D H D6riii PDF

Diunggah oleh

Dennis OlayaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

D H D6riii PDF

Diunggah oleh

Dennis OlayaHak Cipta:

Format Tersedia

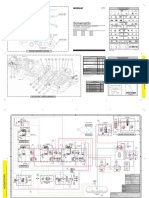

RENR7956-01

June 2006

14

FLUID POWER SYMBOLS

BASIC COMPONENT SYMBOLS

Component Locations

Item

Number

1

2

3

MAIN AUX.

Description

Pump - Implement and Steering

Steering Motor

Valve Gp. - Counter Balance

Valve Gp. - Steering, Dozer Lift/Tilte

Valve Gp. - Steering, Dozer Lift/Tilte (Ripper)

Valve Gp. - Steering, Dozer Lift/Tilte (Winch)

Manifold Gp. - Inlet Manifold with Relief

Valve Gp. - Steering Control

Valve Gp. - Dozer Lift

Valve Gp. - Dozer Tilt

Valve Gp. - Ripper

Valve Gp. - Winch

Cover

Valve Gp. - Ripper Pilot Valve

Valve Gp. - Dozer Pilot Valve

Valve Gp. - Shut Off

Accumulator

Valve Gp. - Pressure Reducing Manifold and

Check Valves

Valve Gp. - Cooler Bypass

Cooler

Valve Gp. - Breather

Element - Implement and Case Drain Return

Valve Gp. - Quick Drop

Cylinder Gp. - Lift (STD)

Cylinder Gp. - Lift (LGP)

Cylinder Gp. - Dual Tilt (Option)

Cylinder Gp. - Tilt

Cylinder Gp. - Ripper Lift

Tank Gp.

Valve Gp. - Winch Pilot Control

Winch Arrangement

Valve Gp. - Counter Balance-Lift Circuit

Valve Gp. - EH Solenoid Valves

Shuttle Valve

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Part

Number

227-0830

159-7156

227-0832

224-4936

224-2937

239-6076

235-0401

235-0402

235-0403

235-0404

235-0405

239-6074

235-0399

167-1177

200-0189

201-0950

200-0750

Schematic

Location

F-2

E-4

E-3

E-5

E-5

E-5

E-5

E-5

D-5

C-5

C-8

C-5

B-5, B-8

B-8

D-1

D-8

D-8

226-4751

D-8

9T-3004

169-3806

3G-4783

1R-0777

227-0831

227-0844

227-0843

227-0841

233-9134

227-0842

224-4946

160-0766

237-5912

239-0681

239-5317

233-6942

A-3

E-2

A-3

A-3

F-1

F-1

F-1

E-1

E-1

E-8

A-3

A-8

F-8

F-2

C-1

C-1

15

PUMP or MOTOR

HA

TWO POSITION

ONE POSITION

CP

F-3

HA

IMPLEMENT PUMP DISCHARGE PRESSURE

E-8

UPSTREAM FILTER PRESSURE

D-3

PILOT SUPPLY PRESSURE

D-8

ACCUMULATOR

D-8

MA

STEERING PORT PRESSURE (A)

F-4

MB

STEERING PORT PRESSURE (B)

E-4

COOLER BYPASS PRESSURE

D-2

P T

SHIFTED POSITION

PRESSURE

D6R Series III Track-Type Tractor

Hydraulic System

SOS

CPG

The pressure reducing manifold (15) is located inside the forward compartment on the

right fender and is situated outboard from the power train oil filter. Service points identified above are:

(HA) Implement pump discharge pressure test port.

(14) Accumulator.

(CP) Pilot supply pressure test port.

(SOS) Hydraulic oil sampling port.

(CPG) Accumulator pressure test port.

