Mitsubishi Freqrol E500

Diunggah oleh

Rodriguez JohannDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Mitsubishi Freqrol E500

Diunggah oleh

Rodriguez JohannHak Cipta:

Format Tersedia

INSTALLATION AND WIRING

2.2 Wiring

2.2.1

Terminal connection diagram

z Three-phase 200V power input

z Three-phase 400V power input

MCCB MC

Three-phase

AC power

supply

24VDC power output and

external transistor common

R(L1)

S(L2)

T(L3)

U

V

W

PC

Note 5

P1

(+)P

PR

Forward rotation start STF

(-)N

Note 2

Reverse rotation start STR

Motor

IM

Earth

(ground)

Jumper

Remove this jumper when

using the optional power-factor

improving DC reactor.

Brake resistor connection

High RH

A

Multi-speed selection Middle RM

Low RL

Output stop MRS

Alarm

output

Reset RES

Contact input common SD

Note 4

RUN

FU

Control input signals

(No voltage input allowed)

SE

Note 3

Frequency setting signals (Analog)

3

(Note 1)

2

Frequency

setting

potentiometer1

1/2W1k Current input(-)

4 to 20mADC(+)

2 0 to 5VDC Selected

FM

0 to 10VDC

4(4 to 20mADC)

Frequency detection

Open collector

output common

Open

collector outputs

Meter

(e.g. frequency meter)

10(+5V)

5(Common)

Note 4

Running

SD

Note 3

When using current input as the

PU connector

frequency setting signal, set "4" in

(RS-485)

any of Pr.180 to Pr.183 (input

terminal function selection) and

Operation panel

assign AU (current input selection)

(With frequency setting

to any of terminal RH, RM, RL, or

potentiometer)

MRS, then turn the AU signal on.

Note: 1.

2.

3.

4.

Calibration

resistor (Note 6)

Moving-coil type

1mA full-scale

Earth

(ground)

Main circuit terminal

Control circuit input terminal

Control circuit output terminal

If the potentiometer is to be operated often, use a 2W1k potentiometer.

0.1K and 0.2K do not contain a transistor.

Terminals SD and SE are isolated.

Terminals SD and 5 are common terminals. Do not earth (ground) them to the

ground. Terminals SD and 5 are not isolated. (Those of the 400V class are isolated.)

5. When terminals PC-SD are used as a 24VDC power supply, be careful not

to short these terminals. If they are shorted, the inverter will be damaged.

6. Not needed when the operation panel or parameter unit (FR-PU04) is used for

calibration. Used when calibration must be made near the frequency meter for

such a reason as a remote frequency meter. However, the frequency meter

needle may not deflect to full-scale if the calibration resistor is connected. In this

case, use this resistor and the operation panel or parameter unit together.

16

INSTALLATION AND WIRING

z Single-phase 200V power input

z Single-phase 100V power input

MCCB

MC

U

V

W

R

S

Power supply

Motor

IM

Earth

(ground)

Note: 1. To ensure safety, connect the power input to the inverter via a magnetic

contactor and earth (ground) leakage circuit breaker or moulded case circuit

breaker, and use the magnetic contactor to switch power on-off.

2. The output is three-phase 200V.

(1) Description of the main circuit terminals

Symbol

Terminal Name

Description

R, S, T

(L1, L2, L3)

(Note)

AC power input

Connect to the commercial power supply. Keep these

terminals open when using the high power factor

converter (FR-HC) or power regeneration common

converter (FR-CV).

U, V, W

Inverter output

Connect a three-phase squirrel-cage motor.

P (+), PR

Brake resistor

connection

Connect the optional brake resistor across terminals PPR (+ - PR) (not for 0.1K and 0.2K).

P (+), N (-)

Brake unit

connection

Connect the optional brake unit, high power factor

converter (FR-HC), and power regeneration common

converter (FR-CV).

P (+), P1

Power factor

improving

DC reactor

connection

Disconnect the jumper from terminals P-P1 (+ - P1) and

connect the optional power factor improving DC reactor.

(can not be connected to the single phase 100V power

input specification inverter)

Earth (Ground)

For earthing (grounding) the inverter chassis. Must be

earthed (grounded).

Note: R, S (L1, L2) terminals for single-phase power input.

17

INSTALLATION AND WIRING

(2) Description of the control circuit terminals

Type

Symbol

STF

Turn on the STF signal to start forward

rotation and turn it off to stop.

Reverse

rotation start

Turn on the STR signal to start reverse

rotation and turn it off to stop.

