Industrialattachmentofopexgroup 140511101158 Phpapp02

Diunggah oleh

Emdad ApmJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Industrialattachmentofopexgroup 140511101158 Phpapp02

Diunggah oleh

Emdad ApmHak Cipta:

Format Tersedia

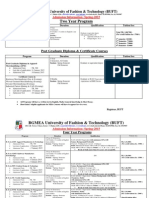

Industrial Attachment Report

2013

INDUSTRIAL TRAINING

Course Code: Tex -4036

INDUSTRIAL ATTACHMENT

OPEX GROUP

OPEX GROUP

Industrial Attachment Report

2013

Industrial

Attachment

Report

At

OPEX GROUP

Industrial Attachment Report

2013

OBJECTIVE OF INDUSTRIAL ATTACHMENT

B. Sc in Textile Technology is the combination of theoretical knowledge along

with the practical experience. We as the Graduates of Textile Technology

must acquire adequate practical knowledge to cope up with the challenge

that we will face in future. This is the why the Industrial Training has been

included in our academic curriculum.

The main objective of this training is to comprehend our theoretical

knowledge along with the practical knowledge. It also enables us to orient

ourselves with the practical environment that we will work in future. We

systematically learned about various steps of garment manufacturing.

Moreover we knew about the man management technique. We also learned

about merchandising and buyer co-ordination.

OPEX GROUP

Industrial Attachment Report

2013

INTRODUCTION

By achieving practical knowledge it is possible to apply the theoretical

knowledge in the technical field. For any technical education, practical

experience is almost equally necessary in association with the theoretical

knowledge. The industrial attachment is the most effective process of achieving

the practical experience. It provides us sufficient practical knowledge about

production management, productivity, evaluation, work study, efficiency,

industrial management, production planning & control, production cost analysis,

inventory control, purchasing, utilities and Maintenance of machinery and their

operation technique etc.

Industrial attachment is an essential part of four years B.Sc. in Textile

technology course of College Of Textile Technology under University of Dhaka.

We had the opportunity to perform the industrial attachment with OPEX

GROUP LTD. During 60 days long attachment, we studied the man, machine,

material, quality control section, planning section, grey fabric inspection,

finished fabric inspection, dyeing & finishing section, merchandising section of

the mill. We also had a short visit in the garments section of the factory.

OPEX GROUP

Industrial Attachment Report

2013

Table of Content

Chapter

Contents

Chapter-i

Chapter-ii

Chapter-iii

Chapter-iv

Chapter-v

Project description

Manpower management

Machine description

Raw materials

Production planning, sequences &

operations

Quality assurance system

Maintenance

Utility services

Store & inventory control

Cost analysis

Marketing activities

Garments washing

Merchandising

Conclusion

Chapter-vi

Chapter-vii

Chapter-viii

Chapter-ix

Chapter-x

Chapter-xi

Chapter-xii

Chapter-xiii

Chapter-xiv

OPEX GROUP

Page

no.

6-12

13-18

19-25

26-27

28-33

34-37

38-44

45-48

49-50

51-52

53-57

58-70

71-70

73-77

Industrial Attachment Report

2013

CHAPTER- I

(PROJECT DESCRIPTION)

OPEX GROUP

Industrial Attachment Report

2013

Name:

OPEX FASHION LTD. (a sister concern of OPEX & SINHA TEXTILE GROUP)

Type:

Ready made garments(100% Export oriented Woven& knit garments Industry).

Status:

Private limited company

Location: Mirpur-13 , Dhaka.

Year of establishment: 1984

Sponsors:

Address:

Anisur Rahman Sinha

a. Dhaka office:

56/1,Block#C,Section-13,Mirpur,

Dhaka-1216

Bangladesh.

Tel: 8015446

8015241

8023726-7

Fax: 880-2-8013522

b. Head Office:

House # 368, Road # 28, New DOHS, Mohakhali

Dhaka-1206, Bangladesh.

Tel: 88-02-8828860-4, 9891390-1

Fax: 880-2-8828856-7

c. Kanchpur Office:

Sinha Textile Complex,Kanchpur ,

Sonargaon,Narayanganj

Tel:7618066,7618055,7617788.

d. Hongkong Office:

Joyful Miles Ltd. 16B Alpha House

Tel: 2721-1950(5 lines), Fax: 2721-1967

E-mail: mhkhan@opexhkg.com.hk

OPEX GROUP

Industrial Attachment Report

2013

Factory Location:

Banani

Cantonment

Kachu

Khet

Mirpur-10

Mirpur-14

OPEX

OPEX GROUP

Industrial Attachment Report

2013

PRODUCT MIX:

a) Woven Garments: Shirt,Jacket,Pant/Trousers,Shorts Jeans item,Ladies &

Children item.

b) Knit garments:

T-shirt, polo shirt, Short / trouser, Knitted pant, Vests

DAILY PRODUCTION CAPACITY:

Garments: 40000 pcs (Dhaka Zone)

No. of line: 32(Dhaka zone) &100 (Kanchpur zone)

MONTHLY EFFICIENCY:

Daily production: 40000 pcs Approx.

Daily production capacity: 45,000 pcs

So, monthly production: 1040000 pcs

Monthly production capacity: 1170000 pcs

So, Monthly production efficiency= 88%

PROJECT COST:

US$1,0000000per year (approx) in 2007

US$1,5000000Projection for 2008.

DIFFERENT DEPARTMENTS:

1. Marketing and Merchandizing

2. Lab department

OPEX GROUP

Industrial Attachment Report

2013

3. Quality Assurance

4. Garments& GGT Lab

. Cutting

Sewing

Finishing

Inspection

Packing

5. Stores

6. Technical Department (Maintenance)

7. Human & Resource and Administration

8. Account and commercial section

9. Batching section

TOTAL AREA OF THE INDUSTRY: 15000 sq. feet & 4 building,

OPEX FASHIONS LTD :

10 Storeyed

OPEX STYLE WEAR LTD:

8STOREYED

SINHA STYLE WEAR LTD : 12 Storeyed

OPEX GROUP

10

Industrial Attachment Report

2013

COMPANY PROFILE:

OPEX

Opex is one of the largest garment manufacturing conglomerates in Asia and has a complete vertical

integrated setup in woven, knit and sweater with most modern and state of the art machineries from

USA, Europe and Japan. It is a private owned company with an annual turn over of US $ 350 million

and annual export is about US $ 250 million.

Garments Division

Opex has over 18000 sewing machines distributed to 300 production lines including 40 Knit garment

lines and 2000 Sweater machinery. It produces over 220,000 pieces of garment every day. The

production lines are broadly earmarked as Bottom lines, Shirt lines and Knit lines.

Bottom Factories

Opex has about 210 bottom production lines and they produce over 140,000 pieces of garments daily.

These are organized into dress pant lines, casual pant lines, cargo short/ pants lines and denim

production lines.

Dress and casual pant lines have some specialized sewing machines like pocket welting machines,

zigzag operations machines, blind stitch machines, front fly J-stitch machines, etc. Finishing of casual

and dress pant is done with lager and topper press machines, seam opening and pressing machines,

curing oven etc. Other than standard denim production line Opex has 16 dedicated specialized denim

production lines, equipped with fully automated computerized sewing and finishing range machines

from Italy. Each line produces 230-250 pieces of 5-pocket jeans in one hour, totaling to 34000-37000

pieces daily.

Shirt factories

Opex has 48 dedicated shirt lines which produces 35,000 to 40,000 pieces of casual, sports and formal

dress shirts daily. The formal and dress shirt lines are equipped with Droukoff Adler sewing machines

of Germany fitted with servo motors and trimmers which ensures consistency in sewing and eliminates

puckering effects. Collar & cuff making and setting, placket making, pocket making & setting and arm

hole fusing are all done with computer controlled automatic machines. The finishing units have

automatic collar, cuff, arm hole and body pressing machines for perfect finish.

Knit Garment Factories

Opexs 40 Knit garment lines have over 2000 sewing machines and it produces about 60,000 pieces of

T-Shirt, Polo Shirts daily. These lines can also be converted to produce shirts or ladies dresses by

changing and adding few machines.