GJB1-UP

WCB1-UP

HDC1-UP

RFC1-UP

TBC1-UP

JEK1-UP

HCD1-UP

HKE1-UP

WRG1-UP

MTJ1-UP

7 MA

ROTATING SHAFTS

FLOW

TEMPERATURE

VENTED

UNIDIRECTIONAL

BIDIRECTIONAL

RETURN ABOVE FLUID LEVEL

PRESSURIZED

RETURN BELOW FLUID LEVEL

COMBINATION CONTROLS

DMK1-UP

LGP1-UP

JDL1-UP

DLM1-UP

LFM1-UP

EXL1-UP

DPS1-UP

EXW1-UP

GMT1-UP

MRT1-UP

SOLENOID

SOLENOID

or MANUAL

SERVO

SOLENOID and

PILOT or MANUAL

SOLENOID

and PILOT

DETENT

THERMAL

MANUAL CONTROL SYMBOLS

MANUAL SHUTOFF

PUSH-PULL LEVER

GENERAL MANUAL

PUSH BUTTON

PEDAL

SPRING

PILOT CONTROL SYMBOLS

RELEASED PRESSURE

EXTERNAL RETURN

REMOTE SUPPLY PRESSURE

INTERNAL RETURN

SIMPLIFIED

CROSSING AND JOINING LINES

ACCUMULATORS

INTERNAL

SUPPLY PRESSURE

COMPLETE

HYDRAULIC AND PNEUMATIC CYLINDERS

PRESSURE MANIFOLD 15

GAS CHARGED

FIXED

DISPLACEMENT

The machine will have an EH pilot manifold installed for blade angle control (29) if the machine

is equipped with a VPAT blade. The EH pilot manifold for blade angle control is located in the

forward compartment on the right fender, directly below the pressure reducing manifold. The

ANGLE RIGHT solenoid controlled pilot valve and the ANGLE LEFT solenoid controlled pilot

valve are identified in the picture below.

SINGLE ACTING

LINES JOINING

LINES CROSSING

DOUBLE ACTING

INTERNAL PASSAGEWAYS

HYDRAULIC MOTORS

EH PILOT MANIFOLD

1 HB

VARIABLE DISPLACEMENT

NON-COMPENSATED

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

UNIDIRECTIONAL

BIDIRECTIONAL

BIDIRECTIONAL

FLOW IN ONE

DIRECTION

TWO

POSITION

THREE

POSITION

INFINITE

POSITIONING

CROSS

FLOW

PARALLEL

FLOW

FLOW ALLOWED IN

EITHER DIRECTION

Pilot Control and Accugrade Ready

Printed in U.S.A.

2006 Caterpillar

All Rights Reserved

Angle Right

(To Blade Angle Control Valve)

Angle Left

To Tank

(Drain)

Electrical Symbols Table

(A)

Angle Left

Angle Right

From Pressure

Reducing Manifold

Hydraulic Symbols (Electrical)

Angle Left

11

PILOT

CONTROLLED

FLUID STORAGE RESERVOIRS

Angle Right

24

SHUTTLE

SPRING

LOADED

BASIC

SYMBOL

INFINITE POSITION

MEASUREMENT

29

9 10 28

CHECK VALVES

AB

P T

NORMAL POSITION

Pilot

supply

FOUR-WAY

THREE-WAY

CONTROL VALVES

AB

Schematic

Location

IMPLEMENT PUMP SIGNAL PRESSURE

TWO-WAY

THREE POSITION

HYDRAULIC PUMPS

HB

CPG

VALVE PORTS

D6R SERIES III BLADE ANGLE EH PILOT MANIFOLD

Description

CP

ATTACHMENT

LINE RESTRICTION

VARIABLE and PRESSURE

COMPENSATED

VALVES

SPRING LOADED

PUMP: VARIABLE and

PRESSURE COMPENSATED

2-SECTION PUMP

HYDRAULIC

PNEUMATIC

ENERGY TRIANGLES

VALVE ENVELOPES

Tap Locations

Pressure, Sampling, and Sensor

Tap

Number

LINE RESTRICTION

(FIXED)

RESTRICTION

PRESSURE

COMPENSATION

LINE RESTRICTION

(VARIABLE)

SPRING

(ADJUSTABLE)

VARIABILITY

CONTROL VALVES

SPRING

FLUID CONDITIONER

20

Illustration (A) shows the EH pilot manifold when the operator has moved the thumb rocker switch

to the BLADE ANGLE RIGHT position. The Machine ECM receives the signal from the thumb

rocker switch and sends a corresponding signal to the ANGLE RIGHT solenoid controlled pilot

valve and the solenoid is ENERGIZED. Pilot supply oil is then directed to the appropriate end of

the blade angle control valve.

