22 Skidmountedbalancepressurefoam

Diunggah oleh

ambition1340cnJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

22 Skidmountedbalancepressurefoam

Diunggah oleh

ambition1340cnHak Cipta:

Format Tersedia

SKID MOUNTED BALANCE PRESSURE

FOAM PROPORTIONING SYSTEM

APPLICATION

Balance Pressure pump skid-proportioning system

accurately controls the flow of foam concentrate in

to the water stream. The system automatically

controls the foam concentrate over a wide range of

flow and pressure, without manual adjustment.

The system is typically used in the fixed foam system

and specialised mobile equipments to protect tank

farm, offshore platform, air craft hanger, marine dock,

loading rack and in many other applications and in all

types of hazard.

SPECIFICATION

The system utilizes the principle of operation based

on the use of a modified venturi device called "Ratio

Controller". As the water flows through a nozzle at

the inlet of ratio controller, a low-pressure area is

created between the inlet nozzle and a down stream

section called diffuser. This low-pressure area causes

foam concentrate to flow through a metering orifice

at the concentrate inlet and into the low-pressure

area. As the system demand varies, the flow through

the ratio controller increase or decreases, which in

turn varies the pressure at low pressure area of ratio

controller, creating a corresponding pressure drop

across the foam concentrate metering orifice. This

corresponding change of pressure results in a foam

concentrate flow, which is proportional to the water

flow through the ratio controller.

The pressure sensing line from the ratio controller

inlet for water pressure, and from the concentrate

supply side above the metering orifice are connected

to a bypass valve. This valve automatically adjusts the

concentrate pressure corresponding to the water

pressure by re-circulating the concentrate in return

line to the concentrate storage tank. Manually the

pressure can also be balanced by using manual

regulating globe valve to read equal pressure of the

water gauge and the foam concentrate gauge (or

through a duplex gauge).

The system is available as a skid mounted unit, in

different flow range, varying from 150 to 18000 LPM.

Each skid consist of a positive displacement pump, a

pump drive, an electric control, a bypass valve, a

manual regulating valve, a ratio controller,

interconnecting piping in stainless steel with various

controlling valves, check valve, flush-in and flush-out

valve. The system is also available for operation in auto

mode.

system at least once in a week. The inspector should

verify that all the valves are in their proper position

as per the system requirement and there is no damage

to any component.

Do not turn off the system or any valve to repair or

test the system, without placing a roving Fire Patrol

in the area covered by the system. The patrol should

continue until the system is back in service. Also inform

the local security guards and control alarm station,

so that a false alarm will not be signalled. The system

must be periodically checked for its normal operating

condition. All the valves must be verified for its normal

operating condition. The electrical controls must also

be verified.

The system must be operated periodically to verify its

normal operating condition as per the instruction for

testing provided with the equipment.

The entire system must be fully tested at least once

in a year in accordance with the applicable NFPA codes,

or in accordance to the guidelines of the organisation

having local jurisdiction.

INSPECTION AND MAINTENANCE

A qualified and trained person must commission the

system. After few initial successful tests, an

authorised person must be trained to perform the

inspection and testing of the system. It is

recommended to carry out physical inspection of the

JANUARY, 2006

PAGE 1 OF 2

HD 190

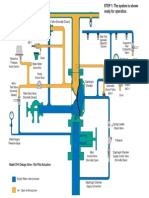

T YPICAL INSTALLATION OF BALANCE PRESSURE FOAM PROPORTIONING SYSTEM

JANUARY, 2006

PAGE 2 OF 2

HD 190

Anda mungkin juga menyukai

- The Coca-Cola Company Struggles With Ethical CrisesDokumen16 halamanThe Coca-Cola Company Struggles With Ethical Crisesambition1340cnBelum ada peringkat

- Inventory Management System: Arina Ramlee, Bruce Chhay, David HenryDokumen9 halamanInventory Management System: Arina Ramlee, Bruce Chhay, David Henryambition1340cnBelum ada peringkat

- Hodgson - Is Socialism Feasible (2019) - Pages-1,5,36-46Dokumen13 halamanHodgson - Is Socialism Feasible (2019) - Pages-1,5,36-46ambition1340cnBelum ada peringkat

- Fomtec Foam Equipment BrochureDokumen7 halamanFomtec Foam Equipment Brochureambition1340cnBelum ada peringkat

- Fire Alarm Tal 1734 Electrical SpecificationDokumen11 halamanFire Alarm Tal 1734 Electrical Specificationambition1340cnBelum ada peringkat

- DV-5 Wet Step by Step PDFDokumen15 halamanDV-5 Wet Step by Step PDFambition1340cnBelum ada peringkat

- Waterflow Indicator PDFDokumen8 halamanWaterflow Indicator PDFambition1340cnBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Feed SystemDokumen77 halamanFeed SystemvinayakBelum ada peringkat