Sweater Factory

OPEX GROUP

11

Industrial Attachment Report

2013

Our major production is on 12 gauge. However we have production facilities in 10 gauge, 7 gauge, 5

and 3 gauge. Presently we have about one hundred thousand production capacity per month but

recently have gone into expansion this will have capacities from Dec 08 about two hundred per

month.

Dry and Wet Processing Facilities

The in house dry and wet processing units of Opex includes sand blasting, brushing, chemical

spraying, laser blasting, heavy, medium and light wash facilities and post cure wrinkle

free processing facilities.

Opex has one of the most modern denim washing facilities in the country equipped with computer

controlled European machines. Denim wash capacity is about 1,00,000 pieces daily. It also has 55

belly type Chinese machines to take care of other washes. It has two modern dry finish units with

modern equipment with curing oven.

Backward Linkage and Vertical Setup of Opex

Customers increasing need of varied range of fabric, shorter lead time, sharper price and consistent

quality, led Opex to set up its own vertical set up in 1995, named as Sinha Textile Group. The

objectives of these facilities are; attaining consistency in fabric quality, developing specialized fabric &

offering competitive price and shorter lead time.

Opex today has the entire chain of backward linkage facilities of spinning, weaving, yarn dyeing, fabric

dyeing & finishing, knitting, knit dyeing and finishing. State of the art machines, Textile experts from

home & abroad have been combined together to make wide range of high quality woven fabric for

bottom, shirt & Knit fabric.

Supporting Establishments

To support garments manufacturing, Opex has its own button factory, label factory, Sewing Thread

manufacturing unit and Embroidery unit. It also has its own Carton and Poly manufacturing factory.

We have also joint venture with IDEAL Zipper factory in Bangladesh.

Opex has done massive expansion in increasing its garments production, washing and finishing

capacities as well as increasing capacity and adding new technology in its backwards integration units

like compact yarn, producing high density fabric, wet sueding and different types of fabric finishing

etc.

Denim Village.

Recently, we have established a massive project named denim village where we are producing, Denim

fabric, Denim garments, Denim Washing, and different types of finishing in one complex.

Opex can convert all its fabric into Garments and will produce about 65000 pcs Denim Jeans and

Jacket per day.

Conclusion.

Opex with over 45,000 work forces is in business for more than two decades. It always tries and

maintains its commitment of on time delivery, quality and competitive price. Over the years, the

business relations with all customers and partners have grown stronger based on mutual trust and

commitment.

Opex is an ethical and compliant company, putting in maximum emphasize on developing human

values, qualities of human life and comfort of work environment. It is committed to ensure ethical

source place for the customer.

OPEX GROUP

12

Industrial Attachment Report

2013

CHAPTER- II

(MANPOWER MANAGEMENT)

OPEX GROUP

13

Industrial Attachment Report

2013

ORGANOGRAM MANPOWER:

Chairman

Executive Director

General Manager

Deputy General Manager

Asst. General Manager

Merchandising Manager

Sinior Merchandiser

Merchandiser

Production Manager

Sample incharge

Operator

Helper

Cutting incharge

Cutting executive

Cutting supervisor

Marker man

Sewing incharge

Line supervisor

Operator

Helper

OPEX GROUP

Quality inchare

Operator

Helper

14

Industrial Attachment Report

2013

Cutterman

MANAGEMENT SYSTEM:

GARMENTS SECTION: 8 hours per day.8 AM-5 PM. Overtime: 2hours.

Offday: Thursday in a week.

RESPONSIBILITIES OF PRODUCTION MANAGER:

RESPONSIBILITIES OF SAMPLE ROOM INCHARGE:

To make pattrn from specification sheet.

When there is no measurement chart then he make specification chart by

his own idea, then send to buyer,if it is ok then he make pattern.

After making sample he check the sample if it is ok , then he order to

make 4 pcs of the sample.

RESPONSIBILITIES OF CUTTING INCHARGE:

Check the relaxation of fabric,order wise quantity measure, patterncutting

with signature,befor sewing to communicate the print embroidery.

To ensure equal input & output.

To check fabric shrinkage, twisting repair.

To make the cutting plan according to operation breakdown.

To give target and style devide in every table.

RESPONSIBILITIES OF QUALITY INCHARGE:

To control the overall quality of the garments.

To brief the incharge about tentative problem of quality.

To make size set of the garments.

To check the measurement of the garments, if required increase or

decrease

RESPONSEBILITIES OF PRODUCTION OFFICER: From getting an

order of upper level all responsibilities are on the production officers. They

work with a troop of operators, helpers, fitters etc. to finish the production in

due time. In the meantime

OPEX GROUP

15

Industrial Attachment Report

2013

Production officers bear all hazards, problems. They have to explain to the

manager for any type of production hamper. So all production activities and its

success depend on the production office.

MANPOWER MANAGEMENT

ADMINISTRATIVE STRUCTURE OF OPEX GROUP:

CHAIRMAN

EXECUTIVE

DIRECTOR

ADMIN

&EESTB

DGM

AGM

CLEANER

&

SANITER

Y

INCHARG

PERSON

E

AL

TIME

ACCOUNT

S

STORE

GM

AGM

UNIT-INCHARGE

INTERNAL

&

EXTERNAL

ADMIN &

DAY

CARE

SECURITY

INCHARG

E

UNIT-INCHARGE

INCHARG

E

TRAINING

INSTITUTE

PRINCIPAL

SECURITY

SUPERVIS

OR

COMPUT

ER

COMPLINCE

D.G.M.

UNIT-INCHARGE

INCHARG

E

MEDICAL

OFFICER

UNIT-INCHARGE

TECHNIC

AL

DGM

MECHANICAL

ELECTRICAL

AGM

AGM

OPEX GROUP

16

Industrial Attachment Report

2013

ORGANOGRAM OF QUALITY CONTROL DEPARTMENT:

GENERAL MANAGER (QUALITY )

ASST. GENERAL MANAGER

MANAGER

ASST. MANAGER

QUALITY- IN-CHARGE

QUALITY CONTROLLER

LINE Q.C.

ORGANOGRAM OF WASHING DEPARTMENT:

OFFICER-IN-CHARGE (O.I.C.)

ASST. OFFICER-IN-CHARGE

MANAGER

FLOOR-IN- CHARGE

ASST. MANAGER

QUALITY INSPECTION CONTROLLER

QUALITY CONTROLLER

OPEX GROUP

17

Industrial Attachment Report

2013

SUPERVISOR

DESCRIPTION

MERCHANDISING STUFF

IT STUFF

SAMLE MAN

Q.A-RAW MAT.

INSPECTOR

Q.A-IN-LINE INSPECTOR

FLOOR Q.C

Q.A AUDITORS

CUTTING SECTION

SEWING SECTION

TRIMMING/ FINISHING

PRESSING & PACKING

PACKING

ELECTRICIAN/MECHANICS

WASHING,SAND

BLASTING & SAND

BRUSHING

PRINTING

PACKAGING

POLY

QUILTING

EMBROIDERY

OFFICE STUFF & OTHERS

NO OF EMPLOYEES

40

04

150

10

250

50

30

200

3200

500

600

250

150

200

TOTAL EMPLOYEES

5976

12

50

30

30

20

200

OPERATOR

TOTAL EMPLOYEES:

OPEX GROUP

18

Industrial Attachment Report

2013

REMARKS:

Production runs with the help of mechanical fitters. For any kind of mechanical

fault of any machine they fix and work under knitting manager. Production

officer takes account of daily production by running after the two supervisors

& workers so on.