22

G

Transducer

(Fluid)

Transducer

(Gas / Air)

Generator

Electric Motor

Components of the AccuGrade EH pilot manifold identified above are the blade raise solenoid, the

blade tilt right solenoid, the AccuGrade Boost solenoid, the blade tilt left solenoid, and the blade

lower solenoid.

The EH pilot manifold receives pilot supply oil from the pressure reducing manifold. The EH pilot

manifold contains four (proportional) solenoid controlled pilot valves that receive PWM signals

from the Machine ECM for operation of the blade lift and the blade tilt functions. When

ENERGIZED, the solenoid controlled pilot valve directs pilot supply oil to the end of the

corresponding implement control valve, in direct proportion to the movement of the dozer control

lever (or as automatically commanded by the AccuGrade system). The EH pilot manifold also

contains the AccuGrade Boost solenoid valve, which uses an ON/OFF solenoid.The AccuGrade

Boost strategy was discussed earlier in the Implement Hydraulics section ofthis presentation.

21

26

29 30

16

18 19 13 14 15

25

17 C

HA CP

23

Electrical Wire

Temperature Switch

D

Electrical Symbols (Electrical)

B

Pressure

Symbol

The implement hydraulic pump (1) is mounted to the rear of the flywheel housing, at the upper

left corner. High pressure supply oil to the implement valve stack is directed through a hose

that connects to the pump discharge port (B). High pressure supply oil to the pressure reducing manifold is directed through a hose that connects to the lower fitting (C) from the pump

discharge port.

Flow

Symbol

Level

Symbol

Temperature

Symbol

Wire Number Identification Codes

Electrical Schematic Example

A pump discharge pressure sensor (D) is installed on the opposite side of the "tee" fitting from

the pressure reducing manifold supply line. This pressure sensor is only present on machines

that are equipped with AccuGrade. It is a necessary component for the calibration of the four

proportional solenoids on the EH pilot manifold that are used for blade control. Machines that

are not equipped with AccuGrade will have an "L" fitting at this location, connecting the pumpsupply line to the pressure reducing manifold.

CPG SOS

Pressure Switch

(Adjustable)

Pressure Switch

Hydraulic Schematic Example

Current Standard

Current Standard

Harness identification code

This example indicates

wire 135 in harness "AG".

Wire

Circuit Number

Identification

Wire Color

325-AG135 PK-14

Other components identified above are:

325-PK

CPG SOS

16

25

26

11

29 30

18

19

13 14 15

HA CP

20

21

IMPLEMENT VALVE STACK

EH PILOT MANIFOLD

Accugrade

Boost

Circuit Identification

Number

E. pump pressure and flow compensator valve

F. fitting for the load sensing signal line (from the signal resolver network)

G. fitting for the case drain line

Wire Gauge

Previous Standard

Wire Color

Wire

This implement pump is identical to the implement pump used in the D6R Series II machines

with differential steering.

To Tank

(Drain)

Wire Color

325-PK-14

Pilot

supply

B

Accugrade Boost Line

Circuit Number

Identification

Tilt

Right

Tilt

Left

Blade

Raise

Blade

Lower

Wire Gauge

(EXAMPLE VALVE)

IMPLEMENT PUMP 1

To Float Pilot

Boost Line

To Blade Tilt

Control Valve

(Tilt Right)

To Blade Tilt

Control Valve

(Tilt Left)

To Blade Tilt

Control Valve

(Tilt Left)

To Blade Lift Control Valve

(Blade Lower/Float)

24

MA 2

1 HB

17 C

9 10 28

MACHINE

COMPONENT LOCATIONS

22 23

The AccuGrade Boost solenoid valve directs pilot supply oil to an external resolver. The blade

lower solenoid controlled pilot valve also directs pilot supply oil to this same external resolver, in

addition to the pilot supply oil that is directed to the LOWER end of the blade lift control valve.

