke treated ready-to-eat

(RTE) meat products for control of Listeria innocua M1. Journal of Food Science, 73,

M179M183.

Milly, P. J., Toledo, R. T., & Ramakrishnan, S. (2005). Determination of minimum inhibitory

concentrations of liquid smoke fractions. Journal of Food Science, 70, M12M17.

Montazeri, N., Himelbloom, B. H., Oliveira, A. C. M., Leigh, M. B., & Crapo, C. A. (2013). Rened liquid smoke: A potential antilisterial additive to cold-smoked sockeye salmon

(Oncorhynchus nerka). Journal of Food Protection, 76, 812819.

Montazeri, N., Oliveira, A. C. M., Himelbloom, B. H., Leigh, M. B., & Crapo, C. A. (2013).

Chemical characterization of commercial liquid smoke products. Food Science &

Nutrition, 1, 102115.

Morey, A., Bratcher, C. L., Singh, M., & McKee, S. R. (2012). Effect of liquid smoke as an

ingredient in frankfurters on Listeria monocytogenes and quality attributes. Poultry

Science, 91, 23412350.

Painter, T. J. (1998). Carbohydrate polymers in food preservation: An integrated view of

the Maillard reaction with special reference to discoveries of preserved foods in

Sphagnum-dominated peat bogs. Carbohydrate Polymers, 36, 335347.

Paranjpye, R. N., Peterson, M., Poysky, F. T., Pelroy, G. A., & Eklund, M. W. (2004). Control

of bacterial pathogens by liquid smoke and sodium lactate during processing of

cold-smoked and dried salmon strips. Journal of Aquatic Food Product Technology,

13, 2939.

Pittman, J. R., Schmidt, T. B., Corzo, A., Callaway, T. R., Carroll, J. A., & Donaldson, J. R.

(2012). Effect of stressors on the viability of Listeria during an in vitro cold-smoking

process. Agriculture, Food & Analytical Bacteriology, 2, 195208.

Poysky, F. T., Paranjpye, R. N., Peterson, M. E., Pelroy, G. A., Guttman, A. E., & Eklund, M. W.

(1997). Inactivation of Listeria monocytogenes on hot-smoked salmon by the interaction of heat and smoke or liquid smoke. Journal of Food Protection, 60, 649654.

Rai, M., & Chikindas, M. (Eds.). (2011). Natural antimicrobials in food safety and quality.

Cambridge, MA: CAB International.

Ramakrishnan, S., & Moeller, P. (2002). Liquid smoke: Product of hardwood pyrolysis. Fuel

Chemistry Division Preprints, 47, 366367.

Ricke, S. C., Koo, O. K., Foley, S., & Nayak, R. (2013). Chapter 7. Salmonella. In R. Labbe, & S.

Garcia (Eds.), Guide to foodborne pathogens 2nd edition (pp. 112137). Oxford, UK:

Wiley-Blackwell.

Ricke, S. C., Van Loo, E. J., Johnson, M. G., & O'Bryan, C. A. (Eds.). (2012). Organic meat

production and processing. New York, NY: Wiley Scientic/IFT (444 pp.).

Rozum, J. J. (2009). Smoke avor. In R. Tart (Ed.), Ingredients in meat products, properties,

functionality and applications (pp. 211226). New York, New York: Springer Science

LLC.

Schmid-Hempel, P., & Frank, S. A. (2007). Pathogenesis, virulence, and infective dose. PLoS

pathogens, 3, e147.

Simko, P. (2005). Factors affecting elimination of polycyclic aromatic hydrocarbons from

smoked meat foods and liquid smoke avorings. Molecular Nutrition & Food Research,

49, 637647.

Simon, R., de la Calle, B., Palme, S., Meier, D., & Anklam, E. (2005). Composition and analysis of liquid smoke avouring primary products. Journal of Separation Science, 28,

871882.

Sirsat, S. A., Muthaiyan, A., & Ricke, S. C. (2009). Antimicrobials for pathogen reduction in

organic and natural poultry production. Journal of Applied Poultry Research, 18,

379388.

Sofos, J. N., Maga, J. A., & Boyle, D. L. (1988). Effect of ether extracts from condensed wood

smokes on the growth of Aeromonas hydrophila and Staphylococcus aureus. Journal of

Food Science, 53, 18401843.

Suen, E. (1998). Minimum inhibitory concentrations of smoke wood extracts against

spoilage and pathogenic micro-organisms associated with food. Letters in Applied

Microbiology, 27, 4548.

Suen, E., Fernandez-Galian, B., & Aristimuo, C. (2001). Antibacterial activity of smoke

wood condensates against Aeromonas hydrophila, Yersinia enterocolitica and Listeria

monocytogenes at low temperature. Food Microbiology, 18, 387393.

Suen, E., Aristimuo, C., & Fernandez-Galian, B. (2003). Activity of smoke wood condensates against Aeromonas hydrophila and Listeria monocytogenes in

vacuum-packaged, cold-smoked rainbow trout stored at 4C. Food Research

International, 36, 111116.

Taormina, P. J., & Bartholomew, G. W. (2005). Validation of bacon processing conditions

to verify control of Clostridium perfringens and Staphylococcus aureus. Journal of Food

Protection, 68, 18311839.

Van Loo, E. J., Babu, D., Crandall, P. G., & Ricke, S. C. (2012). Screening of commercial and

pecan shell-extracted liquid smoke agents as natural antimicrobials against

foodborne pathogens. Journal of Food Protection, 75, 11481152.

Vitt, S. M., Himelbloom, B. H., & Crapo, C. A. (2001). Inhibition of Listeria innocua and

L. monocytogenes in a laboratory medium and cold-smoked salmon containing liquid

smoke. Journal of Food Safety, 21, 111125.

Wier, M., & Calverley, C. (2002). Market potential for organic foods in Europe. British Food

Journal, 104, 4562.

Young, K. M., & Foegeding, P. M. (1993). Acetic, lactic and citric acids and pH inhibition of