CHAPTER-III

(MACHINE DESCRIPTION)

OPEX GROUP

19

Industrial Attachment Report

LOCK STITCHM/C

2013

LOCK STITCH M/C

H/S D/N LOCKSTITCH

4-holed button sewing

OPEX GROUP

20

Industrial Attachment Report

CHAIN STITCH BUTTON SEWER

2013

4 NEEDLE DOUBLE CHAINSTITCH

MULTI-NEEDLE DOUBLE CHAIN STITCH

OPEX GROUP

MAIER BLIND STITCH MACHINE

21

Industrial Attachment Report

SIMPLE PUSH-BUTTON TYPE STITCH

OVERLOCK MACHINES

2013

FLAT-LOCK SEWING MACHINERY

STRAIGHT KNIFE CUTTING M/C

OPEX GROUP

22

Industrial Attachment Report

2013

MACHINE DESCRIPTION

MACHINE DESCRIPTION

Type of Machine

Quantity(Sets)

Sewing Capacity

A. General Sewing

Machine

Single Needle

Double Needle

Over lock

Kansai

Bar Tack

Button Stitch

Button Hole

Eyelet Button Hole

Bottom Hem

Flat Lock

Snap Button

Blind Stitch

Feed of the Arm

Cutter m\c

Heat Cutter

Fusing m\c

Over lock Elastic Attaching

m\c

Arm Hole Sewing m\c

Total

1000

421

320

50

200

150

100

25

50

65

30

25

150

100

15

15

6

40,000 pieces per day

15

2737

OPEX GROUP

23

Industrial Attachment Report

2013

B. Specialized Sewing

Machine

Auto Patch Pocket Setting

Auto Welt Pocket Setting

Waist Belt Setting

Seam Sealing

Zigzag

Elastic Attaching

Pattern Sewing

Auto Loop Attaching

Snap Testing m\c

Pattern(Collar& Cuff) m\c

Pocket Facing

Picoting

Velcro Cutter

Feather Filling

Total

m\c

Cutting Room

Fabric Inspection m\c

Light Box

Gerber Cam

Gerber Auto Spreader

Manual Cutting Table

Manual Cutter

Finishing Room

Needle Detector

Hang Tagger Attaching

Steam Iron

Thread Sucking m/c

CAD Room

Gerber CAD

Gerber Plotter

Gerber Digitizer

Support

Steam Boiler

Generator

Other Projects

Poly Bag Making Project

Carton Making Project

Printing Project

Quilting

Embroidery

2

10

15

15

10

12

10

5

5

5

10

2

10

4

115

05

02

2

5

20

100

5

20

Cutting Capacity

50,000 yards/day

Finishing Capacity

20,000 pieces per day

150

15

2

1

1

02

02

OPEX GROUP

Capacity

1.5 MW

20 heads on each end and up

24

Industrial Attachment Report

2013

to 15 colors

Pin Point Stitch m/c

Vacuum Iron Table

Lay End Cutting m/c

Washing Plant

Type of Machine

Quantity (Sets)

Sample Washing m/c

05

Washing m/c

14

Washing

5

m/c(Tonello+Yilmak)

Hydro Extractor

8

Dryer

12

Sand Blast m/c

02

Laser Blasting

2

Sand Brush m/c

10

E.T.P

1

Average Production Capacity

OPEX GROUP

Capacity

500 lbs

40,760 lbs

12600 lbs

2,610 lbs

32,600 lbs

1000 pcs per day

500 pcs per day

3000 pcs per day

80 cubic meter per hour

30,000 pieces of gt per day

25

Industrial Attachment Report

2013

CHAPTER-IV

RAW MATERIALS

OPEX GROUP

26

Industrial Attachment Report

2013

RAW MATERIALS OF OPEX FASHIONS LTD

Garments Section:

Soucing tag

Fabric woven

Price ticket

Button

Hanger

Zipper

Sizer

Sewing thread

Size sticker

Main label

Poly bag

Care label

Cartoon

Tag pin

SOURCES OF RAW MATERIALS

Required raw materials are purchased from following countries through agent :

a. Taiwan

b. Philippines

c. India

d. Germany

e. Brazil

f. Pakistan

g. South China

OPEX GROUP

27

Industrial Attachment Report

2013

CHAPTER-V

(Production Planning,

Sequences & Operations)

OPEX GROUP

28

Industrial Attachment Report

2013

DESCRIPTION OF PRODUCTION PROCESS(GARMENTS SECTION):

]

Squence Operation for Sample Section:

Product Package

Make Pattern

If not OK

Make Sample

Send to Buyer through Merchandiser

If OK

Collect the approved Sanple

Sequence Operation for Cutting Section:

Fabric Inspection & relaxation

Fabrid spreading

Fabic cutting

Parts numbering

Part inspection

OPEX GROUP

29

Industrial Attachment Report

2013

If any defect is found then make this part

Sequence Operation for Sewing Section:

Front Yoke joining

Elastic join

Topstich

Sleeve join

Front Yoke join

Sleeve join

Elastic tuck

Elastic tuck

Elastic join

Back part piping

Front Yoke+Sleeve+Back Yoke Joining

Elastic Stiching

Vertical tuck

Sleeve opening tuck

OPEX GROUP

30

Industrial Attachment Report

2013

Side seam

Chup tuck

Sleeve opening chup tuck

Hem

Inspection

OPERATION BREAKDOWN : FIVE POCKET JEANS (JC PENNEY)

BACK PART MAKING

Serial

Name of Operation

Machine used

No

1

Back Pocket Rolling

2 Needle Machine

2

Marking Table

3

Back Yoke Joining in Folder System

Feed of the Arm m/c

4

Back Rise Joining

Plain Stitch m/c

5

Back Rise Top

Feed of the Arm m/c

6

Back Pocket Positioning on Marker

Table

7

Back Pocket Joining

Plain Stitch m/c

8

Stitch on Pocket Joining

Plain Stitch m/c

FRONT PART MAKING

Serial

Name of Operation

No

1

Pocket Matching

2

Ironing

3

Coin Pocket Attaching

4

Label Joining

5

Coin Pocket Attaching with Front

Facing

Machine used

2 Needle m/c

Plain Stitch m/c

Plain Stitch m/c

OPEX GROUP

No of Machine

1

1

1

1

1

1

No of Machine

1

1

1

31

Industrial Attachment Report

6

7

8

9

10

11

12

13

14

15

16

17

Number Match with Front Part

Coin Pocket Joining with Front Part

Front Pocket Rolling

Pocket Tuck

Pocketing Over Lock

Single Fly Join with Top Stitch

Pocket Top Stitch

Front Pocket with Front Tucking

Zipper Joining

J - Stitch

Double Fly Joining

Front Rise Stitch

BODY SECTION

Serial No

Name of Operation

1

Back & Front Part Match on

Table

2

In Seam

3

Top Seam on In Seam

4

Side Seam

5

Hemming

6

Waist Belt Matching by

Number

7

Waist Belt Sewing

8

Edge Neatening of Down Part

of the Waist

9

Waist Top Part Making

10

Waist Top Part Edge

Neatening

11

Checking by LQC

12

Belt Loop Matching

13

Loop Tuck on Down Side of

Waist

14

Loop Joining with Top Side of

Waist

15

Final Inspection

16

Loop & Back Part Bar Tacking

17

Side Pocket Tucking

2013

Plain Stitch m/c

2 Needle m/c

Plain Stitch m/c

Over Lock m/c

Plain Stitch m/c

Plain Stitch m/c

Plain Stitch m/c

2 Needle m/c

2 Needle m/c

Plain Stitch m/c

2 Needle m/c

2

1

1

1

1

1

1

1

1

1

1

Machine used

No of Machine

Plain Stitch m/c

Feed of the Arm m/c

Over Lock m/c

Plain Stitch m/c

KANSAI

Plain Stitch m/c

1

1

2

1

2

2

Plain Stitch m/c

Plain Stitch m/c

Plain Stitch m/c

Bar Tack m/c

Plain Stitch m/c

2

1

OPEX GROUP

32

Industrial Attachment Report

2013

SUMMERY

Plain Stitch Machine - 36

2 Needle Machine

- 07

Over Lock Machine

- 04

Bar Tack Machine

- 02

KANSAI

- 02

Feed of Arm Machine 04

Production

- 1000 pieces per day

Manpower

- 94 persons

REMARKS:

As OPEX FASHION LTD a big project; its production quantity is huge.

Production quantity varies as according as buyers demand. It gives approximately 500-ton and

1000000 pcs production per month. In Bangladesh, there are a few mills, which can produce

such quantity of garments.

OPEX GROUP

33

Industrial Attachment Report

2013

CHAPTER-VI

(Quality assurance system)

OPEX GROUP

34

Industrial Attachment Report

2013

QUALITY ASSURANCE SYSTEM:

All rolls are kept in front of the inspection m/c time to time and are inspected over

the grey inspection m/c visually in a pre-set speed against light. For any major or minor faults

like thick-thin, barre marks, fall out, contamination, fly, holes, oil lines, needle lines, slubs,

etc are recorded in grey inspection report to classify the fabric based on the four point system.