Pilot supply oil is directed (through the resolver) to the Float Pilot Boost line when either solenoid

is ENERGIZED. The Float Pilot Boost signal line enters the signal resolver network through the

end cover of the valve stack. In either situation, the pump's flow compensator valve senses the

pilot supply oil as a signal and the implement pump will up stroketo maintain margin pressure

above LOW PRESSURE STANDBY pressure. (If the steering valve or another implement valve

sends a higher signal into the resolver network, the highest pressure is sensed by the compensator valve.)This EH pilot manifold is only present on ARO machines.

EH PILOT MANIFOLDS

28

29

The steering and implement control

valve stack is mounted to a bracket

inside the right fender, below the right

console in the operator compartment.

The implement valve stack consists of

the inlet manifold (5), the steering valve

(6), the blade lift control valve (7), the

blade tilt control valve (8), the optional

blade angle control valve (A), the ripper

(or winch) control valve (9), and the end

cover (10), EH pilot manifold for tilt and

lift. The blade angle control valve and

the ripper/winch control valve may not

be present, depending on how the

machine is equipped.

28

10

Service points on the back of the hydraulic oil

tank that are identified above are:

F

9

A

A.

B.

C.

D.

E.

F.

Steering implement pump suction port.

Valve stack end cover drain port.

Hydraulic oil temperature sensor.

Pilot valve drain port.

Case drain return port (to internal filter).

Fitting for hose to hydraulic oil cooler

(via bypass valve).

G. Implement return oil port (to internal filter).

7

6

5

B

STEERING and IMPLEMENT

CONTROL VALVE

HYDRAULIC OIL TANK 25

24 Page

The EH pilot manifold (28) for blade lift and tilt functions is mounted to the outboard side of the

valve stack bracket, if the machine is equipped with AccuGrade.

RENR7956-01

D6R SERIES III BLADE TILT AND LIFT EH PILOT MANIFOLD

MA

27

20

PUMP DISCHARGE

RAISE

SIGNAL TO PUMP

A1

21

SIGNAL TO PUMP

LOWER

A2

LIFT CYLINDERS

PACCAR WINCH UNIT

REXROTH MOTOR AA6VM80HA1T

HB

5

TILT RIGHT

22

TILT LEFT

MAIN RELIEF VALVE

B1

DUAL TILT OPTION

PUMP FLUSHING

CIRCUIT

24

6

TILT RIGHT

SUCTION

17

MB

SINGLE TILT OPTION

RIPPER LIFT

STEERING

HA

LIFT AND TILT CYLINDERS

PRESSURE LIMITER

15

PS

17

TILT LEFT

B2

DOZ LIFT

DOZ TILT

ELEC. DET.

SOS

CPG

C2

C1

RAISE

ACC

13

D2

PRESSURE

LIMITER

C2

C1

C3

C4

PILOT CONTROL

CP

14

D1

LOWER

C1

C4

CP

C3

CPG

DOZER LIFT

12

C2

PRESSURE

REDUCING

MANIFOLD

C4

C3

D2

TILT RIGHT

29

TILT LEFT

DOZER TILT

D1

24 Page, Color 2

RENR7956-01

DOZER TILT

D1

D2

A1

RAISE

B1

A2

30

CYLINDER CONTROL

PAY OUT

HAUL IN

FLOAT PILOT

BOOST SIGNAL

LOWER

B2

EH SOLENOID VALVES

WINCH

RIPPER

B4

B3

C5

WINCH

RIPPER

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

C1

C5

MAIN PUMP OUTPUT

SUPPLY LINE

DRAIN / RETURN LINE

STEERING CIRCUIT

TILT CYLINDER CIRCUIT

LIFT CYLINDER CIRCUIT

RIPPER CYLINDER CIRCUIT

PACCAR WINCH CIRCUIT

FLOAT AND CTCT LS

BOOST SIGNAL

SHUTTLE VALVE CONTROL CIRCUIT

10

B

RIPPER CONTROL

3

10

LINE PATTERNS

Pressure Line

Pilot / Load Sensing Pressure

11

Drain / Return Lines

Component Group

Attachment

PILOT SUPPLY

Air Line

PILOT DRAIN

3

CALLOUTS

AIR RELIEF

YY

B4

B3

18

FREE SPOOL

16

PAY OUT

HAUL IN

26

Taps (Pressure, Sampling, Sensor) by letter

Components by number

AA

Connections by letter

ARROW PATTERNS

RETURN

RIPPER OR WINCH

ELEC. DET.