RH, RM, Multi-speed

RL

selection

MRS

Output stop

RES

Reset

Input signals

Contact input

STR

Terminal

Name

Forward

rotation start

SD

PC

Description

When the STF

and STR signals

are turned on

simultaneously,

the stop command

is given.

Combine the RH, RM and RL signals as

Input terminal

appropriate to select multiple speeds.

function selection

Turn on the MRS signal (20ms or

(Pr. 180 to Pr.

longer) to stop the inverter output.

183) changes

Used to shut off the inverter output to

terminal

bring the motor to a stop by the

functions.

electromagnetic brake.

Used to reset the protective circuit activated. Turn on the

RES signal for more than 0.1s then turn it off.

Factory setting is for reset always. By setting Pr.75, reset

can be set to enabled only at an inverter alarm occurrence.

(Refer to page 130.) Recover about 1s after reset is

cancelled.

Contact input

common

Common terminal for contact input terminal (sink logic)

(sink)

and terminal FM.

(initial setting)

When connecting the transistor output (open collector

External

output), such as a programmable controller, when source

transistor

logic is selected, connect the external power supply

common

common for transistor output to this terminal to prevent a

(source)

malfunction caused by undesirable currents.

24VDC power Common output terminal for 24VDC 0.1A power supply

(PC terminal).

supply

Isolated from terminals 5 and SE.

common

When connecting the transistor output (open collector

External

output), such as a programmable controller, when sink logic

transistor

is selected, connect the external power supply common for

common

transistor output to this terminal to prevent a malfunction

(sink)

(initial setting) caused by undesirable currents.

Contact input

common

Common terminal for contact input terminal (source logic).

(source)

24VDC power

Can be used as 24VDC 0.1A power supply.

supply

18

INSTALLATION AND WIRING

Analog

Frequency setting

Type

Terminal

Symbol

Name

Frequency

10

setting power

supply

Frequency

setting

(voltage)

Frequency

setting

(current)

Frequency

setting

common

Description

5VDC, permissible load current 10mA

By entering 0 to 5VDC (0 to 10VDC), the maximum output

frequency is reached at 5V (or 10V) and I/O are

proportional. Use Pr. 73 to switch between input 0 to 5VDC

(factory setting) and 0 to 10VDC. Input resistance 10k.

Maximum permissible voltage 20V.

By entering 4 to 20mADC, the maximum output frequency

is reached at 20mA and I/O are proportional. This input

signal is valid only when the AU signal (Note) is on (voltage

input is invalid). Input resistance approximately 250.

Maximum permissible current 30mA.

Common to the frequency setting signals (terminal 2, 1 or

4).

Do not connect to the earth (ground).

Note: Assign the AU signal to any of the terminals using the input terminal function

selection (Pr. 180 to Pr. 183).

* Used as a contact input signal common terminal by switching between sink logic and

source logic. (Refer to page 27.)

19

INSTALLATION AND WIRING

Symbol

A, B, C

RUN

Open collector

Output signals

Contact

Type

FU

RS-485

Communication

Pulse

SE

FM

Terminal

Name

Alarm output

Inverter

running

Frequency

detection

Description

1 changeover contact output indicating that

the output has been stopped by the inverter

protective function activated. 230VAC 0.3A,

30VDC 0.3A. Alarm: discontinuity across BC (continuity across A-C), normal:

continuity across B-C (discontinuity across

A-C).

Output

terminal

Switched low when the inverter output

function

frequency is equal to or higher than the

selection

starting frequency (factory set to 0.5Hz,

variable). Switched high during stop or DC (Pr. 190 to

Pr. 192)

injection brake operation (*1).

changes

Permissible load 24VDC 0.1A. (a voltage

terminal

drop is 3.4V maximum when the signal is

functions.

on)

Switched low when the inverter output

frequency is equal to or higher than the

preset detected frequency and high when

less than the preset detected frequency.

(*1).

Permissible load 24VDC 0.1A

Open collector

Common to the RUN and FU terminals

output common

For meter

One selected from output

frequency, motor current

and output voltage is output

(*2). The output signal is

proportional to the

magnitude of each

monitoring item.

PU connector

With the operation panel connector, communication can

be made using the RS-485 protocol.

Conforming Standard: EIA-485 (RS-485)

Transmission format: Multi-drop link system

Communication speed: Maximum 19200bps

Overall length: 500m

Factory setting of output

item:

Frequency permissible

load current 1mA

1440 pulses/s at 60Hz

*1: Low indicates that the open collector output transistor is on (conducts). High

indicates that the transistor is off (does not conduct).