Collar & cuff are inspected visually under light box, any major & minor faulty

collar/cuff like having wrong ply, hole, needle lines, slubs, wrong design, first line problem

etc properly counted and recorded.

QUALITY ASSURANCE PROCEDURE:

Based on the sequence of grey inspection, the inspector serially numbers each roll

ensuring that all rolls having complete details of the roll.

1) After production of fabric rolls of 8 to 25 kg, m/c operators cut them from the

cloth or batch roller and they are carried to inspection section by the helpers.

2) Almost four inspection workers are for every shift to check the fabric rolls. For

any kind of fault they are checked thoroughly. Skilled inspectors find them and indicate them

by the scissors in some cases.

3) Quality is specified on the basis of 4-points system. Here is the point distribution

for different kinds fault in this system: FOUR POINT GRADING SYSTEM

Size of defects

Penalty

3 inches or less

1 point

Over three inch but not 6 inch

2 point

Over 6 inch but not 9 inch

3 point

Over 9 inch

4 point

QUALITY CLASSIFICATION

1

<20

OK

2

20-30

ASK

OPEX GROUP

3

30>

REJECT

35

Industrial Attachment Report

2013

LIST OF EQUIPMENTS:

In this factory OFL the list of equipments to assure quality: 1) Inspection machine

2) Scissors

3) Weight balance & Microbalance

4) GSM cutter

5) Seal (CHECK-1, OK, REJECT.).

Rejection criteria for Fabrics:

No.

Faults

Response

1.

2.

Needle marks

Stripe

Major needle line is rejected.

Major needle line is rejected.

3.

Barre marks

Rejected

4.

5.

6.

7.

Slubs

Wrong design

Pin holes

Fly & contamination

1 point

Rejected

1 point

Acceptable for color but not for white

8.

9.

Sinker marks

Uneven tension

Do

Discuss with manager

10.

Missing yarn

Use 4 point

11.

Crease line

Do

12.

Uneven tension

Discuss with manager

13.

Oil stripe/line

Do

14.

Thick-thin place

Rejected

15.

Mixed yarn

Discuss with manager

OPEX GROUP

36

Industrial Attachment Report

2013

Rejection criteria for collar & cuff: Following table shows common collar & cuff faults

and response taken by grey inspection section.

No.

Faults

Response

1.

2.

3.

Wrong ply

Hole

Needle line

Reject

Reject

Reject

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

Slubs

Wrong design

Wrong tripping

Fly & contamination

First round problem

Uneven tension

Missing yarn

Crease line

Rust line

Oil stripe

Thick-thin

Wrong tube

Reject

Reject

Reject

Acceptable for color but not for white

Reject

Discuss with manager

Reject

Reject

Reject

Reject

Reject

Reject

QUALITY STANDARD:

Here is the quality standard:1) Fabric width

7) Broken needle /2

2) Fabric length

8) Thick /thin yarn

4) Slub

9) Barre/ Stripe

3) Fabric weight

10) Dirt

5) Hole

11) Oil

6) Needle / Sinker line

12) Press off

REMARKS:

There is hardly any chance of any roll to pass through production on to any buyers by to

by unchecked or disqualified. The inspections are too much experience and they are aware

about their duties and responsibilities. The factory authority and production related personnel

are happy and satisfied with their works

OPEX GROUP

37

Industrial Attachment Report

2013

CHAPTER-VII

(Maintenance)

OPEX GROUP

38

Industrial Attachment Report

2013

MAINTENANCE:

Maintenance of machineries is very important for any type of industries and it is a

must for a knit composite mill. All machines and machines parts of Washing, dyeing and

garments are maintained with extreme care. Because production quality and quantity, both

depends on the maintenance with regularity. OPEX FASHIONLTD lead maintenance with a

troop of skilled mechanical fitters.

MAINTENANCE OF MACHINERY:

In the knitting floor of OFL all machine are maintained regularly and as

necessity requirements. Here, different type of maintenance of machinery, which is taken,

different time on the machineries.

ROUTINE:

1) Daily Maintenance: Every machine is taken maintenance daily by the

operators during production. When the operator starts a production after handing over from

previous shift operator, he takes a routine maintenance on the

machine. He cleans the machine, assures yarn is fed to all needles, cleans the eye pot of

feeder, memminger, signal lamp sensor etc. Before a while of a roll cut from batch or cloth

roller, operator cleans needles, cylinder base plate etc. All around of the machine are kept neat

and clean as if there is no dirt with yarn in the fabric.

2) Schedule/Routine Maintenance: Every machine has a schedule of maintenance

of 10 or 15 days. According to date, schedule maintenance is taken on the machines.

Operators are informed about the time of maintenance. After pre-estimated production, they

hand over the machine to the fitters. Thus, fitters assure all machines are OK. For any time.

3) Break down maintenance: When product quality hampered and to complete

production in due time break down maintenance is taken. There are many faults seen in the

fabric during production due to needle, sinker, take down roller etc. Then operators inform the

mechanical fitters and they fix it.

4) Restorative maintenance: Restorative maintenance is taken for design change

or new design development. According to advice or order of production officer, a machine is

fixed for new design and mechanical fitters rearrange cam and needle system.

Planned and preventive maintenance are not taken on the machineries in this mill.

OPEX GROUP

39

Industrial Attachment Report

2013

MAINTENANCE OF SEWING M/C:

Lubrication:

Since the life of the m/c and its correct working depend to a large extend adequate

and proper lubrication. It is recommended that the instructions given in the lubrication charts

be followed conscientiously. The Company can not be need responsible for faults that arise

from wrong or inadequate lubrication.

Oiling Needles:

Too much oil is preferable to too little. Dark vertical lines in the fabric originate not

from excessive oiling .

The Cleaning of Needle:

Thin oil is most suitable for this work, about one point heated to a temperature not

exceeding 160F poured into the oiling position of the m/c.

General Cleaning Schedule:

Long m/c life, maximum output & trouble free running depend upon proper care

and maintenance. A general overhaul should take place annually when single shifts are

worked & correspondingly at more frequent interval.

MAINTENANCE PROCEDURE:

1) For there is any mechanical fault of machine, which is responsible for

production hamper, operator informs mechanical fitters in duty. Mechanical fitters come and

observe the problem firstly, and then they begin to fix it.

2) If mechanical fitters were unable to fix it, then they inform technical in-charge,

he then comes in spot and fixes it.

3) For there is any electrical problem of machine or serious founding mechanical

problem, mechanical and electrical department are informed, they come and fix the problem.

4) For restorative maintenance, senior production officer orders mechanical

fitters to fit required machine for cam and needle arrangement and other necessary

requirements in case of new design development.

OPEX GROUP

40

Industrial Attachment Report

2013

MAINTENANCE TOOLS/EQUIPMENTS & THEIR FUNCTIONS:

Maintenance tools/equipments

Functions

1. Adjustable wrench

Used for setting nut & bolts

2. Air suctioner

For cleaning machine

3.Spanner

Fixed Spanner for nut & bolts fitting

4.Socket spanner

Handle system for nut & bolt fitting

5. Hammer

To apply load where required

6. Screw driver

To release any screw

7. Punch

Used to fit any worn out shaft

8. Lock opener

To open the clip of bearing

9. Hack saw

To cut any metallic thing

10. Outside calipers

To measure outside dia

11. Inside calipers

To measure inside dia

12. Cutting pliers

To cut thin wires

13. Pulley key

To loosen pulleys

14. Chain ton

To lift heavy load

15. Welding machine

To join metallic parts

16. Grinding machine

To make the smooth fabrics

17. Tester

To test electric circuit

18. Pliers

To grip anything & cut anything

19. Star driver

Screw unlocking

20. Steel tape

To measure length, width & height

21. Chisel

To cut any metal

22. L-key

For loosen & tighten the screw

23. File

To smooth the rough surface

OPEX GROUP

41

Industrial Attachment Report

2013

Repair, maintenance and setting and replacement of different parts of

lockstitch machine:

Apparatus:

1. Flat screw driver

2. Star screw driver

3. Hammer

4. Pliers

5. Lubricating oil

6. Grease

Standard atmospheric condition:

Temperature28c

Relative humidity..62%

Procedure: The repair, maintenance, setting and replacement procedure are described below:1. Repair: Repair work is carried out when a component requires slight modification.