- Olear Ehv GroupDokumen16 halamanOlear Ehv GroupSRINIVAS KOMMINENIBelum ada peringkat

- Bringing Power To Light: Company ProfileDokumen32 halamanBringing Power To Light: Company ProfileYu hongBelum ada peringkat

- BPI BA Field Test Checklist: Discussion With HomeownerDokumen5 halamanBPI BA Field Test Checklist: Discussion With HomeownerbullfrogkillerBelum ada peringkat

- Fasani Pressure Seal Check ValveDokumen5 halamanFasani Pressure Seal Check Valvegm_revankar3942Belum ada peringkat

- 106 206 RPS LHDokumen3 halaman106 206 RPS LHral75Belum ada peringkat

- Drawings For Rack 20 X VM 2-2140Dokumen2 halamanDrawings For Rack 20 X VM 2-2140Nguyễn Anh DanhBelum ada peringkat

- 2016 HSC Engineering StudiesDokumen40 halaman2016 HSC Engineering StudiesR MathewBelum ada peringkat

- 35 Basic Interview QuestionsDokumen8 halaman35 Basic Interview QuestionsVivek BajpaiBelum ada peringkat

- Compressible Flow ExamplesDokumen3 halamanCompressible Flow ExamplesMikaila Denise LoanzonBelum ada peringkat

- BS 1881 Part 208 1996Dokumen14 halamanBS 1881 Part 208 1996resty manuelBelum ada peringkat

- Monopitch Roof Steel Truss (Ware House) 12345Dokumen5 halamanMonopitch Roof Steel Truss (Ware House) 12345FatihBelum ada peringkat

- Environmental Effects On Engineered Materials - Russell H. JonesDokumen517 halamanEnvironmental Effects On Engineered Materials - Russell H. JonesVictorBelum ada peringkat

- Unit I Electrical and Electronic Systems: Electrical Wiring Systems 10Dokumen2 halamanUnit I Electrical and Electronic Systems: Electrical Wiring Systems 10Cebo DharuBelum ada peringkat

- SPEC Pulsatron E PLUS SeriesDokumen2 halamanSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethBelum ada peringkat

- Understanding HOT and Cold PreploymersDokumen13 halamanUnderstanding HOT and Cold PreploymersrafacastillopBelum ada peringkat

- NJ Fto-13Dokumen3 halamanNJ Fto-13nick10686Belum ada peringkat

- MAL Gear 600 Series - Data SheetDokumen4 halamanMAL Gear 600 Series - Data SheetABDUL REHMAN PIPRANIBelum ada peringkat

- Reinforced Masonry LintelsDokumen2 halamanReinforced Masonry LintelsvishalsaiBelum ada peringkat

- Transverse Loading Calculation of Bending Moment and Shear Force in BeamsDokumen18 halamanTransverse Loading Calculation of Bending Moment and Shear Force in Beamsapi-3710585100% (4)

- Eurocode 8 - General Rules and Seismic Actions PDFDokumen22 halamanEurocode 8 - General Rules and Seismic Actions PDFmarineugenBelum ada peringkat

- Fiber Beam-Column Model For Diagonally Reinforced Concrete Coupling Beams Incorporating Shear and Reinforcement Slip EffectsDokumen35 halamanFiber Beam-Column Model For Diagonally Reinforced Concrete Coupling Beams Incorporating Shear and Reinforcement Slip EffectsSinem Kocabaş ŞirikçiBelum ada peringkat

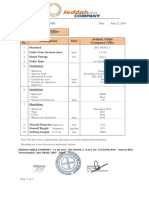

- Jeddah Cable Cu Xlpe-PvcDokumen2 halamanJeddah Cable Cu Xlpe-PvcSoltani AliBelum ada peringkat

- Oval Gear Flow MeterDokumen4 halamanOval Gear Flow MeterEllen ShengBelum ada peringkat

- 22-23-4 Iec60598 - NovalitingDokumen61 halaman22-23-4 Iec60598 - NovalitingLuis Fernando ValenciaBelum ada peringkat

- 5 - Compression Failure Mechanisms in Unidirectional CompositesDokumen45 halaman5 - Compression Failure Mechanisms in Unidirectional CompositesMo 57sBelum ada peringkat

- Pryda Product Training Manual PDFDokumen26 halamanPryda Product Training Manual PDFTehnic RomadriaBelum ada peringkat

- 1.the Prelimary Engineering Plans Including Quantity CalculationsDokumen146 halaman1.the Prelimary Engineering Plans Including Quantity CalculationsDyeri FloresBelum ada peringkat

- Cusn8 Industrial RolledDokumen4 halamanCusn8 Industrial RolledPrakash MakadiaBelum ada peringkat

- TDS Aquamat 208 enDokumen2 halamanTDS Aquamat 208 enHiroshi PhanBelum ada peringkat