AIR VENT

HOUSING DRAIN

25

19

PILOT SUPPLY

THIS SCHEMATIC IS FOR THE D6R SERIES III TRACK-TYPE TRACTOR

PILOT DRAIN

1

PART #: 223-1198 CHG 04

Components are shown installed on a fully operable machine with the key and engine off and

transmission shifter in neutral.

WINCH CONTROL

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations.

Anda mungkin juga menyukai

- Esquema Hidráulico Motoniveladora 140KDokumen22 halamanEsquema Hidráulico Motoniveladora 140KAnonymous Dq7m7Hq7ar100% (1)

- Esquema Hidráulico CS56Dokumen2 halamanEsquema Hidráulico CS56Anonymous Dq7m7Hq7ar100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen33 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- 428c esQUEMA HIDRAULICODokumen2 halaman428c esQUEMA HIDRAULICOJuniOrs RiVera100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen12 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen12 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- Plano Hydo InteractivoDokumen11 halamanPlano Hydo InteractivoalexBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen7 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- Diagrama Electrico PDFDokumen9 halamanDiagrama Electrico PDFhenotharenas100% (1)

- Senr1677senr1677-01 Sis PDFDokumen2 halamanSenr1677senr1677-01 Sis PDFDennis OlayaBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen12 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Claudio CuevasBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen7 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- Senr1678senr1678 Sis PDFDokumen2 halamanSenr1678senr1678 Sis PDFDennis OlayaBelum ada peringkat

- Uenr1382uenr1382-01 Sis PDFDokumen2 halamanUenr1382uenr1382-01 Sis PDFDennis OlayaBelum ada peringkat

- D7R Diag Hyd PDFDokumen4 halamanD7R Diag Hyd PDFluis eduardo corzo enriquezBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen12 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen14 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Vladimir Illich Pinzon100% (2)

- Senr1668senr1668-01 Sis PDFDokumen2 halamanSenr1668senr1668-01 Sis PDFDennis Olaya100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen8 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- Retroexacavadora 430 F Planos HidraulicosDokumen2 halamanRetroexacavadora 430 F Planos Hidraulicosedison barrionuevoBelum ada peringkat

- Kenr5128kenr5128-02 SisDokumen14 halamanKenr5128kenr5128-02 Sisygor valdezBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen11 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Yancarlos Quispe AmayaBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen13 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- 324D Hyd PDFDokumen11 halaman324D Hyd PDFdemetrio castillo obleaBelum ada peringkat

- Parts Manual D6H - 1 PDFDokumen48 halamanParts Manual D6H - 1 PDFBudi Prayitno100% (2)

- D5G Hidraulico Serie RKG PDFDokumen7 halamanD5G Hidraulico Serie RKG PDFAnonymous KOtSfT6qBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen7 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaBelum ada peringkat

- 160k Electrical Accugrade SZMDokumen2 halaman160k Electrical Accugrade SZMqwureyquwery100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen7 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768CARHUAMACA PASCUAL mh100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Solenoid Valve Manufacturers Manufacturer of Solenoid ValveDokumen7 halamanSolenoid Valve Manufacturers Manufacturer of Solenoid ValverotexindiaBelum ada peringkat

- 5 Actuation SystemsDokumen78 halaman5 Actuation Systemsteklaykibrom3Belum ada peringkat

- Dorot Valves CatalogueDokumen45 halamanDorot Valves CatalogueBladimir MonrroyBelum ada peringkat

- Electropneumatics ExercisesDokumen124 halamanElectropneumatics Exercisesvergie orperiaBelum ada peringkat