To carry out such job the machine needs to be switched off first. The component

under repair is then screwed off by suitable apparatus. After repairing, the part is

fixed to its designated place and hence its correctness is measured by running the

machine. In a lockstitch machine bobbin case, bobbin, check spring, feed dog.

Motor belt etc can undergo repair job.

a. Maintenance: Maintenance can be of different types. But following types are

important in this aspect.

b. Routine maintenance: lubrication and regular inspection are the constituent of

routine maintenance. Lubrication ensures long life and safe working of all the

equipment. Inspection tries to detect faults in equipment so that repairs and

replacement may be under taken at the right time.

c. Scheduled maintenance: this type of maintenance provides for inspection,

overhaul lubrication and servicing of the machine, cleaning of all components is

normally done in this manner. It involves opening of the machine into its smallest

component and carry out lubrication.

2. Setting: the setting of the lockstitch machine is of immense importance. Following

setting points need to be ensured before running the machine.

OPEX GROUP

42

Industrial Attachment Report

2013

Stitch density controller: It controls the no of stitch per inch. Before starting the

machine, stitch per inch is determined by rotating the knob and fixing it at the

desired position.

b. Motor: Motor rpm depicts the speed of the machine. The rpm is controlled by

tightening or looseness the belt over machine & motor pulley.

a.

c. Needle: needle undergoes accurate setting to ensure proper sewing. Needle is

attached by means of a screw which needs to be tightened enough to produce easy

sewing. Again the needle size is also important from fabric point of view.

d. Pressure foot: The type of pressure foot to be used & its proper setting is

important which is ensured by proper attachment with the motor through machine

pulley.

e. Feed dog: It is often found that due to random working the feed dog is subjected to

be loose which may cause accident also. Thus the feed dog must be set properly

with the screw.

3. Replacement: The replacement is revealed when the retention of equipment is no

more remain an economical proposition. A replacement is affected when the

equipment is subjected to complete breakage which cannot be used even after repair

or the component has become so obsolete that affects production or it has crossed

its expire date. Replacement can be affected to any components of the machine at

any time. In lockstitch machine components like needle, pressure foot, feed dog etc

undergo frequent replacement.

Precaution: Following precautions must be taken when repair, setting maintenance is carried

out in the lockstitch machine.

1. All repair & maintenance work must be carried out by switching off the

machine.

2. Right tools should be used at right place.

3. Skilled personnel should be involved for specialized job.

4. Careful handling of all the components is necessary.

5. The components should not be too tight or too loose.

OPEX GROUP

43

Industrial Attachment Report

2013

Remarks: The experiment has provided us wide idea regarding the repair, maintenance,

setting & replacement of different components of lockstitch machine .It has given us a basic

knowledge on machine maintenance as a whole. It has also oriented us with different machine

tools & their use those are required for the said job. The gathered knowledge will indeed help

us in our practical life. We hope to important our learning in the days to come.

This mill has a strong maintenance fitters troop to fix up all types problem. Two

groups of two shifts obey their duties responsibly and sincerely. With their different tools or

equipments they perform their duties skillfully

OPEX GROUP

44

Industrial Attachment Report

2013

CHAPTER-VIII

(UTILITY SERVICES)

OPEX GROUP

45

Industrial Attachment Report

2013

UTILITY FACILITIES AVAILABLE:

For smooth functioning of any production unit, uninterrupted and

required utility services are indispensable. Success of any industry largely depends

on this factor. Any irregularity or lack in the required utility services immediately

results in unexpected halt of the production process. An Industry needs various

utilities depending on its manufacturing process.

In OFL the major utilities are available- Power (Electricity)

- Water

- Natural gas

- Compressed air

- Steam

- ETP

SOURCES OF UTILITIES:

The main utility, which is used by OFL, is natural gas. From

natural gas generator produce electricity. From natural gas and electricity in

association with mechanical and electrical apparatus, OFL produce other utilities

like water, steam, compressed air etc.

CAPACITY AND OTHER TECHNICAL DETAILS:

Power (Electricity):

Generator house is the main power producing plants of NCL

There are two generator in generator house.

Generator Type: gas generator

Brand name: Caterpillar

Origin: USA

Frequency: 100 Hz

Voltage: 400 V

STEAM:

Boiler produces the required steam. There is two boiler in OFL

Boiler specification:

Brand name: Industrial boiler Ltd

OPEX GROUP

46

Industrial Attachment Report

2013

Capacity: 8ton / hr

Blower motor: 25 HP

Water supply for the boiler:

Water required for steam production is supplied by deep tube well.

Pretreatment of the boiler water:

Boiler feed water needs special standard. Any deviation from the

required standard may result in scale formation, which eventually reduces the

efficiency of the boiler. This ultimately affects the cost of steam generation and

makes the production cost high. To maintain the required standard of the water,

there should be some means to pretreat the boiler feed water. To protect scale

formation of boiler, NELCO is used as chemical in water feed tank. 200 gm NELCO

is injected per 12 hrs. In OFL there are water softeners that act before the water

enters the boiler.

.

No. Of the softener :

There is one water softener to pretreat the boiler feed water.

COMPRESSED AIR:

The compressed air is supplied from air compressor. There two -air

compressors in OFL.

Compressor Brand name Hitachi Screw Compressor

Origin: Japan

Model no. OSP-55S5 ARI

Maximum working pressure: 15 bar

Average working pressure: 6.5-7.5 bar

Year of construction: 2004

WATER:

The water source OFL is deep tube well.

Water treatment plant: There is no Water treatment plant in Mirpur but one in

Kanchpur.

GAS:

The source of gas is government agency. Gas is required mainly for

generation of electricity, boiler to produce steam, the burners of heat setting m / c.

OPEX GROUP

47

Industrial Attachment Report

2013

As OFL generates their own electricity, the gas consumption is quite high. The gas

consumption is 250-350 m / hr.

COST OF DIFFERENT UTILITIES:

Electricity cost:

REB =3.8 TK / KW-HR

Gas generator = 2.70 TK / KW-HR

Diesel generator = 6.50 TK / KW-HR

Gas cost:

4.94 Tk/m for boiler

3.66 Tk/m for generator

4.5 Tk/m for domestic purpose

Steam cost:

4.30 Tk per kg fabric.

REMARKS:

For smooth running of factory main utilities like gas, electricity or

steam is very essential. Sometimes gas pressure is low than required pressure. When

the gas pressure is low, then diesel generator run. Government should have to ensure

proper gas supply for Industrial purpose.

OPEX GROUP

48

Industrial Attachment Report

2013

(CHAPTER-IX)

STORE & INVENTORY CONTROL

OPEX GROUP

49

Industrial Attachment Report

2013

INVENTORY SYSTEM OF RAW MATERIAL:

It is previously speak that OFL. is a Woven composite industry. The main

raw material of OFL is grey fabric. Grey fabric first produce in knitting department

of this company. Weaving section of OPEX GROUP Produces grey fabric as per

buyers order. Dyeing section get grey fabric from Weaving section. Grey fabric store

officer receive the grey fabric and store the grey fabric in storeroom. Then he

delivers the grey fabric to batch preparation section according to shipment date or

according to production manager of dyeing section instruction.

Other raw materials of OFL are dyes and chemicals. Dyes and

chemicals store officer always keep stock report of dyes and chemicals and also

know the daily or monthly requirements of each dyes or chemicals. If the stock is

bellowing30days then he gives requisition to head office for each product. Head

office indent dyes and chemicals.

SPARES:

Spare store officer keep the spare part in store & make a list of spare parts.

If the spare parts are little in stock he gives requisition to maintenance manager.

Technical manager give requisition to Head office. Head office indent spare parts or

buy local market as per requirements.

FINISHED GOODS INVENTORY:

Finish fabrics from the compactor go to inspection team. From the

inspection table the fabric weighted in weight meter & go to finish fabric storeroom.

Here finished fabric store officer make a list of total finished products. He sends the

finished fabric to OPEX FASHION LTD as per shipment date or requirements of

production manager of OPEX FASHION LTD. He also keeps the delivery list.

REMARKS:

Inventory control system and storing system of OFL. is over all good.