*2: Not output during inverter resetting.

20

Anda mungkin juga menyukai

- Inversor nvf3 Chint PDFDokumen10 halamanInversor nvf3 Chint PDFFAHTIMA CONSTRUCTIONBelum ada peringkat

- Components For Pneumatic Automation: Five ONEDokumen26 halamanComponents For Pneumatic Automation: Five ONEamBelum ada peringkat

- Siemens PXC24Dokumen7 halamanSiemens PXC24Waqar Ahmed KhanBelum ada peringkat

- 56 - A Learning Model For 8051 Microcontroller Case Study On Closed Loop DC Motor Speed Control PDFDokumen7 halaman56 - A Learning Model For 8051 Microcontroller Case Study On Closed Loop DC Motor Speed Control PDFhecirlene vieiraBelum ada peringkat

- MITSUBISHI Manual PLC Fx5 UsersDokumen152 halamanMITSUBISHI Manual PLC Fx5 UsersalbeertoBelum ada peringkat

- MTTCNDokumen296 halamanMTTCNCarlosBelum ada peringkat

- Hướng dẫn kết nối board plc FK3UDokumen7 halamanHướng dẫn kết nối board plc FK3UHiệp Trần100% (1)

- Es35 SW BrochureDokumen4 halamanEs35 SW BrochureThái Trung TàiBelum ada peringkat

- Counter Meter PDFDokumen4 halamanCounter Meter PDFM saleemBelum ada peringkat

- Part 2: IC Design ProcessDokumen55 halamanPart 2: IC Design ProcessMinh QuânBelum ada peringkat

- Chapter 8: Programmable Logic Controller (PLC) : EG2098: Industrial Electronics and Control &topic 8 1 1Dokumen26 halamanChapter 8: Programmable Logic Controller (PLC) : EG2098: Industrial Electronics and Control &topic 8 1 1Saad AliKhanBelum ada peringkat

- Temperature and Humidity Transmitter User Manual: 1. Product DescriptionDokumen8 halamanTemperature and Humidity Transmitter User Manual: 1. Product DescriptionNguyễn Huy HoàngBelum ada peringkat

- Bidirectional Flyback Inverter WithDokumen5 halamanBidirectional Flyback Inverter WithArceu CamposBelum ada peringkat

- Chapter 8 ProblemsDokumen21 halamanChapter 8 Problemskhrid3100% (2)

- BLDC Motor Driver Specification Sheet: DC12 48V ( 10%), Rated Current 20ax2Dokumen16 halamanBLDC Motor Driver Specification Sheet: DC12 48V ( 10%), Rated Current 20ax2Pablo VelaBelum ada peringkat

- Bien-Tan-Siemens Sinamic G120CDokumen151 halamanBien-Tan-Siemens Sinamic G120CTài liệu Công ty TNHH Nam TrungBelum ada peringkat

- Manual On Design of LNA Using ADSDokumen33 halamanManual On Design of LNA Using ADSThabasum Aara SBelum ada peringkat

- PDF 3136325f4d616e75616cDokumen234 halamanPDF 3136325f4d616e75616coprea vasileBelum ada peringkat

- Introduction To VHDL - 2014FSDokumen74 halamanIntroduction To VHDL - 2014FSĐoàn Vũ Phú VinhBelum ada peringkat

- Component Detail Report 3288Dokumen2 halamanComponent Detail Report 3288Богдан РудюкBelum ada peringkat

- DC Motor With Encoder Manual (1.1 W)Dokumen7 halamanDC Motor With Encoder Manual (1.1 W)Saad NajibBelum ada peringkat

- RainBird AutoCAD LegendDokumen3 halamanRainBird AutoCAD LegendFlop ArghBelum ada peringkat

- Faulhaber DatasheetDokumen5 halamanFaulhaber DatasheetMuhammad SharifBelum ada peringkat

- TC 300 Uc InglesDokumen62 halamanTC 300 Uc InglesTamo Activo MusicBelum ada peringkat

- 6SL3244 0BB12 1BA1 Datasheet enDokumen1 halaman6SL3244 0BB12 1BA1 Datasheet engalauBelum ada peringkat

- Toshiba IEDs - GBU200Dokumen48 halamanToshiba IEDs - GBU200Thong Dang SyBelum ada peringkat