- Multi-Fount Washfountains Terreon Models: Parts & Service GuideDokumen34 halamanMulti-Fount Washfountains Terreon Models: Parts & Service GuideTony MitchellBelum ada peringkat

- Governing And Protection System GuideDokumen54 halamanGoverning And Protection System GuideMorassa ChonaBelum ada peringkat

- Quadra PowerDokumen8 halamanQuadra PowerFelipe Ribeiro da CostaBelum ada peringkat

- General Electric Systems Technology Manual Control Rod Drive SystemDokumen37 halamanGeneral Electric Systems Technology Manual Control Rod Drive SystemEN IDBelum ada peringkat

- Model F446 Deluge ValveDokumen8 halamanModel F446 Deluge ValveajaykeshavBelum ada peringkat

- 2/2, 3/2 Manifold Mounting Compact Design High Flow Rate in Excess of 100 - Mio. Cycle Rate Up To 3,6 MM OrificeDokumen4 halaman2/2, 3/2 Manifold Mounting Compact Design High Flow Rate in Excess of 100 - Mio. Cycle Rate Up To 3,6 MM OrificeIgorBelum ada peringkat

- WB Electrohidrúalica BasicaDokumen244 halamanWB Electrohidrúalica Basicarimce77100% (1)

- Armfield PCT53 Datasheet V2a - WebDokumen2 halamanArmfield PCT53 Datasheet V2a - WebADESTI PURNAMA SARIBelum ada peringkat

- Gek 116357Dokumen4 halamanGek 116357kevinmathew27Belum ada peringkat

- Section ADokumen23 halamanSection ARajesh ChoudharyBelum ada peringkat

- 30-10 Solenoid ValvesDokumen31 halaman30-10 Solenoid ValvesadrianioantomaBelum ada peringkat

- Pneumatic SchematicsDokumen15 halamanPneumatic SchematicsAhmad HamoudaBelum ada peringkat

- Pressure Switch and Pressure Sensor CatalogDokumen76 halamanPressure Switch and Pressure Sensor CatalogNandoGonçalvesBelum ada peringkat

- CA GIC 3 BOV Finding Rev 2Dokumen5 halamanCA GIC 3 BOV Finding Rev 2Indra WiriadarmaBelum ada peringkat

- Technical Service Information: Nissan Re5F22ADokumen10 halamanTechnical Service Information: Nissan Re5F22AStephany castroBelum ada peringkat

- Servo Válvula NeumaticaDokumen30 halamanServo Válvula NeumaticaJaime VelazquezBelum ada peringkat

- Walchem - Metering Pumps & AccessoriesDokumen4 halamanWalchem - Metering Pumps & AccessoriesDaNnIe09Belum ada peringkat

- KD6031 2023 Output Transducers Section 8 (Wk11)Dokumen34 halamanKD6031 2023 Output Transducers Section 8 (Wk11)mohamed redaBelum ada peringkat

- LS 25S Parts Manual Generation I Model PDFDokumen76 halamanLS 25S Parts Manual Generation I Model PDFanon_457012148100% (2)

- Manual - Service - PB560 - English (148-160)Dokumen13 halamanManual - Service - PB560 - English (148-160)STEPHANY VANESSA LOMBANA ROJASBelum ada peringkat

- ATTDokumen3 halamanATTforu_kkkBelum ada peringkat

- Principle Design Solenoid ValvesDokumen28 halamanPrinciple Design Solenoid Valveshassan alrokabBelum ada peringkat

- Two-Way Solenoid ValveDokumen10 halamanTwo-Way Solenoid ValveSegundo AlmagroBelum ada peringkat

- 21XN4K1V120Dokumen2 halaman21XN4K1V120Ramius HamdaniBelum ada peringkat

- PCM3 Honeywell AditivaciónDokumen6 halamanPCM3 Honeywell AditivaciónJESUS SANCHEZ GOMEZBelum ada peringkat

- 119 (-001-016) ChairDokumen164 halaman119 (-001-016) ChairaillBelum ada peringkat