OPEX GROUP

50

Industrial Attachment Report

2013

CHAPTER -X

(COST ANALYSIS)

OPEX GROUP

51

Industrial Attachment Report

2013

INTRODUCTION:

Costing is a process by which the setting price of a product is calculated. It is a

very important task for a factory, which runs for business purposes.

And it is also strictly followed in the OFL. Costing of the products considering the raw

materials expenditure, salary and wages of officers and workers, distributions and

advertisement expenses etc. all direct and indirect expenses is done in this factory. It is

determined by a troop of accountants with advice and consultancy of executive director.

PRICE OF THE PRODUCT:

Generally price of product is determined by the required profit adding to the total

expenses. So,

Price of products= (Direct expenses + Indirect expenses + Factory

Overhead) + Required profit

PRICE RANGE OF DIFFERENT PRODUCTS:

Shirt = $11.75 - $28.50 /Pcs

Jacket =$15.00 - $35.50 /Pcs

Kids Wear ==$10- $29/Pcs

REMARKS:

Costing is very important for a productive factory. Without proper costing all production

curriculums will go to vain. Because a factory cannot reach to its goal without achieving good

profit and good profit is not possible without skillful costing. In OFL there are some skillful

personnel to do this job.

OPEX GROUP

52

Industrial Attachment Report

2013

CHAPTER-XI

(MARKETING ACTIVITIES)

OPEX GROUP

53

Industrial Attachment Report

2013

Marketing Strategy:

Marketing strategy is a very important factors to sale the products to the buyer. If the

marketing strategy is not so developed, it will be very hard to reach the goal. In case of

garments marketing the dealings with the buyer is a very important factor.

In Standard Group mainly senior marketing officers, merchandiser & higher officials

deal with the buyer. There are some fixed buyers of the industry. The buyers give their orders

continuously all over the year. The marketing officers & the merchandisers communicate with

the buying houses to collect the orders.

By both side understanding the rate & the order quantity are fixed.

Duties & responsibilities of marketing officer:

Dealing with the buyer & convince the buyer is the main duty of marketing officer. A

marketing officer also has some other duties. The main duties & responsibilities of a

marketing officer are given bellow

To prepare cost sheet by dealing with the buyer

To take different steps by discussing with the high officials & merchandisers

To maintain a regular & good relationship between commercial officer &

merchandisers

To maintain a communication with the buyers and buying houses

Communicate with better criteria of the products

Actually the responsibilities & duties of marketing officer begins from getting order of

buyer & ends after receiving foods by the buyer. So, he should be always smart, energetic

& sincere.

Marketing activities are done of NCL by a skillful team of marketing officers under

the Executive Director. Here are the details of marketing activities.

CONSUMER OF THE PRODUCTS:

The mill has a great number of renowned and international consumers. Following

are some regular consumers:

1) JC Penney

2) Carryfour

3) Levis

4) TCP

5) Oshkosh

6) Target

7) AMC

8) American Eagle

OPEX GROUP

54

Industrial Attachment Report

2013

PRODUCT LABEL:

There are following labels used by this mill:

1) Care Label: It contains washing in hot or cold water, chemical cleaning,

drying conditions etc.

2) Size Label: It contains size of garments.

3) Composition Label: It contains the fabric composition of different fibre type.

4) Decorative Label: Decoration is as buyer or consumer choice wise.

PACKAGE SIZE & LABEL:

Most common sizes are

S - Small

M - Medium

L - Large

XL - Extra large

XLL - Very very large

2XLT

3XLT

REMARKS: OPEX Group has a well learned marketing & merchandising team. They always

communicate with the buyers. Standard Group has some fixed buyers. The marketing section

also looks the quality & quantity buyers.

Marketing activities are very important tasks for a productive factory. In this mill,

there having highly qualified marketing officers. As a result, the mill rises up day by day.

FAULTS OF GREY FABRICS:

1. Patta

Causes:

1. Yarn count variation

2.Yarn tension variation

OPEX GROUP

55

Industrial Attachment Report

Remedies:

2013

Proper yarn count & tension should be maintained.

Remarks:

For dark color & plain single jersey patta very sensitives. But in case of

derivatives of single jersey, rib &interlock light patta considerable.

2. Contamination:

Causes:

1.For unlearned machine & floor.

2.Little space between two adjacent machines.

3. For hairy & color yarn.

Remedies:

1.Proper cleaning of machine & floor.

Remarks:

Protection of every machine from dust & fly. In case of light color

contamination is very bad appearance. As a result garments rejected.

3.Needle mark:

Causes:

For bent hook & latch.

Remedies:

Immediately change faulty needle.

Remarks:

Needle mark is a common faults of knitting because unconscious of

operator. It has very bad effective for dyeing & causes a great loss of company.

4.Hole:

Causes:

1. For needle breakage & wrong adjustment of machine parts.

2. For uneven yarn & deposit of fibre.

OPEX GROUP

56

Industrial Attachment Report

Remedies:

2013

Correct adjustment of machine parts &clean machine.

5.Lycra out & tension variation of Lycra:

Causes: Breakage of Lycra yarn & uneven tension of Lycra.

6. Oil mark

7. Tara &loop.

OPEX GROUP

57

Industrial Attachment Report

2013

CHAPTER-XII

(WASHING)

OPEX GROUP

58

Industrial Attachment Report

2013

SAMPLE WASHING MACHINES (INDIA)

No. of machines: 05

Manufacturing company: STEFAB INDIA LIMITED

Model no: LXS 35.

Manufacturing country: India.

Features:

Single door, front-loading, open pocket.

Machine body and essential parts are made of stainless steel.

Automatic timed. Auto reverse. Automatic 5 water level & auto digital

temperature control.

Electric solenoid water & steam valves.

Non-clog motorised drain valve.

Full electric protection.

Specifications:

Capacity: 35 kg (Dry: Wet =1:10)

Inner cylinder: 950 mm dial X 500mm

Wash motor: 0.75 KW

Extract speed: 200 RPM

Main door opening: 500 mm dial

Water connection consumption: 25 mm dial, 120 litres.

Drain: 75 mm dial, 1 way out

Steam connection consumption: 15 mm dial, 25 Kg/hr.

Electric heating: 12 KW

Overall dimension: 1100mm(W) X 1430mm(D) X 1700mm(H)

OPEX GROUP

59

Industrial Attachment Report

2013

INDUSTRIAL WASHING & DYEING MACHINES (CHINA)

No. of machines: 14

Manufacturing Company :PANYUA XIN XIN Washing Machine Company Limited.

Manufacturing country: CHINA.

Features:

Single door design for general washing, sample washing.

Machine body and essential parts are made of stainless steel.

Preset front and backward rotation.

Specifications:

o Model-AIW-550(5)

o Rated Voltage-380 V

o Steam Pressure-0.4-.06 MPa

o Input Power-7.5 KW

o No Of Production-W.10583

o Related Washing Capacity-250kg

o Related Frequency -50 Hz

o Gross Weight-1900kg

o Overall Dimension -3.2X1.95X2.10

INDUSTRIAL WASHING PROCESSING & DYEING MACHINES

No. of machines: 05

Manufacturing company: STEFAB INDIA LIMITED,

Model no: LXS 280.

Manufacturing country: India.

Features:

Single door, front-loading, open pocket.

Machine body and essential parts are made of stainless steel.

Automatic timed. Auto reverse. Automatic 5 water level & auto digital

temperature control.

OPEX GROUP

60

Industrial Attachment Report

2013

Electric solenoid water & steam valves.

Non-clog motorised drain valve.

Full electric protection.

Specifications:

Capacity: 280 kg (1:10)

Inner cylinder: 1750 mm dial X 1180mm

Wash motor: 7.5 KW

Extract speed: 130 RPM

Main door opening: 1000 mm dial

Inspection door opening: 300 mm dial

Water connection consumption: 50 mm dial, 960 litres.

Drain: 115 mm dial, 2 ways out

Steam connection consumption: 25 mm dial, 200 Kg/hr.

Thermal fluid connection consumption: 1.5 X 1.5 BSP, 80000 KCAL/Hr.

Overall dimension: 1950mm(W) X 2500mm(D) X 2100mm(H)

HYDRO EXTRACTORS (CHINA)

No. of machines: 08

Manufacturing company: Tongxin Ltd.