- Project Report of Line Tracking Robot, 8051 MicrocontrollerDokumen15 halamanProject Report of Line Tracking Robot, 8051 MicrocontrollerZohaib JahanBelum ada peringkat

- Bit Angle ModulationDokumen9 halamanBit Angle Modulationbenjamind82Belum ada peringkat

- Section 2 Microprocessors Course Dr. S.O.Fatemi By: Mahdi HassanpourDokumen77 halamanSection 2 Microprocessors Course Dr. S.O.Fatemi By: Mahdi HassanpoursivnathBelum ada peringkat

- RM3100 Breakout Board Sales SheetDokumen2 halamanRM3100 Breakout Board Sales Sheetkostya_4524Belum ada peringkat

- FK3U Analog 485Dokumen18 halamanFK3U Analog 485PVC XANH QDBelum ada peringkat

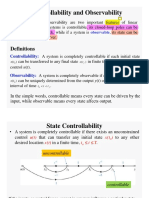

- Controllability and ObservabilityDokumen20 halamanControllability and ObservabilityAya FlyahBelum ada peringkat

- Final 222 2009 SolDokumen6 halamanFinal 222 2009 SolNapsterBelum ada peringkat

- Effects of Voltage Frequency Variations Induction MotorsDokumen2 halamanEffects of Voltage Frequency Variations Induction MotorsKaran Thapar100% (1)

- IpbalanceDokumen1 halamanIpbalancephuceltnBelum ada peringkat

- Stepper Motor PDFDokumen49 halamanStepper Motor PDFP HAMSA DATTABelum ada peringkat

- Kte 5000LTDokumen110 halamanKte 5000LTzalomxisBelum ada peringkat

- Module WIFI TYWE3S User ManualDokumen13 halamanModule WIFI TYWE3S User ManualPen TranBelum ada peringkat

- DVOR Principle 코이카 양식Dokumen71 halamanDVOR Principle 코이카 양식Undral Batbayar100% (1)

- NithDokumen17 halamanNithChamila PrabathBelum ada peringkat

- S7-1200 1214CDokumen14 halamanS7-1200 1214Cnyamai20008234Belum ada peringkat

- 1CD PDFDokumen61 halaman1CD PDFTran Nguyen KhangBelum ada peringkat

- 4X4 Keypad Based Password With ATmega32 (LCD Display)Dokumen6 halaman4X4 Keypad Based Password With ATmega32 (LCD Display)Emin KültürelBelum ada peringkat

- 2CNM203001R2001 m2m Basic Modbus Power MeterDokumen2 halaman2CNM203001R2001 m2m Basic Modbus Power MeterPablo RodriguezBelum ada peringkat

- Flame SensorDokumen6 halamanFlame SensorGst Agung Ngrh ArjayaBelum ada peringkat

- 4axis USBCNC Manual tb60Dokumen31 halaman4axis USBCNC Manual tb60jeju233Belum ada peringkat

- DE2 SchematicDokumen24 halamanDE2 Schematictqminh1990Belum ada peringkat

- Easyport Usb Example Applications enDokumen1 halamanEasyport Usb Example Applications enAlan Rizky BerliantoBelum ada peringkat

- Ky Thuat Dieu Khien Tu Dong - Control System Technology-Lab Tutorials PDFDokumen44 halamanKy Thuat Dieu Khien Tu Dong - Control System Technology-Lab Tutorials PDFwhaywhay whaywhayBelum ada peringkat

- 5W USB Flyback Design ReviewApplication ReportDokumen21 halaman5W USB Flyback Design ReviewApplication ReportleechulmiuBelum ada peringkat

- DE2 115 Pin AssignmentDokumen4 halamanDE2 115 Pin AssignmentKamal HaydarBelum ada peringkat

- BootP LiteDokumen6 halamanBootP LiteOctavio AguirreBelum ada peringkat

- VLSI Design Mid 2Dokumen3 halamanVLSI Design Mid 2mohanBelum ada peringkat

- Application of A PID Controller in A Speed Control of A CarDokumen11 halamanApplication of A PID Controller in A Speed Control of A CarAtchyuth SontiBelum ada peringkat

- Robust Fast Terminal SMC With Prescribed Performance For A Wearable Exoskeleton RobotDokumen6 halamanRobust Fast Terminal SMC With Prescribed Performance For A Wearable Exoskeleton Robotabdelhamid.ghoul93Belum ada peringkat

- JX-300XP HardwareDokumen39 halamanJX-300XP HardwareMesafint KassieBelum ada peringkat