Manufacturing country: China.

Features:

Due to its solid constructions it can be positioned onto firm floorings to

operate.

It has excellent electrical layout in prevention of electricity leakage, shock,

which is important in wet conditions in the operations.

Machine operations are made easy, with convenient start-stop operations for

maximum efficiency.

The inner stainless steel is well balanced, thus achieving longer life span and

assuming energy efficiency of machine.

OPEX GROUP

61

Industrial Attachment Report

2013

Shock absorbers are well paced in the three suspension points to reduce

vibrations.

Stainless steel constructions in major parts ensure durability.

Specifications:

Model no: SHE-42

Capacity: 280 LBS

Inner cylinder: 1067dial X 419mm

Over all dimensions: 2150 mm (W) X 1650 mm (D) X 1050 mm (H).

Wash motor: 7.5 KW

Extract speed: 860 RPM

SAMPLE DRYING MACHINES

No. of machines: 01

Manufacturing company: STEFAB INDIA LIMITED,

Manufacturing country: India.

Features:

Stainless steel inner cylinder and large S.S. loading-unloading door. Outer

body not painted. Long rust free life and sheen.

Built in solvent filter housed in the top tank receives soiled from the base tank

through a powerful centrifugal pump which pushes the soiled solvent through

several fine mesh cylindrical filters for reuse. Maximum recovery of clean

solvent.

Low spin extract. Separate motors for dryclean & extract. Vibrationless during

extraction. Low spin extract makes articles lighter to unload. No solvent

dripping. No wastage of solvent.

OPEX GROUP

62

Industrial Attachment Report

2013

Automatic timed. Auto reverse. Full electrical protection against single phasing

& motor overload. Operators convenience & machine safety. Efficient

cleaning.

Specifications:

Capacity: 18 Kg

Basket size: 700 mm (dial) X 470 mm

Volume: 180 Litres

Dry clean motor: 0.37 KW

Extract motor: 1.5 KW

Extract speed: 220 rpm

Loading door opening: 400 mm (dial)

Base tank capacity: 250 Litres

Filter tank capacity: 250 Litres

Overall dimensions: 1000mm(W) X1080mm (D) X 1730mm(H)

DRYING MACHINES

No. of machines: 12

Manufacturing company: Bengal Heavy Electric Engineering.

Manufacturing country: Bangladesh.

Features:

Stainless steel inner cylinder and large S.S. loading-unloading door. Outer

body painted.

Low spin extract. Vibration less during extraction. Low spin extract makes

articles lighter to unload.

OPEX GROUP

63

Industrial Attachment Report

2013

Automatic timed. Full electrical protection against single phasing & motor

overload. Operators convenience & machine safety. Efficient cleaning.

Specifications:

Capacity: 35 Kg

Basket size: 950 mm (dial) X 500mm

Volume: 350 Litres

Dry clean motor: 0.75 KW

Extract speed: 200 rpm

Loading door opening: 500mm (dial)

Overall dimensions: 1300mm(W) X 1250mm(D) X 2000mm(H)

GARMENTS SAND-BLASTING MACHINES

INDUSTRIAL SAND-BLASTIG GUNS

No. of machines: 03

Manufacturing company: Made in China

Features:

Single door design for general washing, sample washing.

Machine body and essential parts are made of stainless steel.

Preset front and backward rotation.

Specifications:

Model: SBT-650

Capacity: 200 Litres

Dimension: 800mm X 1000mm X 1250mm

Sand contains: 200 Kg

OPEX GROUP

64

Industrial Attachment Report

2013

OTHER COMPONENTS/ACCESSORIES

No. of cabinets: 03

Hopper (for controlling dust in cabinets): 02

Helmet: 07 Pcs

Musk: 07 Pcs

Gloves: 07 pairs.

Air preserver-1, capacity of 2000 c.c.

Air preserver-2, capacity of 900 c.c.

OTHER MACHINES

Spray machines: 03 Nos.

Manufacturing country: Hong Kong

Compressor: 03 Nos.

Two compressors with same following specifications.

o Brand: ELGI

o Capacity: 10 Jule/Bar

o Made in INDIA

One compressor with following specifications:

o Brand: OSD

o Made in ITALY

o Includes Change Over

o MCCB

o Capacity: 10 Jule/Bar

Boiler:

Brand name: Sacca

Manufacturer: Made in ITALY

Production capacity: 1.5 Tons/Hr.

Pressure: 7.5 Jule Bar (5.0 Bar used)

Supply system: Automatic Pressure control.

OPEX GROUP

65

Industrial Attachment Report

2013

Chimney: 50 Feet with 12-inch diameter.

Generator

Four stroke, diesel engines with 1500 RPM by "DEUTZ" and "VOLVO Penta"

production; "STAMFORD"(ST), "MECC Alte"(ME), "Marelli"(MA), "SINCRO"(SI)

alternators. All alternators are three phase, four pole, single bearing, synchronous type,

cosj=0.8, 50Hz.

Water supply pump: 03 Nos.

02 PCs. Deep Tube wells are Submersible, Made in ITALY, BG brand with 30 Horse

Power.

01 PC. Deep Tube well is Sigma branded, Made in ITALY with 42 Horse Power.

PROCESS TECHNIQUE OF SOME WASHING METHODS

ENZYME-BLEACH WASH WITH TINTING:

Batch 60 PCs.

Liquor 400 Litre

Step 01

Water is added (400 Lt)

Desizing

Garments are added

Machine started running

500 gm Soda Ash added

OPEX GROUP

66

Industrial Attachment Report

2013

500 gm Caustic Soda added

200 gm Bio. D added

Steam to raise temp 60C

Process time 25 minutes

Drop liquor

Wash down twice

Step 02

Water is added (400 Lt)

Enzyme Wash

Machine started running

200 ml liquid, 400 gm powder

type Enzyme added

150 ml Acetic Acid Added

200 gm Anti back added

OPEX GROUP

67

Industrial Attachment Report

2013

10 Kg Peumic Stone added

Steam to raise temp 50C

Process time 60 minutes

Drop liquor

Step 03

Water is added (400 Lt)

Bleaching

Machine started running

4 Kg KCI (35% Cl2) added

500 gm Soda Ash added

Steam to raise temp 60C

Process time 10 minutes

Drop liquor

OPEX GROUP

68

Industrial Attachment Report

Step 04

Water is added (400 Lt)

Neutral Wash

2013

Machine started running

500 gm Hypo sulphide added

Steam to raise temp 45C

Process time 10 minutes

Drop liquor

Step 05

Water is added (400 Lt)

Tinting

Machine started running

0.02% Direct Brown GTL &

0.01% Direct Black V-200 added

4 Kg Salt added

OPEX GROUP

69

Industrial Attachment Report

2013

Steam to raise temp 70C

Process time 20 minutes

Check Shade

Drop the liquor

Step 06

Garments are then taken out

Drying

Hydro extracted

Send to dryer for drying of garments.

REMARKS

No live industry can keep place with the advance of technology without continuous

renewal & transformation of its production facilities. Existing equipments must be kept on the

defensive, compelled always to justify its tenure against the challenge of new & more modern

machines. If any piece of existing equipment fails to meet this challenge, it must be displaced,

regardless of its age or condition & regardless of whether it is physically worn out.

Keeping the above in view, this industry is always replacing its existing machines in

order to increase productivity & improve quality.

OPEX GROUP

70

Industrial Attachment Report

2013

CHAPTER-XIII

(COMPLIANCE)

OPEX GROUP

71

Industrial Attachment Report

12.1 Responsibilities & Duties

2013

Compliance

1. To floor visit at least thrice a day.

2. To ensure workers fire safety, fire prevention, fire equipment, health & safety &

comfortable environment at work place.

3. To aware the workers about personal protective equipment.

4. To receive grievance, complain, demand & suggestion from the workers & after

receiving the issue discuss with related persons & local management immediately.

5. Try to find out emotional problem of an employee. The problem may be work related

or personal or family which affects his/her work performance.

6. To provided supportive counseling the sick worker for medicinal support on the

workers requests, complain or situational demand.

7. Try to make aware the existing workers about by company provided all facilities &

necessity of compliance.

8. To perform when social compliance audit.

9. To follow up aisle mark free, fire extinguisher no blocked, emergency exit free, fire

equipment free, stair free from carton in the floor.