- LMD18201 3A, 55V H-Bridge: General DescriptionDokumen8 halamanLMD18201 3A, 55V H-Bridge: General DescriptionNairo FilhoBelum ada peringkat

- 3000W Single Output Power Supply: SeriesDokumen7 halaman3000W Single Output Power Supply: SeriesAlexander PekarovskiyBelum ada peringkat

- E700 WiringDokumen3 halamanE700 WiringTrần HoàngBelum ada peringkat

- RSP 3000 SpecDokumen6 halamanRSP 3000 SpecGrigoriu CodrutaBelum ada peringkat

- ACR2000 Hardware Manual ACR2000 Hardware ManualDokumen53 halamanACR2000 Hardware Manual ACR2000 Hardware ManualTezontepec De Aldama HidalgoBelum ada peringkat

- Tech Manual Timing BeltsDokumen124 halamanTech Manual Timing BeltsyildyusufBelum ada peringkat

- Samsung Un32eh5300f Un40eh5300f Un46eh5300f Un50eh5300f Chassis U76a PDFDokumen90 halamanSamsung Un32eh5300f Un40eh5300f Un46eh5300f Un50eh5300f Chassis U76a PDFSelmar CavalcantiBelum ada peringkat

- MAC E, E Designer - User's Manual MA-00552-D (05.04) PDFDokumen370 halamanMAC E, E Designer - User's Manual MA-00552-D (05.04) PDFAntonio CorripioBelum ada peringkat

- Acr1k PLC WebDokumen16 halamanAcr1k PLC WebRodriguez JohannBelum ada peringkat

- Renesas Rej10b0047 0100HDokumen1.226 halamanRenesas Rej10b0047 0100HRodriguez JohannBelum ada peringkat

- D051 330Dokumen20 halamanD051 330Rodriguez JohannBelum ada peringkat

- Abb Contactor A45!40!00 24 Vac 60 HZDokumen4 halamanAbb Contactor A45!40!00 24 Vac 60 HZRodriguez JohannBelum ada peringkat

- EV Micro DriveDokumen2 halamanEV Micro DriveRodriguez JohannBelum ada peringkat

- Vicor VI MU4 EQ DatasheetDokumen6 halamanVicor VI MU4 EQ DatasheetRodriguez JohannBelum ada peringkat

- VSD ComponentsDokumen20 halamanVSD ComponentsTanya Singh75% (4)

- STD65NF06 STP65NF06: N-Channel 60V - 11.5m - 60A - DPAK/TO-220 Stripfet™ Ii Power MosfetDokumen14 halamanSTD65NF06 STP65NF06: N-Channel 60V - 11.5m - 60A - DPAK/TO-220 Stripfet™ Ii Power MosfetRodriguez JohannBelum ada peringkat

- CB Ts CTDokumen6 halamanCB Ts CTRodriguez JohannBelum ada peringkat

- Flatpac installguideFADokumen8 halamanFlatpac installguideFARodriguez JohannBelum ada peringkat

- Mm440 Cat enDokumen33 halamanMm440 Cat enÖnder ÇiftçiBelum ada peringkat

- Vc34 Kompend eDokumen1 halamanVc34 Kompend eRodriguez JohannBelum ada peringkat

- Benshaw RSC ContactorsDokumen2 halamanBenshaw RSC ContactorsRodriguez JohannBelum ada peringkat

- DS-Dyne and Surface TensionDokumen4 halamanDS-Dyne and Surface TensionRodriguez JohannBelum ada peringkat

- BLM7 R3700Dokumen4 halamanBLM7 R3700Rodriguez JohannBelum ada peringkat

- TAMAGAWA - OIH48 Series Incremental Rotary Encoders: Electronic Kits & I/O Cards & MotorsDokumen1 halamanTAMAGAWA - OIH48 Series Incremental Rotary Encoders: Electronic Kits & I/O Cards & MotorsRodriguez JohannBelum ada peringkat

- Additional Starter RS232 V1 2 enDokumen11 halamanAdditional Starter RS232 V1 2 enRodriguez JohannBelum ada peringkat

- Huf 76439 SDokumen10 halamanHuf 76439 SRodriguez JohannBelum ada peringkat

- T400XW01Dokumen30 halamanT400XW01Rodriguez JohannBelum ada peringkat

- Corespondenta Oteluri 1Dokumen6 halamanCorespondenta Oteluri 1Mihai HorincasBelum ada peringkat