10. To check all production related register if any date mentioned of holiday or not.

11. To conduct orientation program for newly appointed worker.

12. Try to motivate & make them conversant with the company objective, rules &

regulations, buyer code of conduct & local laws.

13. To briefing the employees about all facilities of company, mandatory safety

instruction including all dos & Donts.

14. To make aware the employees about leave procedure, maternity benefits, working

hour & over time system according to local laws.

15. To make aware the employees about personal health & hygiene, HIV/ AIDS/STD.

16. To conduct awareness programs the pregnant workers about safe motherhood.

17. To ensure that no employee each maltreated mentally or physically abused & they

should be treated with respect & dignity.

18. And any other work assigned by the Management.

OPEX GROUP

72

Industrial Attachment Report

2013

CHAPTER-XIV

(MERCHANDISING)

OPEX GROUP

73

Industrial Attachment Report

2013

Garment merchandising is an intricate and detail oriented job. If it can be done properly can

be very rewarding. On the country, if it is done with lack of knowledge, insufficient skill and

thoroughness, it can be destructive.

In the Standard Group very skilled and experienced personnel run the merchandising section.

After receiving an order, the merchandiser with the help of pattern master calculates the total

consumption of fabric. Then according to the cost detail sheet and the price mentioned by the

buyer costing is done. After the price is negotiated with the buyer order is placed to the

suppliers of raw material and accessories.

The manufacturing factory as per the requirement suppliers the fabric and a ledger is

maintained regularly to assess the production status. The accessories such as label, button,

zipper, sewing thread, packing materials are collected from outside [sometime mentioned by

the buyer] through back-to-back L/Cs. The merchandising department also looks for the

sources for procuring yarns to produce fabric.

Merchandising section monitors the production status regularly and ensure timely delivery of

the shipment.

OPEX GROUP

74

Industrial Attachment Report

2013

Main Buyers

-

GAP

JC PENNY

SEARS

AMERICAN EAGLE OUTFITTERS

H&M

TCP

OSHKOSH

VF ASIA

LEVIES

DOCKERS

PERILIES

MIRZA FASHION

AMC

OPEX GROUP

75

Industrial Attachment Report

2013

CHAPTER-XV

(CONCLUSION)

OPEX GROUP

76

Industrial Attachment Report

2013

CONCLUSION:

OPEX GROUP is a pioneer group in garments sector in our country.Bangladesh is a

developing nation. RMG Sector earns the Prime share of our foreign currency.

Development of this sector will definitely bring good fortune for our country. We

being the graduates of Textile Engineering must give our sincere effort to the future

advancement of RMG and related sector. Moreover from 1 January 2005, we will

enter into the quota free world where quality, lesser lead-time and low price will be

the key to success.

When the development of the country was at a stand still position

due to the legacy of shattered economy and the industrialization was stagnant, the

export oriented textile and RMG sector had shown the ray of hope by its allpervasive positive impact on the national economy. At the fag end of the eighty, this

sector started expanding and within a short period of its existence, this nascent

industry became the largest foreign exchange earner.

Standing at the verge of a new millennium, Textile and RMG

sector is now the heart of our national economy. Even after all this achievements,

this industry faces the major challenge of global adjustment in the coming years

when it has to respond the new trading arrangement after 2004.

OPEX GROUP LTD being a part of this decisive sector will have

to take necessary measure to cope with the change of globalization. Modification of

the technical arrangement with the advancement of technologies and good positive

approach will help to survive in this ever-changing global economy.

Hopefully, the confidence and foresight of the entrepreneurs and

the enthusiastic teamwork of the professionals will take OPEX GROUP LTD to an

even better position.

OPEX GROUP

77

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Welding ElectrodesDokumen13 halamanWelding ElectrodesArimoro Cyril ObuseBelum ada peringkat

- Instruction Manual Directional Overcurrent Protection Relay Grd140 - XXXDDokumen438 halamanInstruction Manual Directional Overcurrent Protection Relay Grd140 - XXXDEpsp MedBelum ada peringkat

- PRoductivityDokumen36 halamanPRoductivityEmdad ApmBelum ada peringkat

- PVT PWT PWV Datasheet Moore IndustriesDokumen6 halamanPVT PWT PWV Datasheet Moore IndustrieseamazomBelum ada peringkat

- Siemons - Cello Bowing TechniqueDokumen15 halamanSiemons - Cello Bowing TechniqueMassa Awaj100% (2)

- CH 6 Well ControlDokumen115 halamanCH 6 Well ControlFirdaus KhanBelum ada peringkat

- E-10 Storage Batteries - 1465729800 - E-10Dokumen10 halamanE-10 Storage Batteries - 1465729800 - E-10nicolas.travailBelum ada peringkat

- Automation Direct - An Industry Guide To Control System EngineeringDokumen93 halamanAutomation Direct - An Industry Guide To Control System EngineeringCesar CamachoBelum ada peringkat

- SteamTurbineGenerator Datasheet 500MWDokumen8 halamanSteamTurbineGenerator Datasheet 500MWParantap RahaBelum ada peringkat

- Boletin 6019 - Descontinuar SC-NDokumen2 halamanBoletin 6019 - Descontinuar SC-NPau MundacaBelum ada peringkat

- SMVDokumen70 halamanSMVEmdad Apm100% (1)

- HUAWEI BTS3900E Hardware Structure and Principle-090519-IsSUE1.0-BDokumen78 halamanHUAWEI BTS3900E Hardware Structure and Principle-090519-IsSUE1.0-BJaime Ambaco Matsena100% (1)

- Garment DefectDokumen3 halamanGarment DefectEmdad ApmBelum ada peringkat

- Buft Journal Call Papers - 2014Dokumen1 halamanBuft Journal Call Papers - 2014Emdad ApmBelum ada peringkat

- UlamaDokumen4 halamanUlamaEmdad ApmBelum ada peringkat

- Basic Garments AssignmentDokumen7 halamanBasic Garments AssignmentEmdad ApmBelum ada peringkat

- Admission Info. SpringDokumen2 halamanAdmission Info. SpringEmdad ApmBelum ada peringkat

- Fabric Consumption of A Basic ShirtDokumen7 halamanFabric Consumption of A Basic ShirtEmdad ApmBelum ada peringkat

- Thread Consumption TemplateDokumen7 halamanThread Consumption TemplateEmdad ApmBelum ada peringkat

- 2026 - 1 Specification For Power Trfo - Part 1Dokumen46 halaman2026 - 1 Specification For Power Trfo - Part 1Balamurugan ArumugamBelum ada peringkat

- Analysis of Mechanical SystemDokumen16 halamanAnalysis of Mechanical SystembigbangBelum ada peringkat

- Applied Aerodynamics (2-0) : Text Book "Introduction To Flight" by John D. Anderson, Mcgraw-Hill Ref Books/MaterialDokumen19 halamanApplied Aerodynamics (2-0) : Text Book "Introduction To Flight" by John D. Anderson, Mcgraw-Hill Ref Books/MaterialAhmed Faraz GujjarBelum ada peringkat

- Experiment 4: Friction Laboratory Report: Air Resistance Refers To The ForcesDokumen6 halamanExperiment 4: Friction Laboratory Report: Air Resistance Refers To The ForcesMan DejeloBelum ada peringkat

- Ci Ride Leader - Guide To Cycling On The Road PDFDokumen10 halamanCi Ride Leader - Guide To Cycling On The Road PDFΑυτός είμαι εγώBelum ada peringkat

- Sources of Energy Class 10Dokumen17 halamanSources of Energy Class 10Maan NmBelum ada peringkat

- ABC Dry Chemical - WikipediaDokumen4 halamanABC Dry Chemical - WikipediaMohamed Abou El hassanBelum ada peringkat

- NFPA 25 Form AES 5.4 ITM Electric Fire Pump Annual 2013 - 4 of 7Dokumen1 halamanNFPA 25 Form AES 5.4 ITM Electric Fire Pump Annual 2013 - 4 of 7Mark Louie GuintoBelum ada peringkat

- ShipRight - Design Code For Unmanned Marine Systems - 2017Dokumen39 halamanShipRight - Design Code For Unmanned Marine Systems - 2017RISHABH JAMBHULKARBelum ada peringkat