- Huf 76439 SDokumen10 halamanHuf 76439 SRodriguez JohannBelum ada peringkat

- Se-44 GBDokumen2 halamanSe-44 GBRodriguez JohannBelum ada peringkat

- Using Toshiba TA8080K Motor Driver ICsDokumen3 halamanUsing Toshiba TA8080K Motor Driver ICsRodriguez JohannBelum ada peringkat

- Tajima Opciones TFHX-IICDokumen2 halamanTajima Opciones TFHX-IICRodriguez JohannBelum ada peringkat

- PMC 2 TechnicalDokumen91 halamanPMC 2 TechnicalThomas CanoyBelum ada peringkat

- Deep Sea Electronics PLC: DSE103 MKII Speed Switch PC Configuration Suite LiteDokumen14 halamanDeep Sea Electronics PLC: DSE103 MKII Speed Switch PC Configuration Suite LiteMostafa ShannaBelum ada peringkat

- Lozada V Bracewell DigestDokumen3 halamanLozada V Bracewell DigestMickey OrtegaBelum ada peringkat

- Curriculum Vitae H R VijayDokumen8 halamanCurriculum Vitae H R VijayvijaygowdabdvtBelum ada peringkat

- Hilti AnchorDokumen5 halamanHilti AnchorGopi KrishnanBelum ada peringkat

- Techgig Open Round CompetitionDokumen6 halamanTechgig Open Round CompetitionAnil Kumar GodishalaBelum ada peringkat

- A88438-23 Critical Procedure 11-01 - Pipeline Cut Outs - A5X9W9Dokumen7 halamanA88438-23 Critical Procedure 11-01 - Pipeline Cut Outs - A5X9W9mahmoudBelum ada peringkat

- Orthopanton Villa System MedicalDokumen61 halamanOrthopanton Villa System MedicalOscarOcañaHernándezBelum ada peringkat

- Assignment 03 Investments in Debt SecuritiesDokumen4 halamanAssignment 03 Investments in Debt SecuritiesJella Mae YcalinaBelum ada peringkat

- Personal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553Dokumen6 halamanPersonal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553MirelaRoșcaBelum ada peringkat

- Estanislao Vs CADokumen2 halamanEstanislao Vs CAChammy0% (1)

- 02Dokumen257 halaman02shaney navoaBelum ada peringkat

- Non-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDokumen2 halamanNon-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDiana ArredondoBelum ada peringkat

- Reterta V MoresDokumen13 halamanReterta V MoresRam Migue SaintBelum ada peringkat

- Eudemon8000E XDokumen2 halamanEudemon8000E XGladys Medina100% (1)

- Wiring DiagramsDokumen69 halamanWiring DiagramsMahdiBelum ada peringkat

- Pa 28 151 161 - mmv1995 PDFDokumen585 halamanPa 28 151 161 - mmv1995 PDFJonatan JonatanBernalBelum ada peringkat

- Rajkumar Kitchen Model Oil Expeller - INRDokumen1 halamanRajkumar Kitchen Model Oil Expeller - INRNishant0% (1)

- 2023 Reso-01Dokumen3 halaman2023 Reso-01John Mark Mercado JubelagBelum ada peringkat

- VKC Group of Companies Industry ProfileDokumen5 halamanVKC Group of Companies Industry ProfilePavithraPramodBelum ada peringkat

- New VLSIDokumen2 halamanNew VLSIRanjit KumarBelum ada peringkat

- Radix Sort - Wikipedia, The Free EncyclopediaDokumen13 halamanRadix Sort - Wikipedia, The Free EncyclopediasbaikunjeBelum ada peringkat

- DenmarkDokumen4 halamanDenmarkFalcon KingdomBelum ada peringkat

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateDokumen6 halamanEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubBelum ada peringkat

- AMCHAM Press ReleaseDokumen1 halamanAMCHAM Press ReleaseAnonymous FnM14a0Belum ada peringkat

- CPI As A KPIDokumen13 halamanCPI As A KPIKS LimBelum ada peringkat

- Application Problems 1 Through 3Dokumen5 halamanApplication Problems 1 Through 3api-4072164490% (1)

- Book Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDokumen10 halamanBook Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDataVersed100% (1)

- My New ResumeDokumen1 halamanMy New Resumeapi-412394530Belum ada peringkat

- Civpro RevDokumen102 halamanCivpro RevJocelyn Baliwag-Alicmas Banganan BayubayBelum ada peringkat

- Text That Girl Cheat Sheet NewDokumen25 halamanText That Girl Cheat Sheet NewfhgfghgfhBelum ada peringkat